Abstract

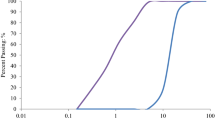

This study focusses on upgrading the fresh and hardened properties of fly ash-based geopolymer mix samples such as initial and final setting time, flow table test and compressive strength with the substitution of ground granulated blast furnace slag at varied percentage levels and with different alkali binder ratios. Substitution of slag in geopolymer mix samples is important so as to achieve fast setting characteristics in the product. For studying these effects on the microstructure of the product, scanning electron microscopy (SEM) with energy dispersive spectroscopy and Fourier transform infrared spectroscopy were conducted. The experimental outcomes stated that an increase in slag substitution has decreased the setting time and increased the compressive strength of geopolymer mix samples. SEM images have revealed the occurrence of a dense matrix with the slag substitution. FTIR results stated that shifting in wavenumbers of characteristic bands to lower numbers for varied slag substitution levels indicates a greater extent of geopolymerization.

Similar content being viewed by others

Data Availability

All data, models and code generated or used during the study are presented in the manuscript suitably.

References

Abdulkareem OA, Kamarudin H, Nizar K (2012) The effect of damp sand content on the geopolymerization reaction of fly ash-based geopolymer mortars. In: The 2nd international Malaysia-Ireland joint symposium on engineering. science and business (IMIEJS2012)

Aboulayt A, Jaafri R, Samouh H, El Idrissi AC, Roziere E, Moussa R, Loukili A (2018) Stability of a new geopolymer grout: Rheological and mechanical performances of metakaolin-fly ash binary mixtures. Constr Build Mater 181:420–436

Ahmed MM, El-Naggar KAM, Tarek D, Ragab A, Sameh H, Zeyad AM, Tayeh BA, Maafa IM, Yousef A (2021) Fabrication of thermal insulation geopolymer bricks using ferrosilicon slag and alumina waste. Case Stud Constr Mater 15:e00737

Al Bakri Abdullah MM, Kamarudin H, Abdulkareem OAKA, Ghazali CMR, Rafiza AR, Norazian MN (2012) Optimization of alkaline activator/fly ash ratio on the compressive strength of manufacturing fly ash-based geopolymer. In: Applied mechanics and materials. Trans Tech Publ, pp 734–739

Almutairi AL, Tayeh BA, Adesina A, Isleem HF, Zeyad AM (2021) Potential applications of geopolymer concrete in construction: a review. Case Stud Constr Mater 15:e00733

Bakharev T (2006) Thermal behaviour of geopolymers prepared using class F fly ash and elevated temperature curing. Cem Concr Res 36:1134–1147

Bernal SA, San Nicolas R, Myers RJ, de Gutiérrez RM, Puertas F, van Deventer JSJ, Provis JL (2014) MgO content of slag controls phase evolution and structural changes induced by accelerated carbonation in alkali-activated binders. Cem Concr Res 57:33–43

Bilondi MP, Toufigh MM, Toufigh V (2018) Experimental investigation of using a recycled glass powder-based geopolymer to improve the mechanical behavior of clay soils. Constr Build Mater 170:302–313

Blash AMA, Lakshmi TVSV (2016) Properties of geopolymer concrete produced by silica fume and ground-granulated blast-furnace slag. Int J Sci Res 5:319–323

Bui LA, Hwang C, Chen C, Lin K, Hsieh M (2012) Manufacture and performance of cold bonded lightweight aggregate using alkaline activators for high performance concrete. Constr Build Mater 35:1056–1062

Çevik A, Alzeebaree R, Humur G, Niş A, Gülşan ME (2018) Effect of nano-silica on the chemical durability and mechanical performance of fly ash based geopolymer concrete. Ceram Int 44:12253–12264

Cherki El Idrissi A, Roziere E, Loukili A, Darson S (2018) Design of geopolymer grouts: the effects of water content and mineral precursor. Eur J Environ Civ Eng 22:628–649

Chindaprasirt P, Chareerat T, Sirivivatnanon V (2007) Workability and strength of coarse high calcium fly ash geopolymer. Cem Concr Compos 29:224–229

Coduto DP (1999) Geotechnical engineering: principles and practices

Dalinaidu A, Das BB, Singh DN (2007) Methodology for rapid determination of pozzolanic activity of materials. J ASTM Int 4:1–11

Das BB, Kondraivendhan B (2012) Implication of pore size distribution parameters on compressive strength, permeability and hydraulic diffusivity of concrete. Constr Build Mater 28:382–386

Das BB, Pandey SP (2011) Influence of fineness of fly ash on the carbonation and electrical conductivity of concrete. J Mater Civ Eng 23:1365–1368

Das BB, Singh DN, Pandey SP (2007) Some investigations for establishing suitability of watson’s strength-porosity model for concrete. J ASTM Int 5:1–10

Das BB, Singh DN, Pandey SP (2010) A comparative study for determining pore volume of concrete. Indian Concr J 84:7

