Abstract

In this work, the influence of the filler–matrix adhesion on the tensile properties of laser-sintered parts built with Polyamide 613 filled with glass beads was investigated. For this purpose, dry blends of glass beads with and without organosilane coupling agents and polyamide powder were prepared and processed into tensile specimens on an EOS P396 laser sintering system. The samples were tested both in the dry state and after an accelerated conditioning in a climate chamber. Furthermore, finite element method (FEM) simulations were performed to model the extreme cases of optimum adhesion and no adhesion. By correlating the tensile tests with the simulation results and by analyzing the fracture surfaces, it was shown that the filler–matrix adhesion is sufficient in the dry state but is strongly degraded by conditioning. Even the presence of various organosilane thin films could not prevent a strong deterioration of the filler–matrix adhesion and the associated deterioration of the mechanical properties. Since a comparison with an injection-molded sample of the same polymer filler combination shows identical behavior after conditioning, it is assumed that this problem is not limited to additively manufactured parts.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Due to the high design freedom and comparatively good productivity, there is a trend to use polymer laser sintering (LS) for the direct production of final components [1, 2]. In laser sintering, thermoplastic polymer powder is deposited in thin layers, preheated and selectively melted by a laser to create plastic components [2,3,4]. Compared to the production of design prototypes, most series components must meet higher requirements in terms of mechanical properties and wear or heat resistance. These requirements often cannot be met by the standard Polyamide 12 (PA12) material [5, 6]. In addition to the use of a different base polymer, the addition of fillers is another way of influencing the material properties [7, 8]. For example, mechanical properties or heat and abrasion resistance can be improved while simultaneously reducing the material cost [6, 7, 9, 10]. Additionally, the conductivity or the flame retardancy can be altered by adding functional fillers [11,12,13]. While the processing of filled plastics in injection molding is the industry standard [14], filled materials are in comparison rarely used in laser sintering.

Even though there are some commercially available filled powders on the market, there often is a lack of knowledge about the material behavior of these materials under the conditions of use [15]. Different authors are working on this topic and already investigated various aspects regarding the processability [16,17,18,19,20] and the mechanical properties [21,22,23,24,25] of laser-sintered dry blends. The advantage of dry blending is the possibility to quickly produce powders with different fillers and filling ratios. In comparison, the production of powders in which the filler is contained within the plastic particles is significantly more complex [6]. Dry blending requires the filler to be present in a suitable particle size for the LS process (preferably around 20–80 µm [3, 24, 26]). The effects of humidity on the filler–matrix adhesion and the resulting mechanical properties have not been investigated systematically so far, even though, it is known from conventional manufacturing that the filler–matrix adhesion has a critical influence on material properties [10, 27, 28].

In previous work, it was shown that dry blends of spherical fillers and Polyamide 613 (PA613) can be processed well with adapted parameters and generally exhibit an improved stiffness. However, at the same time, it was found that the component properties of glass-bead-filled PA613 are impacted heavily by moisture absorption [19]. This work, therefore, investigates to what extent the filler–matrix adhesion of laser-sintered components can be influenced using organosilanes or glass beads with a different chemical composition. Furthermore, it is investigated whether differences in filler–matrix adhesion occur between injection-molded and laser-sintered components. For modeling the material properties, finite element method (FEM) simulations for the extreme cases “no adhesion” and “optimal adhesion” are carried out. There are some analytical models available for modeling particle filled polymers, for example from Kerner, Hashin or Christensen [29,30,31,32,33,34]. However, these models generally assume good filler–matrix adhesion and are, therefore, not suited. Finally, the mechanical properties of the real LS components were compared with the extreme cases from the simulation to quantify the filler–matrix adhesion.

