Abstract

An experimental study has been executed to examine long-term strength and durability characteristics of concrete mixes incorporating three types of supplementary cementitious materials (SCMs), namely rice husk ash (RHA); metakaolin (MK); and silica fume (SF) as substitution to cement content. These SCMs were mixed in binary- and/or ternary-blended form in the cement-bound composites having percentages of replacement in range between 5 and 10%. Seven different types of mixes were prepared and assessed for workability, compressive strength, splitting tensile strength and water absorption. For evaluating short- and long-term strengths, the concrete specimens were tested at curing age of 3, 7, 28, 56 and 180 days, whereas 28, 56 and 180 days of curing age were chosen to assess the water absorption value. Results revealed that considered SCMs decrease the strength of matrix up to 28 days of curing but aids in restoring it in later ages. For all mixes, experimental results indicate that the substitution of RHA and MK, or RHA and SF while altering cement content increases the composite potential in resisting higher loads in compression as well in tension, while on other side, degrades the water absorption capacity. A multivariable nonlinear regression model having higher order of accuracy has also been proposed for estimating compression strength, tension strengths and the water absorption capacity along with analysing cost and economic benefits of utilising SCM concrete.

Similar content being viewed by others

References

Lehne J, Preston F (2018) Chatham house report making concrete change innovation in low-carbon cement and concrete #ConcreteChange. Chatham House Rep. https://doi.org/10.1088/1742-6596/1015/3/032163

Reytier T, Bes C, Marechal P et al (2012) Generation of correlated stress time histories from continuous turbulence power spectral density for fatigue analysis of aircraft structures. Int J Fatigue. https://doi.org/10.1016/j.ijfatigue.2011.08.013

Bapat JD (2012) Mineral admixtures in cement and concrete. CRC Press, Boca Raton

Malhotra VM (2008) Mineral admixtures. In: Nawy EG (ed) Concrete construction engineering handbook, 2nd edn. CRC Press, Boca Raton, pp 29–78

Singh B (2018) Rice husk ash. In: Waste and supplementary cementitious materials in concrete. Woodhead Publishing, pp 417–460. https://doi.org/10.1016/B978-0-08-102156-9.00013-4

Madandoust R, Ranjbar MM, Moghadam HA, Mousavi SY (2011) Mechanical properties and durability assessment of rice husk ash concrete. Biosyst Eng 110:144–152. https://doi.org/10.1016/j.biosystemseng.2011.07.009

Wang F, Kovler K, Provis JL et al (2018) Metakaolin. In: RILEM state-of-the-art reports, vol 25, pp 153–179. https://doi.org/10.1007/978-3-319-70606-1_5

Khatib JM, Baalbaki O, ElKordi AA (2018) Metakaolin. In: Siddique R, Cachim P (eds) Waste and supplementary cementitious materials in concrete. Woodhead, Cambridge, pp 493–511

Panesar DK (2019) Supplementary cementing materials. In: Developments in the formulation and reinforcement of concrete, pp 55–85. https://doi.org/10.1016/B978-0-08-102616-8.00003-4

Lewis RC (2018) Silica fume. In: RILEM state-of-the-art reports, pp 99–121. https://doi.org/10.1007/978-3-319-70606-1_3

ASTM (2012) Standard specification for silica fume used in cementitious mixtures. ASTM C1240, pp 1–7. https://doi.org/10.1520/C1240-14.2

Wild S, Khatib JM, Jones A (1996) Relative strength, pozzolanic activity and cement hydration in superplasticised metakaolin concrete. Cem Concr Res 26:1537–1544. https://doi.org/10.1016/0008-8846(96)00148-2

Frías M, De Rojas MIS, Cabrera J (2000) Effect that the pozzolanic reaction of metakaolin has on the heat evolution in metakaolin-cement mortars. Cem Concr Res 30:209–216. https://doi.org/10.1016/S0008-8846(99)00231-8

