Abstract

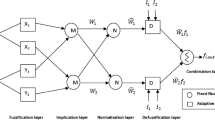

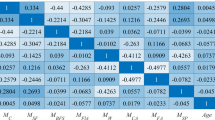

Adaptive neuro-fuzzy inference system (ANFIS) which possesses adaptive framework that integrates neural network and fuzzy-logic principles was adapted in this study for the optimization of mechanical strength properties of green concrete. The gains derived from deploying soft-computing methods help to handle multiple constraints associated with recycling and re-use of waste materials/derivatives to achieve sustainability and eco-efficient construction materials. Sixty-two datasets extracted from the experiments evaluating the mechanical properties of green concrete with varying replacement ratios of saw dust ash (SDA) and quarry dust (QD) for cement and fine aggregates, respectively, from 0 to 50% were deployed for the ANFIS model development. The outcome of the mechanical strength response shows that SDA and QD can be effective concrete admixture with significant improvement recorded at 0.5% and 0.225% replacement by cement and fine aggregates, respectively. Using ANFIS-toolbox in MATLAB software a smart-intelligent model was developed with hybrid method of optimization and subclustering method of FIS using Gaussian membership function. Mix variations of SDA cement and QD fine aggregates in the matrix were the input variables, while compressive strength result is the output variable. The developed model performance was evaluated using statistical methods, and the computed results showed indicate MAE of 0.144, RMSE of 0.429, MSE of 0.1837 and correlation of 97.20%, while MLR model presents a coefficient of determination of 82.46%.

Similar content being viewed by others

References

Alaneme GU, Elvis MM (2019) Optimization of flexural strength of palm nut fibre concrete using Scheffe’s theory. Mater Sci Energy Technol 2(2):272–287. https://doi.org/10.1016/j.mset.2019.01.006

Etim RK, Attah IC, Bassey OB (2017) Assessment of periwinkle shell ash blended cement concrete in crude oil polluted environment. FUW Trends Sci Technol J 2(2):879–885

Etim RK, Attah IC, Yohanna P (2020) Experimental study on potential of oyster shell ash in structural strength improvement of lateritic soil for road construction. Int J Pavement Res Technol. https://doi.org/10.1007/s42947-020-0290-y

Attah IC, Etim RK, Alaneme GU, Bassey OB (2020) Optimization of mechanical properties of rice husk ash concrete using Scheffe’s theory. SN Appl Sci, Springer Nat Switz AG 2:928. https://doi.org/10.1007/s42452-020-2727-y

Kamau J, Ahmed A, Hirst P, Kangwa J (2016) Suitability of corncob ash as a supplementary cementitious material. Int J Mater Sci Eng 4(4):215–228

Attah IC, Agunwamba JC, Etim RK, Ogarekpe NM (2019) Modelling and predicting of CBR values of lateritic soil treated with metakaolin for road material. ARPN Journal of Engineering and Applied Science 14(20):3609–3618

Raheem AA, Adenuga OA (2013) Wood ash from bread bakery as partial replacement for cement in concrete. Int J Sustain Constr Eng Technol 4(1):75–815

Elinwa AU, Mamuda AM (2014) Sawdust ash as powder material for self-compacting concrete containing naphthalene sulfonate. Adv Civil Eng. https://doi.org/10.1155/2014/129276

Attah IC, Etim RK, Usanga IN (2021) (2021) Potentials of cement kiln dust and rice husk ash blend on strength of tropical soil for sustainable road construction material. IOP Conf Ser: Mater Sci Eng 1036:012072. https://doi.org/10.1088/1757-899X/1036/1/012072

Attah IC, Okafor FO, Ugwu OO (2021) Optimization of California bearing ratio of tropical black clay soil treated with cement kiln dust and metakaolin blend. Int J Pavement Res Technol 14(6):655–667. https://doi.org/10.1007/s42947-020-0003-6

K Onyelowe, AB Salahudeen, A Eberemu, C Ezugwu, T Amhadi, G Alaneme, F Sosa (2020) Utilization of solid waste derivative materials in soft soils Re-engineering’, Springer Nature Switzerland AG 2020 H. Ameen et al. (Eds.): GeoMEast 2019, SUCI, pp. 49–57, 2020. https://doi.org/10.1007/978-3-030-34199-2_3

Chowdhury S, Mishra M, Suganaya O (2014) The incorporation of wood waste ash as a partial cement replacement material for making structural grade concrete: an overview. Ain Shams Eng J. https://doi.org/10.1016/j.asej.2014.11.005

Hamid Z, Rafiq S (2020) A comparative study on strength of concrete using wood ash as partial replacement of cement. IOP Conf Ser: Mat Sci Eng 955:012043. https://doi.org/10.1088/1757-899X/955/1/012043

