Abstract

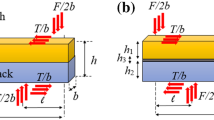

Interface fracture in additively manufactured multi-materials is a leading cause of failure and it is critical to understand and characterize it. Here a simple methodology is presented to quantify the interfacial failure in additively manufactured acrylonitrile butadiene styrene (ABS) and thermoplastic polyurethane (TPU) bimaterials. Double cantilever beam (DCB) specimens were 3D-printed where a TPU layer is sandwiched between two ABS substrates. The printed specimens were loaded under mode I until failure, and the crack initiation load was identified using a verified stiffness drop method. This method overcame the significant crack blunting issues in visual crack detection methods, caused by the TPU inelastic deformation. A finite element model was used to obtain the J-integral fracture energy values. The measured fracture energy presented the adhesion strength between ABS and TPU, as the failure was purely adhesive in nature. The effect of the specimen geometry on the ABS/TPU interface fracture energy was then analyzed. It was found that the fracture energy is independent of the precrack length, but it is strongly affected by the TPU layer thickness, which was related to enlargement of the damage zone ahead of crack tip. This methodology provides a simple route to characterize interfacial adhesion in various additively manufactured multi-materials.

Similar content being viewed by others

Data availability

The data is available upon request.

References

Diegel O, Nordin A, Motte D (2019) Additive Manufacturing Technologies. Springer, Singapore, pp 19–39

Crump SS (1991) Fast, precise, safe prototypes with FDM. Solid freeform fabrication symposium, pp 115–122. https://utw10945.utweb.utexas.edu/Manuscripts/1991/1991-15-Wales.pdf

Hopkinson N, Hague RJM, Dickens PM (2006) Rapid manufacturing: an industrial revolution for the digital age. https://doi.org/10.1002/0470033991

Ait-Mansour I, Kretzschmar N, Chekurov S et al (2020) Design-dependent shrinkage compensation modeling and mechanical property targeting of metal FFF. Progress Addit Manuf 5:51–57. https://doi.org/10.1007/s40964-020-00124-8

Harris M, Potgieter J, Archer R, Arif KM (2019) Effect of material and process specific factors on the strength of printed parts in fused filament fabrication: A review of recent developments. Materials. https://doi.org/10.3390/ma12101664

Angelopoulos PM, Samouhos M, Taxiarchou M (2020) Functional fillers in composite filaments for fused filament fabrication a review. Mater Today Proc. https://doi.org/10.1016/j.matpr.2020.07.069

Brenken B, Barocio E, Favaloro A et al (2018) Fused filament fabrication of fiber-reinforced polymers: A review. Addit Manuf 21:1–16. https://doi.org/10.1016/j.addma.2018.01.002

Lee CS, Kim SG, Kim HJ, Ahn SH (2007) Measurement of anisotropic compressive strength of rapid prototyping parts. J Mater Process Technol 187–188:627–630. https://doi.org/10.1016/j.jmatprotec.2006.11.095

Ameli A, Datla NV, Azari S et al (2012) Prediction of environmental degradation of closed adhesive joints using data from open-faced specimens. Compos Struct 94:779–786. https://doi.org/10.1016/j.compstruct.2011.09.017

Khosravani MR, Berto F, Ayatollahi MR, Reinicke T (2020) Fracture behavior of additively manufactured components: A review. Theoret Appl Fract Mech 109:102763. https://doi.org/10.1016/j.tafmec.2020.102763

Nadimpalli SPV, Spelt JK (2010) R-curve behavior of Cu-Sn3.0Ag0.5Cu solder joints: Effect of mode ratio and microstructure. Mater Sci Eng A 527:724–734. https://doi.org/10.1016/j.msea.2009.08.046

Datla NV, Ameli A, Azari S et al (2012) Effects of hygrothermal aging on the fatigue behavior of two toughened epoxy adhesives. Eng Fract Mech 79:61–77. https://doi.org/10.1016/j.engfracmech.2011.10.002

Hart KR, Dunn RM, Sietins JM et al (2018) Increased fracture toughness of additively manufactured amorphous thermoplastics via thermal annealing. Polymer 144:192–204. https://doi.org/10.1016/j.polymer.2018.04.024

