Abstract

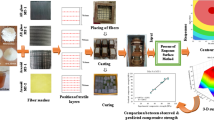

Natural fibers and pozzolan have gained prominence in the development of concrete; however, there are few studies that have considered the combination of banana fiber and waste glass powder. In this work, 0.5%, 1.0%, and 1.5% banana fiber (BF) was employed as fiber reinforcement, while glass powder (GP) was used as pozzolan, partially replacing cement at 10%, 20%, and 30%. Using the response surface method (RSM), the experimental data on the 7-, 28-, and 56-day concrete compressive strengths were analysed, modeled and optimized via the response surface approach. The result revealed that the variables played an important role on the trend of the 7-, 28-, and 56-day compressive strengths. The optimal combination of 1.0%, 1.1%, and 1.0% banana fiber at 17.4%, 20.8%, and 21.0% GP cement replacement yielded improvements of 11.0, 22.1, and 27.0% over the reference concrete at 7, 28, and 56 days, respectively. The developed predictive models for compressive strength were affirmed to be statistically fit for future prediction.

Similar content being viewed by others

References

Wichrowska KK, Pawluczuk E, Boltryk M, Jimenez JR, Rodriguez JMF, Morales DS (2022) The performance of concrete made with secondary products-recycled coarse aggregates, recycled cement mortar, and fly ash-slag mix. Materials 15:1438. https://doi.org/10.3390/ma15041438

Abed AA, Bas YJ, Al-Hasani A, Kamal I (2022) Investigation of some properties of hardened cement biogenic ash composites. IOP Conf Series Mater Eng Sci 2660:020054. https://doi.org/10.1063/5.0108715

Qu F, Li W, Dong W, Tam VW, Yu T (2021) Durability deterioration of concrete under marine environment from material to structure: a critical review. J Build Eng 35:102074. https://doi.org/10.1016/j.jobe.2020.102074

Safiuddin M, Kaish AMA, Woon CO, Raman SN (2018) Early-age cracking in concrete: causes, consequences, remedial measures, and recommendations. Appl Sci 8(10):1730. https://doi.org/10.3390/app8101730

Garcia MBD, Cardenas YD, Quesada JR, Hernandez FM (2022) Evaluation of the shrinkage produced with the use of cements with pozzolan additions in the production of concrete. Minerals 12:1175. https://doi.org/10.3390/min12091175

Ahmad J, Majdi A, Deifalla AF, El-Shorbagy MA (2022) Concrete reinforced with sisal fibers (SSF): overview of mechanical and physical properties. Crystals 12:952. https://doi.org/10.3390/cryst12070952

Nugraha AD, Nuryanta MI, Sean L, Budiman K, Kusni M, Muflikhun MA (2022) Recent progress on natural fibers mixed with CFRP and GFRP: properties, characteristics, and failure behavior. Polymers 14(23):5138. https://doi.org/10.3390/polym14235138

Nishiwaki T, Kwon S, Homma D, Yamada M, Mihashi H (2014) Self-healing capability of fiber-reinforced cementitious composites for recovery of watertightness and mechanical properties. Materials 7(3):2141–2154. https://doi.org/10.3390/ma7032141

Amran M, Fediuk R, Abdelgader HS, Murali G, Ozbakkaloglu T, Lee YH, Lee YY (2022) Fiber-reinforced alkali-activated concrete: a review. J Build Eng 45:103638. https://doi.org/10.1016/j.jobe.2021.103638

Rajak DK, Wagh PH, Linul E (2022) A review on synthetic fibers for polymer matrix composites: performance, failure models and applications. Materials 15(14):4790. https://doi.org/10.3390/ma15144790

Mohajerani A, Hui SQ, Mirzababaei M, Arulrajah A, Horpibulsuk S, Kadir AA, Rahman T, Maghool F (2019) Amazing types, properties, and application of fibers in construction materials. Materials 12:2513. https://doi.org/10.3390/ma12162513

Wibowo A, Alandro D, Killian MS, Nugroho G, Raghu SNV, Muflikhun MA (2023) Mechanical evaluation and characterization of hybrid surgarcane bagasse microfibrillated cellulose with added filler materials for use as disposable utensils. Adv Compos Mater. https://doi.org/10.1080/09243046.2023.2180793

