Abstract

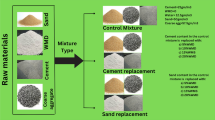

In recent years, researches on the use of mineral wastes in concrete have increased. These researches aim both to sustain waste management and to improve the mechanical properties of concrete. In the present study, the usability of fluorite mineral wastes, which are harmful to the environment and human health, in concrete as natural aggregate replacement was investigated. In this context, by substituting 5%, 10% and 20% fluorite mineral waste in the concrete mix instead of natural aggregate, the compressive strength, splitting tensile strength, flexural tensile strength, direct tensile strength and abrasion resistance were compared with the reference sample. Experimental studies revealed improvements in mechanical properties of samples containing fluorite mineral waste compared to control samples. Especially, 7-day compressive strengths of samples containing fluorite waste increased by 9.3%, 9.9% and 12.5% compared to control samples, and also 90-day abrasion resistances were increased by 6.61%, 15.52% and 25.95%, respectively. As a result of the study, it has been determined that fluorite waste can be used in concrete mixtures that require early strength and in floor applications exposed to friction effects. In this way, both a waste that is harmful in nature can be disposed of and the mechanical properties of concrete will be improved.

Similar content being viewed by others

References

Prabhu GG, Hyun JH, Kim YY (2014) Effects of foundry sand as a fine aggregate in concrete production. Constr Build Mater 70:514–521

Neville AM (2011) Properties of concrete, 4th. Lond Pearson Educ Ltd 443(846):444

Hebhoub H, Aoun H, Belachia M, Houari H, Ghorbel E (2011) Use of waste marble aggregates in concrete. Constr Build Mater 25:1167–1171

Aliabdo AA, Elmoaty AEMA, Auda EM (2014) Re-use of waste marble dust in the production of cement and concrete. Constr Build Mater 50:28–41

Saidani K, Ajam L, Ouezdou MB (2015) Barite powder as sand substitution in concrete: effect on some mechanical properties. Constr Build Mater 95:287–295

Sadowski Ł, Piechówka-Mielnik M, Widziszowski T, Gardynik A, Mackiewicz S (2019) Hybrid ultrasonic-neural prediction of the compressive strength of environmentally friendly concrete screeds with high volume of waste quartz mineral dust. J Clean Product 212:727–740

Shettima AU, Hussin MW, Ahmad Y, Mirza J (2016) Evaluation of iron ore tailings as replacement for fine aggregate in concrete. Constr Build Mater 120:72–79

Gao Z, Wang C, Sun W, Gao Y, Kowalczuk PB (2021) Froth flotation of fluorite: a review. Adv Colloid Interface Sci. https://doi.org/10.1016/j.cis.2021.102382

Allen RD (1952) Variations in chemical and physical properties of fluorite. Am Mineral J Earth Planet Mater 37(11–12):910–930

Berman R (1957) Some physical properties of naturally irradiated fluorite. Am Mineral J Earth Planet Mater 42(3–4):191–203

Gutiérrez Claverol M, Luque Cabal C, García Álvarez JR, Rodríguez Terente LM (2009) La Fluorita. Un siglo de minería en Asturias. Published by the authors, Oviedo

Shannon MA, Bohn PW, Elimelech M, Georgiadis JG, Marinas BJ, Mayes AM (2008) Science and technology for water purification in the coming decades. Nat 452(7185):301–311

Susheela AK (2001) Fluorosis: Indian scienario: A treatise on fluorosis. Fluorosis Research and Rural Development Foundation, Delhi

Bhussry BR, Demole V, Hodge HC, Jolly SS, Singh A, Taves DR (1970) Toxic effects of larger doses of fluoride. Monograph series. World Health Organization 59:225–271

Zhavoronkov AA (1977) Non-skeletal forms of fluorosis. Arkh Patol 39(3):83–91

Monsoru PA, Kruger BJ (1985) Effect of fluroide on soft tissues in vertebrates. A review. Fluoride 18(1):53–61

Mullenix PJ, Denbesten PK, Schunior A, Kernan WJ (1995) Neurotoxicity of sodium fluoride in rats. Neurotoxicol Teratol 17(2):169–177

Forjan R, Baragano D, Boente C, Fernandez-Iglesias E, Rodriguez-Valdes E, Gallego JR (2019) Contribution of fluorite mining waste to mercury contamination in coastal systems. Mar Pollut Bull 149:110576

ASTMC150 (2012) Standard specification for Portland cement publication. American Standard Testing of Materials, West Conshohocken

TS EN 12620 (2003) Aggregates for concrete. Turkish Standard Institution, Ankara

ASTMC127 (2013) Standard test method for relative density (specific gravity) and absorption of coarse aggregate. American Standard Testing of Materials, West Conshohocken

ASTMC128 (2013) Standard test method for relative density (specific gravity) and absorption of fine aggregate. American Standard Testing of Materials, West Conshohocken

