Abstract

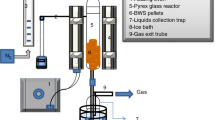

This work aimed to investigate the combustion characteristics of rubberwood sawdust pellet (RSP), teak sawdust pellet (TSP), eucalyptus bark pellet (EBP), cassava rhizomes pellet (CRP), and their corresponding raw biomass. The experiments were performed in a thermogravimetric (TG) analyzer and a fluidized-bed combustor (FBC). Thermogravimetric analysis (TGA) was conducted in the temperature range of 30–1000 °C at a heating rate of 10 °C/min in a dry air atmosphere. The combustion experiments were conducted in a twin-cyclone FBC at 120 kilowatts (kWth) heat input with three values of excess air (EA): 40, 50, and 60%. The combustion reactivity of the pellets was lower than raw biomasses, as indicated by higher values of peak, ignition, and burnout temperatures, as well as a lower comprehensive performance index value. The activation energies of the biomass pellets were greater than the as-received biomasses, indicating that the biomass pellets required higher energy and temperature and a longer time for complete combustion. The pellet fuels had a higher residence time and better mixing of the fuel and bed particles, leading to higher combustion intensity in a fluidized bed. Carbon monoxide (CO), hydrocarbon (CxHy), and nitric oxide (NO) emissions of the combustor when firing the pellets were lower compared to the burning of as-received biomasses. When firing the pellets at optimal EA (about 40%), the combustor operated at high combustion efficiency of 99.0–99.8%. This study indicated that the biomass pellets have desirable combustion characteristics that could be used as alternative fuels for sustainable energy production.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- A:

-

Ash content in fuel (wt.%)

- A :

-

Pre-exponential factor

- C:

-

Carbon content in fuel (wt.%)

- Cfa :

-

Unburned carbon content in fly ash (wt.%)

- CO:

-

Carbon monoxide (ppm)

- CR:

-

Cassava rhizomes

- CRP:

-

Cassava rhizomes pellet

- CxHy :

-

Hydrocarbon (ppm)

- DTG:

-

Differential thermogravimetric

- DTGmax :

-

Maximum burning rate (%/min)

- DTGmean :

-

Average weight loss rate (%/min)

- E a :

-

Activation energy (kJ/mol)

- EA:

-

Excess air (%)

- EB:

-

Eucalyptus bark

- EBP:

-

Eucalyptus bark pellet

- FBC:

-

Fluidized-bed combustor

- FC:

-

Fixed carbon content in fuel (wt.%)

- H:

-

Hydrogen content in fuel (wt.%)

- LHV:

-

Lower heating value, kJ/kg

- m τ :

-

Actual mass (at time τ) of the sample (kg)

- m 0 :

-

Initial mass of the sample (kg)

- m f :

-

Final mass of the sample (kg)

- n :

-

Reaction order

- N:

-

Nitrogen content in fuel (wt.%)

- NO:

-

Nitric oxide, ppm

- O:

-

Oxygen content in fuel (wt.%)

- q ic :

-

Heat loss due to incomplete combustion (%)

- q uc :

-

Heat loss due to unburned carbon (%)

- r :

-

Correlation coefficient

- RS:

-

Rubberwood sawdust

- RSP:

-

Rubberwood sawdust pellet

- S:

-

Sulfur content in fuel (wt.%)

- S i :

-

Comprehensive performance index (%2/min2·°C3)

- T :

-

Absolute temperature (°C)

- T b :

-

Burnout temperature (°C)

- TG:

-

Thermogravimetric

- TGA:

-

Thermogravimetric analysis

- T ig :

-

Ignition temperature (°C)

- T p :

-

Peak temperature (°C)

- TS:

-

Teak sawdust

- TSP:

-

Teak sawdust pellet

- u :

-

Superficial air velocity at the air distributor exit (m/s)

- u mff :

-

Minimum velocity of full fluidization (m/s)

- V dg@6% O2 :

-

Volume of flue gas per 1 kg fuel on a dry basis and at 6% O2 (m3/kg)

- VM:

-

Volatile matter in fuel, wt.%, on as received basis

- W:

-

Moisture content in fuel, wt.%, on as received basis

- Z :

-

Level along the combustor height above the air distributor, m

- α :

-

Mass conversion ratio

- β :

-

Heating rate (ºC/min)

- η c :

-

Combustion efficiency (%)

References

Basu P, Kefa C, Jestin L (2000) Boilers and burners: design and theory. Springer, New York

