Abstract

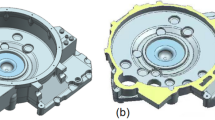

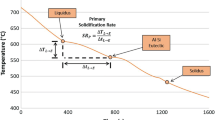

Effects of indirect squeeze casting process parameters on the microstructure and mechanical properties of an A356.2 alloy engine hanger were studied. A 4-factor, 4-level orthogonal test was used to study the effects of applied pressure, punch velocity, pouring temperature and mold preheating temperature. The pressure, punch speed, pouring temperature and mold preheating temperature of the optimum process parameters were determined by range analysis (RA) as 100 MPa, 60 mm/s, 700 °C and 200 °C, respectively. The analysis of variance (ANOVA) showed that the only significant factor affecting the microstructure and mechanical properties was pouring temperature, while the other three factors were not significant. The specimens demonstrated mechanical characteristics akin to forged hangers, boasting a tensile strength of 297 MPa, 10.2% post-fracture elongation, and 105 HBW hardness. After T6 heat treatment, except the eutectic silicon morphology changed significantly, the microstructure basically maintained its as-cast characteristics. The samples’ microstructure were categorized into three regions: coarse grain α-Al (A), eutectic structure (B), and fine grain structure (C). It was found that elevated pouring temperature could keep the pressure transmission channel open, which was helpful to improve the feeding ability and form a refined grain structure in zone C. However, with the excessive increase in casting temperature, α-Al grains in region A would be coarse, which would lead to the decline of mechanical properties. Therefore, 700 °C was determined as the best pouring temperature.

Similar content being viewed by others

References

Y.Y. Li, W.W. Zhang, H.D. Zhao et al., Research progress on squeeze casting in China. China Foundry 11(4), 239–246 (2014)

M.R. Ghomashchi, A. Vikhrov, Squeeze casting: an overview. J. Mater. Process. Tech. 101(1), 1–9 (2000). https://doi.org/10.1016/S0924-0136(99)00291-5

S.W. Youn, C.G. Kang, P.K. Seo, thermal fluid/solidification analysis of automobile part by horizontal squeeze casting process and experimental evaluation. J. Mater. Process. Technol. 146(3), 294–302 (2004). https://doi.org/10.1016/j.jmatprotec.2003.11.005

H.B. Yang, X.S. Zhao, W.Z. Fan et al., Development status and applications prospect of squeeze casting technology. Adv. Mater. Res. 538–541, 1154–1157 (2012). https://doi.org/10.4028/www.scientific.net/AMR.538-541.1154

O.O. Edosa, F.K. Tekweme, K. Gupta, Squeeze casting for metal alloys and composites: an overview of influence of process parameters on mechanical properties and microstructure. China Foundry 20, 148–158 (2023). https://doi.org/10.1007/s41230-022-2030-1

M. Kiuchi, Recent trend of squeeze casting. Tetsu-to-Hagané 71(1), 12–18 (1985). https://doi.org/10.2355/tetsutohagane1955.71.1_12. (in Japanese)

R.X. Li, L.J. Liu, L.J. Zhang, J.H. Sun, Y.J. Shi, B.Y. Yu, Effect of squeeze casting on microstructure and mechanical properties of hypereutectic Al–xSi alloys. J. Mater. Sci. Technol. 33(4), 404–410 (2017). https://doi.org/10.1016/j.jmst.2017.02.004

A. Karthik, R. Karunanithi, S.A. Srinivasan, M. Prashanth, The optimization of squeeze casting process parameter for AA2219 alloy by using the Taguchi method. Mater. Today Proc. 27, Part 3, 2556–2561 (2020). https://doi.org/10.1016/j.matpr.2019.10.136

P. Senthil, K.S. Amirthagadeswaran, Optimization of squeeze casting parameters for non symmetrical AC2A aluminium alloy castings through Taguchi method. J. Mech. Sci. Technol. 26, 1141–1147 (2012). https://doi.org/10.1007/s12206-012-0215-z

Q.M. Chang, C.J. Chen, S.C. Zhang, D. Schwam, J.F. Wallace, Effects of process parameters on quality of squeeze casting A356 alloy. Int. J. Cast Met. Res. 23(1), 30–36 (2010). https://doi.org/10.1179/174313309X449309