2 Materials and methods

The method used to produce a filled LS polymer powder is dry blending a commercially available base polymer powder with fillers. Polyamide 613 powder produced by Evonik (VESTOSINT 3D 8754HT1 [35]) is used as the base polymer and glass beads manufactured by Sigmund Lindner (Silibeads 40–70 [36]) and by Potters Industries (Spheriglass 3000E [37]) are used as fillers with volume fractions of 20 and 40 vol%. The Silibeads are made from recycled soda lime glass (A-Glass) and have a d50 of 58 µm while the Spheriglass beads are made of borosilicate glass (E-Glass) and have a d50 of 32 µm. The powders are mixed inside a drum hoop mixer for 30 min with a rotational speed of 30 rpm. It was confirmed with CT images that a homogeneous mixture was achieved. This result is in line with different authors using mixing durations in between 30 min and 24 h, reporting a homogenous mixture already after 30 min [24, 38].

The glass beads were ordered with a silane coupling agent recommended by the manufacturer based on their experience with injection molding and without a coating. The manufacturer-coated Silibeads have a γ-aminopropyltriethoxysilane (APTES) coating. The coating of the Spheriglass has not been specified by the manufacturer. In addition, custom silane coatings were applied to uncoated glass spheres in our labs to have complete knowledge regarding the used coating and the application process. Therefore, (3-aminopropyl)triethoxysilane, (3-aminopropyl)trimethoxysilane, and dodecyltriethoxysilane (Sigma-Aldrich) were applied to both types of glass beads in an aqueous solution. For this purpose, the glass spheres were first cleaned in a diluted piranha solution (one part sulfuric acid, one part hydrogen peroxide, five parts distilled water), rinsed, and then coated while stirring in a 0.5% solution of distilled water and silane for 1 h at pH 4 and room temperature. Afterward, the glass beads were rinsed and dried. Figure 1 shows the intended reaction of an alkoxysilane with the surface of a cleaned glass bead in an aqueous solution. The -X symbolizes the functional group of the silane. After bonding to the glass surface, this group can be used to form a bond with the polymer, and thus improve the matrix–filler adhesion. Reaction time and temperature were limited to prevent uncontrolled growth of the silane layer [39, 40].

Intended reaction of an alkoxysilane with a pre-cleaned glass surface in an aqueous solution based on [39]

X-ray photoelectron spectroscopy (XPS) was carried out using an Omicron ESCA + system equipped with a hemi-spherical energy analyzer at a base pressure of less than 10–9 mbar to analyze the glass bead surface before and after the silanization process. The glass beads were dispersed in ethanol and applied onto gold-coated silicon wafers. Spectra were recorded at pass energies of 100 eV for survey spectra and 20 eV for element spectra with neutralization. A monochromatic Al Kα (1486.3 eV) X-ray source with a spot diameter of 0.6 mm was used. The take-off angle of the detected photoelectrons was set at 30° in relation to the surface plane. Spectra were internally calibrated to the C1s peak (285.0 eV). Data analysis was performed with a Shirley type background correction. Measurements showed that nitrogen is present at the glass surface after custom (3-aminopropyl)triethoxysilane coating but is absent in the reference surface. An analysis of the N1s and C1s peak region indicated the existence of amino groups; thus, it was possible to ensure that the organosilane films were applied correctly to the glass spheres before processing. XPS data can be found online within the supplementary information (Fig. S1).

After the production of the different polymer filler blends, they were further processed into tensile specimens according to DIN EN ISO 527 by laser sintering and injection molding. For laser sintering, an EOS P396 system was used with the parameters listed in Table 1. Build chamber temperature was set to 206.5 °C and a layer height of 0.12 mm was used with double contour and alternating hatch scanning. The development of feasible parameters for dry blends has been described previously [19].

For the injection-molded tensile test specimens, the dry blended powders were first granulated at a processing temperature of 240 °C using a twin-screw extruder. The granulate was then further processed into tensile specimens on a single-screw injection molding machine. Tensile tests according to DIN 527 were carried out with tests specimens in the dry state and after conditioning the samples at 70 °C and 62% rel. humidity for 7 days according to DIN EN ISO 1110 [41, 42].

