Abstract

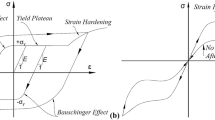

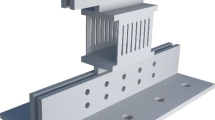

A new type of torsional metallic damper was proposed. The restraint device, loading control component, energy dissipating metallic tube, rotating arm and pin bearing were composed the proposed damper. A total of six specimens were fabricated. The quasi-static low-cycle reciprocating loading tests were carried out, while the mechanical and finite element model of the damper was established. The results show that compared with the damper under combined bending-shear-torsion deformation, the damper under pure torsional deformation possesses higher bearing capacity, higher energy dissipation capacity and better ductility performance. The yielding bearing capacity of the damper with the wall thickness of 2 mm and 3 mm of energy dissipating metallic tube is increased by 10.3% and 8.1%, respectively. While the ultimate bearing capacity of that is increased by 16.3% and 10.1%, respectively. The yielding area of the energy dissipating metallic tube of the damper under pure torsional deformation diffuses from the middle to both ends. Besides, the yielding areas of that are more dispersed. Moreover, the distribution of stress and strain of that is more uniform. The mechanical model of the damper is established based on the theory of material mechanics. Theoretical calculation results about the initial stiffness and the yielding bearing capacity are basically consistent with that obtained from the test. The established finite element model can accurately predict the mechanical properties of the damper. The suggested formulas about the yielding bearing capacity, the ultimate bearing capacity and the cumulative energy dissipation of the damper under different parameters were also given.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Wang W, Luo QR, Xu SW, Wang BJ, Sun ZZ (2022) Application research of corrugated mild metal shear damper based on damage control and energy-dissipation improvement. J Build Eng 47:103840. https://doi.org/10.1016/j.jobe.2021.103840

Mahmoudi M, Abdi MG (2012) Evaluating response modification factors of TADAS frames. J Constr Steel Res 71:162–170. https://doi.org/10.1016/j.jcsr.2011.10.015

Mohammadi RK, Nasri A, Ghaffary A (2017) TADAS dampers in very large deformations. Int J Steel Struct 17:515–524. https://doi.org/10.1007/s13296-017-6011-y

Li HN, Li G (2007) Experimental study of structure with “dual function” metallic dampers. Eng Struct 29(8):1917–1928. https://doi.org/10.1016/j.engstruct.2006.10.007

Guo W, Chen XY, Yu YJ, Bu D, Li S, Fang WB, Wang XY, Zeng C, Wang Y (2021) Development and seismic performance of bolted steel dampers with X-shaped pipe halves. Eng Struct 239:112327. https://doi.org/10.1016/j.engstruct.2021.112327

Guo W, Li S, Zhai ZP, Li ZY, Tan S, Ding FX (2022) Seismic performance of a new S-shaped mild steel damper with varied yielding cross-sections. J Build Eng 45:103508. https://doi.org/10.1016/j.jobe.2021.103508

Gullu A, Smyrou E, Khajehdehi A, Ozkaynak H, Bai LE, Yuksel E, Karadogan F (2019) Numerical modelling of energy dissipative steel cushions. Int J Steel Struct 19(4):1331–1341. https://doi.org/10.1007/s13296-019-00213-7

Chen Y, Chen C, Jiang HJ, Liu T, Wan ZW (2019) Study of an innovative graded yield metal damper. J Constr Steel Res 160:240–254. https://doi.org/10.1016/j.jcsr.2019.05.028

Varzaneh MN, Hosseini M (2019) Cyclic performance and mechanical characteristics of the oval-shaped damper. KSCE J Civ Eng 23(11):4747–4757. https://doi.org/10.1007/s12205-019-1382-6

Qu B, Dai CX, Qiu J, Hou HT, Qiu CX (2019) Testing of seismic dampers with replaceable U-shaped steel plates. Eng Struct 179:625–639. https://doi.org/10.1016/j.engstruct.2018.11.016

Demir S, Husem M (2018) Saw type seismic energy dissipaters: development and cyclic loading test. J Constr Steel Res 150:264–276. https://doi.org/10.1016/j.jcsr.2018.08.015

Lee CH, Ju YK, Min JK, Lho SH, Kim SD (2015) Non-uniform steel strip dampers subjected to cyclic loadings. Eng Struct 99:192–204. https://doi.org/10.1016/j.engstruct.2015.04.052

Zibasokhan H, Behnamfar F, Azhari M (2019) Experimental study of a new pure bending yielding dissipater. Bull Earthq Eng 17(7):4389–4410. https://doi.org/10.1007/s10518-019-00616-1

Chen ZY, Ge HB, Usami T (2005) Hysteretic performance of shear panel dampers. In Fourth International Conference on Advances in Steel Structures II: 1223–1228. https://doi.org/10.1016/B978-008044637-0/50181-5

Chen ZY, Ge HB, Usami T (2006) Hysteretic model of stiffened shear panel dampers. J Struct Eng 132(3):478–483. https://doi.org/10.1061/(ASCE)0733-9445(2006)132:3(478)

Vetr MG, Ghamari A, Bouwkamp J (2017) Investigating the nonlinear behavior of eccentrically braced frame with vertical shear links (V-EBF). J Build Eng 10:47–59. https://doi.org/10.1016/j.jobe.2017.02.002