Muthadhi A, Kothandaraman S (2013) Experimental investigations of performance characteristics of rice husk ash-blended concrete. J Mater Civ Eng 25:1115–1118. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000656

Zareei SA, Ameri F, Dorostkar F, Ahmadi M (2017) Rice husk ash as a partial replacement of cement in high strength concrete containing micro silica: evaluating durability and mechanical properties. Case Stud Constr Mater 7:73–81. https://doi.org/10.1016/j.cscm.2017.05.001

Sahoo KK, Sarkar P, Davis R (2019) Mechanical properties of silica fume concrete designed as per construction practice. Proc Inst Civ Eng Constr Mater 172:20–28. https://doi.org/10.1680/jcoma.16.00085

Hassan AA, Mawat MJ, Dawood AS (2019) Prediction of compressive strength of concrete containing pozzolanic materials by applying neural networks. Int J Civ Eng Technol 10:526–537

Azimi-Pour M, Eskandari-Naddaf H (2018) ANN and GEP prediction for simultaneous effect of nano and micro silica on the compressive and flexural strength of cement mortar. Constr Build Mater 189:978–992. https://doi.org/10.1016/j.conbuildmat.2018.09.031

Golafshani EM, Behnood A (2019) Estimating the optimal mix design of silica fume concrete using biogeography-based programming. Cem Concr Compos 96:95–105. https://doi.org/10.1016/j.cemconcomp.2018.11.005

IS-8112 (2013) Ordinary Portland cement, 43 grade-Specification. Bur Indian Stand New Delhi. https://doi.org/10.1002/hep.20373

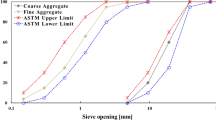

IS383-2016 (2016) Coarse and fine aggregate for concrete, 3rd ed. Indian Stand Code

Chandra S, Berntsson L (2002) Supplementary cementing materials. In: Lightweight aggregate concrete, pp 67–90. eBook ISBN: 9780815518204

Le HT, Nguyen ST, Ludwig HM (2014) A study on high performance fine-grained concrete containing rice husk ash. Int J Concr Struct Mater 8:301–307. https://doi.org/10.1007/s40069-014-0078-z

Indian Standards (2000) IS-456: 2000—plain and reinforced concrete—code of practice (fourth revision)

ASTM C192/C192M (2016) Standard practice for making and curing concrete test specimens in the laboratory. Am Soc Test Mater, pp 1–8. https://doi.org/10.1520/C0192

IS 9103/IS 9103 (1999) Indian standards. Specif Concr Admixtures

C494/C494M Ast (2004) Standard specification for chemical admixtures for concrete. ASTM Int. https://doi.org/10.1520/C0494

Saravanan MM, Sivaraja M (2016) Mechanical behavior of concrete modified by replacement of cement by rice husk ash. Braz Arch Biol Technol. https://doi.org/10.1590/1678-4324-2016161072

Getahun MA, Shitote SM, Gariy ZCA (2018) Experimental investigation on engineering properties of concrete incorporating reclaimed asphalt pavement and rice husk ash. Buildings. https://doi.org/10.3390/buildings8090115

Krishna NK, Sandeep S, Mini KM (2016) Study on concrete with partial replacement of cement by rice husk ash. In: IOP conference series: materials science and engineering

Abalaka AE (2013) Strength and some durability properties of concrete containing rice husk ash produced in a charcoal incinerator at low specific surface. Int J Concr Struct Mater. https://doi.org/10.1007/s40069-013-0058-8

ACI (2019) 318-19 Building code requirements for structural concrete and commentary

Code C (1993) CEB-FIB model code 1990, design code. Thomas Telford, Telford

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest in performing present investigation.

Rights and permissions

About this article

Cite this article

Khan, R.A., Haq, M. Long-term mechanical and statistical characteristics of binary- and ternary-blended concrete containing rice husk ash, metakaolin and silica fume. Innov. Infrastruct. Solut. 5, 53 (2020). https://doi.org/10.1007/s41062-020-00303-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-020-00303-0