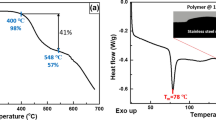

The FEM software Ansys mechanical was used for the simulation of the mechanical properties. An elastic material model was used for glass and an elastic–plastic material model was fitted for Polyamide 613 based on tensile tests of laser-sintered unfilled PA613 tested in the dry and in the conditioned state. For the simulation, it was assumed that the particles are arranged in a simple cubic lattice, so that a simplified simulation of only one filler particle with the surrounding polymer material could be carried out. For this purpose, the boundary conditions of the simulation were selected in such a way that the cubical unit cells can be joined together to form a complete component even after deformation. However, local necking of the macroscopic component cannot be represented with this simplification, so that the simulated strengths will tend to be higher than in reality. Both, for the dry and conditioned state, the two extreme cases of perfect adhesion and no adhesion were simulated (Fig. 2).

3 Material properties

First, laser-sintered tensile specimens filled with different volume fractions of Silibeads and Spheriglass were tested, and the results are compared to the FEM material model (Fig. 3). The stiffness of the test specimens in dry state is increased with increasing amount of filler by up to 200%. In the dry state, Silibeads (A-Glass) without coating have achieved the same increase in stiffness as Silibeads with the aminosilane coupling agent recommended by the manufacturer. At a filler content of 40 vol%, the increase in stiffness by adding Spheriglass with manufacturer's coating (E-Glass) is slightly lower than for Silibeads. The tensile strength in the dry state hardly changes with the addition of 20 vol% of glass beads. With a high filler content of 40 vol%, the tensile strength decreases slightly. Again, Silibeads with and without coating behave similarly. As expected, the elongation at break decreases significantly with increasing filling ratios for all tested fillers.

Comparing the results of the tensile tests and the FEM simulation (Fig. 2) for the extreme cases “optimum adhesion” and “no adhesion”, it can be assumed that the adhesion in the dry state is good. The results of the FEM simulation are given in Fig. 3. For a filler volume fraction of 20%, the measured values for stiffness for all glass beads are close to the simulation for optimum adhesion. The measured tensile strength of the blends is somewhat below the theoretically calculated optimum. With increasing filler content, the stress peaks between the neighboring filler particles increase, since the strain is strongly restrained locally and only a thin layer of plastic lies between the radii of the individual glass spheres. Due to the stress peaks, local detachment between filler and matrix is more likely to occur, thus decreasing the strength with increasing filler load.

This also explains why the measured modulus of elasticity of the Silibeads in the dry state corresponds to the simulated optimum case, but the strength is below it. According to the DIN EN ISO 527, the modulus of elasticity is tested between 0.05% and 0.25% elongation. This results in a comparatively low average stress of approx. 15 MPa for a material with an elastic modulus of 6000 MPa. Accordingly, it can be assumed that at the beginning of the tensile test, there is an optimum transfer of forces between the matrix polymer and the glass spheres. With increasing load, however, local detachment between matrix and filler can occur due to stress peaks, so that in reality, the optimum simulated strength is not quite achieved. This illustrates that the filler–matrix adhesion is more critical for the component strength than for the stiffness, since the latter is measured under a comparatively low load.

Considering the tensile properties after conditioning, it becomes clear that the moisture absorption has a significant effect, which exceeds the known plasticizing effect of water in unfilled polyamides. The good mechanical properties of unfilled polyamides are based on the strong hydrogen bond network between the polar amide groups in the polymer chain. The intercalation of water molecules loosens this hydrogen bond network in between the polymer chains, by replacing the existing amide–amide hydrogen bonds with amide–water hydrogen bonds [43]. Due to this effect, the defined conditioning of polyamide specimens before testing is critical [41]. The water absorption decreases the glass transition temperature, stiffness, and tensile strength while increasing the elongation at break, which has already been described for laser-sintered parts [44].

The plasticizing effect of conditioning is visible for the unfilled test specimens. The stiffness decreases from 2150 to 1510 MPa (− 30%) while the tensile strength decreases by 14% and the elongation at break increases by 36%. Comparing these effects to the impact of conditioning on glass-bead-filled polyamide, the difference is very clear. The modulus of PA613 filled with 40 vol% Silibeads is decreased by 75% after conditioning. Furthermore, the tensile strength is reduced by 63% and elongation at break is increased by 1369%. The changes in the filled material properties can, therefore, not be exclusively explained with the changing properties of the polyamide matrix material.

