Abstract

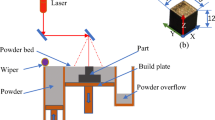

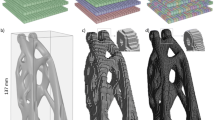

Selective Laser Sintering (SLS) is a Powder Bed Fusion technology that embraces a large number of variables influencing the properties of the parts produced. The well-known dependence and complex interaction established between the main process parameters demands continuous empirical research for effective SLS monitoring. The assessment of the energy density supplied by the laser beam to the powder bed during the process, that depends on the combination of the laser power, hatch distance, scan speed and layer thickness, is frequently considered for that purpose. Therefore, this research intends to evaluate the influence of the energy density on the dimensional, geometric, mechanical and morphological properties of SLS parts produced with conventional Polyamide 12 material. In this study, we considered different hatching and contour parameters in the energy range between 0.158 J/mm3 and 0.398 J/mm3 through single and multiple exposure types defining individual and combined parameterization sets, respectively. Results from X-ray computed tomography, tensile tests and scanning electron microscopy show that the implementation of a skin/core configuration allows the production of SLS parts with a valuable set of properties, minimizing the trade-off between mechanical strength and overall accuracy.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

ASTM (2012) ASTM F2792 12a - Standard Terminology for Additive Manufacturing Technologies

Chatham CA, Long TE, Williams CB (2019) A review of the process physics and material screening methods for polymer powder bed fusion additive manufacturing. Prog Polym Sci 93:68–95. https://doi.org/10.1016/j.progpolymsci.2019.03.003

Wörz A, Wudy K, Drummer D et al (2018) Comparison of long-term properties of laser sintered and injection molded polyamide 12 parts. J Polym Eng 38:573–582. https://doi.org/10.1515/polyeng-2017-0227

Kumar S (2003) Selective laser sintering: a qualitative and objective approach. J Miner Met Mater Soc 55:43–47

Bourell DL, Watt TJ, Leigh DK, Fulcher B (2014) Performance limitations in polymer laser sintering. Phys Procedia 56:147–156. https://doi.org/10.1016/j.phpro.2014.08.157

Gibson I, Rosen D, Stucker B (2010) Powder bed fusion processes. In: Additive manufacturing technologies - rapid prototyping to direct digital manufacturing. Springer International Publishing, Boston, pp 103–142

Duan B, Wang M (2011) Selective laser sintering and its application in biomedical engineering. MRS Bull 36:998–1005. https://doi.org/10.1557/mrs.2011.270

Pavan M, Faes M, Strobbe D et al (2017) On the influence of inter-layer time and energy density on selected critical-to-quality properties of PA12 parts produced via laser sintering. Polym Test 61:386–395. https://doi.org/10.1016/j.polymertesting.2017.05.027

Pilipović A, Drstvenšek I, Šercer M et al (2014) Mathematical model for the selection of processing parameters in selective laser sintering of polymer products. Adv Mech Eng. https://doi.org/10.1155/2014/648562

Hofland EC, Baran I, Wismeijer DA (2017) Correlation of process parameters with mechanical properties of laser sintered PA12 parts. Adv Mater Sci Eng. https://doi.org/10.1155/2017/4953173

Kiani A, Khazaee S, Badrossamay M et al (2020) An investigation into thermal history and its correlation with mechanical properties of PA12 parts produced by selective laser sintering process. J Mater Eng Perform 29:832–840. https://doi.org/10.1007/s11665-020-04640-0

Majewski C, Zarringhalam H, Hopkinson N (2008) Effect of the degree of particle melt on mechanical properties in selective laser-sintered Nylon-12 parts. Proc Inst Mech Eng Part B J Eng Manuf 222:1055–1064. https://doi.org/10.1243/09544054JEM1122

Amado-Becker A, Ramos-Grez J, José Yañez M et al (2008) Elastic tensor stiffness coefficients for SLS Nylon 12 under different degrees of densification as measured by ultrasonic technique. Rapid Prototyp J 14:260–270. https://doi.org/10.1108/13552540810907929

Beitz S, Uerlich R, Bokelmann T et al (2019) Influence of powder deposition on powder bed and specimen properties. Materials. https://doi.org/10.3390/ma12020297

Shi D, Gibson I (1997) Material properties and fabrication parameters in selective laser sintering process. Rapid Prototyp J 3:129–136. https://doi.org/10.1108/13552549710191836

Caulfield B, McHugh PE, Lohfeld S (2007) Dependence of mechanical properties of polyamide components on build parameters in the SLS process. J Mater Process Technol 182:477–488. https://doi.org/10.1016/j.jmatprotec.2006.09.007

Beard MA, Ghita OR, Evans KE (2011) Monitoring the effects of selective laser sintering (SLS) build parameters on polyamide using near infrared spectroscopy. J Appl Polym Sci 121:3153–3158

Tong Q, Xue K, Wang T, Yao S (2020) Laser sintering and invalidating composite scan for improving tensile strength and accuracy of SLS parts. J Manuf Process 56:1–11. https://doi.org/10.1016/j.jmapro.2020.04.056

Czelusniak T, Amorim FL (2020) Influence of energy density on selective laser sintering of carbon fiber-reinforced PA12. Int J Adv Manuf Technol 111:2361–2376. https://doi.org/10.1007/s00170-020-06261-2

Chunze Y, Yusheng S, Zhaoqing L et al (2020) Selective laser sintering forming accuracy control. In: selective laser sintering additive manufacturing technology. Academic Press, Cambridge, pp 671–716