Sofi A, Saxena A, Agrawal P, Sharma AR, Sharma K (2015) Strength predictions of saw dust and steel fibers in concrete. Int J Innov Res Sci, Eng Technol 4(12):12473–12477

Elahi M, Zia A (2019) Suitability of local wood ash for concrete as a partial replacement of cement. 1st Conference on sustainability in Civil Engineering, Capital University of Science and Technology, Islamabad, Pakistan. 1st August, 2019. 1–7

Naik TR (1999) Tests of wood ash as a potential source for construction materials. Report NoCBU-1999–09. Milwauke: UWM Center for By-products, Department of Civil Engineering and Mechanics, University of Wisconsin-Milwauke, p. 61

ASTM (2001) C618: Standard specification for coal fly ash and raw or calcined natural pozzolana for use as mineral admixture. American Society for Testing and Materials, West Conshocken, P A., USA

Alaneme GU, Mbadike EM, Iro UI, Udousoro IM, Ifejimalu WC (2021) Adaptive neuro-fuzzy inference system prediction model for the mechanical behaviour of rice husk ash and periwinkle shell concrete blend for sustainable construction. Asian J Civil Eng 22:959–974. https://doi.org/10.1007/s42107-021-00357-0

Alaneme GU, Mbadike EM (2021) Optimisation of strength development of bentonite and palm bunch ash concrete using fuzzy logic. Int J Sustain Eng 14(4):835–851. https://doi.org/10.1080/19397038.2021.1929549

Kankam CK, Meisuh BK, Sossou G, Buabin TK (2017) Stress-strain characteristics of concrete containing quarry rock dust as partial replacement of sand. Case Stud Constr Mater 7:66–72

Ilangovana R, Mahendrana N, Nagamanib K (2008) Strength and durability properties of concrete containing quarry rock dust as fine aggregate. ARPN J Eng Appl Sci 3:20–26

KC Onyelowe, D Bui Van, O Ubachukwu, C Ezugwu, B Salahudeen, M Nguyen Van, C Ikeagwuani, T Amhadi, F Sosa, W, TT Duc, A Eberemu, TP Duc, O Barah, C Ikpa, F Orji, G Alaneme, E Amanamba, H Ugwuanyi, V Sai, C Kadurumba, S Subburaj, B Ugorji (2019) Recycling and reuse of solid wastes; a hub for ecofriendly, ecoefficient and sustainable soil, concrete, wastewater and pavement reengineering, Int J Low-Carbon Technol 1–12 , The Author(s). Published by Oxford University Press. Doi: https://doi.org/10.1093/ijlct/ctz028

Alaneme G, Mbadike E (2020) Modelling of the compressive strength of palm-nut-fibre concrete using Scheffe’s theory. Comput Eng Phys Model 3(1):31–40. https://doi.org/10.22115/cepm.2020.212999.1076

Onyelowe KC, Alaneme GU, Van Bui D, Van Nguyen M, Ezugwu C, Amhadi T, Sosa F, Orji F, Ugorji B (2019) Generalized review on EVD and constraints simplex method of materials properties optimization for civil engineering. Civil Eng J 5(3):729–749. https://doi.org/10.28991/cej-2019-03091283

Gullu H, Fedakar HI (2017) Response surface methodology for optimization of stabilizer dosage rates of marginal sand stabilizer with sludge ash and fiber based on UCS performances. KSCE J Civil Eng 21(5):1717–1727. https://doi.org/10.1007/s12205-016-0724-x

Sabarish KV, Akish RM, Paul P (2019) Optimizing the concrete materials by Taguchi optimization method. IOP Conf Ser: Mat Sci cEng 574:012002. https://doi.org/10.1088/1757-899X/574/1/012002

Alaneme GU, Onyelowe KC, Onyia ME, Van Bui D, Mbadike EM, Ezugwu CN, Dimonyeka MU, Attah IC, Ogbonna C, Abel C, Ikpa CC, Udousoro IM (2020) Modelling volume change properties of hydrated-lime activated rice husk ash modified soft soil for construction purposes by artificial neural network. Umudike J Eng Technol 6(1):88–110. https://doi.org/10.33922/j.ujet_v6i1_9

Okonkwo UN, Agunwamba JC (2016) Classical optimization of bagasse ash content in cement-stabilized lateritic soil. Nigerian J Technol 35(3):481–490

Trivedi JS, Nair S, Iyyunni C (2013) Optimum utilization of fly ash for stabilization of sub-grade soil using genetic algorithm. Proc Eng 51:250–258