Comparing the tensile strength after conditioning to the FEM simulations, there is a good correlation to the simulations where no filler–matrix adhesion was assumed. The smaller Spheriglass (E-glass) performed slightly better than Silibeads (A-glass). Despite the lower stress occurring during the modulus measurement, the filler–matrix adhesion of the Silibeads in conditioned state was not sufficient to transfer the forces. This is also a possible explanation for the fact that increasing the filling ratio of uncoated Silibeads actually decreased the stiffness and increased the elongation at break. Since the filler particles do not transmit forces, they almost act comparable to spherical voids. No significant improvements could be achieved with the adhesion promoting γ-aminopropyltriethoxysilane coating, even though the moisture absorption was slightly reduced with an aminosilane (0.75%) compared to Silibeads without coating (0.80%). In oTo analyze the filler–matrix adhesion in more detail, SEM images of the fracture surfaces of tensile specimens tested in dry and conditioned state, respectively, were examined. Some exemplary images are shown in Fig. 4.

The pictures on the left side show the fracture surface after a test in dry condition. The fracture occurs close to the glass spheres, but the glass spheres do not detach from the plastic and still have plastic adhering to them after fracture. After conditioning, the fracture pattern changes fundamentally. The glass spheres detach completely from the plastic matrix and no longer have any adherent plastic after breakage. It seems as if the resulting pores with glass beads inside them are stretched in load direction, comparable to the effect that can be seen in the FEM simulation with no adhesion. The fracture, therefore, is, as suspected, initiated by a failure of the filler–matrix adhesion. In the SEM investigations, glass spheres with silane coupling agents applied by the manufacturer also showed the same behavior as uncoated glass spheres.

The formation of a good filler–matrix adhesion requires, on the one hand, good wetting of the filler by the polymer and, on the other hand, the formation of stable bonds [7, 45, 46]. Based on the images from the dry tested tensile specimens, good wetting can be confirmed. According to the theoretical chemical model, an aminosilane in combination with a polyamide should also provide stable bonds. The amino group of the silane can react with the carboxyl group at the end of the polyamide chains and form a strong covalent bond. This bond should not be weakened by moisture uptake of the polyamide. Since the experimental investigations showed that the bond was indeed weakened significantly, it could be assumed that no or only few covalent bonds were formed between the polyamide end groups and the glass beads via the silane coating or that the silane layer itself detached from the glass surface. The reason could be either that the coatings were not suitable at all or that the conditions during laser sintering did not allow for a reaction of polymer chains and silanes. The polymer is only heated up by the laser for a short period of time and then cools down to the build chamber temperature relatively fast, limiting the polymer chain mobility and the reaction rates. Combined with the fact that no pressure or sheer rate is applied to the polymer, this could mean that the reactive polymer chain ends do not come in contact with the functional groups of the silane very often. Another hypothesis is that the laser already degrades the silane coating of the glass spheres and that this, therefore, brings no advantage.

The good adhesion in the dry state can be explained by the polar interactions between the hydroxyl groups on the glass surface and the amide groups in the polymer. The intercalation of water molecules likely replaces the hydrogen bonds in between the glass surface and the amide groups with hydrogen bonds in between polymer and water molecule. The same effect is known as the plasticizing effect of unfilled polyamides [43]. Therefore, the adhesion between the glass surface and the polymer is strongly degraded after conditioning. Since the surface of the glass spheres is very smooth, there is no mechanical interlocking effect with the polymer.

It is assumed that the E-glass behaves somewhat better after conditioning, since, on the one hand, the average particle size is smaller, and thus more surface area is available to transfer the forces and, on the other hand, molecules of the A-glass beads itself could be dissolved from the surface by water, which would further deteriorate the adhesion to the plastic [47].

To be able to rule out industrial silane coating as a cause, tests were subsequently carried out with self-coated glass spheres. Before processing the glass beads, XPS measurements showed that amine groups could be applied to the glass surface as desired.

