Abstract

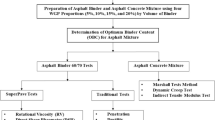

In this study, waste glass was utilised as an aggregate substitution. Hydrofluoric acid (HF) was applied as an etching agent to roughen waste glass’ surface. Five mix designs incorporating untreated and acid-treated waste glass were fabricated to facilitate the study. Laboratory measurements, namely Marshall stability test, indirect tensile stiffness modulus test, moisture susceptibility test, and dynamic creep test, were performed to analyse the performance of asphalt mixture containing glass aggregate. The results showed that roughening glass aggregate’s surface texture by acid treatment significantly enhances the mechanical properties of asphalt mixture, namely resilient modulus, tensile strength, and creep resistance of the asphalt mixture. Utilising treated glass increased resilient modulus by 250 MPa, improved tensile strength ratio values by five percentage points, and enhanced creep resistance by 1.5 times. Herein, HF acid was deemed feasible for use as glass etching agent. As spent HF acid is an industrial waste, utilising waste HF as an acid-treatment agent can give value-add not only for treating glass aggregate but also to the reuse of spent HF acid itself.

Similar content being viewed by others

Data availability

Some or all data, models, or code generated or used during the study are available from the corresponding author upon reasonable request.

References

National Environment Agency (NEA). Waste statistics and overall recycling. Accessed from Jan 2022. https://www.nea.gov.sg/our-services/waste-management/waste-statistics-and-overall-recycling

Salem ZTA, Khedawi TS, Baker MB, Abendeh R (2017) Effect of waste glass on properties of asphalt concrete mixtures. Jordan J Civ Eng 11(1):117–131

Lu JX, Poon CS (2019) New trends in eco-efficient and recycled concrete. Woodhead Publishing Series in Civil and Structural Engineering, England, pp 153–167

Kandhal PS (1993) Waste materials in hot mix asphalt an overview. In: Waller FH (ed) Use of waste materials in hot mix asphalt, vol 1193. American Society for Testing and Materials, Philadelphia

Cheng M, Chen M, Wu S, Yang T, Zhang J, Zhao Y (2021) Effect of waste glass aggregate on performance of asphalt micro-surfacing. Construct Build Mater 307:125133. https://doi.org/10.1016/j.conbuildmat.2021.125133

Wu SP, Yang W, Xue Y (2005) Preparation and properties of glass-asphalt concrete. Wuhan University of Technology, Wuhan

Du Y, Dai M, Deng H, Deng D, Wei T, Kong L (2020) Laboratory investigation on thermal and road performances of asphalt mixture containing glass microsphere. Construct Build Mater 264:120710. https://doi.org/10.1016/j.conbuildmat.2021.125133

Tahmoorian F, Samali B, Yeaman J, Crabb R (2018) The use of glass to optimize bitumen absorption of hot mix asphalt containing recycled construction aggregates. Materials 11:1053. https://doi.org/10.3390/ma11071053

Zakaria NM, Hassan MK, Ibrahim ANH, Rosyidi SAP, Yusoff NIM, Mohamed AA, Hassan N (2018) The use of mixed waste recycled plastic and glass as an aggregate replacement in asphalt mixture. Jurnal Teknologi (Sciences & Engineering) 80(1):79–88

Issa Y (2016) Effect of adding crushed glass to asphalt mix. Arch Civ Eng 63(2):35–44

He Z, Yang Y, Zeng H, Chang J, Shi J, Liu B (2020) Waste glass powder and its effect on the fresh and mechanical properties of concrete: a state of the art review. Adv Concr Const 10(5):417–429. https://doi.org/10.12989/acc.2020.10.5.417

Pápa Z, Budai J, Farkas B, Toth Z (2011) Investigation of surface roughness on etched glass surfaces. Thin Solid Films 519:2903–2906. https://doi.org/10.1016/j.tsf.2010.12.236

Zhang Q, Gu X, Chen Z, Jiang J, Zhang Z, Wei J, Li F, Jin X, Song Y, Li Q (2017) Enhancing extraction efficiency of quantum dot light-emitting diodes by surface engineering. Optic Express 25:17683–17694. https://doi.org/10.1364/OE.25.017683

