Abstract

The information of vital parameters within the concrete form the basis of maintenance, rehabilitation, repairing, upgradation or rebuilding of concrete structures. The information from the concrete helps in preempting further action or sequence of procedures, for long and sustainable service life. The objective of this review paper is to update and analyze the research that has been undertaken to capture and assess the thermal and humidity changes in concrete structure through sensors. The review while discussing the importance of structural health monitoring of concrete structures assesses the performances of the latest relevant sensor technology in vogue. Due to the environmental robustness, minimal size, quick response and high accuracy, major emphasis has been laid on the design of sensors based on fiber optic and Bragg grating. Both these technologies shall continue progress and generate more efficient and path breaking sensors in near future. Currently, the problems of relay, recalibration or replacement over a long period of time remain the big issues, in sensor technology and its advancement.

Similar content being viewed by others

Data availability

Relevant data will be made available upon request.

References

Hobbs DW (2001) Concrete deterioration: causes, diagnosis, and minimizing risk. Int Mater Rev 46(3):117–144

Abdel-Jaber H, Glisic B (2016) Structural health monitoring methods for the evaluation of prestressing forces and prerelease cracks. Front Built Environ 2:20

Brownjohn JM (2007) Structural health monitoring of civil infrastructure. Philos Trans A Math Phys Eng Sci 365(1851):589–622

López-Higuera JM, Rodriguez Cobo L, Incera Q, Cobo A (2011) Fiber optic sensors in structural health monitoring. J Lightwave Technol 29(4):587–608

Antonella T (2013) Photonics for safety and security. World Scientific Publishing, USA

Lynch JP, Loh KJ (2006) A summary review of wireless sensors and sensor networks for structural health monitoring. Shock Vib Digest 38(2):91–130

Balageas D (2010) Introduction to structural health monitoring. In: Balageas D, Fritzen CP, Güemes A (eds) Structural health monitoring. Wiley, New Jersey, pp 13–44

Ramakrishnan M, Rajan G, Semenova Y, Boczkowska A, Doma´ nski A, Wolinski T, Farrell G, (2013) Measurement of thermal elongation induced strain of a composite material using a polarization maintaining photonic crystal fiber sensor. Sens Actuat A Phys 190:44–51

Noel AB, Abdaoui A, Elfouly T, Ahmed MH, Badawy A, Shehata MS (2017) Structural health monitoring using wireless sensor networks: a comprehensive survey. IEEE Commun Surv Tut 19(3):1403–1423

Ou J, Li H (2010) Structural health monitoring in mainland china: review and future trends. Struct Health Monit 9(3):219–231

French CE, Shield CK, Stolarski HK, Hedegaard BD, Jilk BJ (2012) Instrumentation, Monitoring, and Modeling of the I-35W Bridge, Report MN/RC 2014–39, Monitoring Instrumentation of I35W Bridge, Minnesota Department of Transportation, St. Paul.

Hedegaard BD (2014) Modeling and Monitoring the Long-term Behavior of Posttensioned Concrete Bridges, University of Minnesota.

Zhang M, Liu ZH, Ma YW, Zhang Y, Zhang YX, Yang XH, Zhang JZ, Geng T, Yuan LB (2022) Gelatin-coated long period fiber grating humidity sensor with temperature compensation. Opt Eng 61(2):027104

Chen N, Zhou X, Li XG (2021) Highly sensitive humidity sensor with low temperature cross-sensitivity based on a polyvinyl alcohol coating tapered fiber. IEEE Trans Instrum Meas 70:1–8

Cheng JN (2020) In-fiber Mach-Zehnder interferometer based on multi-core microfiber for humidity and temperature sensing. Appl Opt 59(3):756–763

Pevec S, Donlagic D (2015) Miniature all-silica fiber-optic sensor for simultaneous measurement of relative humidity and temperature. Opt Lett 40(23):5646–5649

Merzbacher C, Kersey A, Friebele E (1999) Fiber optic sensors in concrete structures: a review, in: K.T.V. Grattan, B.T. Meggitt (Eds.), Optical Fiber Sensor Technology. Optoelectronics, Imaging and Sensing Series, Springer, USA, 1–24

Glisic B, Inaudi D (2008) Fibre optic methods for structural health monitoring. Wiley, New Jersey

Lee B (2003) Review of the present status of optical fiber sensors. Opt Fiber Technol 9(2):57–79

Leung CKY (2001) Fiber optic sensors in concrete: the future. Ndt E Int 34(2):85–94

Ramakrishnan M, Rajan G, Semenova Y, Farrell G (2016) Overview of fiber optic sensor technologies for strain/temperature sensing applications in composite materials. Sensors 16(1):99

Ansari F (1997) State-of-the-art in the applications of fiber-optic sensors to cementitious composites. Cem Concr Compos 19(1):3–19

Maria de Fátima FD, Radwan A (2017) Optical Fiber Sensors for LoT and Smart Devices, Springer.