The tensile properties of the dry blends with self-coated glass beads are shown in Fig. 5. Since it was not possible to process large quantities of glass spheres for silane coating on a laboratory scale, small tensile test specimens type 1BA were used.

The comparison between uncoated glass spheres and those with silane coupling agents shows that there was hardly any improvement in the mechanical properties. After conditioning, tensile strength is still significantly below the expected values for good adhesion (see material model Fig. 2 for 20 vol% filler content).

While coating with aminosilanes tended to improve properties slightly in the dry and conditioned states, coating with dodecyltriethoxysilane caused a significant drop in tensile strength in the dry state. Dodecyltriethoxysilane has a non-polar hydrocarbon chain as its functional group. This obviously worsens the adhesion in the dry state, similar to the effect of conditioning, by preventing the formation of hydrogen bonds between the polyamide and the glass surface.

The decisive influence of dodecyltriethoxysilane on the material properties shows that the silane coating is apparently not thermally destroyed in the LS process. Nevertheless, no very significant improvements in the conditioned properties were obtained with the aminosilane coatings. To test the hypothesis that the reaction conditions in the LS process are unsuitable for generating a covalent bond between polyamide and silane, samples were produced in the injection molding process.

Figure 6 shows the comparison of tensile properties of injection-molded and laser-sintered tensile specimens of PA613 with 20 vol% Spheriglass with a commercial adhesion promoting coating. The tensile behavior of the injection-molded and laser-sintered specimens is very similar. The stiffness and tensile strength of the laser-sintered specimens are slightly higher in both the dry and conditioned states, presumably due to the higher crystallinity of laser-sintered components [48, 49]. The elongation at break is almost the same in the dry state, but after conditioning, the elongation at break of the injection-molded specimen is several times higher. After conditioning, the filler–matrix adhesion is impaired significantly also for the injection-molded specimens, and therefore the material properties are dictated by the load-bearing matrix material. It is known for unfilled polymers that injection-molded test specimens have a higher elongation at break due to their lower crystallinity, lower surface roughness, and lower porosity [50]. Since the decrease in strength due to conditioning is the same for both manufacturing processes, it can be assumed that the silane coupling agent cannot ensure sufficiently good filler–matrix adhesion for the injection molding process either. The loss of filler–matrix adhesion was confirmed with SEM imaging (Fig. S2) and is similar to what has been observed for laser-sintered specimens (Fig. 4). It seems that the filler–matrix adhesion of the material is even slightly better for the LS specimens. Here, more polymer adheres to the glass beads after fracture compared to the injection-molded specimens.

The results indicate a general adhesion problem between glass beads and polyamides for the tested silane coatings after conditioning, although the material combination of glass and polyamide is frequently used in injection molding. The difference, however, is that instead of beads, glass fibers are normally used. Due to the larger aspect ratio, more surface area is available to transfer the forces between matrix and filler. However, it is not possible to process long glass fibers in the laser sintering process, since they severely limit powder flowability and cause defects [24]. Furthermore, shorter fibers align in the recoater direction, and thus generate an anisotropy perpendicular to the build direction [51, 52]. Accordingly, efficient reinforcement of laser-sintered components under humid operating conditions is not trivial, since filler–matrix adhesion is problematic with spherical glass fillers and processing of long fibers is not possible.

4 Summary and outlook

In this work, the effect of dry blending glass beads with PA613 laser sintering powder on tensile properties was analyzed with special regard to filler–matrix adhesion. SEM images and correlation of tensile tests with simulation results showed that the glass beads have sufficiently good adhesion to the polyamide matrix in the dry state, regardless of whether they have a silane coating or not. This can be explained with polar bonding forces between the amide groups and hydroxyl groups on the glass surface. After conditioning, the filler–matrix adhesion of all investigated glass bead–polyamide blends deteriorated strongly. Contrary to theoretical considerations, the silane coatings used could hardly provide any advantage over uncoated glass beads. XPS measurements ensured that amino groups were applied to the glass surface, and the experiments with dodecyltriethoxysilane showed that the coating was not destroyed by the laser sintering process. Nevertheless, it is assumed that too few covalent bonds could be established between the silane and the polyamide. Due to the lack of covalent bonds, intercalated water molecules could destroy the adhesion between polyamide and filler by replacing the hydrogen bonds between the hydroxyl groups on the glass surface and the amide groups of the plastic with interactions to the polar water molecules. Injection-molded specimens from the same material combination have shown the same behavior after conditioning as laser-sintered specimens. These results show the importance of conditioning tensile specimens before testing according to the conditions of use. Technical data sheets of materials for additive manufacturing usually only contain information on the material properties in the dry state which can change drastically for filled materials after contact with moisture.

