Abstract

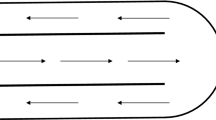

A homogenous model for simulating flow characteristics in a capillary tube-suction line heat exchanger (CT-SL HX) is developed based on conservation of mass, momentum, and energy. The numerical model is completely validated by 102 experimental data for both concentric and lateral types of CT-SL HX. The agreements of ± 10% and ± 15% on the prediction of the mass flow rate for the just mentioned CT-SL HX, respectively, and ± 35% on the heat transfer rate are reported. The model investigates the impacts of the convergence criteria setting, and the findings suggest that the outlet pressure of ± 0.01 MPa on the capillary tube and the temperature of ± 0.5 °C for the suction pipe inlet as the proven convergence criteria. The model is ready to be used for parametric studies with the noted error band just mentioned and can be applied as an important reference for heat exchanger design engineers to optimize the performance of the CT-SL HX in the refrigeration industry.

Similar content being viewed by others

Abbreviations

- A:

-

Cross-section area, m2

- A and B :

-

Constants from the fluid flow regimes

- Cc :

-

Coefficient of the contraction

- D:

-

Diameter, mm

- dE :

-

Change in energy

- \(d\dot{E}\) :

-

Differential increment energy change

- dh :

-

Differentiated Enthalpy

- dP :

-

Pressure difference, kPa or MPa

- dt :

-

Time difference, s

- dV :

-

Velocity difference, ms−1

- dz :

-

Step size for length

- f :

-

Friction factor

- G :

-

Mass flux, kgs−1 m−2

- g :

-

Gravity force, 9.81 ms−2

- h :

-

Enthalpy, kJ/kg

- k :

-

Thermal conductivity, W/m K

- \(\dot{m}\) :

-

Mass flow rate, kg s−1 or kg/h

- Nu :

-

Nusselt number

- P :

-

Pressure, kPa or MPa

- Pr:

-

Prandtl number

- Q :

-

Heat Transfer Rate (kW)

- R 1, R 2, …:

-

Thermal resistance, kW−1

- Re:

-

Reynolds number

- U :

-

Overall heat transfer coefficient based on area, W/m2 K

- v :

-

Specific volume, m3 kg−1

- COP:

-

Coefficient of performance

- CV:

-

Control volume

- CT:

-

Capillary tube

- CT-SL HX:

-

Capillary tube suction line heat exchanger

- θ :

-

Inclination angle of capillary tube suction line heat exchanger

- ϕ :

-

Two phase friction factor multiplier

- σ :

-

Ratio of A1 to A2

- τ :

-

Shear stress, kPa

- 1 :

-

Inlet of control volume

- 2 :

-

Exit of control volume

- 2ϕ :

-

Two-phase

- brazed :

-

Brazing material

- c :

-

Capillary tube

- contract :

-

Contraction

- Concentric :

-

Concentric configuration of CT-SL HX

- enlarge :

-

Enlargement

- f :

-

Fluid

- g :

-

Gas

- HX :

-

Heat exchange

- i :

-

Inner

- Lateral :

-

Lateral configuration of CT-SL HX

- lo :

-

Local

- o :

-

Outer or outlet

- s :

-

Suction pipe

References

Bansal PK, Xu B (2003) A parametric study of refrigerant flow in non-adiabatic capillary tubes. Appl Therm Eng 23:397–408

Bansal PK, Yang C (1998) Reverse heat transfer and re-condensation phenomenon in non-adiabatic capillary tubes. Appl Therm Eng 25:3187–3202

Churchill SW (1977) Friction factor equation spans all fluid flow regimes. Chem Eng 84:91–92

Collier JG, Thome JR (1994) Convective boiling and condensation, 3rd edn. Oxford University Press, New York

Hermes CJL, Melo C, Gonçalves JM (2008) Modeling of non-adiabatic capillary tube flows: a simplified approach and comprehensive experimental validation. Int J Refrig Revue Int Du Froid 31(8):1358–1367

Incropera FP, DeWitt DP (2007) Fundamentals of heat and mass transfer, 6th edn. Wiley, Hoboken

Kline S, Mcclintock F (1953) Describing uncertainties in single-sample experiments. Mech Eng 75(1):3–8