Moyo P, Brownjohn JMW, Suresh R (2005) Tjin, Development of fiber Bragg grating sensors for monitoring civil infrastructure. Eng Struct 27(12):1828–1834

Hill KO, Meltz G (1997) Fiber Bragg grating technology fundamentals and overview. J Lightwave Technol 15(8):1263–1276

Yashiro S, Okabe T, Toyama N, Takeda N (2007) Monitoring damage in holed laminates using embedded chirped FBG sensors. Int J Solids Struct 44:603–613

Rao YJ (2006) Recent progress in fiber-optic extrinsic fabry-perot interferometric sensors. Opt Fiber Technol 12:227–237

Lee BH, Kim YH, Park KS, Eom JB, Kim MJ, Rho BS, Choi HY (2012) Interferometric fiber optic sensors. Sensors 12:2467–2486

Ohtsu M (1996) The history and development of acoustic emission in concrete engineering. Mag Concr Res 48(177):321–330

Dumoulin C, Karaiskos G, Sener JY, Deraemaeker A (2014) Online monitoring of cracking in concrete structures using embedded piezoelectric transducers. Smart Mater Struct 23(11):115016

Nanni F, Ruscito G, Forte G, Gusmano G (2007) Design, manufacture and testing of self-sensing carbon fibre-glass fibre reinforced polymer rods. Smart Mater Struct 16(6):2368–2374

Ceysson O, Risson T, Salvia M (1996) Carbon fibres: sensor components for smart materials. In: proc SPIE 2779, 3rd international conference on intelligent materials and 3rd european conference on smart structures and materials, pp 136–142

Chen PW, Chung DD (1993) Carbon fiber reinforced concrete for smart structures capable of non-destructive flaw detection. Smart Mater Struct 2(1):22

Wang X, Fu X, Chung D (1999) Strain sensing using carbon fiber. J Mater Res 14(3):790–802

Cosentino P, Grossman B (1997) Development of fiber optic dynamic weigh-inmotion system, Florida Department of Transportation, Tallahassee, FL

Mimbela L, Pate J, Copeland S, Kent P, Hamrick J (2003) Applications of fiber optics sensors in weigh-in-motion (WIM) systems for monitoring truck weights on pavements and structures, New Mexico Department of Transportation, Santa Fe, NM,

Fuhr P, Huston D (1998) Corrosion detection in reinforced concrete roadways and bridges via embedded fiber optic sensors. Smart Mater Struct 7(2):217

Weng X, Zhu H-H, Chen J, Liang D, Shi B, Zhang C-C (2014) Experimental investigation of pavement behavior after embankment widening using a fiber optic sensor network. Struct Health Monit Int J 14(1):46–56

Wang J, Tang J, Chang H (2006) Fiber Bragg grating sensors for use in pavement structural strain-temperature monitoring, in: Proc. SPIE 6174, Smart Structures and Materials 2006: Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems, San Diego

Oliveira R, Bilro L, Nogueira R, Marques THR, Cordeiro CMB (2019) Simultaneous detection of humidity and temperature through an adhesive based Fabry-P´erot cavity combined with polymer fiber Bragg grating. Opt Lasers Eng 114:37–43

Buenfeld N (2011) Editorial: automated monitoring of concrete structures: research opportunities. Mag Concr Res 63(2):79–80

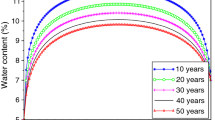

Norris A, Saafi M, Romine P (2008) Temperature and moisture monitoring in concrete structures using embedded nanotechnology/microelectromechanical systems (MEMS) sensors. Constr Build Mater 22(2):111–120

Dai X, Gao S, Pan K, Zhu J, Rashvand HF (2017) Wireless piezoelectric sensor systems for defect detection and localization. In: Rashvand HF, Abedi A (eds) Wireless sensor systems for extreme environments: space. Wiley, Underwater, pp 201–219

