Abstract

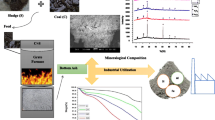

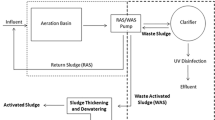

Wastewater treatment in the textile factory produces sludge classified as toxic and hazardous waste, which is harmful if left untreated. This study assessed the potential of utilizing sludge from a textile factory in Bandung Regency, Indonesia, as a co-firing fuel in coal boiler furnaces employed in the factory. The study aimed to improve the performance of sludge to meet the required standards for fuel substitution. The analysis involved proximate, ultimate, and ash element tests with correlation of the results with calorific values. The sludge was mixed with coal bottom ash produced by the textile factory and biomass (local refuse-derived fuel) at different ratios. An environmental impact analysis was also carried out with the toxicity characteristic leaching procedure (TCLP) and air emission testing. The results showed that the sludge did not meet the fuel substitution requirements if it was used as a single material. However, the sludge could be used as a substitute for coal by mixing it with bottom ash and biomass; the optimum composition was a ratio of 20% sludge, 40% bottom ash, and 40% biomass by weight. TCLP and air emission test results showed that this mixture was safe for human health and the environment and met the fuel substitution requirements. This study provides a practical solution to the problem of reducing toxic and hazardous waste.

Similar content being viewed by others

References

Ali AA, Akilli H (2019) Fuel characterization study and simulation of dewatered domestic wastewater sludge gasification using ASPEN plus. Acad Perspect Procedia 2(3):954–963. https://doi.org/10.33793/acperpro.02.03.107

Anggoro B, Aprilian A, Halimi B (2017) Potency of waste to energy-Bandung city case study. In: 2017 International conference on high voltage engineering and power systems (ICHVEPS), pp 135–139. https://doi.org/10.1109/ICHVEPS.2017.8225929

Anwar TB, Behrose B, Ahmed S (2018) Utilization of textile sludge and public health risk assessment in Bangladesh. Sustain Environ Res 28(5):228–233. https://doi.org/10.1016/j.serj.2018.04.003

Arbunowo AA, Purwanto PP, Budihardjo MA (2019) Waste to product: Bisolum-bricks, incorporation of WWTP sludge of textile industry into bricks for wall pairs. Jurnal Riset Teknologi Pencegahan Pencemaran Industri 10(2):29–35. https://doi.org/10.21771/jrtppi.2019.v10.no2.p29-35

Awere E, Bonoli A, Obeng PA (2020) Solids-liquid separation and solar drying of palm oil mill wastewater sludge: potential for sludge reuse. Case Stud Chem Environ Eng 2(100057):1–6. https://doi.org/10.1016/j.cscee.2020.100057

Chang YM, Hung CY, Chen JH, Chang CT, Chen CH (2009) Minimum feeding rate of activated carbon to control dioxin emissions from a large-scale municipal solid waste incinerator. J Hazard Mater 161(2–3):1436–1443. https://doi.org/10.1016/j.jhazmat.2008.04.128

Chuah LF, Aziz ARA, Yusup S, Bokhari A, Klemeš JJ, Abdullah MZ (2015) Performance and emission of diesel engine fuelled by waste cooking oil methyl ester derived from palm olein using hydrodynamic cavitation. Clean Technol Environ Policy 17(8):2229–2241. https://doi.org/10.1007/s10098-015-0957-2

Chuah LF, Yusup S, Aziz ARA, Klemeš JJ, Bokhari A, Abdullah MZ (2016a) Influence of fatty acids content in non-edible oil for biodiesel properties. Clean Technol Environ Policy 18(2):473–482. https://doi.org/10.1007/s10098-015-1022-x

Chuah LF, Yusup S, Aziz ARA, Bokhari A, Abdullah MZ (2016b) Cleaner production of methyl ester using waste cooking oil derived from palm olein using a hydrodynamic cavitation reactor. J Clean Prod 112(5):4505–4514. https://doi.org/10.1016/j.jclepro.2015.06.112

Cullis CF, Mulcahy MFR (1972) The kinetics of combustion of gaseous sulphur compounds. Combust Flame 18(2):225–292. https://doi.org/10.1016/S0010-2180(72)80139-1

Damayanti R (2018) Abu batubara dan pemanfaatannya: Tinjauan teknis karakteristik secara kimia dan toksikologinya. Jurnal Teknologi Mineral Dan Batubara 14(3):213–231. https://doi.org/10.30556/jtmb.Vol14.No3.2018.966

Das S, Lee SH, Kumar P, Kim KH, Lee SS, Bhattacharya SS (2019) Solid waste management: scope and the challenge of sustainability. J Clean Prod 228:658–678. https://doi.org/10.1016/j.jclepro.2019.04.323