Wei J, Meyer C (2016) Degradation of natural fibers in ternary blended cement composites containing metakaolin and montmorillonite. Corros Sci. https://doi.org/10.1016/j.corsci.2016.12.004

Wei J, Meyer C (2013) Improving degradation resistance of sisal fiber in concrete through fiber surface treatment. Appl Surf Sci 289:511–523. https://doi.org/10.1016/j.apsusc.2013.11.024

Zunino F, Dhandapani Y, Haha MB, Skibsted J, Joseph S, Krishnan S, Parashar A, Juenger MCG, Hanein T, Bernal SA, Scrivener KL, Avet F (2022) Hydration and mixture design of calcined clay blended cements: review by RILEM TC 282-CCL. Mater Struct 55:234. https://doi.org/10.1617/s11527-022-02060-1

Khater HM, Ghareeb M (2022) Influence of nano-glass powder on the characteristics properties as well as stability against firing for geopolymer composites. Arab J Sci Eng. https://doi.org/10.1007/s13369-022-07419-8

Sierra OM, Paya J, Monzo J, Borrachero MV, Soriano L, Quinonez J (2022) Characterization and reactivity of natural Pozzolans from Guatemala. Appl Sci 12:11145. https://doi.org/10.3390/app122111145

Balogun OA, Akinwande AA, Adediran AA, Ogunsanya OA, Ademati AO, Kumar MS, Erinle TJ, Akinlabi ET (2022) Microstructure and particle size effects on selected mechanical properties of waste glass reinforced aluminum matrix composites. Mater Today Proceed. https://doi.org/10.1016/j.matpr.2022.05.330

Talabi H, Ojomo AM, Folorunsho OE, Akinfolarin JF, Kumar JP, Mohan RR, Akinwande AA, Kumar MS (2022) Development of hybrid aluminum alloy composites modified with locally sourced environmental wastes. Adv Mater Process Technol. https://doi.org/10.1080/2374068X.2022.2096831

Folorunso DO, Akinwande AA, Balogun OA (2021) Property evaluation and compliance level analysis of glass wastes reinforced ceramic composites for masonry application. Int J Adv Acad Res 7(5):1–14. https://doi.org/10.46654/ij.24889849.e7305

Folorunso DO, Akinwande AA (2021) Applications of compliance to cost ratio (C-CR) analysis in the determination of optimum mix of insulating bricks in masonry. J Miner Mater Charact Eng 09(02):134–147. https://doi.org/10.4236/jmmce.2021.92010

Sinkhonde D, Onchiri RO, Oyawa WO, Mwero JN (2021) Response surface methodology-based optimization of cost and compressive strength of rubberized concrete incorporating burnt clay brick powder. Heliyon 7:e08565. https://doi.org/10.1016/j.heliyon.2021.e08565

Hamada HM, Al-Attar AA, Tayeh B, Yahaya FBM (2022) Optimizing the concrete strength of lightweight concrete containing nano palm oil fuel ash and palm oil clinker using response surface method. Case Stud Constr Mater 16:e01061. https://doi.org/10.1016/j.cscm.2022.e01061

Guneyisi E, Gesoglu M, Algun Z, Mermerdas K (2014) Optimization of concrete mixture with hybrid blends of metakaolin and fly ash using response surface method. Composite B 60:707–715. https://doi.org/10.1016/j.compositeb.2014.01.017

Haque M, Ray S, Mita AF, Bhattacharjee S, Shams JB (2021) Prediction and optimization of the fresh and hardened properties of concrete containing rice husk ash and glass fiber using response surface methodology. Case Stud Constr Mater 14:e00505. https://doi.org/10.1016/j.cscm.2021.e00505

Ahmed T, Ray S, Haque M, Nahim TT, Mita AF (2022) Optimization of properties of concrete prepared with waste glass aggregate and condensed milk can fiber using response surface methodology. Clean Eng Technol 8:100478. https://doi.org/10.1016/j.clet.2022.100478

Ramadan R, Jahami A, Khatib J, El-Hassan H, Elkordi A (2023) Improving structural performance of reinforced concrete beams with phragmites Australis fiber and waste glass additives. Appl Sci 13(7):4206. https://doi.org/10.3390/app13074206

Jahami A, Khatib J, Raydan R (2022) Production of low-cost, high-strength concrete with waste glass as fine aggregates replacement. Buildings 12(12):2168. https://doi.org/10.3390/buildings12122168