Aliheidari N, Christ J, Tripuraneni R et al (2018) Interlayer adhesion and fracture resistance of polymers printed through melt extrusion additive manufacturing process. Mater Design 156:351–361. https://doi.org/10.1016/j.matdes.2018.07.001

Aliheidari N, Tripuraneni R, Ameli A, Nadimpalli S (2017) Fracture resistance measurement of fused deposition modeling 3D printed polymers. Polym Test 60:94–101. https://doi.org/10.1016/j.polymertesting.2017.03.016

Hart KR, Wetzel ED (2017) Fracture behavior of additively manufactured acrylonitrile butadiene styrene (ABS) materials. Eng Fract Mech 177:1–13. https://doi.org/10.1016/j.engfracmech.2017.03.028

Thaler D, Aliheidari N, Ameli A (2019) Mechanical, electrical, and piezoresistivity behaviors of additively manufactured acrylonitrile butadiene styrene/carbon nanotube nanocomposites. Smart Mater Struct. https://doi.org/10.1088/1361-665X/ab256e

McLouth TD, Severino JV, Adams PM et al (2017) The impact of print orientation and raster pattern on fracture toughness in additively manufactured ABS. Addit Manuf 18:103–109. https://doi.org/10.1016/j.addma.2017.09.003

Papon EA, Haque A (2019) Fracture toughness of additively manufactured carbon fiber reinforced composites. Addit Manuf 26:41–52. https://doi.org/10.1016/j.addma.2018.12.010

Hart KR, Dunn RM, Wetzel ED (2020) Increased fracture toughness of additively manufactured semi-crystalline thermoplastics via thermal annealing. Polymer. https://doi.org/10.1016/j.polymer.2020.123091

Vaezi M, Chianrabutra S, Mellor B, Yang S (2013) Multiple material additive manufacturing–Part 1: a review. Virtual Phys Prototyp 8:19–50. https://doi.org/10.1080/17452759.2013.778175

Espalin D, Ramirez JA, Medina F, Wicker R (2014) Multi-material, multi-technology FDM: Exploring build process variations. Rapid Prototyp J 20:236–244. https://doi.org/10.1108/RPJ-12-2012-0112

Bandyopadhyay A, Heer B (2018) Additive manufacturing of multi-material structures. Mater Sci Eng R: Rep 129:1–16. https://doi.org/10.1016/j.mser.2018.04.001

Espalin D, Ramirez J, Medina F, Wicker R (2012) Multi-material, multi-technology FDM system. 23rd Annual International Solid Freeform Fabrication Symposium-An Additive Manufacturing Conference, SFF 2012 828–835

Loke G, Yuan R, Rein M et al (2019) Structured multimaterial filaments for 3D printing of optoelectronics. Nat Commun. https://doi.org/10.1038/s41467-019-11986-0

Christ JF, Aliheidari N, Pötschke P, Ameli A (2018) Bidirectional and stretchable piezoresistive sensors enabled by multimaterial 3D printing of carbon nanotube/thermoplastic polyurethane nanocomposites. Polymers. https://doi.org/10.3390/polym11010011

Christ JF, Aliheidari N, Ameli A, Pötschke P (2017) 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites. Mater Design 131:394–401. https://doi.org/10.1016/j.matdes.2017.06.011

Hohimer CJ, Petrossian G, Ameli A et al (2020) 3D printed conductive thermoplastic polyurethane/carbon nanotube composites for capacitive and piezoresistive sensing in soft pneumatic actuators. Addit Manuf 34:101281. https://doi.org/10.1016/j.addma.2020.101281

Zhu F, Cheng L, Yin J et al (2016) 3D Printing of Ultratough Polyion Complex Hydrogels. ACS Appl Mater Interf 8:31304–31310. https://doi.org/10.1021/acsami.6b09881

Sabantina L, Kinzel F, Ehrmann A, Finsterbusch K (2015) Combining 3D printed forms with textile structures - Mechanical and geometrical properties of multi-material systems. IOP Conf Series Mater Sci Eng. https://doi.org/10.1088/1757-899X/87/1/012005