Ho HCH, Gibson I, Cheung WL (1999) Effects of energy density on morphology and properties of selective laser sintered polycarbonate. J Mater Process Technol 89–90:204–210. https://doi.org/10.1016/S0924-0136(99)00007-2

Dewulf W, Pavan M, Craeghs T, Kruth J-P (2016) Using X-ray computed tomography to improve the porosity level of polyamide-12 laser sintered parts. CIRP Ann Manuf Technol 65:205–208. https://doi.org/10.1016/j.cirp.2016.04.056

Wu J, Xu X, Zhao Z et al (2018) Study in performance and morphology of polyamide 12 produced by selective laser sintering technology. Rapid Prototyp J 24:813–820. https://doi.org/10.1108/RPJ-01-2017-0010

Ling Z, Wu J, Wang X et al (2018) Experimental study on the variance of mechanical properties of polyamide 6 during multi-layer sintering process in selective laser sintering. Int J Adv Manuf Technol 6:1–8. https://doi.org/10.1007/s00170-018-3004-8

Kummert C, Schmid HJ (2018) The Influence of Contour Scanning Parameters and Strategy on Selective Laser Sintering PA613 Build Part Properties. Proc 29th Annu Int Solid Free Fabr Symp 1582–1591

Beal VE, Paggi RA, Salmoria GV, Lago A (2009) Statistical evaluation of laser energy density effect on mechanical properties of polyamide parts manufactured by selective laser sintering. J Appl Polym Sci 113:2910–2919

Bacchewar PB, Singhal SK, Pandey PM (2007) Statistical modelling and optimization of surface roughness in the selective laser sintering process. Proc Inst Mech Eng Part B J Eng Manuf 221:35–52. https://doi.org/10.1243/09544054JEM670

Goodridge RD, Tuck CJ, Hague RJM (2012) Laser sintering of polyamides and other polymers. Prog Mater Sci 57:229–267. https://doi.org/10.1016/j.pmatsci.2011.04.001

Jain PK, Pandey PM, Rao PVM (2009) Effect of delay time on part strength in selective laser sintering. Int J Adv Manuf Technol 43:117–126. https://doi.org/10.1007/s00170-008-1682-3

Franco A, Lanzetta M, Romoli L (2010) Experimental analysis of selective laser sintering of polyamide powders: an energy perspective. J Clean Prod 18:1722–1730. https://doi.org/10.1016/j.jclepro.2010.07.018

Pilipović A, Bogdan V, Brajlih T, et al (2010) Influence of Laser Sintering Parameters on Mechanical Properties of Polymer Products. 3rd International Conference on Additive Technologies iCAT2010 Proceedings. DAAAM International, Vienna

Starr TL, Gornet TJ, Usher JS (2011) The effect of process conditions on mechanical properties of laser-sintered nylon. Rapid Prototyp J 17:418–423. https://doi.org/10.1108/13552541111184143

Wegner A, Witt G (2012) Correlation of process parameters and part properties in laser sintering using response surface modeling. Phys Procedia 39:480–490. https://doi.org/10.1016/j.phpro.2012.10.064

Franco A, Romoli L (2012) Characterization of laser energy consumption in sintering of polymer based powders. J Mater Process Technol 212:917–926. https://doi.org/10.1016/j.jmatprotec.2011.12.003

Castoro M (2013) Impact of laser power and build orientation on the mechanical properties of selectively laser sintered parts. In: Proceedings of the national conference on undergraduate research (NCUR). University of Wisconsin La Crosse, WI, 11–13 April 2013

Wegner A, Harder R, Witt G, Drummer D (2015) Determination of optimal processing conditions for the production of polyamide 11 parts using the laser sintering process. IJEP 3:5–12

Pilipović A, Brajlih T, Drstvenšek I (2018) Influence of processing parameters on tensile properties of SLS polymer product. Polymers. https://doi.org/10.3390/polym10111208

Lopes AC, Sampaio AM, Silva CS, Pontes AJ (2021) Prediction of SLS parts properties using reprocessing powder. Rapid Prototyp J 27:496–506. https://doi.org/10.1108/RPJ-04-2020-0076

EOS GmbH (2016) Printed operations manual written and provided by EOS GmbH when purchasing the SLS equipment

Moylan S, Slotwinski J, Cooke A et al (2014) An additive manufacturing test artifact. J Res Natl Inst Stand Technol 119:429–459

International Organization for Standardization (ISO) (1996) BS EN ISO 527-2:1996, BS 2782-3: Method 322: ISO 527 Plastics — Determination of tensile properties. ISO 527-2 | Section 6: Test specimens. Annex A | Small test specimens - Figure A.1

Puncochar DE (1997) Interpretation of geometric dimensioning and tolerancing, 3th ed. Industrial Press, Inc., New York

Funding

This work was co-funded by the European Regional Development Fund through the Operational Competitiveness and Internationalization Programme (COMPETE 2020) [Project No. 47108, “SIFA”; Funding Reference: POCI-01-0247-FEDER-047108] and by the Foundation for Science and Technology (FCT) through the PhD scholarship 2020.04520.BD.

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare.

Rights and permissions

About this article

Cite this article

Lopes, A.C., Sampaio, A.M. & Pontes, A.J. The influence of the energy density on dimensional, geometric, mechanical and morphological properties of SLS parts produced with single and multiple exposure types. Prog Addit Manuf 7, 683–698 (2022). https://doi.org/10.1007/s40964-021-00254-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-021-00254-7