TS EN 933-1 (2012) Tests for geometrical properties of aggregates—part 1: determination of particle size distribution—sieving method. Turkish Standard Institution, Ankara

ASTMC494 (2013) Standard specification for chemical admixtures for concrete. American Standard Testing of Materials, West Conshohocken

Uras Y, Yaman S, Öner F (2004) İsahocalı (Kırşehir) ve Feke (Adana) fluoritlerinde nadir toprak elementi (NTE) jeokimyası. Geosound 44–45:125–136

ACI 211.1-91 (2009) Standard practice for selecting proportions for normal, Heavyweight and Mass Concrete. American Concrete Institute, West Conshohocken

TS EN 12390-3 (2010) Concrete–hardened concrete experiments—sect. 3: determination of the mechanical strength in the test specimens. Turkish Standard Institute, Ankara

TS EN 12390-4 (2009) Compressive strength specification for testing machines. Turkish Standard Institute, Ankara

Rocco C (2001) Review of the splitting-test standards from a fracture mechanics point of view. Cem Concr Res 31(1):73–82

Kadleček V, Modrý S (2002) Size effect of test specimens on tensile splitting strength of concrete: general relation. Mater Struct 35(1):28–34

TS EN 12390-6 (2010) Concrete–hardened concrete experiments—sect. 6: determination of the splitting tensile strength of the test specimens. Turkish Standard Institute, Ankara

TS 12390-5 (2009) Concrete–hardened concrete experiments—sect. 5: flexural strength of test specimens. Turkish Standard Institute, Ankara

Krishnaraja AR, Kandasamy S, Kowsalya M (2018) Influence of polymeric and non-polymeric fibers in hybrid engineered cementitious composites. Revista Romana de Mater 48(4):507

TS 2824 (2005) Zemin Döşemesi için Beton Kaplama Blokları-Gerekli Şartlar ve Deney Metotları. Turkish Standard Institute, Ankara

DIN52108 (2010) Testing of inorganic non-metallic materials—Wear test using the grinding wheel according to Böhme—grinding wheel method. German National Standard Germany

Argane R, Benzaazoua M, Bouamrane A, Hakkou R (2015) Cement hydration and durability of low sulfide tailings-based renders: a case study in Moroccan constructions. Miner Eng 76:97–108

Gallala W, Hayouni Y, Gaied ME, Fusco M, Alsaied J, Bailey K, Bourham M (2017) Mechanical and radiation shielding properties of mortars with additive fine aggregate mine waste. Ann Nucl Energy 101:600–606

Bouregba A, Diouri A, Elghattas B, Boukhari A, Guedira T (2018) Influence of fluorine on Clinker burnability and mechanical properties of CPA Moroccan cement. In: MATEC web of conferences, vol 149. EDP Sciences, p 01075

Lee YL, Wang WH, Lin FH, Lin CP (2017) Hydration behaviors of calcium silicate-based biomaterials. J Formos Med Assoc 116(6):424–431

Chindaprasirt P, Phoongernkham T, Hanjitsuwan S, Horpibulsuk S, Poowancum A, Injorhor B (2018) Effect of calcium-rich compounds on setting time and strength development of alkali-activated fly ash cured at ambient temperature. Case Stud Constr Mater 9:e00198

Barbudo A, De Brito J, Evangelista L, Bravo M, Agrela F (2013) Influence of water-reducing admixtures on the mechanical performance of recycled concrete. J Clean Product 59:93–98

Keshavarz Z, Mostofinejad D (2019) Porcelain and red ceramic wastes used as replacements for coarse aggregate in concrete. Constr Build Mater 195:218–230

TS 500 (2000) Requirements for design and construction of reinforced concrete structures. Turkish Standard Institute, Ankara

Güleç A, Avcı U (2021) Investigation of the size effect of self-compacting concrete on direct tensile strength. El-Cezeri 8(2):827–840

Papenfus N (2003) Applying concrete technology to abrasion resistance. In: Proceedings of the 7th international conference on concrete block paving, Sun City, South Africa

De Larrard F, Belloc A (1997) The influence of aggregate on the compressive strength of normal and high-strength concrete. Mater J 94(5):417–426

Kumar GR, Sharma UK (2014) Abrasion resistance of concrete containing marginal aggregates. Constr Build Mater 66:712–722

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

AG: conceptualization, data curation, formal analysis, funding, investigation, methodology, project administration, resources, validation, visualization, writing original draft and editing. MAO: visualization, writing original draft and editing.

Corresponding author

Ethics declarations

Conflict of interest

The author declares no conflicting or competing interests with anyone whatsoever, that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Güleç, A., Oğuzhanoğlu, M. Fluorite mineral waste as natural aggregate replacement in concrete. J Build Rehabil 6, 26 (2021). https://doi.org/10.1007/s41024-021-00122-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41024-021-00122-5