Abstract

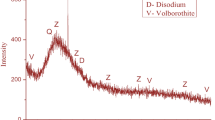

High-performance concrete (HPC) is a relatively recent advancement in cementitious composite materials with mechanical and durability properties which far exceed those of conventional concrete. Three different binary blends of HPC mixes utilizing distinctive supplementary cementitious materials at various substitution rates with ordinary Portland cement have been designed and cast to explore the durability performance and microstructure analysis of HPC. The water and chloride transport properties have also been investigated. The phase identification analysis of the cementitious materials has been performed using X-Ray diffractogram. The microstructure evolution of HPC has experimentally been studied by scanning electron microscope. The results revealed that all the mixes were less porous as compared to the control mix and showed “low-range” chloride penetration. An attempt has been made to develop correlation between compressive strength and durability parameters of concrete.

Similar content being viewed by others

References

ACI Committee 363 (1992) State-of-the-art report on high-strength concrete (ACI 363R-92). ACI J Proc, vol 92

CEB-FIP C (1991) Model code 1990, Com Euro-International Du Beton, Paris, pp 87–109. https://doi.org/10.1680/ceb-fipmc1990.35430

Kumar Mehta P, Burrows RW (2001) Building durable structures in the 21st century. Indian Concr J

Alexander MG, Santhanam M, Ballim Y (2010) Durability design and specification for concrete structures––the way forward. Int J Adv Eng Sci Appl Math. https://doi.org/10.1007/s12572-011-0027-x

Alkaysi M, El-Tawil S, Liu Z, Hansen W (2016) Effects of silica powder and cement type on durability of ultra high performance concrete (UHPC). Cem Concr Compos. https://doi.org/10.1016/j.cemconcomp.2015.11.005

Wu Z, Khayat KH, Shi C (2019) Changes in rheology and mechanical properties of ultra-high performance concrete with silica fume content. Cem Concr Res. https://doi.org/10.1016/j.cemconres.2019.105786

Abdulkareem OM, Fraj B, Bouasker M, Khelidj A (2017) Mechanical and durability properties of environmentally friendly UHCPC AFGC-ACI-Fib-RILEM. Int Symp Ultra High Perform Fibre Reinforced Concr

A.M. W. Gildas Cédric DOUAMBA, Abdou LAWANE, Latifou BELLO, Effect of metakaolin as partial substitution to Portland cement on the mechanical and durability properties of high performance concrete. Am J Civ Eng. ArchitA (2018). https://doi.org/https://doi.org/10.12691/ajcea-6-6-4.

Shen D, Liu K, Wen C, Shen Y, Jiang G (2019) Early-age cracking resistance of ground granulated blast furnace slag concrete. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2019.06.028

Li J, Wu Z, Shi C, Yuan Q, Zhang Z (2020) Durability of ultra-high performance concrete—A review. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.119296

M.I. Khan, R. Siddique, A. Mardani-Aghabaglou, G. Inan Sezer, K. Ramyar, M. Cyr, M. Trinh, B. Husson, G. Casaux-Ginestet, A. Borosnyói, D.M. Roy, P. Arjunan, M.R. Silsbee, H.S. Wong, H.A. Razak, Effect of cement type on metakaolin efficiency, Cem. Concr. Res. 57 (2014) 30–35. https://doi.org/https://doi.org/10.1016/j.resconrec.2011.09.016.

Du H, Du S, Liu X (2014) Durability performances of concrete with nano-silica. Constr Build Mater 73:705–712. https://doi.org/10.1016/j.conbuildmat.2014.10.014

Khan MI, Siddique R (2011) Utilization of silica fume in concrete: Review of durability properties. Resour Conserv Recycl 57:30–35. https://doi.org/10.1016/j.resconrec.2011.09.016

Dobias D, Pernicova R, Mandlik T (2016) Water transport properties and depth of chloride penetration in ultra high performance concrete. Key Eng Mater.