Further investigations regarding the filler–matrix adhesion of particle fillers with rougher surfaces or smaller particle sizes are to be carried out in the future. In addition to chemical adhesion, mechanical interlocking can be utilized with rough particle surfaces to transfer forces. By lowering the mean particle size, the surface area of the filler is increased for the same filling ratio. This might help to transmit forces in between matrix and filler. Initial investigations with Cerabeads showed potential for particles with a higher surface roughness [19].

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its Supplementary Information files. Should any raw data files be needed in another format they are available from the corresponding author upon reasonable request.

References

Wohlers T, Campbell RI, Diegel O et al (2020) Wohlers report 2020: 3D printing and additive manufacturing state of the industry. Wohlers Associates, Fort Collins, Colo

Schmid M (2015) Selektives Lasersintern (SLS) mit Kunststoffen. Hanser eLibrary, Hanser, München

Goodridge RD, Tuck CJ, Hague R (2012) Laser sintering of polyamides and other polymers. ProgMater Sci 57:229–267. https://doi.org/10.1016/j.pmatsci.2011.04.001

Breuninger J, Becker R, Wolf A et al (2013) Generative Fertigung mit Kunststoffen. Springer, Berlin Heidelberg

Sculpteo (2021) The sate of 3d printing: 2021 edition. https://www.sculpteo.com/de/ebooks/state-of-3d-printing-report-2021/. Accessed 09 Dec 2021

Tan LJ, Zhu W, Zhou K (2020) Recent progress on polymer materials for additive manufacturing. Adv Funct Mater 30:2003062. https://doi.org/10.1002/adfm.202003062

Xanthos M (2005) Functional fillers for plastics. Wiley, Weinheim

Kaiser W (2021) Kunststoffchemie für Ingenieure: Von der Synthese bis zur Anwendung, 5, neu bearbeitete und erweiterte Auflage. Hanser eLibrary, Hanser, München

Osswald TA (2006) International plastics handbook: the resource for plastics engineers, 1st edn. Hanser, Munich, Cincinnati

Eyerer P, Hirth T, Elsner P (eds) (2008) Polymer Engineering: Technologien und Praxis. Chemische Technik/Verfahrenstechnik. Springer, Berlin Heidelberg

Domininghaus H, Elsner P, Eyerer P et al (2012) Kunststoffe. Springer, Berlin Heidelberg

Jianjun L, Yuxiang O (2019) Theory of flame retardation of polymeric materials. De Gruyter, Berlin, Boston

Lanzl L, Wudy K, Greiner S et al (2019) Selective laser sintering of copper filled polyamide 12: characterization of powder properties and process behavior. Polym Compos 40:1801–1809. https://doi.org/10.1002/pc.24940

Mallick PK (2007) Fiber-reinforced composites. CRC Press

van de Werken N, Tekinalp H, Khanbolouki P et al (2020) Additively manufactured carbon fiber-reinforced composites: state of the art and perspective. Addit Manuf 31:100962. https://doi.org/10.1016/j.addma.2019.100962

Mousa AA, Pham DT, Shwe SP (2014) Preprocessing studies for selective laser sintering of glass beads-filled PA12. IJRAPIDM 4:28. https://doi.org/10.1504/IJRAPIDM.2014.062036

Mazzoli A, Moriconi G, Pauri MG (2007) Characterization of an aluminum-filled polyamide powder for applications in selective laser sintering. Mater Des 28:993–1000. https://doi.org/10.1016/j.matdes.2005.11.021

