Abstract

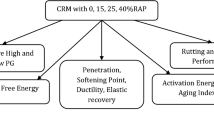

Recycled asphalt pavement (RAP) and waste cooking oil (WCO) are classes of solid wastes, which have significant environmental implications. Although RAP is being used in asphalt pavements to a certain extent, the usage of high RAP content poses several challenges, which can be addressed by using WCO as a rejuvenator. The optimum combination of two materials will significantly reduce the environmental impact and may address solid waste utilization. This study conducted rheological and chemical investigations on crumb rubber-modified asphalt binder with high RAP content using WCO as a rejuvenator. The crumb rubber-modified binder was chosen in this study as past studies mostly concentrated on unmodified binders. Three concentrations of WCO, such as 5.0, 7.5, and 10% by weight of the total binder, were mixed with the 50 and 60% RAP binder content to find the optimum WCO dose. The rheological tests indicated that asphalt binder with 50% RAP + 5.0% WCO and 60% RAP + 7.5% WCO depicted properties similar to the virgin binder. The fatigue performance of binders with 50 and 60% RAP was significantly better than long-term aged binders. The stripping test of asphalt indicates a slightly higher stripping in binders with RAP compared to the virgin binder. The thermogravimetry analysis revealed the binders had similar thermal stability and mass loss. The Fourier transform infrared spectroscopy (FTIR) indicated a lower presence of aliphatic hydrocarbons and higher aromatics content in the RAP binder modified with WCO. This can be mainly attributed to the peptizing power of WCO.

Similar content being viewed by others

References

Analytics ADI (2021) Asphalt Binder Market Assessment 1:1–62

García Á, Schlangen E, van de Ven M, Sierra-Beltrán G (2010) Preparation of capsules containing rejuvenators for their use in asphalt concrete. J Hazard Mater 184:603–611. https://doi.org/10.1016/j.jhazmat.2010.08.078

Xiaohu L, Isacsson U (1998) Chemical and rheological evaluation of ageing properties of sbs polymer modified bitumens. Fuel 77:961–972. https://doi.org/10.1016/s0016-2361(97)00283-4

Lastra-gonzález P, Calzada-pérez MA, Castro-fresno D, Indacoechea-vega I (2018) Asphalt mixtures with high rates of recycled aggregates and modified bitumen with rubber at reduced temperature. Road Mater Pavement Design 19:1489–1498. https://doi.org/10.1080/14680629.2017.1307264

Guo N, You Z, Tan Y, Zhao Y (2017) Performance evaluation of warm mix asphalt containing reclaimed asphalt mixtures. Int J Pavement Eng 18:981–989. https://doi.org/10.1080/10298436.2016.1138114

Widyatmoko I (2008) Mechanistic-empirical mixture design for hot mix asphalt pavement recycling. Constr Build Mater 22:77–87. https://doi.org/10.1016/j.conbuildmat.2006.05.041

Shen J, Amirkhanian S, Tang B (2007) Effects of rejuvenator on performance-based properties of rejuvenated asphalt binder and mixtures. Constr Build Mater 21:958–964. https://doi.org/10.1016/j.conbuildmat.2006.03.006

Im S, Zhou F, Lee R, Scullion T (2014) Impacts of rejuvenators on performance and engineering properties of asphalt mixtures containing recycled materials. Constr Build Mater 53:596–603. https://doi.org/10.1016/j.conbuildmat.2013.12.025

García Á, Schlangen E, Van De Ven M (2011) Properties of capsules containing rejuvenators for their use in asphalt concrete. Fuel 90:583–591. https://doi.org/10.1016/j.fuel.2010.09.033

Zaumanis M, Mallick RB, Frank R (2014) 100% recycled hot mix asphalt: a review and analysis. Resour Conserv Recycl 92:230–245. https://doi.org/10.1016/j.resconrec.2014.07.007

Eltwati A, Enieb M, Ahmeed S (2022) Effects of waste engine oil and crumb rubber rejuvenator on the performance of 100% RAP binder. J Innov Transp 3:8–15. https://doi.org/10.53635/jit.1072888

