Abstract

The purpose of this study was to evaluate the repurposed use of lapidated industrial glass waste in substitution of Portland cement in conventional concretes. Replacement ratios of 0%, 10%, 20% and 30% with respect to mass of cement were tested. The glass residue was subjected to laser granulometry and X-ray fluorescence to determine its granulometry, specific mass, surface area and pozzolanic activity. The effects of cement substitution on performance were evaluated with compression strength tests, physical property measurements, capillary water absorptivity, electrical resistance and ultrasonic wave propagation in samples aged 7 days, 28 days, 56 days and 90 days. Chemical analysis determined the decrease of some elements due to pozzolanic and expansion reactions while pozzolanic activity was measured at 98%. Electrical resistance, which was related to concrete durability, obtained significant results with a 30% substitution ratio. Capillary water absorption was mostly unchanged with slight improvements with a 20% replacement ratio. Physical properties and ultrasonic wave propagation were consistent with compression strength results: higher strength was related to lower void index and total absorption, which resulted in higher density and higher wave propagation speed. Although no substantial results were obtained, the relative increase in compression strength was high, which highlighted the effectiveness of substituting cement with repurposed ground glass waste.

Similar content being viewed by others

References

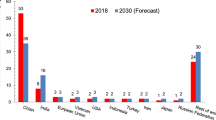

Harder J (2018) Glass recycling—current market trends. http://www.recovery-worldwide.com/en/artikel/glass-recycling-current-market-trends_3248774.html. Accessed 20 Dec 2021

ABRAVIDRO (2019) O mercado vidreiro em números 2019. O mercado vidreiro em números. 12. http://abravidro.org.br/wp-content/uploads/2019/05/panorama_abravidro_20192.pdf. Accessed 19 Dec 2021

ABRABE (2021) Glass is Goog. http://www.abrabe.org.br/glass-is-good/. Accessed 19 Dec 2021

LBRE (2020) Stanford recycling: land, buildings & real estate—Peninsula Sanitary Service/Stanford Recycling. lbre.stanford.edu

Williams L (2018) The glass recycling problem: what’s behind it, and what to do. http://greatforest.com/sustainability101/the-glass-recycling-problem/#:~:text=Glass is becoming the contaminant, and cardboard%2C lowering their value.

Nassar RUD, Soroushian P (2012) Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Construct Build Mater 29:368–377. https://doi.org/10.1016/j.conbuildmat.2011.10.061

de Moura JMBM, Pinheiro IG, Aguado A, Rohden AB (2021) Sustainable pervious concrete containing glass powder waste: performance and modeling. J Clean Product. https://doi.org/10.1016/j.jclepro.2021.128213

Matos AM, Sousa-Coutinho J (2012) Durability of mortar using waste glass powder as cement replacement. Construct Build Mater 36:205–215. https://doi.org/10.1016/j.conbuildmat.2012.04.027

Lopes RK, Piovesan JC, Tutikian BF, Grondona AEB (2021) Partial replacement of Portland cement with industrial glass waste in mortars. Revista IBRACON de Estruturas e Materiais 14(2):1–12. https://doi.org/10.1590/S1983-41952021000200014

Kashani A, Ngo TD, Hajimohammadi A (2019) Effect of recycled glass fines on mechanical and durability properties of concrete foam in comparison with traditional cementitious fines. Cement Concr Composites 99:120–129. https://doi.org/10.1016/j.cemconcomp.2019.03.004

Kalakada Z, Doh JH, Zi G (2020) Utilisation of coarse glass powder as pozzolanic cement—a mix design investigation. Construct Build Mater 2:40. https://doi.org/10.1016/j.conbuildmat.2019.117916

Islam GMS, Rahman MH, Kazi N (2017) Waste glass powder as partial replacement of cement for sustainable concrete practice. Int J Sustain Built Environ 6(1):37–44. https://doi.org/10.1016/j.ijsbe.2016.10.005

Elaqra HA, Haloub MAA, Rustom RN (2019) Effect of new mixing method of glass powder as cement replacement on mechanical behavior of concrete. Construct Build Mater 203:75–82. https://doi.org/10.1016/j.conbuildmat.2019.01.077