Czelusniak T, Amorim FL (2020) Selective laser sintering of carbon fiber–reinforced PA12: Gaussian process modeling and stochastic optimization of process variables. Int J Adv Manuf Technol 110:2049–2066. https://doi.org/10.1007/s00170-020-05993-5

Kletetzka I, Gawlikowicz R, Schmid H-J (2022) Effects of spherical Fillers on the Processability and mechanical Properties of PA613 and PP-based Laser Sintering Dry Blends. In: Laboratory for Freeform Fabrication and University of Texas at Austin (ed) Proceedings of the 33nd Annual International Solid Freeform Fabrication Symposium, vol 33, Austin

Wudy K, Lanzl L, Drummer D (2016) Selective laser sintering of filled polymer systems: bulk properties and laser beam material interaction. Phys Procedia 83:991–1002. https://doi.org/10.1016/j.phpro.2016.08.104

Arai S, Tsunoda S, Yamaguchi A et al (2018) Effects of short-glass-fiber content on material and part properties of poly(butylene terephthalate) processed by selective laser sintering. Addit Manuf 21:683–693. https://doi.org/10.1016/j.addma.2018.04.019

Cano AJ, Salazar A, Rodríguez J (2018) Effect of temperature on the fracture behavior of polyamide 12 and glass-filled polyamide 12 processed by selective laser sintering. Eng Fract Mech 203:66–80. https://doi.org/10.1016/j.engfracmech.2018.07.035

Forderhase P, McAlea K, Booth R (1995) The Development of a SLS Plastic Composite Material. In: SFF (ed) SFF Symposium Preceedings 1995, pp 287–297

Kleijnen RG, Sesseg JPW, Schmid M et al. (2017) Insights into the development of a short-fiber reinforced polypropylene for laser sintering. In: AIP (ed) AIP Conference Proceedings. Author(s), p 190002

Seltzer R, de La Escalera FM, Segurado J (2011) Effect of water conditioning on the fracture behavior of PA12 composites processed by selective laser sintering. Mater Sci Eng: A 528:6927–6933. https://doi.org/10.1016/j.msea.2011.05.045

Shi Y, Zhang Y (2008) Simulation of random packing of spherical particles with different size distributions. Appl Phys A 92:621–626. https://doi.org/10.1007/s00339-008-4547-6

Kausch HH, Beguelin P, Fischer M (2000) Failure of particulate reinforced polymers. Mech Compos Mater 36:177–184. https://doi.org/10.1007/BF02681868

Bergeret A, Ferry L, Ienny P (2009) Influence of the fibre/matrix interface on ageing mechanisms of glass fibre reinforced thermoplastic composites (PA-6,6, PET, PBT) in a hygrothermal environment. Polym Degrad Stab 94:1315–1324. https://doi.org/10.1016/j.polymdegradstab.2009.04.009

Affdl JCH, Kardos JL (1976) The Halpin-Tsai equations: a review. Polym Eng Sci 16:344–352. https://doi.org/10.1002/pen.760160512

Christensen RM, Lo KH (1979) Solutions for effective shear properties in three phase sphere and cylinder models. J Mech Phys Solids 27:315–330. https://doi.org/10.1016/0022-5096(79)90032-2

Eshelby JD (1957) The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc R Soc Lond A 241:376–396. https://doi.org/10.1098/rspa.1957.0133

Hashin Z (1962) The elastic moduli of heterogeneous materials. J Appl Mech 29:143–150. https://doi.org/10.1115/1.3636446

Kerner EH (1956) The elastic and thermo-elastic properties of composite media. Proc Phys Soc B 69:808–813. https://doi.org/10.1088/0370-1301/69/8/305

Lewis TB, Nielsen LE (1970) Dynamic mechanical properties of particulate-filled composites. J Appl Polym Sci 14:1449–1471. https://doi.org/10.1002/app.1970.070140604