Elyamany HE, Abd Elmoaty M, Elshaboury AM (2018) Magnesium sulfate resistance of geopolymer mortar. Constr Build Mater 184:111–127

Escalante García JI, Campos-Venegas K, Gorokhovsky A, Fernández A (2006) Cementitious composites of pulverised fuel ash and blast furnace slag activated by sodium silicate: effect of Na2O concentration and modulus. Adv Appl Ceram 105:201–208

Fang Y, Kayali O (2013) The fate of water in fly ash-based geopolymers. Constr Build Mater 39:89–94

Fly T Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use. pp 1–5. https://doi.org/10.1520/C0618-19.2

Garcia-Lodeiro I, Palomo A, Fernández-Jiménez A (2015) An overview of the chemistry of alkali-activated cement-based binders. Handb Alkali-Activ Cem Mortars Concr. https://doi.org/10.1533/9781782422884.1.19

Goudar SK, Das BB, Arya SB, Shivaprasad KN (2020) Influence of sample preparation techniques on microstructure and nano-mechanical properties of steel-concrete interface. Constr Build Mater 256:119242

Güllü H, Agha AA (2021) The rheological, fresh and strength effects of cold-bonded geopolymer made with metakaolin and slag for grouting. Constr Build Mater 274:122091

Hardjito D, Cheak CC, Ing CHL (2008) Strength and setting times of low calcium fly ash-based geopolymer mortar. Mod Appl Sci 2:3–11

IS 12089 (1987) Specification for granulated slag for the manufacture of Portland slag cement

IS 4031 (1988) Methods of physical tests for hydraulic cement

Islam A, Alengaram UJ, Jumaat MZ, Bashar II, Kabir SMA (2015) Engineering properties and carbon footprint of ground granulated blast-furnace slag-palm oil fuel ash-based structural geopolymer concrete. Constr Build Mater 101:503–521

Ismail I, Bernal SA, Provis JL, Hamdan S, van Deventer JSJ (2013) Microstructural changes in alkali activated fly ash/slag geopolymers with sulfate exposure. Mater Struct 46:361–373

Ismail I, Bernal SA, Provis JL, San Nicolas R, Hamdan S, van Deventer JSJ (2014) Modification of phase evolution in alkali-activated blast furnace slag by the incorporation of fly ash. Cem Concr Compos 45:125–135

Kong DLY, Sanjayan JG, Sagoe-Crentsil K (2007) Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cem Concr Res 37:1583–1589

Kumar S, Kumar R, Mehrotra SP (2010) Influence of granulated blast furnace slag on the reaction, structure and properties of fly ash based geopolymer. J Mater Sci 45:607–615

Lee WKW, Van Deventer JSJ (2002) Structural reorganisation of class F fly ash in alkaline silicate solutions. Colloids Surfaces A Physicochem Eng Asp 211:49–66

Li X, Wang Z, Jiao Z (2013) Influence of curing on the strength development of calcium-containing geopolymer mortar. Materials (Basel) 6:5069–5076

Lyon RE, Balaguru PN, Foden A, Sorathia U, Davidovits J, Davidovics M (1997) Fire-resistant aluminosilicate composites. Fire Mater 21:67–73

Mallikarjuna Rao G, Gunneswara Rao TD (2015) Final setting time and compressive strength of fly ash and GGBS-based geopolymer paste and mortar. Arab J Sci Eng 40:3067–3074

Marjanović N, Komljenović M, Baščarević Z, Nikolić V, Petrović R (2015) Physical–mechanical and microstructural properties of alkali-activated fly ash–blast furnace slag blends. Ceram Int 41:1421–1435

Mozgawa W, Deja J (2009) Spectroscopic studies of alkaline activated slag geopolymers. J Mol Struct 924:434–441

MR H (1990) Engineering principles of ground modifications

Mustafa R, Shivaprasad KN, Das BB (2019) Effect of various additives on the properties of fly ash based geopolymer mortar. In: Sustainable construction and building materials. Springer, pp 707–715

Pacheco-Torgal F, Castro-Gomes J, Jalali S (2008) Alkali-activated binders: a review. Part 2. About materials and binders manufacture. Constr Build Mater 22:1315–1322

Palacios M, Banfill PFG, Puertas F (2008) Rheology and setting of alkali-activated slag pastes and mortars: effect of organic admixture. ACI Mater J 105:140

Prasanna KM, Tamboli S, Das BB (2021a) Characterization of mechanical and microstructural properties of FA and GGBS-based geopolymer mortar cured in ambient condition. In: Recent developments in sustainable infrastructure. Springer, pp 751–768

Prasanna KM, Theodose I, Shivaprasad KN, Das BB (2021b) Fast setting steel fibre geopolymer mortar cured under ambient temperature. In: Recent developments in sustainable infrastructure. Springer, pp 769–787

Provis JL, Duxson P, van Deventer JSJ (2010) The role of particle technology in developing sustainable construction materials. Adv Powder Technol 21:2–7