Li LG, Zhu J, Huang ZH, Kwan AKH, Li LJ (2017) Combined effects of micro-silica and nano-silica on durability of mortar. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2017.09.105

Wu K, Shi H, Xu L, Ye G, De Schutter G (2016) Microstructural characterization of ITZ in blended cement concretes and its relation to transport properties. Cem Concr Res. https://doi.org/10.1016/j.cemconres.2015.09.018

Cyr M, Trinh M, Husson B, Casaux-Ginestet G (2014) Effect of cement type on metakaolin efficiency. Cem Concr Res 64:63–72. https://doi.org/10.1016/j.cemconres.2014.06.007

Wong HS, Razak HA (2005) Efficiency of calcined kaolin and silica fume as cement replacement material for strength performance. Cem Concr Res 35:696–702. https://doi.org/10.1016/j.cemconres.2004.05.051

Wang XY (2014) Effect of fly ash on properties evolution of cement based materials. Constr Build Mater 69:32–40. https://doi.org/10.1016/j.conbuildmat.2014.07.029

Borosnyói A (2016) Long term durability performance and mechanical properties of high performance concretes with combined use of supplementary cementing materials. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2016.02.224

Kumar S, Rai B (2018) A review on wider application of supplementary cementitious materials on the development of high-performance concrete. Int J Civ Eng Technol 9:187–204

Neville A, Aïtcin P-C (1998) High performance concrete—an overview. Mater Struct 31:111–117. https://doi.org/10.1007/BF02486473

Aïtcin PC, High-performance concrete, 1998.

Aitcin PC, Neville A, Acker P (1997) Integrated view of shrinkage deformation. Concr Int 19: 35–41. https://www.concrete.org/publications/internationalconcreteabstractsportal.aspx?m=details&ID=68.

Hassan KE, Cabrera JG, Maliehe RS (2000) Effect of mineral admixtures on the properties of high-performance concrete. Cem Concr Compos 22:267–271. https://doi.org/10.1016/S0958-9465(00)00031-7

Langan BW, Weng K, Ward MA (2002) Effect of silica fume and fly ash on heat of hydration of Portland cement. Cem Concr Res. https://doi.org/10.1016/S0008-8846(02)00742-1

A.C. E-701 (2001) Cementitious materials for concrete. ACI Educ Bull, pp E3–01

ACI Committee 209 (2005) Report on factors affecting shrinkage and creep of hardened concrete, Am Concr Inst

Malhotra VM, Zhang M, Read PH, Ryell J (2000) Long-term mechanical properties and durability characteristics of high-strength/high performance concrete incorporating supplementary cementing materials under outdoor exposure conditions. ACI Mater J 97:518–525

Li G, Zhao X (2003) Properties of concrete incorporating fly ash and ground granulated blast-furnace slag. Cem Concr Compos. https://doi.org/10.1016/S0958-9465(02)00058-6

Neville AM (1996) Properties of concrete. In: 4th Final Ed. Wiley, New York

ACI Committee 211 (2013) Standard practice for selecting proportions for normal heavyweight, and mass concrete, ACI 211.1-91 (Reapproved 2009), In: Man Concr Pract

ACI211 (1998) Guide for Selecting proportions for high-strength concrete with Portland cement and fly ash, ACI 211.4R-93

Duval R, Kadri EH (1998) Influence of silica fume on the workability and the compressive strength of high-performance concretes. Cem Concr Res 28:533–547. https://doi.org/10.1016/S0008-8846(98)00010-6

Banthia N, Mindess S (1989) Water permeability of cement paste. Cem Concr Res 19:727–736. https://doi.org/10.1016/0008-8846(89)90043-4

Yu R, Spiesz P, Brouwers HJH (2014) Mix design and properties assessment of ultra-high performance fibre reinforced concrete (UHPFRC). Cem Concr Res. https://doi.org/10.1016/j.cemconres.2013.11.002

Lee T, Lee J (2020) Setting time and compressive strength prediction model of concrete by nondestructive ultrasonic pulse velocity testing at early age. Constr Build Mater 252:119027. https://doi.org/10.1016/j.conbuildmat.2020.119027

Alaskar A, Hooton D (2016) The effect of ground granulated blast furnace slag and silica fume on the durability of high performance concrete in bridge decks. Proc Annu Conf Can Soc Civ Eng

Wiciak P, Cascante G, Polak MA (2020) Frequency and geometry effects on ultrasonic pulse velocity measurements of concrete specimens. ACI Mater J. Doi: https://doi.org/10.14359/51722399.