Xu LY, Nie X, Fan JS (2016) Cyclic behaviour of low-yield-point steel shear panel dampers. Eng Struct 126:391–404. https://doi.org/10.1016/j.engstruct.2016.08.002

Chan RW, Albermani F, Kitipornchai S (2013) Experimental study of perforated yielding shear panel device for passive energy dissipation. J Constr Steel Res 91:14–25. https://doi.org/10.1016/j.jcsr.2013.08.013

Formisano A, Lombardi L, Mazzolani FM (2016) Perforated metal shear panels as bracing devices of seismic-resistant structures. J Constr Steel Res 126:37–49. https://doi.org/10.1016/j.jcsr.2016.07.006

Cheraghi A, Zahrai SM (2019) Cyclic testing of multilevel pipe in pipe damper. J Earthq Eng 23(10):1695–1718. https://doi.org/10.1080/13632469.2017.1387191

Zahrai SM, Cheraghi A (2017) Improving cyclic behavior of multi-level pipe damper using infill or slit diaphragm inside inner pipe. Struct Eng Mech 64(2):195–204. https://doi.org/10.12989/sem.2017.64.2.195

Hu GX, Huang W, Xie HQ (2022) Mechanical behavior of a replaceable energy dissipation device for precast concrete beam-column connections. J Constr Steel Res 164:105816. https://doi.org/10.1016/j.jcsr.2019.105816

Zarei D, Tasnimi AA (2019) New fused steel-coupling beam with optimized shear panel damper. Int J Civ Eng 17(10):1513–1526. https://doi.org/10.1007/s40999-019-00430-5

Deng KL, Pan P, Li W, Xue YT (2015) Development of a buckling restrained shear panel damper. J Constr Steel Res 106:311–321. https://doi.org/10.1016/j.jcsr.2015.01.004

Oinam RM, Sahoo DR (2017) Seismic rehabilitation of damaged reinforced concrete frames using combined metallic yielding passive devices. Struct Infrastruct Eng 13(6):816–830. https://doi.org/10.1080/15732479.2016.1190766

Li ZJ, Shu GP, Huang Z (2019) Development and cyclic testing of an innovative shear-bending combined metallic damper. J Constr Steel Res 158:28–40. https://doi.org/10.1016/j.jcsr.2019.03.008

Aghlara R, Tahir MM (2018) A passive metallic damper with replaceable steel bar components for earthquake protection of structures. Eng Struct 159:185–197. https://doi.org/10.1016/j.engstruct.2017.12.049

Jarrah M, Khezrzadeh H, Mofid M, Jafari K (2019) Experimental and numerical evaluation of piston metallic damper (PMD). J Constr Steel Res 154:99–109. https://doi.org/10.1016/j.jcsr.2018.11.024

Franco JM, Cahís X, Gracia L, López F (2010) Experimental testing of a new anti-seismic dissipator energy device based on the plasticity of metals. Eng Struct 32(9):2672–2682. https://doi.org/10.1016/j.engstruct.2010.04.037

Milani AS, Dicleli M (2017) Low-cycle fatigue performance of solid cylindrical steel components subjected to torsion at very large strains. J Constr Steel Res 129:12–27. https://doi.org/10.1016/j.jcsr.2016.10.019

Mahyari SL, Riahi HT, Hashemi M (2019) Investigating the analytical and experimental performance of a pure torsional yielding damper. J Constr Steel Res 161:385–399. https://doi.org/10.1016/j.jcsr.2019.07.010

Lie WC, Wu CX, Luo WL, Wu CG, Li CH, Li DB, Wu CY (2022) Cyclic behaviour of a novel torsional steel-tube damper. J Constr Steel Res 188:107010. https://doi.org/10.1016/j.jcsr.2021.107010

The Chinese national Standardization Administration Committee (2010) Metallic materials: tensile testing: part 1: method of test of room temperature. Standards Press of China, Beijing

Dong Q, Yang P, Xu G, Deng JL (2016) Mechanisms and modeling of low cycle fatigue crack propagation in a pressure vessel steel Q345. Int J Fatigue 89:2–10. https://doi.org/10.1016/j.ijfatigue.2016.03.026

Buyuk M, Kan S, Loikkanen MJ (2009) Explicit finite-element analysis of 2024–T3/T351 aluminum material under impact loading for airplane engine containment and fragment shielding. J Aerosp Eng 22(3):287–295. https://doi.org/10.1061/(ASCE)0893-1321(2009)22:3(287)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 52008385), the Scientific Research Project of Education Office of Liaoning Province (Grant No. LJKMZ20220860), Natural Science Foundation of Shandong Province (Grant No. ZR2018BEE041), Postdoctoral Application Research Program of Qingdao City (Grant No. 861605040024). The authors would like to express their gratitude for the support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Besides, no conflict of interest exits in the submission of this manuscript, and manuscript is approved by all authors for publication. I would like to declare on behalf of my co-authors that the work described is original research that has not been published previously, and not under consideration for publication elsewhere. All the authors listed have approved the manuscript that is enclosed. We deeply appreciate your consideration of our manuscript.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, D., Zhang, Y., Fan, G. et al. Experimental Research and Theoretical Analysis of Mechanical Behavior of Torsional Metallic Damper. Int J Civ Eng 21, 857–874 (2023). https://doi.org/10.1007/s40999-023-00818-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-023-00818-4