Lopez DMB, Ahmad R (2020) Tensile mechanical behaviour of multi-polymer sandwich structures via fused deposition modelling. Polymers. https://doi.org/10.3390/polym12030651

Shih Y-C, Mohamed M, Ge J et al (2023) Application of interlaminar shear strength and finite element modeling for failure analysis of 3D printed continuous fiber-reinforced composites. Prog Addit Manuf 8:1501–1516. https://doi.org/10.1007/s40964-023-00417-8

Khudiakova A, Arbeiter F, Spoerk M et al (2019) Inter-layer bonding characterisation between materials with different degrees of stiffness processed by fused filament fabrication. Addit Manuf 28:184–193. https://doi.org/10.1016/j.addma.2019.05.006

Khan AS, Ali A, Hussain G, Ilyas M (2019) An experimental study on interfacial fracture toughness of 3-D printed ABS / CF-PLA composite under mode I, II, and mixed-mode loading. J Thermoplast Composit Mater. https://doi.org/10.1177/0892705719874860

Rabbi MF, Chalivendra V (2021) Interfacial fracture characterization of multi-material additively manufactured polymer composites. Composit Part C: Open Access 5:100145. https://doi.org/10.1016/j.jcomc.2021.100145

Gul JZ, Sajid M, Rehman MM et al (2018) 3D printing for soft robotics–a review. Sci Technol Adv Mater 19:243–262. https://doi.org/10.1080/14686996.2018.1431862

Ma RR, Belter JT, Dollar AM (2015) Hybrid Deposition Manufacturing: Design Strategies for Multimaterial Mechanisms Via Three- Dimensional Printing and Material Deposition. J Mech Robot 7:1–10. https://doi.org/10.1115/1.4029400

Culbertson H, Schorr SB, Okamura AM (2018) Haptics: The Present and Future of Artificial Touch Sensation. Annu Rev Control, Robot, Auton Syst 1:385–409. https://doi.org/10.1146/annurev-control-060117-105043

Rossa-Sierra A, Sánchez-Soto M, Illescas S, Maspoch ML (2009) Study of the interface behaviour between MABS/TPU bi-layer structures obtained through over moulding. Mater Design 30:3979–3988. https://doi.org/10.1016/j.matdes.2009.05.037

Yin J, Lu C, Fu J et al (2018) Interfacial bonding during multi-material fused deposition modeling (FDM) process due to inter-molecular diffusion. Mater Design 150:104–112. https://doi.org/10.1016/j.matdes.2018.04.029

Harris CG, Jursik NJS, Rochefort WE, Walker TW (2019) Additive Manufacturing With Soft TPU – Adhesion Strength in Multimaterial Flexible Joints. Front Mech Eng 5:1–6. https://doi.org/10.3389/fmech.2019.00037

El Hassan A, Ahmed W, Zaneldin E (2022) Investigating the Impact of Inclusions on the Behavior of 3D-Printed Composite Sandwich Beams. Buildings 12:1448. https://doi.org/10.3390/buildings12091448

Ahmed W, Ahmed S, Alnajjar F, Zaneldin E (2021) Mechanical performance of three-dimensional printed sandwich composite with a high-flexible core. Proc Inst Mech Eng, Part L: J Mater: Design Appl 235:1382–1400. https://doi.org/10.1177/14644207211011729

Yavas D, Liu Q, Zhang Z, Wu D (2022) Design and fabrication of architected multi-material lattices with tunable stiffness, strength, and energy absorption. Mater Design 217:110613. https://doi.org/10.1016/j.matdes.2022.110613

ASTM D5528-13 (2013) Standard test method for mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites. ASTM International

Duan K, Hu X, Mai Y-W (2004) Substrate constraint and adhesive thickness effects on fracture toughness of adhesive joints. J Adhes Sci Technol 18:39–53. https://doi.org/10.1163/156856104322746992