Raydan R, Khatib J, Jahami A, El Hamoui A, Chamseddine F (2022) Prediction of the mechanical strength of concrete containing glass powder as partial cement replacement material. Innov Infrastruct Solut. https://doi.org/10.1007/s41062-022-00896-8

Castoldi R, Souza LMS, Souto R, Liebscher M, Mechtcherine V, Silva FA (2022) Effect of alkaline treatment on physical-chemical properties of sisal fibers and adhesion towards cement-based matrices. Constr Build Mater 345(3):128363. https://doi.org/10.1016/j.conbuildmat.2022.128363

Girijappa YGY, Rangappa SM, Parameswaranpillai J, Siengchin S (2019) Natural fibers as sustainable and renewable resource for development of eco-friendly composites: a comprehensive review. Front Mater 6:226. https://doi.org/10.3389/fmats.2019.00226

Adediran AA, Balogun OA, Akinwande AA, Adesina OS, Olasoju OS (2020) Influence of chemical treatment on the properties of cement-paper hybrid composites for ceiling board application. Heliyon 6:e04512. https://doi.org/10.1016/j.heliyon.2020.e04512

Ahmad J, Zhou Z, Usanova I, Vatin NI, El-Shorbagy MA (2022) A step towards concrete with partial substitution of waste glass in concrete. Materials 15:2525. https://doi.org/10.3390/ma15072525

Caballero CM, Castillo FC, Bernabe JLM, Ramirez RA, Rivera MES (2017) Effect of compressive and flexural strength of agave fiber reinforced adobes. J Nat Fibers 15(4):575–585. https://doi.org/10.1080/15440478.2017.1349709

Gong Y, Song J, Lin S, Yang J, He Y, Tan G (2020) Design optimization of rubber-basalt fiber-modified concrete mix ratios based on a response surface method. Appl Sci 10:6753. https://doi.org/10.3390/app10196753

Panda S, Sarkar P, Davis R (2020) Effect of water-cement ratio on mix design and mechanical strength of copper slag aggregate concrete. IOP Conf Series Mech Struct 937:012019. https://doi.org/10.1088/1757-899X/936/1/012019

Reddy KO, Reddy KRN, Zhang J, Zhang J, Rajulu AV (2013) Effect of alkali treatment on the properties of century fiber. J Nat Fibers 10:282–296. https://doi.org/10.1080/15440478.2013.800812

Loganathan TM, Sultan MTH, Ahsan Q, Jawaid M, Naveen J, Shah AUM, Hua LS (2020) Characterization of alkali treated new cellulosic fiber from cyrtostachys renda. J Mater Res Technol 9(3):3537–3546. https://doi.org/10.1016/j.jmrt.2020.01.091

ASTM C 618, 2019. Standard specification for coal fly ash and raw calcined natural pozzolan for use in concrete. ASTM International. West Conshohocken, PA

ASTM C1314–21 (2022). Standard test method for compressive strength of masonry prisms. ASTM International. West Conshohocken, PA. USA.

Ademati AO, Akinwande AA, Balogun OA, Romanovski V (2022) Optimization of bamboo fiber-reinforced composite-clay bricks for development of low-cost farm settlements toward boosting rural agribusiness in Africa. J Mater Civil Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0004489

Akinwande AA, Folorunso DO, Balogun OA, Romanovski V (2022) Mathematical modelling, multi-objective optimization, and compliance reliability of paper-derived eco-composites. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-022-20714-z

Adediran AA, Akinwande AA, Balogun OA, Bello OS, Akinbowale MK, Adesina OS, Ojo AA (2022) Mechanical and optimization studies of polypropylene hybrid biocomposite. Sci Rep 12(1):1–18. https://doi.org/10.1038/s41598-022-06304-6

Balogun OA, Akinwande AA, Ogunsanya OA, Ademati AO, Adediran AA, Erinle TJ, Akinlabi ET (2022) Central composite design and optimization of selected stir casting parameters on flexural strength and fracture toughness mTiO2p/Al 7075 composites. Mater Today Proceed. https://doi.org/10.1016/j.matpr.2022.05.315

Islam GSM, Rahman MH, Kazi N (2017) Waste glass powder as partial replacement of cement for sustainable concrete practice. Int J Sustain Built Environ 6:37–44