Lin S, Kwok CCK, Li RY, Chen ZH, Chen ZY (1991) Local frictional pressure drop during vaporization of R12 through capillary tubes. Int J Multiphase Flow 17(1):95–102

Liu Y, Bullard CW (1997) An experimental and theoretical analysis of capillary tube-suction line heat exchangers. ACRC-TR-109, University of Illinois, Illinois

NIST (2017) Reference fluid thermodynamic and transport properties database (REFPROP): version 9.1. https://www.nist.gov/srd/refprop. Accessed Mar 2017

Park SG, Son K, Jeong JH, Kim LS (2008a) A Simulation for predicting the refrigerant flow characteristics including metastable region in non-adiabatic capillary tube. Paper presented at the international refrigeration and air conditioning conference, Purdue

Park SG, Son K, Jeong JH, Kim LS (2008b) Simulation of the effects of a non-adiabatic capillary tube on refrigerant cycle. Paper presented at the international refrigeration and air conditioning conference Purdue

Pate MB, Tree DR (1984) A linear quality model for capillary tube-suction line heat exchangers. ASHRAE Trans 90:3–17

Peixoto RA, Bullard CW (1994) A design model for capillary tube suction line heat exchangers, ACRC-TR-53. University of Illinois, Illinois

Poh HH (2011) Parametric study of flow behaviour and heat exchange characteristics of a non-adiabatic capillary tube. M.Eng. in mechanical engineering thesis, Department of Mechanical Engineering, University of Malaya, Kuala Lumpur, Malaysia

Sarker D, Jeong JH (2012) Development of empirical correlations for non-adiabatic capillary tube based on mechanistic model. Int J Refrig 35(4):974–983. https://doi.org/10.1016/j.ijrefrig.2012.01.021

Wallis GB (1969) One-dimensional two-phase flow. McGraw-Hill, New York

Wolf DA, Pate MB (2002) Capillary tube heat exchanger performance with alternative refrigerants. ASHRAE final report 948-RP, Atlanta

Wolf DA, Bittle RR, Pate MB (1995) Adiabatic capillary tube performance with alternative refrigerants. ASHRAE final report 762-RP, Atlanta

Wong TN, Ooi KT (1996) Evaluation of capillary tube performance for CFC-12 and HFC-134a. Int Commun Heat Mass Transf 23(7):993–1001

Wongwises S, Songnetichaovalit T, Lokathan R, Kritsadathikam P, Suchatawat M (2000) A comparison of the flow characteristics of refrigerants flowing through adiabatic capillary tubes. Int Commun Heat Mass Transf 27(5):611–621

Xu B, Bansal PK (2002) Non-adiabatic capillary tube flow: a homogenous model and process description. Appl Therm Eng 22:1801–1819

Yang C, Bansal PK (2005) Numerical investigation of capillary tube-suction line heat exchanger performance. Appl Therm Eng 25:2014–2028

Yau YH, Poh H (2018) Study on Flow behavior and heat exchange characteristics of a capillary tube-suction line heat exchanger. Heat Transf Eng. https://doi.org/10.1080/01457632.2018.1436420

Yin JM (1998) A theoretical model for predicting adiabatic capillary tube performance: an analysis and improvement. University of Illinois, ACRC-TR-139, Illinois

Acknowledgements

The authors would like to thank University of Malaya for providing Partnership Grant RK005-2020 and IIRG Grant IIRG014A-2019 to the authors for research work to be conducted at University of Malaya. Thanks are extended to Daikin Fellowship Grant PV018-2016 for the partial financial assistance provided to the co-author, Ms. H.H. Poh, for conducting the research work at the HVAC&R Lab at the Department of Mechanical Engineering, University of Malaya. Special thanks are also extended to Dr. W.M. Chin, Head of Division, Development Support of Daikin R&D (Malaysia), for providing technical help during the critical period of the research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Yau, Y.H., Poh, H.H. Novel Numerical Modeling of Concentric and Lateral Capillary Tube Suction Line Heat Exchangers. Iran J Sci Technol Trans Mech Eng 46, 693–704 (2022). https://doi.org/10.1007/s40997-022-00495-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40997-022-00495-z