Batcha MFM, Othaman MF, Sabudin S, Mohammed AN, Abdullah MK, Ali MFM (2020) Combustion and emission of pelletized empty fruit bunch and oil palm shell in a swirling fluidized bed combustor. Biomass Convers Biorefin 10(3):755–763. https://doi.org/10.1007/s13399-020-00903-x

Cai J, Wu W, Liu R (2014) An overview of distributed activation energy model and its application in the pyrolysis of lignocellulosic biomass. Renew Sust Energ Rev 36:236–246. https://doi.org/10.1016/j.rser.2014.04.052

Chirone R, Salatino P, Scala F, Solimene R, Urciuolo M (2008) Fluidized bed combustion of pelletized biomass and waste-derived fuels. Combust Flame 155:21–36. https://doi.org/10.1016/j.combustflame.2008.05.013

Coats AW, Redfern JP (1964) Kinetic parameters from thermogravimetric data. Nature 201(4914):68–69. https://doi.org/10.1038/201068a0

DEDE (2020) Department of Alternative Energy Development and Efficiency, Thailand Alternative Energy Situation 2020. https://www.dede.go.th/download/stat63/Thailand%20Alternative%20Energy%20Situation%202020.pdf Accessed 10 Oct 2021

Duan F, Zhang JP, Chyang CS, Wang YJ, Tso J (2014) Combustion of crushed and pelletized peanut shells in a pilot-scale fluidized-bed combustor with flue gas recirculation. Fuel Process Technol 128:28–35. https://doi.org/10.1016/j.fuproc.2014.06.022

Edreis EMA, Luo G, Yao H (2014) Investigations of the structure and thermal kinetic analysis of sugarcane bagasse char during non-isothermal CO2 gasification. Anal Appl Pyrolysis 107:107–115. https://doi.org/10.1016/j.jaap.2014.02.010

Gil MV, Casal D, Pevida C, Pis JJ, Rubiera F (2010) Thermal behaviour and kinetics of coal/biomass blends during co-combustion. Bioresour Technol 101(14):5601–5608. https://doi.org/10.1016/j.biortech.2010.02.008

Guo F, Zhong Z (2017) Experimental studies on combustion of composite biomass pellets in fluidized bed. Sci Total Environ 599–600:926–933. https://doi.org/10.1016/j.scitotenv.2017.05.026

Haykiri-Acma H, Yaman S, Kucukbayrak S (2010) Comparison of the thermal reactivities of isolated lignin and holocellulose during pyrolysis. Fuel Process Technol 91:759–764. https://doi.org/10.1016/j.fuproc.2010.02.009

Idris SS, Rahman NA, Ismail K, Alias AB, Rashid ZA, Aris MJ (2010) Investigation on thermochemical behaviour of low rank Malaysian coal, oil palm biomass and their blends during pyrolysis via thermogravimetric analysis (TGA). Bioresour Technol 101(12):4584–4592. https://doi.org/10.1016/j.biortech.2010.01.059

Idris SS, Rahman NA, Ismail K (2012) Combustion characteristics of Malaysian oil palm biomass, sub-bituminous coal and their respective blends via thermogravimetric analysis (TGA). Bioresour Technol 123:581–591. https://doi.org/10.1016/j.biortech.2012.07.065

Jiang L, Yuan X, Li H, Xiao Z, Liang J, Wang H, Wu Z, Chen X, Zeng G (2015) Pyrolysis and combustion kinetics of sludge–camphor pellet thermal decomposition using thermogravimetric analysis. Energ Convers Manage 106:282–289. https://doi.org/10.1016/j.enconman.2015.09.046

Kaewklum R, Kuprianov VI (2010) Experimental studies on a novel swirling fluidized-bed combustor using an annular spiral air distributor. Fuel 89(1):43–52. https://doi.org/10.1016/j.fuel.2009.07.027

Kastanaki E, Vamvuka D (2006) A comparative reactivity and kinetic study on the combustion of coal–biomass char blends. Fuel 85(9):1186–1193. https://doi.org/10.1016/j.fuel.2005.11.004

Kongto P, Palamanit A, Ninduangdee P, Singh Y, Chanakaewsomboon I, Hayat A, Wae-hayee M (2022) Intensive exploration of the fuel characteristics of biomass and biochar from oil palm trunk and oil palm fronds for supporting increasing demand of solid biofuels in Thailand. Energy Rep 8:5640–5652. https://doi.org/10.1016/j.egyr.2022.04.033

Kuprianov VI, Arromdee P (2013) Combustion of peanut and tamarind shells in a conical fluidized-bed combustor: a comparative study. Bioresour Technol 140:199–210. https://doi.org/10.1016/j.biortech.2013.04.086