Eskak E, Salma IR (2020) Kajian pemanfaatan limbah perkebunan untuk substitusi bahan pewarna batik. Jurnal Industri Hasil Perkebunan 15(2):27–37

Ghasri-Khouzani M, Meratian M, Panjepour M (2009) Effect of mechanical activation on structure and thermal decomposition of aluminum sulfate. J Alloy Compd 472(1–2):535–539. https://doi.org/10.1016/j.jallcom.2008.05.012

Hannon J, Zaman A (2018) Exploring the phenomenon of zero waste and future cities. Urban Sci 2(90):1–26. https://doi.org/10.3390/urbansci2030090

Haraguchi M, Siddiqi A, Narayanamurti V (2019) Stochastic cost-benefit analysis of urban waste-to-energy systems. J Clean Prod 224:751–765. https://doi.org/10.1016/j.jclepro.2019.03.099

Haryono H, Faizal DM, Liamita NC, Rostika A (2018) Pengolahan limbah zat warna tekstil terdispersi dengan metode elektroflotasi. EduChemia (jurnal Kimia Dan Pendidikan) 3(1):94–105. https://doi.org/10.30870/educhemia.v3i1.2625

Hussein BA, Tsegaye AA, Abdulahi A (2021) Assessment of the environmental and health impacts of disposal plastics in Gode town, Somali regional state, Eastern Ethiopia. J Mater Environ Sci 12(3):455–471

Igoni AH, Harry SK (2017) Design models for anaerobic batch digesters producing biogas from municipal solid waste. Energy Environ Eng 5(2):37–53. https://doi.org/10.13189/eee.2017.050202

James AK, Thring RW, Helle S, Ghuman HS (2012) Ash management review-applications of biomass bottom ash. Energies 5(10):3856–3873. https://doi.org/10.3390/en5103856

Jouhara H, Czajczyńska D, Ghazal H, Krzyżyńska R, Anguilano L, Reynolds AJ, Spencer N (2017) Municipal waste management systems for domestic use. Energy 139:485–506. https://doi.org/10.1016/j.energy.2017.07.162

Kim KH, Seo YC, Nam H, Joung HT, You JC, Kim DJ, Seo YC (2005) Characteristics of major dioxin/furan congeners in melted slag of ash from municipal solid waste incinerators. Microchem J 80(2):171–181. https://doi.org/10.1016/j.microc.2004.07.022

Kumar M, Kumar S, Singh S (2021) Waste management by waste to energy initiatives in India. Int J Sustain Energy Environ Res 10(2):58–68. https://doi.org/10.18488/journal.13.2021.102.58.68 ((in progress))

Kurniawan T, Hakiki R, Sidjabat FM (2018) Wastewater sludge as an alternative energy resource: a review. J Environ Eng Waste Manag 3(1):1–12. https://doi.org/10.33021/jenv.v3i1.396

Lombardi L, Carnevale E, Corti A (2015) A review of technologies and performances of thermal treatment systems for energy recovery from waste. Waste Manag 37:26–44. https://doi.org/10.1016/j.wasman.2014.11.010

Maalouf A, El-Fadel M (2019) Towards improving emissions accounting methods in waste management: a proposed framework. J Clean Prod 206:197–210. https://doi.org/10.1016/j.jclepro.2018.09.014

Mahatmanti W, Kusumastuti E, Rengga W (2019) Membran padat kitosan-silika-PEG sebagai membran pemisah ion logam bivalen dan rhodamin B pada limbah cair industri tekstil. JC-T (journal Cis-Trans) Jurnal Kimia Dan Terapannya 3(2):12–17. https://doi.org/10.17977/um0260v3i22019p012

Mahyudin RP (2017) Kajian permasalahan pengelolaan sampah dan dampak lingkungan di TPA (Tempat Pemrosesan Akhir). Jukung Jurnal Teknik Lingkungan 3(1):66–74. https://doi.org/10.20527/jukung.v3i1.3201

Marafon AC, Amaral AFC, Lemos EEP (2019) Characterization of bamboo species and other biomasses with potential for thermal energy generation. Pesquisa Agropecuária Tropical 49:1–5. https://doi.org/10.1590/1983-40632019v4955282

Marganingrum D, Estiaty LM (2020) Value increasing of reject coal with biomass adding as bio-coal briquette. Indones J Urban Environ Technol 3(2):123–135. https://doi.org/10.25105/urbanenvirotech.v3i2.5110

Marganingrum D, Estiaty LM, Irawan C, Hidawati (2020) The biomass coal fermented (BCF) briquette as an alternative fuel. In: MSCEIS 2019 conference proceeding 1:811–819. https://doi.org/10.4108/eai.12-10-2019.2296375