Provis JL, Myers RJ, White CE, Rose V, Van Deventer JSJ (2012) X-ray microtomography shows pore structure and tortuosity in alkali-activated binders. Cem Concr Res 42:855–864

Rafeet A, Vinai R, Soutsos M, Sha W (2019) Effects of slag substitution on physical and mechanical properties of fly ash-based alkali activated binders (AABs). Cem Concr Res 122:118–135

Sahoo S, Das BB, Mustakim S (2017) Acid, alkali, and chloride resistance of concrete composed of low-carbonated fly ash. J Mater Civ Eng 29:4016242

Samantasinghar S, Singh SP (2019) Fresh and hardened properties of fly ash–slag blended geopolymer paste and mortar. Int J Concr Struct Mater 13:1–12

Sathonsaowaphak A, Chindaprasirt P, Pimraksa K (2009) Workability and strength of lignite bottom ash geopolymer mortar. J Hazard Mater 168:44–50

Sharath BP, Shivaprasad KN, Athikkal MM, Das BB (2018) Some studies on sustainable utilization of iron ore tailing (IOT) as fine aggregates in fly ash based geopolymer mortar. In: IOP conference series: materials science and engineering. IOP Publishing, p 92010

Shivaprasad KN, Das BB (2017) Influence of alkali binder dosage on the efficiency of pelletization of aggregates from iron ore tailing and fly ash. Int J Eng Res Mechan Civ Eng 2:388–392

Shivaprasad KN, Das BB (2018a) Determination of optimized geopolymerization factors on the properties of pelletized fly ash aggregates. Constr Build Mater 163:428–437

Shivaprasad KN, Das BB, Sharath BP (2020) Pelletisation factors on the production of fly-ash aggregates and its performance in concrete. Proc Inst Civ Eng Mater. https://doi.org/10.1680/jcoma.19.00053

Shivaprasad KN, Das BB (2018b) Effect of duration of heat curing on the artificially produced fly ash aggregates. In: IOP conference series: materials science and engineering. IOP Publishing, p 92013

Singh DN, Pandey SP, Das BB (2014) Influence of initial curing humidity on compressive strength and ultrasonic properties of concrete. Indian Concr J 88:48–56

Snehal K, Das BB (2021) Acid, alkali and chloride resistance of binary, ternary and quaternary blended cementitious mortar integrated with nano-silica particles. Cem Concr Compos 123:104214

Snehal K, Das BB, Akanksha M (2020) Early age, hydration, mechanical and microstructure properties of nano-silica blended cementitious composites. Constr Build Mater 233:117212

Snehal K, Das BB, Barbhuiya S (2022) Influence of aggressive exposure on the degradation of nano-silica admixed cementitious mortar integrated with phase change materials. Constr Build Mater 335:127467

Soutsos M, Boyle AP, Vinai R, Hadjierakleous A, Barnett SJ (2016) Factors influencing the compressive strength of fly ash based geopolymers. Constr Build Mater 110:355–368

Taher SMS, Saadullah ST, Haido JH, Tayeh BA (2021) Behavior of geopolymer concrete deep beams containing waste aggregate of glass and limestone as a partial replacement of natural sand. Case Stud Constr Mater 15:e00744

Tayeh BA, Zeyad AM, Agwa IS, Amin M (2021) Effect of elevated temperatures on mechanical properties of lightweight geopolymer concrete. Case Stud Constr Mater 15:e00673

Thakur RN, Ghosh S (2009) Effect of mix composition on compressive strength and microstructure of fly ash based geopolymer composites. ARPN J Eng Appl Sci 4:68–74

van Deventer JSJ, Provis JL, Duxson P, Brice DG (2010) Chemical research and climate change as drivers in the commercial adoption of alkali activated materials. Waste Biomass Valoriz 1:145–155

Van Deventer JSJ, Provis JL, Duxson P (2012) Technical and commercial progress in the adoption of geopolymer cement. Miner Eng 29:89–104

Wang H, Li H, Yan F (2005) Synthesis and mechanical properties of metakaolinite-based geopolymer. Colloids Surfaces A Physicochem Eng Asp 268:1–6

Wijaya SW, Hardjito D (2016) Factors affecting the setting time of fly ash-based geopolymer. In: Materials science forum. Trans Tech Publ, pp 90–97

Xu H, Gong W, Syltebo L, Izzo K, Lutze W, Pegg IL (2014) Effect of blast furnace slag grades on fly ash based geopolymer waste forms. Fuel 133:332–340

Xu J, Kang AH, Wu ZG, Xiao P, Li B, Lu YM (2021) Research on the formulation and properties of a high-performance geopolymer grouting material based on slag and fly ash. KSCE J Civ Eng 25:3437–3447

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Prasanna, K.M., Sharath, B.P., Choukade, H. et al. Research on Setting Time, Compressive Strength and Microstructure of Fly Ash-Based Geopolymer Mixture Containing Slag. Iran J Sci Technol Trans Civ Eng 47, 1503–1517 (2023). https://doi.org/10.1007/s40996-022-01010-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40996-022-01010-9