Aliabdo AA, Abd Elmoaty AEM, Aboshama AY (2016) Utilization of waste glass powder in the production of cement and concrete. Construct Build Mater 124:866–877. https://doi.org/10.1016/j.conbuildmat.2016.08.016

Özkan Ö, Yüksel I (2008) Studies on mortars containing waste bottle glass and industrial by-products. Construct Build Mater 22(6):1288–1298. https://doi.org/10.1016/j.conbuildmat.2007.01.015

Pereira-De-Oliveira LA, Castro-Gomes JP, Santos PMS (2012) The potential pozzolanic activity of glass and red-clay ceramic waste as cement mortars components. Construct Build Mater 31:197–203. https://doi.org/10.1016/j.conbuildmat.2011.12.110

Kalakada Z, Doh JH, Chowdhury S (2019) Glass powder as replacement of cement for concrete—an investigative study. Eur J Environ Civ Eng. https://doi.org/10.1080/19648189.2019.1695149

Idir R, Cyr M, Tagnit-Hamou A (2011) Pozzolanic properties of fine and coarse color-mixed glass cullet. Cement Concr Composites 33(1):19–29. https://doi.org/10.1016/j.cemconcomp.2010.09.013

Elaqra H, Rustom R (2018) Effect of using glass powder as cement replacement on rheological and mechanical properties of cement paste. Construct Build Mater 179:326–335. https://doi.org/10.1016/j.conbuildmat.2018.05.263

Kamali M, Ghahremaninezhad A (2015) Effect of glass powders on the mechanical and durability properties of cementitious materials. Construct Build Mater 98:407–416. https://doi.org/10.1016/j.conbuildmat.2015.06.010

Terzian P, Helene PRL (1992) Manual de dosagem e controle do concreto. In: Concreto: ensino, pesquisa e realizações. 353

Associação Brasileira de Normas Técnicas (2015) NBR 8953. Concreto para fins estruturais—Classificação pela massa específica, por grupos de resistência e consistência

Associação Brasileira de Normas Técnicas (2020) NBR 16889. Concreto—Determinação da consistência pelo abatimento do tronco de cone

Associação Brasileira de Normas Técnicas (2015) NBR 5738. Concreto — Procedimento para moldagem e cura de corpos de prova

Associação Brasileira de Normas Técnicas (2019) NBR 5739. Concreto — Ensaio de compressão de corpos de prova cilíndricos

Associação Brasileira de Normas Técnicas (2009) NBR 9778. Argamassa e concreto endurecidos – Determinação da absorção de água, índice de vazios e massa específica

Associação Brasileira de Normas Técnicas (2012) NBR 9779. Argamassa e concreto endurecidos — Determinação da absorção de água por capilaridade

Associação Brasileira de Normas Técnicas (2011) NBR 7222. Concreto e argamassa—Determinação da resistência à tração por compressão diametral de corpos de prova cilíndricos

American Society for Testing and Materials (2020) Standard test method for measurement of soil resistivity using the Wenner four-electrode method

Comite Euro-International du Beton (1988) CEB 192: diagnosis and assessment of concrete structures—state-of-art report. Bulletin d’Information

Associação Brasileira de Normas Técnicas (2019) NBR 8802. Concreto endurecido—Determinação da velocidade de propagação de onda ultrassônica

Bignozzi MC, Saccani A, Barbieri L, Lancellotti I (2015) Glass waste as supplementary cementing materials: the effects of glass chemical composition. Cement Concr Composites 55:45–52. https://doi.org/10.1016/j.cemconcomp.2014.07.020

Associação Brasileira de Normas Técnicas (2015) NBR 12653. Materiais pozolânicos—Requisitos

Associação Brasileira de Normas Técnicas (2014) NBR 5752. Materiais pozolânicos—Determinação do índice de desempenho com cimento Portland aos 28 dias

Shayan A, Xu A (2004) Performance of glass powder as a pozzolanic material in concrete: a field trial on concrete slabs. Cement Concr Res. https://doi.org/10.1016/j.cemconres.2005.12.012