Madhiyanon T, Lapirattanakun A, Sathitruangsak P, Soponronnarit S (2006) A novel cyclonic fluidized-bed combustor (ψ-FBC): combustion and thermal efficiency, temperature distributions, combustion intensity, and emission of pollutants. Combust Flame 146(1):232–425. https://doi.org/10.1016/j.combustflame.2006.03.008

Magdziarz A, Wilk M (2013) Thermal characteristics of the combustion process of biomass and sewage sludge. J Therm Anal Calorim 114:519–529. https://doi.org/10.1007/s10973-012-2933-y

Malico I, Pereira RN, Gonçalves AC, Sousa AMO (2019) Current status and future perspectives for energy production from solid biomass in the European industry. Renew Sust Energ Rev 112:960–977. https://doi.org/10.1016/j.rser.2019.06.022

Martsri A, Yodpijit N, Jongprasithporn M, Junsupasen S (2021) Energy, economic and environmental (3E) analysis for sustainable development: a case study of a 9.9 MW biomass power plant in Thailand. Appl Sci Eng Prog 14(3):378–386. https://doi.org/10.14416/j.asep.2020.07.002

Mian I, Li X, Dacres OD, Wang J, Wei B, Jian Y, Zhong M, Liu J, Ma F, Rahman N (2020) Combustion kinetics and mechanism of biomass pellet. Energy 205:117909. https://doi.org/10.1016/j.energy.2020.117909

Ninduangdee P, Kuprianov VI (2014) Combustion of palm kernel shell in a fluidized bed: optimization of biomass particle size and operating conditions. Energ Convers Manage 85:800–808. https://doi.org/10.1016/j.enconman.2014.01.054

Ninduangdee P, Kuprianov VI (2018) Fluidized bed co-combustion of rice husk pellets and moisturized rice husk: the effects of co-combustion methods on gaseous emissions. Biomass Bioenergy 112:73–84. https://doi.org/10.1016/j.biombioe.2018.02.016

Ninduangdee P, Kuprianov VI, Cha EY, Kaewrath R, Youngyuen P, Atthawethworawuth W (2015) Thermogravimetric studies of oil palm empty fruit bunch and palm kernel shell: TG/DTG analysis and modeling. Energy Procedia 79:453–458. https://doi.org/10.1016/j.egypro.2015.11.518

Ninduangdee P, Arromdee P, Se C, Kuprianov VI (2020) Effects of (co-)combustion techniques and operating conditions on the performance and NO emission reduction in a biomass-fueled twin-cyclone fluidized-bed combustor. Waste Biomass Valori 11(10):5375–5391. https://doi.org/10.1007/s12649-020-01124-z

Niu S, Chen M, Li Y, Xue F (2016) Evaluation on the oxy-fuel combustion behavior of dried sewage sludge. Fuel 178:129–138. https://doi.org/10.1016/j.fuel.2016.03.053

Niu S, Chen M, Li Y, Lu T (2017) Combustion characteristics of municipal sewage sludge with different initial moisture contents. J Therm Anal Calorim 129(2):1189–1199. https://doi.org/10.1007/s10973-017-6262-z

PCD (2013) Pollution control department, ministry of natural resources and environment, Thailand, Air pollution standards for industrial sources. http://www.pcd.go.th/info_serv/reg_std_airsnd03.html. Accessed 26 Jan 2022

Permchart W, Kouprianov VI (2004) Emission performance and combustion efficiency of a conical fluidized-bed combustor firing various biomass fuels. Bioresour Technol 92:83–91. https://doi.org/10.1016/j.biortech.2003.07.005

Quan LM, Kamyab H, Yuzir A, Ashokkumar V, Hosseini SE, Balasubramanian B, Kirpichnikova I (2022) Review of the application of gasification and combustion technology and waste-to-energy technologies in sewage sludge treatment. Fuel 316:123199. https://doi.org/10.1016/j.fuel.2022.123199

Rokni E, Ren X, Panahi A, Levendis YA (2018) Emissions of SO2, NOx, CO2, and HCl from Co-firing of coals with raw and torrefied biomass fuels. Fuel 211:363–374. https://doi.org/10.1016/j.fuel.2017.09.049

Saikia M, Ali AA, Borah RC, Bezbarua MS, Saikia BK, Saikia N (2018) Effects of biomass types on the co-pyrolysis behaviour of a sub-bituminous high-sulphur coal. Energ Ecol Environ 3(5):251–265. https://doi.org/10.1007/s40974-018-0097-8