McKay G (2002) Dioxin characterisation, formation and minimisation during municipal solid waste (MSW) incineration: review. Chem Eng J 86(3):343–368. https://doi.org/10.1016/S1385-8947(01)00228-5

Naje AS, Chelliapan S, Zakaria Z, Ajeel MA, Alaba PA (2017) A review of electrocoagulation technology for the treatment of textile wastewater. Rev Chem Eng 33(3):263–292. https://doi.org/10.1515/revce-2016-0019

Nayono SE (2009) Anaerobic digestion of organic solid waste for energy production. Thesis, Karlsruhe University

Ni Y, Zhang H, Fan S, Zhang X, Zhang Q, Chen J (2009) Emissions of PCDD/Fs from municipal solid waste incinerators in China. Chemosphere 75(9):1153–1158. https://doi.org/10.1016/j.chemosphere.2009.02.051

Oladeji JT (2015) Theoretical aspects of biomass briquetting: a review study. J Energy Technol Policy 5(3):72–82

Olatunji OO, Akinlabi S, Madushele N, Adedeji PA (2019) Estimation of the elemental composition of biomass using hybrid adaptive neuro-fuzzy inference system. Bioenergy Res 12(3):642–652. https://doi.org/10.1007/s12155-019-10009-6

Özyuğuran A, Yaman S, Küçükbayrak S (2018) Prediction of calorific value of biomass based on elemental analysis. Int Adv Res Eng J 02(03):254–260

Pandapotan CD, Mukhlis M, Marbun P (2017) Pemanfaatan limbah lumpur padat (sludge) pabrik pengolahan kelapa sawit sebagai alternatif penyediaan unsur hara di tanah ultisol. Jurnal Agroekoteknologi Universitas Sumatera Utara 5(2):271–276

Parikh J, Channiwala SA, Ghosal GK (2005) A correlation for calculating HHV from proximate analysis of solid fuels. Fuel 84(5):487–494. https://doi.org/10.1016/j.fuel.2004.10.010

Pasek AD, Gultom KW, Suwono A (2013) Feasibility of recovering energy from municipal solid waste to generate electricity. J Eng Technol Sci 45(3):241–256. https://doi.org/10.5614/j.eng.technol.sci.2013.45.3.3

Peprah K, Amoah ST, Thomas G, Achana W (2015) Assessing ‘3Rs’ model in relation to municipal solid waste management in Wa, Ghana. World Environ 5(3):112–120. http://article.sapub.org/10.5923.j.env.20150503.03.html

Popli K, Sudibya GL, Kim S (2017) A review of solid waste management using system dynamics modeling. J Environ Sci Int 26(10):1185–1200. https://doi.org/10.5322/jesi.2017.26.10.1185

Prabawanti BE (2021) Application of green marketing in the use of coffee waste as a business creative industry based on social enterprise. Jurnal Manajemen Dan Organisasi 11(3):136–142. https://doi.org/10.29244/jmo.v11i3.32886

Putri AP, Sukandar S (2013) Studi pemanfaatan limbah B3 sludge produced water sebagai bahan baku refuse derived fuel (Rdf). Jurnal Tehnik Lingkungan 19(1):1–10. https://doi.org/10.5614/jtl.2013.19.1.1

Rathna R, Varjani S, Nakkeeran E (2018) Recent developments and prospects of dioxins and furans remediation. J Environ Manag 223:797–806. https://doi.org/10.1016/j.jenvman.2018.06.095

Ribeiro AP, Dalmolin S (2020) Biomass energy as a possibility for innovative agriculture initiatives. Energy Ecol Environ. https://doi.org/10.1007/s40974-020-00201-2

Rugatiri J (2021) Assessing solid waste management strategy in Higher Education Institutions of Indonesia: a case study of IPB. Thesis, IPB University

Santos RE, Santos IFS, Barros RM et al (2019) Generating electrical energy through urban solid waste in Brazil: an economic and energy comparative analysis. J Environ Manag 231:198–206. https://doi.org/10.1016/j.jenvman.2018.10.015

Sarbassov Y, Duan L, Manovic V, Anthony EJ (2018) Sulfur trioxide formation/emissions in coal-fired air- and oxy-fuel combustion processes: a review. Greenhouse Gases Sci Technol 8(3):402–428. https://doi.org/10.1002/ghg.1767

Siddiqi MM, Naseer MN, Wahab YA et al (2019) Potential in urban Pakistan. Process 7(848):1–13. https://doi.org/10.3390/pr7110848

Skaggs RL, Coleman AM, Seiple TE, Milbrandt AR (2018) Waste-to-Energy biofuel production potential for selected feedstocks in the conterminous United States. Renew Sustain Energy Rev 82:2640–2651. https://doi.org/10.1016/j.rser.2017.09.107

Somneuk P (2020) Enabling circular economy in local solid waste management the case of Muang Kalasin Municipality, Thailand. Thesis, Uppsala University, Villavägen 16, SE- 752 36 Uppsala, Sweden.