Evonik Industries AG (2022) INFINAM® PA. POLYAMIDE 613 POWDERS (NYLONS). https://3d-printing.evonik.com/en/additive-manufacturing-materials/polymer-powders/polyamide-613. Accessed 28 June 2022

Sigmund Lindner (2022) Silibeads Solid: durable and resilient products. https://www.sigmund-lindner.com/wp-content/uploads/2018/09/SiLibeads_Solid_de.pdf. Accessed 06 Jan 2022

Potters Industries (2020) Spheriglass® 3000E CP03. www.pottersindustries.com. Accessed 04 May 2022

Chung H, Das S (2006) Processing and properties of glass bead particulate-filled functionally graded Nylon-11 composites produced by selective laser sintering. Mater Sci Eng, A 437:226–234. https://doi.org/10.1016/j.msea.2006.07.112

Böing J (2003) Modifizierung von Glas- und Titanoberflächen zur Verbesserung der Biokompatibilität. Dissertation, Rheinisch-Westfälischen Technischen Hochschule Aachen

Zhu M, Lerum MZ, Chen W (2012) How to prepare reproducible, homogeneous, and hydrolytically stable aminosilane-derived layers on silica. Langmuir 28:416–423. https://doi.org/10.1021/la203638g

DIN EN ISO 1110 (2019) Kunststoffe – Polyamide – Beschleunigte Konditionierung von Probekörpern. Accessed on 20 Apr 2021

DIN EN ISO 527 (2019) Kunststoffe - Bestimmung der Zugeigenschaften. Accessed on 19 May 2021

Laurati M, Sotta P, Long DR et al (2012) Dynamics of water absorbed in polyamides. Macromolecules 45:1676–1687. https://doi.org/10.1021/ma202368x

Rüsenberg S (2015) Prozessqualifizierung zur verlässlichen Herstellung von Produkten im Polymer Lasersinterverfahren. Dissertation, Universität Paderborn, Shaker Verlag

Etcheverry M, Barbosa SE (2012) Glass fiber reinforced polypropylene mechanical properties enhancement by adhesion improvement. Materials (Basel) 5:1084–1113. https://doi.org/10.3390/ma5061084

Maier R-D, Schiller M (eds) (2016) Handbuch Kunststoff-Additive, 4, vollständig neu, bearbeitete. Hanser, München

Jebsen-Marwedel H, Brückner R (2011) Glastechnische Fabrikationsfehler. Springer, Berlin Heidelberg, Berlin, Heidelberg

Baur E, Brinkmann S, Osswald TA et al (2013) Saechtling Kunststoff Taschenbuch, 31st edn. Hanser, München

Josupeit S (2019) On the influence of thermal histories within part cakes on the polymer laser sintering process. Dissertation, Shaker; Shaker Verlag

van Hooreweder B, Moens D, Boonen R et al (2013) On the difference in material structure and fatigue properties of nylon specimens produced by injection molding and selective laser sintering. Polym Testing 32:972–981. https://doi.org/10.1016/j.polymertesting.2013.04.014

Jansson A, Pejryd L (2016) Characterisation of carbon fibre-reinforced polyamide manufactured by selective laser sintering. Addit Manuf 9:7–13. https://doi.org/10.1016/j.addma.2015.12.003

Arai S, Tsunoda S, Yamaguchi A et al (2019) Effect of anisotropy in the build direction and laser-scanning conditions on characterization of short-glass-fiber-reinforced PBT for laser sintering. Opt Laser Technol 113:345–356. https://doi.org/10.1016/j.optlastec.2019.01.012

Acknowledgements

We would like to thank all DMRC industry partners for their sharing of knowledge.

Funding

Open Access funding enabled and organized by Projekt DEAL. Research activities have been funded by the DMRC Industrial consortium. Open-access funding is enabled and organized by project DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kletetzka, I., Kosanke, M., Meinderink, D. et al. Influence of the filler–matrix adhesion and the effects of conditioning on tensile properties of laser-sintered parts built with polyamide–glass bead dry blends. Prog Addit Manuf (2023). https://doi.org/10.1007/s40964-023-00501-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40964-023-00501-z