S.B. Bin, S.M. Xing, L.M. Tian et al., Influence of technical parameters on strength and ductility of AlSi9Cu3 alloys in squeeze casting. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 23(4), 977–982 (2013). https://doi.org/10.1016/S1003-6326(13)62555-8

C.F. Zhao, H.Y. Xu, Z.S. Ji, Hu.M.L. Wei Liu, B. Jiang, Effect of near-liquidus squeeze casting temperature on microstructure and mechanical property of AZ91D alloy differential support. Mater. Lett. 270, 127681 (2020). https://doi.org/10.1016/j.matlet.2020.127681

A. Maleki, B. Niroumand, A. Shafyei, Effects of squeeze casting parameters on density, macrostructure and hardness of LM13 alloy. Mater. Sci. Eng. A 428(1–2), 135–140 (2006). https://doi.org/10.1016/j.msea.2006.04.099

V. Dao, S. Zhao, W. Lin, C. Zhang, Effect of process parameters on microstructure and mechanical properties in AlSi9Mg connecting-rod fabricated by semi-solid squeeze casting. Mater. Sci. Eng. A 558, 95–102 (2012). https://doi.org/10.1016/j.msea.2012.07.084

A. Maleki, A. Shafyei, B. Niroumand, Effects of squeeze casting parameters on the microstructure of LM13 alloy. J. Mater. Process. Technol. 209(8), 3790–3797 (2009). https://doi.org/10.1016/j.jmatprotec.2008.08.035

E. Hajjari, M. Divandari, An investigation on the microstructure and tensile properties of direct squeeze cast and gravity die cast 2024 wrought Al alloy. Mater. Des. 29(9), 1685–1689 (2008). https://doi.org/10.1016/j.matdes.2008.04.012

A.R. Ravikumar, K.S. Amirthagadeswaran, P. Senthil, Parametric optimization of squeeze cast AC2A-Ni coated SiCp composite using Taguchi technique. Adv. Mater. Sci. Eng. 2014, 1–10 (2014). https://doi.org/10.1155/2014/160519

J.X. Deng, B. Xie, D.D. You et al., Process parameters design of squeeze casting through an improved KNN algorithm and existing data. J. Manuf. Process. 84, 1320–1330 (2022). https://doi.org/10.1016/j.jmapro.2022.10.074

L. Snugovsky, J.F. Major, Silicon segregation in aluminium casting alloy. Mater. Sci. Technol. 16(2), 125–128 (2000). https://doi.org/10.1179/026708300101507604

B. Dang, C.C. Liu, F. Liu et al., Effect of as-solidified microstructure on subsequent solution-treatment process for A356 Al alloy. Trans. Nonferrous Met. Soc. China 26(3), 634–642 (2016). https://doi.org/10.1016/S1003-6326(16)64152-3

J.J. Kim, D.H. Kim, K.S. Shin et al., Modification of Mg2Si morphology in squeeze cast Mg–Al–Zn–Si alloys by Ca or P addition. Scr. Mater. 41(3), 333–340 (1999). https://doi.org/10.1016/s1359-6462(99)00172-4

P. Suwanpinij, U. Kitkamthorn, I. Diewwanit et al., Influence of copper and iron on solidification characteristics of 356 and 380-type aluminum alloys. Mater. Trans. 44(5), 845–852 (2003). https://doi.org/10.2320/matertrans.44.845

F. Paray, J.E. Gruzleski, Modification—a parameter to consider in the heat treatment of Al–Si alloys. Cast Met. 5(4), 187–198 (1992). https://doi.org/10.1080/09534962.1992.11819112

H.J. Sun, S.M. Xing, B.W. Zhao et al., Study on the influence of solution temperature on the synergistic effect of precipitation strengthening and fine grain strengthening of AA6061. Mater. Today Commun. 33, 104312 (2022). https://doi.org/10.1016/j.mtcomm.2022.104312

Funding

No funding was received to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

XJ: Writing—original draft, Conceptualization, Investigation, Data curation. SX: Writing—review & editing, Conceptualization. HS: Methodology, Validation and Writing. GY: Investigation. QH: Validation.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiang, X., Xing, S., Sun, H. et al. Investigation of the Influence of Indirect Squeeze Casting Process Parameters on the Solidification Microstructure and Properties of A356.2 Aluminum Alloy. Inter Metalcast (2023). https://doi.org/10.1007/s40962-023-01178-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40962-023-01178-4