Singapore Statutes Online (SSO) (2000) Environmental Public Health (Toxic Industrial Waste) Regulations 1988–Revised Edition 2000. G.N. No. S 111/1988, Singapore

Androjić I, Dimter S (2016) Properties of hot mix asphalt with substituted waste glass. Mater Struct 49:249–259. https://doi.org/10.1617/s11527-014-0492-3

Gedik A (2021) An exploration into the utilization of recycled waste glass as a surrogate powder to crushed stone dust in asphalt pavement construction. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2021.123980

DelRio-Prat M, Sanchez-Alonso E, Vega-Zamanillo A, Castro-Fresno D (2011) Effects of aggregate shape and size and surfactants on the resilient modulus of bituminous mixes. Can J Civ Eng 38:893–899

Yeggoni N, Button J, Zollinger D (1994) Influence of coarse aggregate shape and surface texture on rutting of hot mix asphalt concrete. Federal Highway Administration (FHWA), Washington D. C

Tarmuzi NA, Jaya RP, Yaacob H (2015) Aggregate angularity effect on porous asphalt engineering properties and performance. Jurnal Teknologi 73(4):99–104

Kusumawardani DM, Wong YD (2020) The influence of aggregate shape properties on aggregate packing in porous asphalt mixture (PAM). Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.119379

Kusumawardani DM, Wong YD (2021) Effect of aggregate shape properties on performance of porous asphalt mixture (PAM). J Mater Civ Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003801

Read J, Whiteoak D (2003) The shell bitumen handbook. Thomas Telford Publishing, London

Chen JS, Lin KY, Chang MK (2005) Influence of coarse aggregate shape on the strength of asphalt concrete mixtures. J East Asia Soc Transp Stud 6:1062–1075

Do TC, Tran VP, Le VP, Lee HJ, Kim WJ (2019) Mechanical characteristics of tensile strength ratio method compared to other parameters used for moisture susceptibility evaluation of asphalt mixtures. J Traffic Transp Eng (English Edition) 6(6):621–630

Kusumawardani DM, Zulkati A, Wong YD (2022) Composite effect of fillers on creep characteristic of asphalt mixture. Int J Pavement Res Technol. https://doi.org/10.1007/s42947-022-00230-6

Mansour F, Vahid V (2016) Effect of liquid nano material and hydrated lime in improving the moisture behaviour of HMA. Transp Res Procedia 17:506–512. https://doi.org/10.1016/j.trpro.2016.11.10

Singh B, Jain S (2021) Effect of lime and cement fillers on moisture susceptibility of cold mix asphalt. Road Mater Pavement Des 23(10):2433–2449. https://doi.org/10.1080/14680629.2021.1976254

Nataadmadja AD, Prahara E, Setyandito E (2020) The effect of hydrated lime addition in improving the moisture resistance of hot mix asphalt (HMA). IOP Conf Ser Earth Environ Sci 426:012023. https://doi.org/10.1088/1755-1315/426/1/012023

Mahmud MH, Jaya RP, Yaacob H, Hassan NA (2014) Laboratory investigation on the effects of flaky aggregates on dynamic creep and resilient modulus of asphalt Mixtures. Jurnal Teknologi 70(4):107–110

Li J, Zhang J, Qian J, Zheng J, Zhang Y (2019) Three-dimensional simulation of aggregate and asphalt mixture using parameterized shape and size gradation. J Mater Civ Eng 31(3):04019004

Cui P, Xiao Y, Yan B, Li M, Wu S (2018) Morphological characteristics of aggregates and their influence on the performance of asphalt mixture. Constr Build Mater 186:303–312

US Army Corps of Engineers (1999) Recycled crushed glass cullet as a construction aggregate. Cold Region Research and Engineering Laboratory

Acknowledgements

The authors gratefully acknowledge Singapore Safety Glass Ltd. for providing industrial waste glass. The authors would also like to express their gratitude for Prof. Sun Delai Darren for assisting and providing the chemical and equipment for glass etching.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical statement

Not applicable.

Consent statement

Not applicable.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kusumawardani, D.M., Wong, Y.D., Lwin, M.A. et al. Evaluation of the feasibility of treated waste glass as aggregate in asphalt mixture. Innov. Infrastruct. Solut. 8, 131 (2023). https://doi.org/10.1007/s41062-023-01095-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-023-01095-9