Abstract

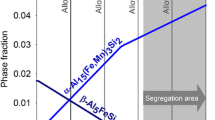

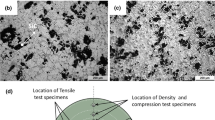

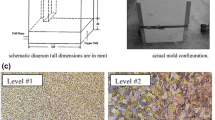

High alloyed by Si cast iron with spherical graphite (SGI) has a unique combination of mechanical properties at room temperature and high oxidation resistance at elevated temperature. The performance of this cast material can be improved by precise alloying and for the development of desired microstructural dispersity, using an effective melt inoculation in combination with an optimal cooling rate during solidification. There is consensus in the metalcasting community that high microstructural dispersity is desirable for good mechanical performance of high Si SGI at room temperature. However, it could not be the case for high-temperature applications. In this study, static high-temperature oxidation of heavy (100 mm), medium (18 mm), and thin (5 mm) wall castings from two SGI (base, referred to as SiMo and alloyed by 3% Al (SiMoAl) were investigated. Microstructural dispersity was characterized in 2D sections and in 3D space by µCT. Surface degradation was quantified by SEM and TEM analysis in cross sections after 100 h static oxidation in air at 800 °C. Carbon analysis was used to decouple the scale formation and decarburization (deC) processes which occurred simultaneously. Scale topology was determined by microcomputed tomography (µCT) analysis. Additional thermo-cycling tests of constrained specimens were performed to determine resistance to SGI failure during transient thermomechanical loading. These methods provided the quantification of the effects of microstructural dispersity parameters on high-temperature performance in SGI. The different trends were observed in the base SiMo and alloyed SiMoAl SGI. Methods for improving high-temperature performance by optimizing microstructural dispersity are suggested based on trends in surface degradation.

Similar content being viewed by others

References

Standard SAE J2582: Standard Specification for High-Silicon Molybdenum Ferritic Iron Castings, SAE, 2018.

D. Li, R. Perrin, G. Burger, D. McFarlan, B. Black, R. Logan, R. Williams, Solidification Behavior, Microstructure, Mechanical Properties, Hot Oxidation and Thermal Fatigue Resistance of High Silicon SiMo Nodular Cast Irons; SAE Technical Paper 2004-01-0792 (SAE International, Warrendale, 2004)

M.M. Ibrahim, A. Nofal, M.M. Mourad, Metall. Mater. Trans. B 48, 1149 (2016)

I. Riposan, S. Stan, D. Anca et al., Structure characteristics of high-Si ductile cast irons. Int. J. Metalcast. (2023). https://doi.org/10.1007/s40962-022-00938-y

D. Franzen, B. Pustal, A. Bührig-Polaczek, Influence of graphite-phase parameters on the mechanical properties of high-silicon ductile iron. Int. Metalcast. 17, 4–21 (2023). https://doi.org/10.1007/s40962-022-00761-5D

S. Lekakh, A. Bofah, L. Godlewski, M. Li, Effect of micro-structural dispersity of SiMo ductile iron on high temperature performance during static oxidation. Metals 12(4), 616 (2022)

S. Lekakh, A. Bofah, M. Wei-TingChen, L. Godlewski, M. Li, Prevention of high-temperature surface degradation in SiMo cast irons by Cr and Al alloying. Met. Mater. Trans. B 51B, 2542 (2020)

S. Lekakh, V. Athavale, L. Bartlett, L. Godlewski, M. Li, Effect of micro-structural dispersity of SiMo ductile iron on thermal cycling performance. Int. J. Metalcast. 2, 2 (2022). https://doi.org/10.1007/s40962-022-00915-5

Acknowledgements

This paper is an invited submission to the IJMC selected from presentations at the 7th Keith Millis Symposium on Ductile Iron held October 18–20, 2023, at the Crown Plaza Atlanta Perimeter at Ravinia, Atlanta, GA. It is published in the IJMC by permission of the DIS (Ductile Iron Society). Great thanks to students A. Bofah, and C. Johnson for helping with experiments.

Funding

This research was supported by the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE) under the Award Number DE-EE0008458.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper is an invited submission to IJMC selected from presentations at the 7th Keith Millis on Ductile Iron held October 18–20, 2023, at the Crown Plaza Atlanta Perimeter at Ravinia, Atlanta, GA. It is published in the IJMC by permission of the DIS (Ductile Iron Society).

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lekakh, S.N., Bartlett, L., Godlewski, L. et al. Improvement of High-Temperature Performance of High Si SGI by Al Alloying and Optimizing Microstructural Dispersity. Inter Metalcast (2024). https://doi.org/10.1007/s40962-023-01228-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40962-023-01228-x