Ogunbiyi O, Tian Y, Akinwande AA, Rominiyi AL (2023) AA7075/HEA composites fabricated by microwave sintering: assessment of the microstructural features and response surface optimization. Intermetallics 155:107830. https://doi.org/10.1016/j.intermet.2023.107830

Cheng Z, Yan W, Sui Z, Tang J, Yuan C, Chu L, Feng H (2021) Effect of fiber content on the mechanical properties of engineered cementitious composites with recycled fine aggregate from clay brick. Materials 14(33721):1–22. https://doi.org/10.3390/ma14123272

Gupta SD, Aftab MS, Zakaria HM, Karmakar C (2020) Scope of improving mechanical characteristics of concrete using natural fiber as a reinforcing material. Malays J Civil Eng 32(2):49–57. https://doi.org/10.11113/mjce.v32n2.654

Syed H, Nerella R, Madduru SRC (2020) Role of coconut coir fiber in concrete. Mater Today Proceed. https://doi.org/10.1016/j.matpr.2020.01.477

Azevedo RG, Klyuev S, Marvilla MT, Vatin N, Alfimova N, Lima TES, Fediuk R, Olisov A (2020) Investigation of the potential use of Curaua fiber for reinforcing mortar. Fibers 8(69):1–13. https://doi.org/10.3390/fib8110069

Islam MS, Ahmed SJ (2018) Influence of jute fiber on concrete properties. Constr Build Mater 189(2018):768–776. https://doi.org/10.1016/j.conbuildmat.201809.048

Bheel N, Adesina A (2020) Influence of binary blend of corn cob ash and glass powder as partial replacement of cement in concrete. SILICON. https://doi.org/10.1007/s12633-020-00557-4

Sakale R, Jain S, Singh S (2016) Experimental investigation on strength of glass powder replacement by cement in concrete with different dosages. Int J Sci Technol Eng 2(8):76–86

Olofinnade OM, Ede AN, Ndambuki JM (2017) Sustainable green environment through utilization of waste soda-lime glass for production of concrete. J Mater Environ Sci 8(4):1139–1152

Ayegbokiki ST, Atoyebi AA, Zubair SA, Adeleke OI (2019) Characteristics strength of sandcrete hollow block with partial replacement of fine sand with crushed glass. Int Conf Sci Eng Environ Technol 4(15):118–124

Zanwar AB, Patil YD (2021) Utilization of waste glass powder as cementitious material in concrete. IOP Conf Series Mater Sci Eng 1070:012040. https://doi.org/10.1088/1757-899X/1070/1/012040

Serati M, Jakson N, Asche H, Basireddy S, Malgotra G (2022) Sustaionable shotcrete production with waste glass aggregates. SN Appl Sci 4:82. https://doi.org/10.1007/s42452-022-04967-4

Ahmad J, Martinez-Garcia R, De-Prado-Gil J, Irshad K, El-Shorbagy MA, Fediuk R, Vatin NI (2022) Concrete with partial substitution of waste glass and recycled concrete aggregate. Materials 15(430):1–20. https://doi.org/10.3390/ma15020430

Akinwande AA, Balogun OA, Adediran AA, Adesina OS, Romanovski V, Jen TC (2023) Experimental analysis, statistical modeling, and parametric optimization of quinary-(CoCrFeMnNi)100–x/TiCx high-entropy-alloy (HEA) manufactured by additive manufacturing. Res Eng 17:100802. https://doi.org/10.1016/j.rineng.2022.100802

Akinwande AA, Adesina OS, Adediran AA, Balogun OA, Mukuro D, Balogun OP, Tee KF, Kumar MS (2023) Microstructure, process optimization, and strength response modelling of green-aluminium-6061 composite as automobile material. Ceramics 6:386–415. https://doi.org/10.3390/ceramics6010023

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interest that may affect the publication or readership of this work.

Ethical approval

Not applicable.

Informed consent

For this type of study formal consent is not required.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Olukayode, O.M., Akinwande, A.A., Balogun, O.A. et al. Applicability of the response surface method in the optimization of compressive strengths of banana-fiber-reinforced concrete using waste glass as partial cement replacement. Innov. Infrastruct. Solut. 8, 207 (2023). https://doi.org/10.1007/s41062-023-01178-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-023-01178-7