Ineos Styrolution ABS Terluran GP-35 Technical Data Sheet

Peterson AM (2019) Review of acrylonitrile butadiene styrene in fused filament fabrication: A plastics engineering-focused perspective. Addit Manuf 27:363–371. https://doi.org/10.1016/j.addma.2019.03.030

BASF Elastollan ® 1185AW TPU Technical Data Sheet. https://www.ulprospector.com/plastics/en/datasheet/239310/elastollan-1185aw

Hohimer C, Aliheidari N, Mo C, Ameli A (2017) Mechanical behavior of 3D printed multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites. Proceedings of the ASME 2017 conference on smart materials, adaptive structures and intelligent systems, SMASIS2017-3808. https://doi.org/10.1115/SMASIS2017-3808

D’Amico A, Peterson AM (2018) An adaptable FEA simulation of material extrusion additive manufacturing heat transfer in 3D. Addit Manuf 21:422–430. https://doi.org/10.1016/j.addma.2018.02.021

Pourali M, Peterson AM (2019) Thermal Modeling of Material Extrusion Additive Manufacturing. ACS Symp Series 1315:115–130. https://doi.org/10.1021/bk-2019-1315.ch007

Kalia K, Ameli A (2020) Interfacial bond strength of various rigid/soft multi-materials printed via fused filament fabrication process. In: ASME 2020 conference on smart materials, adaptive structures and intelligent systems. American Society of Mechanical Engineers, Virtual, Online, p V001T01A010. https://doi.org/10.1115/SMASIS2020-2298

Coasey K, Hart KR, Wetzel E et al (2020) Nonisothermal welding in fused filament fabrication. Addit Manuf. https://doi.org/10.1016/j.addma.2020.101140

ASTM International (2013) (ASTM D 5045)-Standard test methods for plane-strain fracture toughness and strain energy release rate of plastic materials. ASTM Book Stand 99:1–9. https://doi.org/10.1520/D5045-14.priate

Newman JC, James MA, Zerbst U (2003) A review of the CTOA/CTOD fracture criterion. Eng Fract Mech 70:371–385. https://doi.org/10.1016/S0013-7944(02)00125-X

Newman J, James MA (2001) A review of the CTOA/CTOD fracture criterion-why it works! Collection of Technical Papers-AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 2, pp 1042–1051. AIAA-2001-1324

Raju IS (1987) Simple formulas for strain energy release rates with higher order and singular finite elements. Eng Fract Mech 28:251–274 (Report/Patent Number NAS 1.26:178186 (NASA-CR-178186))

Qi HJ, Boyce MC (2005) Stress–strain behavior of thermoplastic polyurethanes. Mech Mater 37:817–839. https://doi.org/10.1016/j.mechmat.2004.08.001

Anderson TL (2017) Fracture mechanics: fundamentals and applications, 3rd edn. CRC Press. ISBN 13: 978-0849316562

Rice JR (1988) Elastic Fracture Mechanics Concepts for Interfacial Cracks. J Appl Mech 55:98–103. https://doi.org/10.1115/1.3173668

Swadener JG, Liechti KM, Lozanne ALD (1999) The intrinsic toughness and adhesion mechanisms of a glass/epoxy interface. J Mech Phys Solids 47:223–258. https://doi.org/10.1016/S0022-5096(98)00084-2

Rice JR (1964) A path independent integral and the approximate analysis of strain concentration by notches and cracks. J Appl Mech, Trans ASME 35:379–388. https://doi.org/10.1115/1.3601206

Yang X, Fu M, Wang X, Liu X (2011) Nonlinear finite element analysis of crack growth at the interface of rubber-like bimaterials. Sci China Phys Mech Astron 54:1866. https://doi.org/10.1007/s11433-011-4444-4

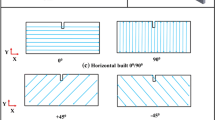

Casavola C, Cazzato A, Moramarco V, Pappalettere C (2016) Orthotropic mechanical properties of fused deposition modelling parts described by classical laminate theory. Mater Design 90:453–458. https://doi.org/10.1016/j.matdes.2015.11.009