Xiao F, Amirkhanian SN, Shen J, Putman B (2009) Influences of crumb rubber size and type on reclaimed asphalt pavement (RAP) mixtures. Constr Build Mater 23:1028–1034. https://doi.org/10.1016/j.conbuildmat.2008.05.002

Asli H, Ahmadinia E, Zargar M, Karim MR (2012) Investigation on physical properties of waste cooking oil—rejuvenated bitumen binder. Constr Build Mater 37:398–405. https://doi.org/10.1016/j.conbuildmat.2012.07.042

Kazmierowski T, Marks P, Lee S (1999) Ten-year performance review of in situ hot-mix recycling in Ontario. Transp Res Rec. https://doi.org/10.3141/1684-23

Zhu J, Zhang K, Liu K, Shi X (2019) Performance of hot and warm mix asphalt mixtures enhanced by nano-sized graphene oxide. Constr Build Mater 217:273–282. https://doi.org/10.1016/j.conbuildmat.2019.05.054

Azahar WNAW, Jaya RP, Hainin MR, Bujang M, Ngadi N (2016) Chemical modification of waste cooking oil to improve the physical and rheological properties of asphalt binder. Constr Build Mater 126:218–226. https://doi.org/10.1016/j.conbuildmat.2016.09.032

Sheinbaum C, Balam MV, Robles G, De Larrea SL, Mendoza R (2015) Biodiesel from waste cooking oil in Mexico City. Waste Manag Res 33:730–9. https://doi.org/10.1177/0734242X15590471

Lombardi L, Me GV (2010) Life cycle assessment (LCA) and exergetic life cycle assessment (ELCA) of the production of biodiesel from used cooking oil (UCO) Centre of Environmental Science Leiden. Energy 35:889–93. https://doi.org/10.1016/j.energy.2009.07.013

Azahar WNAW, Jaya RP, Hainin MR, Bujang M, Ngadi N (2017) Mechanical performance of asphaltic concrete incorporating untreated and treated waste cooking oil. Constr Build Mater 150:653–663. https://doi.org/10.1016/j.conbuildmat.2017.06.048

Al-Omari AA, Khedaywi TS, Khasawneh MA (2018) Laboratory characterization of asphalt binders modified with waste vegetable oil using SuperPave specifications. Int J Pavement Res Technol 11:68–76. https://doi.org/10.1016/j.ijprt.2017.09.004

Eriskin E, Karahancer S, Terzi S, Saltan M (2017) Waste frying oil modified bitumen usage for sustainable hot mix asphalt pavement. Arch Civ Mech Eng 17:863–870. https://doi.org/10.1016/j.acme.2017.03.006

Asli H, Karim MR (2011) Implementation of waste cooking oil as RAP rejuvenator. J East Asia Soc Transp Stud 9:1336–1350

Rasman M, Hassan NA, Hainin MR, Jaya RP, Haryati Y, Shukry NAM, Abdullah ME, Kamaruddin NHM (2018) Engineering properties of bitumen modified with bio-oil. In: MATEC web conference

Zargar M, Ahmadinia E, Asli H, Karim MR (2012) Investigation of the possibility of using waste cooking oil as a rejuvenating agent for aged bitumen. J Hazard Mater 233–234:254–258. https://doi.org/10.1016/j.jhazmat.2012.06.021

Li H, Dong B, Wang W, Zhao G, Guo P, Ma Q (2019) Effect of waste engine oil and waste cooking oil on performance improvement of aged asphalt. Appl Sci. https://doi.org/10.3390/app9091767

Khan J, Hussain A, Haq F, Ahmad K, Mushtaq K (2019) Performance evaluation of modified bitumen with replaced percentage of waste cooking oil and tire rubber with bagasse ash as modifier. Civ Eng J 5:587. https://doi.org/10.28991/cej-2019-03091270