Sabbağ N, Uyanık O (2017) Prediction of reinforced concrete strength by ultrasonic velocities. J Appl Geophys. https://doi.org/10.1016/j.jappgeo.2017.04.005

Pal P (2019) Dynamic Poisson’s ratio and modulus of elasticity of pozzolana Portland cement concrete. Int J Eng Technol Innov

Bhalla N, Sharma S, Sharma S, Siddique R (2018) Monitoring early-age setting of silica fume concrete using wave propagation techniques. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2017.12.032

Benyahia KA, Ghrici M, Kenai S, Breysse D, Sbartai ZM (2017) Analysis of the relationship between nondestructive and destructive testing of low concrete strength in new structures. Asian J Civ Eng 18:191–205

Y. Lin, S.F. Kuo, C. Hsiao, C.P. Lai, Investigation of pulse velocity-strength relationship of hardened concrete. ACI Mater J (2007). https://doi.org/https://doi.org/10.14359/18823.

Yoon H, Kim Y, Kim HS, Kang JW, Koh HM (2017) Evaluation of early-age concrete compressive strength with ultrasonic sensors. Sensors (Switzerland). https://doi.org/10.3390/s17081817

Ye G, Lura P, Van Breugel K, Fraaij ALA (2004) Study on the development of the microstructure in cement-based materials by means of numerical simulation and ultrasonic pulse velocity measurement. Cem Concr Compos. https://doi.org/10.1016/S0958-9465(03)00081-7

IS 4031:1996 (Part1to15) (1996) Ed. Various laboratory tests of cement. Bureau of Indian Standards, n.d.

IS 3812:1981 (1981) Ed. Specifications for fly—ash for use as pozzolana and admixture. Bureau of Indian Standards, n.d.

IS:15388 (2003) Specifications for silica fume. Bur Indian Stand. New Delhi, India

Bureau of Indian Standard(BIS) (1959) IS 1199–1959: methods of sampling and analysis of concrete. Bur Indian Stand. Delhi

IS: 516 (1959) Method of test for strength of concrete. Bur Indian Stand. New Delhi

IS 13311 (Part 1) (1992) Non-destructive testing of concrete—methods of test. Bur Indian Satandards, pp 1–7.

Bureau of Indian Standard(BIS) (1965) IS:3085–196, Method of test for permeability of cement mortar and concrete

ASTM C1202 (2012) Standard test method for electrical indication of concrete’s ability to resist chloride ion penetration. Am. Soc Test Mater, pp 1–8. Doi: https://doi.org/10.1520/C1202-12.2.

Kovler K, Roussel N (2011) Properties of fresh and hardened concrete. Cem Concr Res. https://doi.org/10.1016/j.cemconres.2011.03.009

Astm C989–04 (2004) Standard specification for ground granulated blast-furnace slag for use in concrete. Annu B ASTM Stand

Ganesh Babu K, Sree Rama Kumar V (2000) Efficiency of GGBS in concrete. Cem Concr Res 30: 1031–1036. Doi: https://doi.org/10.1016/S0008-8846(00)00271-4.

Bilim C, Atiş CD, Tanyildizi H, Karahan O (2009) Predicting the compressive strength of ground granulated blast furnace slag concrete using artificial neural network. Adv Eng Softw. https://doi.org/10.1016/j.advengsoft.2008.05.005

Chidiac SE, Panesar DK (2008) Evolution of mechanical properties of concrete containing ground granulated blast furnace slag and effects on the scaling resistance test at 28 days. Cem Concr Compos. https://doi.org/10.1016/j.cemconcomp.2007.09.003

Bentz DP (2006) Influence of water-to-cement ratio on hydration kinetics: simple models based on spatial considerations. Cem Concr Res. https://doi.org/10.1016/j.cemconres.2005.04.014

IS 10262 (2009) Ed. Indian standards recommended guidelines for concrete mix design, 2009th ed. Bureau of Indian Standards, n.d.