Srivastava RK, Miller CA, Erickson C, Jambhekar R (2004) Emissions of sulfur trioxide from coal-fired power plants. J Air Waste Manag Assoc 54(6):750–762. https://doi.org/10.1080/10473289.2004.10470943

Suhendra E, Kardena E (2013) Potensi keberadaan polutan kloroanilin di Sungai Citarum akibat biotranformasi pewarna azo dari air limbah tekstil. Prosiding Seminar Nasional Pengelolaan Sumberdaya Alam dan Lingkungan:475–481.

Tagawa H (1984) Thermal decomposition temperatures of metal sulfates. Thermochim Acta 80(1):23–33. https://doi.org/10.1016/0040-6031(84)87181-6

Tompkins FC (1976) Decomposition reactions. In: Treatise on solid state chemistry. Springer, US, pp 193–231. https://doi.org/10.1007/978-1-4684-8082-5_4

Toscano G, Pedretti EF (2009) Calori value determination of solid biomass fuel by simplified method. J Agric Eng 40(3):1–6. https://doi.org/10.4081/jae.2009.3.1

Utomo HD, Yu LS, Yi DCZ, Jun OJ (2017) Recycling solid waste and bioenergy generation in MFC dual-chamber model. Energy Procedia 143:424–429. https://doi.org/10.1016/j.egypro.2017.12.706

Valerie, Wijaya JC, Pinontoan R (2018) Pemanfaatan mikroba yang berpotensi sebagai agen bioremediasi limbah pewarna tekstil. FaST-Jurnal Sains Dan Teknologi 2(1):32–47

Wirahadi M (2016) Elemen interior berbahan baku pengolahan sampah styrofoam dan sampah kulit jeruk. Jurnal INTRA 5(2):144–153

Xu S, He H, Luo L (2016) Status and prospects of municipal solid waste to energy technologies in China. In: Environmental footprints and eco-design of products and processes, pp. 31–54. https://doi.org/10.1007/978-981-10-0150-5_2

Yaman S (2004) Pyrolysis of biomass to produce fuels and chemical feedstocks. Energy Convers Manag 45(5):651–671. https://doi.org/10.1016/S0196-8904(03)00177-8

Yusbindar, Fatimah E, Suhendrayatna (2020) Aspek teknis operasional yang mempengaruhi timbulan sampah di kecamatan. Jurnal Arsip Rekayasa Sipil Dan Perencanaan 3(2):118–127. https://doi.org/10.24815/jarsp.v3i2.16562

Zannikos F, Kalligeros S, Anastopoulos G, Lois E (2013) Converting biomass and waste plastic to solid fuel briquettes. J Renew Energy 2013:1–9. https://doi.org/10.1155/2013/360368

Zhao Y, Ma Q, Liu Y, He H (2016) Influence of sulfur in fuel on the properties of diffusion flame soot. Atmos Environ 142:383–392. https://doi.org/10.1016/j.atmosenv.2016.08.001

Acknowledgements

The authors would like to thank the Ministry of Finance of the Republic of Indonesia for providing financial assistance to conduct this research through the LPDP RISPRO program in 2019–2020. The authors also thank the management and staff members of textile factory in the Bandung Regency, where this study was conducted. The authors are grateful to the Laboratory of the Research Center for Geotechnology (LIPI), the Laboratory of the Ministry of Energy and Mineral Resources, and the Laboratory for Environmental Quality Control, PDAM Tirtawening, Bandung, for their support in testing the samples.

Author information

Authors and Affiliations

Contributions

DM contributed to conceptualization, methodology, analysis on data of proximate, ultimate, calorific value, wastewater quality, TCLP, heavy metal, chlorine, air emission, and writing, review and editing; H contributed to analysis of sulfur content, and writing; SJSD contributed to conceptualization, analysis on data of proximate, ultimate, calorific value, sulfur content, and writing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest in the publication of this article. The authors also confirm that the data are original and the paper is free of plagiarism.

Rights and permissions

About this article

Cite this article

Marganingrum, D., Hidawati & Djaja, S.D.S. A preliminary study of fuel mixtures of industrial sludge, bottom ash, and municipal solid waste for co-firing in coal boilers. Energ. Ecol. Environ. 7, 186–198 (2022). https://doi.org/10.1007/s40974-021-00229-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40974-021-00229-y