Alaneme GU, Attah IC, Etim RK, Dimonyeka MU (2021) Mechanical Properties Optimization of Soil—Cement Kiln Dust Mixture Using Extreme Vertex Design. Int J Pavement Res Technol. https://doi.org/10.1007/s42947-021-00048-8

Topcu IB, Sarıdemir M (2008) Prediction of mechanical properties of recycled aggregate concretes containing silica fume using artificial neural networks and fuzzy logic. Comput Mater Sci 42(1):74–82

Baykasoglu A, Dereli T, Tanis S (2004) Prediction of cement strength using soft computing techniques. Cem Concr Res 34(11):2083–2090

Naderpour H, Rafiean AH, Fakharian P (2018) Compressive strength prediction of environmentally friendly concrete using artificial neural networks. J Build Eng 16:213–219

Cevik A, Ozturk S (2009) Neuro-fuzzy model for shear strength of reinforced concrete beams without web reinforcement. Civ Eng Environ Syst 26:263–277

Jang JSR, Sun CT, Mizutani E (1997) Neuro-fuzzy and soft computing, a computational approach to learning and machine intelligence. Prentice Hall

Rameshkumar A, Arumugam S (2011) A neuro-fuzzy integrated system for nonlinear buck and quasi-resonant buck converter. Eur J Sci Res 51(1):66–78

Samandar A (2011) A model of adaptive neural-based fuzzy inference system (ANFIS) for prediction of friction coefficient in open channel flow. Acad J Sci Res Essays 6(5):1020–1027

Shing J, Jang R (1993) ANFIS: Adaptive network-based fuzzy inference system. IEEE Trans Syst, Man, Cybern 23(3):665–685

Sriraman A, Mayorga RV (2004) A fuzzy inference system approach for greenhouse climate control. Environ Inform Arch 2:699–710

Yousefi M, Hooshyar D, Remezani A, Sahari KSM, Khaksar W, Alnaimi FBI (2015) Short-term wind speed forecasting by an adaptive network-based fuzzy inference system (ANFIS): an attempt towards an ensemble forecasting method. Int J Adv Intell Inform 1(3):140–149

Alaneme GU, Elvis M (2019) Modelling of the mechanical properties of concrete with cement ratio partially replaced by aluminium waste and sawdust ash using artificial neural network. M SN Appl Sci 1:1514. https://doi.org/10.1007/s42452-019-1504-2

Simon MJ (2003) Concrete mixture optimization using statistical method. Final Report. Federal Highway Administration, Maclean VA, pp 120–127

Nigerian Industrial Standard (NIS) 444–1 (2003) Composition, specifications and conformity criteria for common cements. Standard Organization of Nigeria

Onyelowe KC, Alaneme G, Igboayaka C, Orji F, Ugwuanyi H, Van Bui D, Van Nguyen M (2019) Scheffe optimization of swelling California bearing ratio, compressive strength, and durability potentials of quarry dust stabilized soft clay soil. Mater Sci Energy Technol 2(1):67–77. https://doi.org/10.1016/j.mset.2018.10.005

B Standard (BS) EN 12620 (2002) Aggregates for concrete. British Standard Institution, London

BS 3797–1 (1964) Lightweight aggregate for concrete

ASTM C125–16 (2016) Standard terminology relating to concrete and concrete aggregates. ASTM International, West Conshohocken

ASTM C1602/C1602M-12 Standard Specification for Mixing Water Used in the Production of Hydraulic Cement Concrete

BS 8615–1:2019 Specification for pozzolanic materials for use with Portland cement. Natural pozzolana and natural calcined pozzolana

ASTM specification C618 – 78. “Specification for fly ash and raw or calcined natural pozzolan for use as a mineral admixture in Portland Cement Concrete”

Cheah CB, Ramli M (2011) The implementation of wood waste ash as a partial cement replacement material in the production of structural grade concrete and mortar: an overview review article. Resour Conserv Recycl 55(1):669–685

Alaneme GU, Mbadike EM (2021) Experimental investigation of Bambara nut shell ash in the production of concrete and mortar. Innov Infrastruct Solut 6:66. https://doi.org/10.1007/s41062-020-00445-1

Smith DK, Johnson GG, Ruud J, Clayton O (2001) Clay mineral analysis by automated powder diffraction analysis using the whole diffraction pattern. Powder Diffr 16:181–185. https://doi.org/10.1154/1.1423284

Chimmaobi O, Mbadike EM, Alaneme GU (2020) Experimental investigation of cassava peel ash in the production of concrete and mortar. Umudike J Eng Technol 6(2):10–21. https://doi.org/10.33922/j.ujet_v6i1_1