Wang Q, Feng J, Yan P (2012) The microstructure of 4-year-old hardened cement-fly ash paste. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2011.08.088

Papadakis VG (1999) Effect of fly ash on Portland cement systems: part I. low-calcium fly ash. Cem Concr Res 29:1727–1736. https://doi.org/10.1016/S0008-8846(99)00153-2

Papadakis VG, Pedersen EJ, Lindgreen H (1999) AFM-SEM investigation of the effect of silica fume and fly ash on cement paste microstructure. J Mater Sci. https://doi.org/10.1023/A:1004500324744

Papadakis S, Tsimas VG (2002) Supplementary cementing materials in concrete part I: efficiency and design. Cem Concr Res 3:1525–1532. https://doi.org/10.1016/S0008-8846(02)00827-X

Elsen J (2006) Microscopy of historic mortars-a review. Cem Concr Res. https://doi.org/10.1016/j.cemconres.2005.12.006

Khan MN, Singla S, Garg R, Garg R (2020) Effect of Microsilica on Strength and Microstructure of the GGBS-based Cement composites. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/961/1/012007

Abstract of: Guide for the Use of Silica Fume in Concrete (ACI 234R). ACI Mater J (1995). Doi: https://doi.org/10.14359/978.

Gedam BA, Bhandari NM, Upadhyay A (2016) Influence of supplementary cementitious materials on shrinkage, creep, and durability of high-performance concrete. J Mater Civ Eng 28:1–11. https://doi.org/10.1061/(asce)mt.1943-5533.0001462

Diamond S (2004) The microstructure of cement paste and concrete-a visual primer. Cem Concr Compos 26: 919–933. https://doi.org/https://doi.org/10.1016/j.cemconcomp.2004.02.028.

Baert G, Hoste S, De Schutter G, De Belie N (2008) Reactivity of fly ash in cement paste studied by means of thermogravimetry and isothermal calorimetry. J Therm Anal Calorim 94:485–492. https://doi.org/10.1007/s10973-007-8787-z

Liu J, Xing F, Dong B, Ma H, Pan D (2014) Study on water sorptivity of the surface layer of concrete. Mater Struct Constr. https://doi.org/10.1617/s11527-013-0162-x

Ma H (2013) Multi-scale modeling of the microstructure and transport properties of contemporary concrete. The Hong Kong University of Science and Technology, Hong Kong

Zhang Y, Sun W, Liu S (2002) Study on the hydration heat of binder paste in high-performance concrete. Cem Concr Res. https://doi.org/10.1016/S0008-8846(02)00810-4

Mobasher B, Shekarchi M, Bonakdar A, Bakhshi M, Mirdamadi A (2010) Transport properties in metakaolin blended concrete. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2010.04.035

Demirboǧa R, Türkmen I, Karakoç MB (2004) Relationship between ultrasonic velocity and compressive strength for high-volume mineral-admixtured concrete. Cem Concr Res 34:2329–2336. https://doi.org/10.1016/j.cemconres.2004.04.017

Türkmen I, Öz A, Aydin AC (2010) Characteristics of workability, strength, and ultrasonic pulse velocity of SCC containing zeolite and slag. Sci Res Essays 5:2055–2064

Khatib JM (2008) Performance of self-compacting concrete containing fly ash. Constr Build Mater 22:1963–1971. https://doi.org/10.1016/j.conbuildmat.2007.07.011

Shariq M, Prasad J, Masood A (2013) Studies in ultrasonic pulse velocity of concrete containing GGBFS. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2012.11.070

Owaid HM, Hamid R, Taha MR (2014) Strength - Ultrasonic pulse velocity relationship of thermally activated alum sludge multiple blended high performance concretes. Key Eng Mater.

Uysal M, Yilmaz K, Ipek M (2012) The effect of mineral admixtures on mechanical properties, chloride ion permeability and impermeability of self-compacting concrete. Constr Build Mater 27:263–270.

Gavela S, Nikoloutsopoulos N, Papadakos G, Sotiropoulou A (2020) Combination of compressive strength test and ultrasonic pulse velocity test with acceptable uncertainty. Mater Des Process Commun. https://doi.org/10.1002/mdp2.171

Mohamed OA (2019) Effect of mix constituents and curing conditions on compressive strength of sustainable self-consolidating concrete. Sustain, pp 11. Doi: https://doi.org/10.3390/su1102094.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Kumar, S., Rai, B. Durability performance and microstructure of binary blended high-performance concrete. Innov. Infrastruct. Solut. 6, 152 (2021). https://doi.org/10.1007/s41062-021-00525-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-021-00525-w