Luo W, Zhang Y, Cong P (2017) Investigation on physical and high temperature rheology properties of asphalt binder adding waste oil and polymers. Constr Build Mater 144:13–24. https://doi.org/10.1016/j.conbuildmat.2017.03.105

Liu S, Zhou S, Peng A, Li W (2020) Investigation of physiochemical and rheological properties of waste cooking oil/SBS/EVA composite modified petroleum asphalt. J Appl Polym Sci 137:1–13. https://doi.org/10.1002/app.48828

Ruikun D, Huifang Y, Mengzhen Z (2022) Preparation of asphalt modifier made of waste tire crumb rubber and waste cooking oil. J Mater Civ Eng 34:1–11. https://doi.org/10.1061/(ASCE)MT.1943-5533.0004323

Saboo N, Sukhija M, Singh G (2021) Effect of nanoclay on physical and rheological properties of waste cooking oil-modified asphalt binder. J Mater Civ Eng 33:04020490. https://doi.org/10.1061/(asce)mt.1943-5533.0003598

Zahoor M, Nizamuddin S, Madapusi S, Giustozzi F (2021) Sustainable asphalt rejuvenation using waste cooking oil: a comprehensive review. J Clean Prod 278:123304. https://doi.org/10.1016/j.jclepro.2020.123304

Azahar WNAW, Bujang M, Jaya RP, Hainin MR, Ngadi N, Abdullah MMAB (2016) Performance of waste cooking oil in asphalt binder modification. Key Eng Mater 700:216–226. https://doi.org/10.4028/www.scientific.net/KEM.700.216

Gui MM, Lee KTÃ, Bhatia S (2008) Feasibility of edible oil vs non-edible oil vs waste edible oil as biodiesel feedstock. Energy 33:1646–53. https://doi.org/10.1016/j.energy.2008.06.002

Math MC, Prem S, Chetty SV (2010) Energy for sustainable development technologies for biodiesel production from used cooking oil-—a review. Energy Sustain Dev 14:339–345. https://doi.org/10.1016/j.esd.2010.08.001

Kim JH, Oh YR, Hwang J, Kang J, Kim H, Jang YA (2021) Valorization of waste-cooking oil into sophorolipids and application of their methyl hydroxyl branched fatty acid derivatives to produce engineering bioplastics. Waste Manag 124:195–202. https://doi.org/10.1016/j.wasman.2021.02.003

Zanzotto L, Kennepohl GJ (1996) Development of rubber and asphalt binders by depolymerization and devulcanization of scrap tires in asphalt. Transp Res Rec. https://doi.org/10.3141/1530-07

Kök BV, Çolak H (2011) Laboratory comparison of the crumb-rubber and SBS modified bitumen and hot mix asphalt. Constr Build Mater 25:3204–3212. https://doi.org/10.1016/j.conbuildmat.2011.03.005

Hong W, Li Q, Lv Z, Guan G, Xing G (2011) Preparation and properties of anion rubber-modified asphalt. In: ICMREE2011—proceedings of the 2011 international conference on materials for renewable energy and environment, vol 1, pp 932–935. https://doi.org/10.1109/ICMREE.2011.5930955

Dantas Neto SA, Farias MM, Pais JC, Pereira PAA, Sousa JB (2006) Influence of crumb rubber and digestion time on the asphalt rubber binders. Road Mater Pavement Des 7:131–148. https://doi.org/10.1080/14680629.2006.9690030

Lo PD (2013) Recycled tyre rubber modified Bitumens for road asphalt mixtures: a literature review. Constr Build Mater 49:863–881. https://doi.org/10.1016/j.conbuildmat.2013.09.007

ASTM D4124 - 09. Standard test method for separation of asphalt into four fractions. Aterials, West Conshohocken

Pradhan SK, Sahoo UC (2019) Performance assessment of aged binder rejuvenated with Polanga oil. J Traffic Transp Eng (English Ed) 6:608–620. https://doi.org/10.1016/j.jtte.2018.06.004

Lu X, Soenen H, Laukkanen OV (2017) Aging of bituminous binders in asphalt pavements and laboratory tests. In: Proceedings of the 10th international conference on the bearing capacity of roads, railways and airfields, BCRRA 2017, pp 273–80. https://doi.org/10.1201/9781315100333-40

Chen M, Xiao F, Putman B, Leng B, Wu S (2014) High temperature properties of rejuvenating recovered binder with rejuvenator, waste cooking and cotton seed oils. Constr Build Mater 59:10–16. https://doi.org/10.1016/j.conbuildmat.2014.02.032

ASTM D2872 - 19. Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). American Society for Testing and Materials, West Conshohocken, PA, United States.: n.d.