Rodríguez JF, Thomas JP, Renaud JE (2003) Mechanical behavior of acrylonitrile butadiene styrene fused deposition materials modeling. Rapid Prototyp J 9:219–230. https://doi.org/10.1108/13552540310489604

Arruda EM, Boyce MC (1993) A three-dimensional constitutive model for the large stretch behavior of rubber elastic materials. J Mech Phys Solids 41:389–412. https://doi.org/10.1016/0022-5096(93)90013-6

Smith M (2020) ABAQUS/Standard User’s Manual, Version 2020. Dassault Systemes Simulia Corp

Yavas D, Zhang Z, Liu Q, Wu D (2021) Fracture behavior of 3D printed carbon fiber-reinforced polymer composites. Composit Sci Technol 208:108741. https://doi.org/10.1016/j.compscitech.2021.108741

Song Y, Li Y, Song W et al (2017) Measurements of the mechanical response of unidirectional 3D-printed PLA. Mater Design 123:154–164. https://doi.org/10.1016/j.matdes.2017.03.051

Ameli A, Papini M, Schroeder JA, Spelt JK (2010) Fracture R-curve characterization of toughened epoxy adhesives. Eng Fract Mech 77:521–534. https://doi.org/10.1016/j.engfracmech.2009.10.009

Shokrieh MM, Salamat-talab M, Heidari-Rarani M (2014) Effect of initial crack length on the measured bridging law of unidirectional E-glass/epoxy double cantilever beam specimens. Mater Design 55:605–611. https://doi.org/10.1016/j.matdes.2013.09.064

Shokrieh MM, Heidari-Rarani M, Ayatollahi MR (2012) Interlaminar fracture toughness of unidirectional DCB specimens: A novel theoretical approach. Polym Test 31:68–75. https://doi.org/10.1016/j.polymertesting.2011.08.012

Han X, Jin Y, da Silva LFM et al (2020) On the effect of adhesive thickness on mode I fracture energy - an experimental and modelling study using a trapezoidal cohesive zone model. J Adhes 96:490–514. https://doi.org/10.1080/00218464.2019.1601087

Ji G, Ouyang Z, Li G et al (2010) Effects of adhesive thickness on global and local Mode-I interfacial fracture of bonded joints. Int J Solids Struct 47:2445–2458. https://doi.org/10.1016/j.ijsolstr.2010.05.006

Banea MD, da Silva LFM, Campilho RDSG (2015) The Effect of Adhesive Thickness on the Mechanical Behavior of a Structural Polyurethane Adhesive. J Adhes 91:331–346. https://doi.org/10.1080/00218464.2014.903802

Azari S, Papini M, Spelt JK (2011) Effect of adhesive thickness on fatigue and fracture of toughened epoxy joints – Part I: Experiments. Eng Fract Mech 78:153–162. https://doi.org/10.1016/j.engfracmech.2010.06.025

Azari S, Papini M, Spelt JK (2011) Effect of adhesive thickness on fatigue and fracture of toughened epoxy joints–Part II: Analysis and finite element modeling. Eng Fract Mech 78:138–152. https://doi.org/10.1016/j.engfracmech.2010.07.006

De León AS, Domínguez-Calvo A, Molina SI (2019) Materials with enhanced adhesive properties based on acrylonitrile-butadiene-styrene (ABS)/thermoplastic polyurethane (TPU) blends for fused filament fabrication (FFF). Mater Design 182:108044. https://doi.org/10.1016/j.matdes.2019.108044

Zitzumbo R, Avalos F, Alonso S (2016) Nanostructural complex in ABS/TPU immiscible mixtures. Polym Polym Composit 24:205–212. https://doi.org/10.1177/096739111602400305

De R, Bruno JC, Silva MTMB, Nunes RCR (1993) An etching technique for morphological investigation of TPU/ABS blends by SEM. Polym Test 12:393–400. https://doi.org/10.1016/0142-9418(93)90011-D

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pakhare, A.S., Kalia, K., Nadimpalli, S.P.V. et al. Interface fracture characterization of 3D-printed rigid/flexible dissimilar polymers. Prog Addit Manuf (2024). https://doi.org/10.1007/s40964-024-00575-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40964-024-00575-3