Gallucci L, Menna C, Angrisani L, Asprone D, Moriello RSL, Bonavolontà F, Fabbrocino F (2017) An embedded wireless sensor network with wireless power transmission capability for the structural health monitoring of reinforced concrete structures. Sensors 17(11):2566

Cabezas J, Sánchez-Rodríguez T, Gómez-Galán J, Cifuentes H, González Carvajal R (2018) Compact embedded wireless sensor-based monitoring of concrete curing. Sensors 18(3):876

Bundesnetzagentur (2019) RFID, das kontaktlose Informations system; Technical Report; Bundesministerium für Wirtschaft und Energie: Berlin, Germany

Tamimi AK, Abdalla JA, Sakka ZI (2008) Prediction of long term chloride diffusion of concrete in harsh environment. Constr Build Mater 22(5):829–836

Romanova A, Mahmoodian M, Alani MA (2014) Influence and interaction of temperature, H2S and pH on concrete sewer pipe corrosion. Int J Civ Architect Struct Urban Sci Eng 8(6):592–595

Vollertsen J, Nielsen AH, Jensen HS, Wium-Andersen T, Hvitved- Jacobsen T (2008) Corrosion of concrete sewers-the kinetics of hydrogen sulfide oxidation. Sci Total Environ 394(1):162–170

Sun X (2015) Improving the understanding of concrete sewer corrosion through investigations of the gaseous hydrogen sulfide uptake and transformation processes in the corrosion layer doctoral thesis. Central South University, PR China

Bofang Z (2013) Thermal stresses and temperature control of mass concrete. Butterworth-Heinemann

Deng J, Li Y, Wu S (2016) The research on temperature control of mass concrete, in: Advances in Energy, Environment and Materials Science: Proceedings of the International Conference on Energy, Environment and Materials Science (EEMS 2015), CRC Press, pp 349–352

Mathas C (2011) Temperature Sensors-The Basics, [Available from: https://www.digikey.com.au/en/articles/techzone/2011/oct/temperature-sensors-thebasics], digikey.com.

Huynh T (2015) Fundamentals of thermal sensors, in: C.M. Jha (Ed.), Thermal Sensors, Springer: London 2015, pp 5–42

Baeza FJ, Galao O, Zornoza E, Garces P (2013) Effect of aspect ratio on strain sensing capacity of carbon fiber reinforced cement composites. Mater Des 51:1085–1094

Han B, Yu X, Ou J (2014) Sensing properties of self-sensing concrete Self-Sensing Concrete in Smart Structures. Elsevier, Amsterdam, The Netherlands, pp 95–162

Demirel B, Yazicioglu S, Orhan N (2006) Electrical behaviour of carbon fibre-reinforced concrete with increasing loading in varying and constant frequencies. Mag Concr Res 58:691–697

Han B, Ding S, Yu X (2015) Intrinsic self-sensing concrete and structures: a review. Measurement 59:110–128

Strangfeld C, Johann S, Bartholmai M (2019) Smart RFID sensors embedded in building structures for early damage detection and long-term monitoring MDPI. Sensor 19(24):5541

Meltz G., Dunphy J., Glenn, Farina J., Leonberger F. (1987) Fiber optic temperature and strain sensors, in: Proc. SPIE 0798, Fiber Optic Sensors II, pp 104– 115

Alwis LS, Sun T, Grattan KT (2016) Fibre grating-based sensor design for humidity measurement in chemically harsh environment. Proc Eng 168:1317–1320

Fernando C, Bernier A, Banerjee S, Kahandawa G, Eppaarchchi GJ (2017) An investigation of the use of embedded FBG sensors to measure temperature and strain inside a concrete beam during the curing period and strain measurements under operational loading, 6th Asia pacific workshop on structural health monitoring. Proced Eng 188:393–399

Rinaudo P, Torre BS, Paya-Zaforteza I, Calderón PA, Sales S (2015) Evaluation of new regenerated fiber Bragg grating high-temperature sensors in an ISO834 fire test. Fire Saf J 71:332–339

Torres Górriz B, Payá-Zaforteza I, CalderónGarcía PA, Sales MS (2017) New fiber optic sensor for monitoring temperatures in concrete structures during fires. Sens Actuat A 254:116–125

Barrera D, Finazzi V, Villatoro J, Sales S, Pruneri V (2012) Packaged optical sensors based on regenerated fiber Bragg gratings for high temperature applications. IEEE Sens J 12(1):107