Shimizu T, Han J, Choi S, Kim L, Kim H (2006) Fluidized-bed combustion characteristics of cedar pellets by using an alternative bed material. Energy Fuels 20:2737–2742. https://doi.org/10.1021/ef0601723

Sirisomboon K, Charernporn P (2017) Effects of air staging on emission characteristics in a conical fluidized-bed combustor firing with sunflower shells. J Energy Inst 90(2):316–323. https://doi.org/10.1016/j.joei.2015.12.001

Sun Z, Jin B, Zhang M, Liu R, Zhang Y (2008) Experimental studies on cotton stalk combustion in a fluidized bed. Energy 33:1224–1232. https://doi.org/10.1016/j.energy.2008.04.002

Tumuluru JS (2018) Effect of pellet die diameter on density and durability of pellets made from high moisture woody and herbaceous biomass. Carbon Resour Convers 1(1):44–54. https://doi.org/10.1016/j.crcon.2018.06.002

Turns S (2006) An introduction to combustion. McGraw-Hill, Boston

Vamvuka D, Kakaras E, Kastanaki E, Grammelis P (2003) Pyrolysis characteristics and kinetics of biomass residuals mixtures with lignite. Fuel 82(15):1949–1960. https://doi.org/10.1016/S0016-2361(03)00153-4

Van Soest PJ, Robertson JB, Lewis BA (1991) Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci 74(10):3583–3597. https://doi.org/10.3168/jds.S0022-0302(91)78551-2

Wang X, Si J, Tan H, Niu Y, Xu C, Xu T (2012) Kinetics investigation on the combustion of waste capsicum stalks in Western China using thermogravimetric analysis. J Therm Anal Calorim 109(1):403–412. https://doi.org/10.1007/s10973-011-1556-z

Werther J, Saenger M, Hartge EU, Ogada T, Otara S (2000) Combustion of agricultural residues. Prog Energy Combust Sci 26:1–27. https://doi.org/10.1016/S0360-1285(99)00005-2

Winter F, Wartha C, Hofbauer H (1999) NO and N2O formation during the combustion of wood, straw, malt waste and peat. Bioresour Technol 70(1):39–49. https://doi.org/10.1016/S0960-8524(99)00019-x

Wongsapai W, Achawangkul Y, Thepsaskul W, Daroon S, Fongsamootr T (2020) Biomass supply chain for power generation in southern part of Thailand. Energy Rep 6:221–227. https://doi.org/10.1016/j.egyr.2019.11.066

Acknowledgements

The authors would like to sincerely acknowledge the financial support received from Thailand Science Research and Innovation (TSRI), Phetchaburi Rajabhat University, and the Department of Mechanical Engineering, Faculty of Engineering and Industrial Technology, Silpakorn University.

Author information

Authors and Affiliations

Contributions

PA: Designed and performed experiments, and undertook systematic review, statistical analysis, original drafting, and revision writing. PN: Undertook conceptualization, performed experiments, undertook data curation interpretation, writing, reviewing, revision writing and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Appendix A: Models for determining combustion-related heat losses and combustion efficiency

Appendix A: Models for determining combustion-related heat losses and combustion efficiency

The heat-loss method (Basu et al., 2000) was used to quantify combustion efficiency of the twin-cyclone FBC when firing the proposed biomass.

The heat loss owing to unburned carbon, quc (%LHV) was predicted by using the measured fraction of unburned carbon in fly ash carried over from the combustor (Cfa, wt%) determined using a "Perkin Elmer PE2400 Series II" CHNS/O elemental analyzer, the fuel-ash content (A, wt%, on as-received basis), and the fuel lower heating value (LHV, kJ/kg, on an as-received basis) as:

The heat loss owing to incomplete combustion, qic (%LHV), was quantified using the above-calculated quc and CO and CxHy (as CH4) emissions (in ppm, on a dry gas basis and at 6% O2) as:

where Vdg@6% O2 is calculated according to Kuprianov and Arromdee (2013) using the fuel composition on “as-received” basis. The combustion efficiency of the fluidized-bed combustors, \(\eta_{{\text{c}}}\) (%LHV), was then determined as:

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arromdee, P., Ninduangdee, P. Combustion characteristics of pelletized-biomass fuels: a thermogravimetric analysis and combustion study in a fluidized-bed combustor. Energ. Ecol. Environ. 8, 69–88 (2023). https://doi.org/10.1007/s40974-022-00263-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40974-022-00263-4