Sobhani J, Najimi M, Pourkhorshidi AR, Parhizkar T (2010) Prediction of the compressive strength of no-slump concrete: a comparative study of regression, neural network and ANFIS models. Constr Build Mater 24:709–718

Alaneme GU, Onyelowe KC, Onyia ME, Van Bui D, Mbadike EM, Dimonyeka MU, Attah IC, Ogbonna C, Iro UI, Kumari S, Firoozi AA, Oyagbola I (2020) Modelling of the swelling potential of soil treated with quicklime-activated rice husk ash using fuzzy logic. Umudike J Eng Technol 6(1):1–22. https://doi.org/10.33922/j.ujet_v6i1_1

Elinwa AU, Ejeh SP, Mamuda AM (2008) Assessing of the fresh concrete properties of self-compacting concrete containing sawdust ash. Constr Build Mater 22(6):1178–1182

Al-Rawas AA, Hago AW, Corcoran TC, Al-Ghafri KM (1998) Properties of Omani artificial pozzolana (sarooj). Appl Clay Sci 13:275–292

Elinwa AU, Mahmoodb YA (2002) Ash from timber waste as cement replacement material. Cement Concr Compos 24(2):219–222

Sivakumar A, Prakash M (2011) Characteristic studies on the mechanical properties of quarry dust addition in conventional concrete. J Civil Eng Constr Technol 2(10):218–235

Massazza F (2001) Pozzolana and pozzolanic cements. Lea's Chemistry of Cement and Concrete. Butterworth-Heinemann: 471–636

Nigerian code of practice part 1 (NCP 1) (1973). The structural use of concrete in building. Nigeria Standards Organization. Federal Ministry of Industries, Lagos 28

British standard (BS) 8110 part 1 (1997) Structural use of concrete, code of practice for design and construction. British Standard Institution, London

Jang JSR, Sun CT (1995) Nuro-fuzzy modeling and control. Proceedings of IEEE 83(3). Doi: https://doi.org/10.1109/5.364486

Sobhani J, Najimi M, Pourkhorshidi AR, Parhizkar T (2010) Prediction of the compressive strength of no-slump concrete: a comparative study of regression, neural network and ANFIS models. Cons Build Mat 24:709–718

AnandaKumar K, Punithavalli M (2011) Efficient cancer classification using fast adaptive neuro-fuzzy inference system (FANFIS) based on statistical techniques. Int J Adv Comput Sci Appl, Spec Issue Artificial Intell 1:132–137

Yilmaz I, Yuksek G (2009) Prediction of the strength and elasticity modulus of gypsum using multiple regression, ANN, and ANFIS models. Int J Rock Mech Min Sci 46(4):803–810

Erdirencelebi D, Yalpir S (2011) Adaptive network fuzzy inference system modeling for the input selection and prediction of anaerobic digestion effluent quality. Appl Math Model 35:3821–3832. https://doi.org/10.1016/j.apm.2011.02.015

Sadrmomtazi A, Sobhani J, Mirgozar MA (2013) Modeling compressive strength of EPS lightweight concrete using regression, neural network and ANFIS. Constr Build Mater 42:205–216

Alaneme GU, Ezeokpube GC, Mbadike EM (2020) Failure analysis of a partially collapsed building using analytical hierarchical process. J Fail Anal and Preven. https://doi.org/10.1007/s11668-020-01040-3

Kim S, Heeyoung K (2016) A new metric of absolute percentage error for intermittent demand forecasts. Int J Forecast 32(3):669–679. https://doi.org/10.1016/j.ijforecast.2015.12.003

Colin CA, Windmeijer FAG (1997) An R-squared measure of goodness of fit for some common nonlinear regression models. J Econom 77(2):1790. https://doi.org/10.1016/s03044076(96)01818-0

Onyelowe KC, Alaneme GU, Onyia ME, Bui Van D, Dimonyeka MU, Nnadi E, Ogbonna C, Odum LO, Aju DE, Abel C, Udousoro IM, Onukwugha E (2021) Comparative modelling of strength properties of hydrated-lime activated rice-husk-ash (HARHA) modified soft soil for pavement construction purposes by artificial neural network (ANN) and fuzzy logic (FL). Jurnal Kejuruteraan 33 (2)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no recorded conflicts of interests in this research work. We also affirm that the content of this work is original and has followed the journal template. Compliance with ethical standards was strictly observed.

Rights and permissions

About this article

Cite this article

Alaneme, G.U., Mbadike, E.M., Attah, I.C. et al. Mechanical behaviour optimization of saw dust ash and quarry dust concrete using adaptive neuro-fuzzy inference system. Innov. Infrastruct. Solut. 7, 122 (2022). https://doi.org/10.1007/s41062-021-00713-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-021-00713-8