Rahma A, El Naber N, Issa IS (2017) Effect of glass powder on the compression strength and the workability of concrete. Cogent Eng. https://doi.org/10.1080/23311916.2017.1373415

Taha B, Nounu G (2009) Utilizing waste recycled glass as sand/cement replacement in concrete. J Mater Civ Eng 21(12):709–721. https://doi.org/10.1061/(ASCE)0899-1561(2009)21:12(709)

Du H, Tan KH (2017) Properties of high volume glass powder concrete. Cement Concr Composites 75:22–29. https://doi.org/10.1016/j.cemconcomp.2016.10.010

Hassoun MN, Al-Manaseer A (2015) Structural concrete: theory and design, 6th edn. Wiley, Hoboken, p 1072

Tamanna N, Tuladhar R (2020) Sustainable use of recycled glass powder as cement replacement in concrete. Open Waste Manag J 13(1):1–13. https://doi.org/10.2174/1874347102013010001

Guignone GC, Vieira GL, Zulcão R, Degen MK, Mittri SHM, Teles CR (2020) Performance of concrete with the incorporation of waste from the process of stoning and polishing of glass as partial replacement of cement. Revista IBRACON de Estruturas e Materiais. 13(3):613–627. https://doi.org/10.1590/S1983-41952020000300011

Raju AS, Anand KB, Rakesh P (2019) Partial replacement of Ordinary Portland cement by LCD glass powder in concrete. Mater Today Proc 46:5131–5137. https://doi.org/10.1016/j.matpr.2020.10.661

Ramakrishnan K, Pugazhmani G, Sripragadeesh R, Muthu D, Venkatasubramanian C (2017) Experimental study on the mechanical and durability properties of concrete with waste glass powder and ground granulated blast furnace slag as supplementary cementitious materials. Construct Build Mater 156:739–749. https://doi.org/10.1016/j.conbuildmat.2017.08.183

Zhang SP, Zong L (2014) Evaluation of relationship between water absorption and durability of concrete materials. Adv Mater Sci Eng. https://doi.org/10.1155/2014/650373

Chen CT, Chang JJ, Yeih WC (2014) The effects of specimen parameters on the resistivity of concrete. Construct Build Mater 71:35–43. https://doi.org/10.1016/j.conbuildmat.2014.08.009

Hoppe TF (2005) Resistividade elétrica de concretos contendo diferentes teores de cinza de casca de arroz. Universidade Federal de Santa Maria

Raisdorfer JW (2015) Influência da adição ou substituição de adições minerais ao cimento Portland: efeitos na carbonatação, absorção capilar e resistividade de concretos. Universidade Federal do Paraná

Khatib JM, Negim EM, Sohl HS, Chileshe N (2012) Glass powder utilisation in concrete production. Eur J Appl Sci 4(4):173–176. https://doi.org/10.5829/idosi.ejas.2012.4.4.1102

Cánovas MF (1988) Patologia e terapia do concreto armado. PINI, São Paulo

Ichikawa T (2009) Alkali-silica reaction, pessimum effects and pozzolanic effect. Cement Concr Res 39(8):716–726. https://doi.org/10.1016/j.cemconres.2009.06.004

Associação Brasileira de Normas Técnicas (2015) NBR 12655. Concreto de cimento Portland—preparo, controle, recebimento e aceitação—Procedimento

Acknowledgements

This work received support through from CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico), number 310369/2021-5 (PQ2).

Funding

The author Regina Modolo received support from CNPQ (Brazilian National Council for Scientific and Technological Development)—Process 310369/2021-5 (PQ2). The other authors received no funding for the work reported.

Author information

Authors and Affiliations

Contributions

Conceptualization: BCC and FRCR; methodology: BCC and FP; validation: FRCR and RCEM; formal analysis: BCC and FRCR; investigation: BCC and FP; writing—original draft preparation: BCC and FRCR; writing—review and editing: FP and RCEM; visualization: FRCR; supervision: FP. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cadore, B.C., Ribeiro, F.R.C., Modolo, R.C.E. et al. Performance analysis of concrete with repurposed industrial glass waste. J Build Rehabil 8, 1 (2023). https://doi.org/10.1007/s41024-022-00230-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41024-022-00230-w