Habisreuther T, Elsmann T, Pan Z, Graf A, Willsch R, Schmidt MA (2015) Sapphire fiber Bragg gratings for high temperature and dynamic temperature diagnostics. Appl Therm Eng 91(2015):860–865

Bao Y, Hoehler MS, Smith CM, Bundy M, Chen G (2017) Temperature measurement and damage detection in concrete beams exposed to fire using PPP-BOTDA based fiber optic sensors. Smart Mater Struct 26:105034–105045

Bao Y, Chen Y, Hoehler MS, Smith CM, Bundy M, Chen G (2016) Experimental analysis of steel beams subjected to fire enhanced by Brillouin scattering based fiber optic sensor data. J Struct Eng 143(1):04016143

Haoyang Peng H, Peng Li P, Yunfei Xiang Y, Chen W, Zhou S, Ning Yang N, Qiao Y (2020) A positioning method of temperature sensors for monitoring dam global thermal field. Front Mater 7:587738

Kim J, Luis R, Smith MS, Figueroa JA, Malocha DC, Nam BH (2015) Concrete temperature monitoring using passive wireless surfaceacoustic wave sensor system. Sens Actuat A 224:131–139

Chen H, Zhou S, Deng F, Zou J, Wu X, Fu WZ (2018) Novel concrete-temperature monitoring method by using embedded passive wireless sensor. Mag Concr Res 70(9):452–458

Chen Z, Deng F, Fu Z, Wu X (2018) Design of an ultra-low power wireless temperature sensor based on backscattering mechanism. Sens Imag 19(28):1

Deng F, He Y, Li B, Zhang L, Wu X, Fu Z, Zuo L (2015) Design of an embedded CMOS temperature sensor for passive RFID tag chips. Sensors 15(5):11442–11453

Liu Y, Deng F, He Y, Li B, Liang Z, Zhou S (2017) Novel concrete temperature monitoring method based on an embedded passive RFID sensor tag. Sensors 17(7):1463

Federico MD, Ceminari P (2019) Novel time-domain CMOS temperature sensor for passive RFID Tag, 2019 argintine conference on electronics, IEEE Explore, 18656076.

Farahani H, Wagiran R, Hamidon M (2014) Humidity sensors principle, mechanism, and fabrication technologies: a comprehensive review. Sensors 14(5):7881–7939

Yamazoe N, Shimizu Y (1986) Humidity sensors: principles and applications. Sens Actuat 10(3–4):379–398

Gupta B (2001) A novel probe for a fiber optic humidity sensor. Sens Actuat B Chem 80(2):132–135

Khijwania SK, Srinivasan KL, Singh JP (2005) Performance optimized optical fiber sensor for humidity measurement. Opt Eng 44(3):034401

Michie WC, Thursby G, McLean A, Culshaw B, Verwilghen B, Voet M (1997) Fibre optic sensor for distributed water ingress detection and humidity measurement. In: 12th international conference on optical fiber sensors, Optical Society of America, OFB4, 634–637.

Michie W, Culshaw B, McKenzie I, Konstantakis M, Graham N, Moran C, Santos F, Bergqvist E, Carlstrom B (1995) Distributed sensor for water and pH measurements using fiber optics and swellable polymeric systems. Opt Lett 20(1):103–105

André PS, Varum H, Antunes P, Ferreira L, Sousa MG (2012) Monitoring of the concrete curing process using plastic optical fibers. Measurement 45(3):556–560

Strangfeld C, Johann S, Müller M, Bartholmai M (2017) Embedded passive RFIDbased sensors for moisture monitoring in concrete. IEEE Sens 311:1–3

Kuang Q, Lao C, Wang ZL, Xie Z, Zheng L (2007) High-sensitivity humidity sensor based on a single SnO2 nanowire. J Am Chem Soc 129(19):6070–6071

Zhang Y, Yu K, Jiang D, Zhu Z, Geng H, Luo L (2005) Zinc oxide nanorod and nanowire for humidity sensor. Appl Surf Sci 242(1–2):212–217

Mintova S, Mo S, Bein T (2001) Humidity sensing with ultrathin LTA-type molecular sieve films grown on piezoelectric devices. Chem Mater 13(3):901–905

Li J, Zhang J, Sun H, Yang Y, Ye Y, Cui J, He W, Yong X, Xie Y (2020) An optical fiber sensor based on carboxymethyl cellulose/carbon nanotubes composite film for simultaneous measurement of relative humidity and temperature. Optics Commun 467:125740