ASTM D6521 - 19a. Standard practice for accelerated aging of asphalt binder using a pressurized aging vessel (PAV). American Society for Testing and Materials, West Conshohocken, PA, USA

AASHTO M 323, Standard Specification for Superpave Volumetric Mix Design, (2017).

ASTM D5555 - 95. Standard test method for determination of free fatty acids contained in animal, marine, and vegetable fats and oils used in fat liquors and stuffing compounds. American Society for Testing and Materials, West Conshohocken, PA, USA

ASTM D7175 - 15. Standard test method for determining the rheological properties of asphalt binder using a dynamic shear rheometer. American Society for Testing and Materials, West Conshohocken, PA, USA

Singh D, Ashish PK, Kataware A, Habal A (2019) Effects of WMA additives and hydrated lime on high-stress and high-temperature performance of Elvaloy®- and PPA-modified asphalt binder. Road Mater Pavement Des 20:1354–1375. https://doi.org/10.1080/14680629.2018.1446040

Jing R, Varveri A, Liu X, Scarpas A, Erkens S (2020) Rheological, fatigue and relaxation properties of aged bitumen. Int J Pavement Eng 21:1024–1033. https://doi.org/10.1080/10298436.2019.1654609

Liu Q, Wu J, Zhou P, Oeser M (2021) The master-curve band considering measurement and modeling uncertainty for bituminous materials. Adv Mater Sci Eng. https://doi.org/10.1155/2021/5543279

ASTM D7405 - 15. Standard test method for multiple stress creep and recovery (MSCR) of asphalt binder using a dynamic shear rheometer. american society for testing and materials, West Conshohocken, PA, USA

AASHTO TP 101, Standard method of test for estimating damage tolerance of asphalt binders using the linear amplitude sweep (2014).

Indian Standard IS:6241. Method of test for determination of stripping value of road aggregate. Indian Stand 1971.

Yu H, Leng Z, Gao Z (2016) Thermal analysis on the component interaction of asphalt binders modified with crumb rubber and warm mix additives. Constr Build Mater 125:168–174. https://doi.org/10.1016/j.conbuildmat.2016.08.032

Hofko B, Porot L, Falchetto Cannone A, Poulikakos L, Huber L, Lu X (2018) FTIR spectral analysis of bituminous binders: reproducibility and impact of ageing temperature. Mater Struct Constr. https://doi.org/10.1617/s11527-018-1170-7

Jamal M, Hafeez I, Yaseen G, Aziz A (2020) Influence of Cereclor on the performance of aged asphalt binder. Int J Pavement Eng 21:1309–20. https://doi.org/10.1080/10298436.2018.1542694

Zhao Y, Chen M, Wu S, Jiang Q, Xu H, Zhao Z, Lv Y (2022) Effects of waterborne polyurethane on storage stability, rheological properties, and VOCs emission of crumb rubber modified asphalt. J Clean Prod. https://doi.org/10.1016/j.jclepro.2022.130682

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest among the authors.

Ethical approval

The study complies with ethical standards as per Committee on Publication Ethics (COPE) guidelines.

Rights and permissions

About this article

Cite this article

Jain, S., Chandrappa, A.K. Rheological and chemical investigation on asphalt binder incorporating high recycled asphalt with waste cooking oil as rejuvenator. Innov. Infrastruct. Solut. 7, 267 (2022). https://doi.org/10.1007/s41062-022-00871-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-022-00871-3