Li M, Ma C, Li D, Bao S, Jin J, Zhang Y, Liu Q, Liu M, Zhang Y, Li T, Hu H, Wu J (2023) Dual-parameter optical fiber sensor for temperature and humidity based on PMMA-microsphere and FBG composite structure. Opt Fiber Technol 78:103292

Dan S, Qiao XG, Rong QZ, Sun H, Zhang J, Bai ZY, Du YY, Feng DY, Wang YP, Hu ML, Feng ZY (2013) A fiber Fabry-P´erot interferometer based on a PVA coating for humidity measurement. Opt Commun 311:107–110

Zhao Y, Tong RJ, Chen MQ, Xia F (2019) Relative humidity sensor based on hollow core fiber filled with GQDs-PVA. Sens Actuat B 284:96–102

Li M, Yin JW, Yan WL, Cong AM, Li HJ, Ma WQ (2021) Ultra-longer fiber cantilever taper for simultaneous measurement of temperature and relative humidity. Chin Phys B 30(11):114210

Dong ZY, Zhang GB, Jin YQ, Zhou J, Guan JN, Tong ZJ, Wei ZC, Tan CH, Wang FQ, Meng HY (2022) Hydroxyethyl cellulose sensitized SMDMS structure with optical fiber relative humidity and temperature simultaneous measurement sensor. Opt Express 30(2):1152–1166

Peters K (2010) Polymer optical fiber sensors—a review. Smart Mater Struct 20(2010):013002

Corres JM, Matias IR, Hernaez M, Bravo J, Arregui FJ (2008) Optical fiber humidity sensors using nanostructured coatings of SiO2 nanoparticles. IEEE Sens J 8:281–285

Sharma AK, Gupta A (2013) Design of a plasmonic optical sensor probe for humidity-monitoring. Sens Actuat B 188:867–871

Lokman A, Nodehi S, Batumalay M, Arof H, Ahmad H, Harun SW (2014) Optical fiber humidity sensor based on a tapered fiber with hydroxyethylcellulose/polyvinylidenefluoride composite. Microw Opt Technol Lett 56:380–382

Yan G, Liang Y, Lee E-H, He S (2015) Novel Knob-integrated fiber Bragg grating sensor with polyvinyl alcohol coating for simultaneous relative humidity and temperature measurement. Opt express 23:15624–15634

SmartRock2TM (2018) [Available from: https://www.giatecscientific.com/smartrock2/], Giatec.

The effects of temperature on concrete curing (2018) [Available from: https://www.tempcon.co.uk/temperature-monitoring-concrete-curing/], TEMPCON.

Concrete Sensors (2018) [Available from: http://www.concretesensors.com/durable-wireless-sensors/]

Chang CY, Hung SS (2012) Implementing RFIC and sensor technology to measure temperature and humidity inside concrete structures. Constr Build Mater 26(1):628–637

Barroca N, Borges LM, Velez FJ, Monteiro F, Górski M, Castro-Gomes J (2013) Wireless sensor networks for temperature and humidity monitoring within concrete structures. Constr Build Mater 40:1156–1166

Zou X, Chao A, Tian Y, Wu N, Zhang H, Yu TY, Wang X (2012) An experimental study on the concrete hydration process using fabry-perot fiber optic temperature sensors. Measurement 45(5):1077–1082

Qu Z, Jiang P, Zhang W (2020) Development and application of infrared thermography non-destructive testing techniques. Sensors 20(14):3851

Author information

Authors and Affiliations

Contributions

The manuscript properly credits the meaningful contributions of co-authors and co-researchers. KZF contributed to methodology, writing, reviewing and editing. ASS contributed to reviewing and editing. MIA contributed to reviewing and editing. Prof. RD contributed to reviewing and editing.

Corresponding author

Ethics declarations

Conflict of interest

This is to certify that the authors of the above listed paper have no conflict of interest. The authors declare that they have no competing interest and the work is original.

Ethical approval

Ethics approval was not required for this review manuscript.

Informed consent

Informed consent was not required for this review manuscript.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Farhan, K.Z., Shihata, A.S., Anwar, M.I. et al. Temperature and humidity sensor technology for concrete health assessment: a review. Innov. Infrastruct. Solut. 8, 276 (2023). https://doi.org/10.1007/s41062-023-01255-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-023-01255-x