Abstract

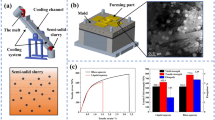

Rheological squeeze casting is a novel metal forming process, which can realize the integration of preparation and forming, and achieve the effect of energy saving and emission reduction. In order to investigate the application of rheological squeeze casting process on beryllium bronze alloy and to verify the improvement in beryllium bronze properties under the condition of rare-earth lanthanum addition, in this paper, a beryllium bronze workpiece with rare-earth La (0–0.30 wt%) was formed by rheological squeeze casting. The results revealed that with the increase in La content, the grain size gradually refined and became spherical, and the hardness increased from 158 to 213 HBW (by 34.8%). The rheological squeeze casting process greatly improves the nucleation rate, resulting in grain refinement. La and its compounds result in constitutional undercooling and heterogeneous nucleation, and the pressure applied in the rheological squeeze casting process affects solute diffusion and deepens the degree of undercooling. The dual effects of these aspects enhance grain refinement and result in an increase in hardness.

Similar content being viewed by others

References

C. Lin, S.S. Wu, S.L. Lü, P. An, H.B. Wu, Effects of high pressure rheo-squeeze casting on Fe-containing intermetallic compounds and mechanical properties of Al-17Si-2Fe-(0, 0.8) V alloys. Mater. Sci. Eng. A. 713, 105 (2017). https://doi.org/10.1016/j.msea.2017.12.050

A. Jahangiri, S.P.H. Marashi, M. Mohammadaliha, V. Ashofte, The effect of pressure and pouring temperature on the porosity, microstructure, hardness and yield stress of AA2024 aluminum alloy during the squeeze casting process. J. Mater. Process. Technol. 245, 1 (2017). https://doi.org/10.1016/j.jmatprotec.2017.02.005

P. Das, B. Bhuniya, S.K. Samanta, P. Dutta, Studies on die filling of A356 Al alloy and development of a steering knuckle component using rheo pressure die casting system. J. Mater. Process. Technol. 271, 293 (2019). https://doi.org/10.1016/j.jmatprotec.2019.04.014

T. Arunkumar, V. Pavanan, V.A. Murugesan, V. Mohanavel, K. Ramachandran, Influence of nanoparticles reinforcements on aluminium 6061 alloys fabricated via novel ultrasonic aided rheo-squeeze casting method. Met. Mater. Int. 28(1), 145 (2022). https://doi.org/10.1007/s12540-021-01036-0

D. Zhou, X. Su, C. Yang, Z. Kang, Z. Li, A systematic approach to model and optimize qualities of castings produced by squeeze casting process. Int. J. Metalcast. (2022). https://doi.org/10.1007/s40962-022-00887-6

P. Yan, W. Mao, J. Fan, B. Wang, Y. Liu, Microstructural evolution, segregation and fracture behavior of A390 alloy prepared by combined Rheo-HPDC processing and Sr-modifier. J. Alloys Compd. 835, 155297 (2020). https://doi.org/10.1016/j.jallcom.2020.155297

J.F. Hao, B.Y. Yu, J.C. Bian, L. Zheng, S.N. Nie, R.X. Li, Comparison of the semisolid squeeze casting and gravity casting process on the precipitation behavior and mechanical properties of the Al-Si-Cu-Mg alloy. Mater. Charact. 180, 111404 (2021). https://doi.org/10.1016/j.matchar.2021.111404

J. Hao, H. Luo, J. Bian, Y. Shi, B. Yu, R. Li, The effect of squeeze casting process on the microstructure, mechanical properties and wear properties of hypereutectic Al–Si–Cu–Mg alloy. Int. J. Metalcast. 16(1), 153–165 (2022). https://doi.org/10.1007/s40962-021-00575-x

C.L. Wang, Z.Y. Dong, K. Li, M. Sun, J.L. Wu, K. Wang et al., A novel process for grain refinement of Mg-RE alloys by low frequency electro-magnetic stirring assisted near-liquidus squeeze casting. J. Mater. Process. Technol. 303, 117537 (2022). https://doi.org/10.1016/j.jmatprotec.2022.117537

T. Zhang, W. Yu, C. Ma, W. Chen, L. Zhang, S. Xiong, The effect of different high pressure die casting parameters on 3D microstructure and mechanical properties of AE44 magnesium alloy. J. Magn. Alloys (2022). https://doi.org/10.1016/j.jma.2022.05.001

Z. Chang, Q. Deng, Q. Lan, J. Feng, D. Li, B. Liu et al., Microstructure and mechanical properties of Mg-Gd-Y-Zn-Zr alloy prepared by rheo-diecasting. Mater. Sci. Eng. A. 848, 143287 (2022). https://doi.org/10.1016/j.msea.2022.143287

X. Fang, S. Lü, L. Zhao, J. Wang, L. Liu, S. Wu, Microstructure and mechanical properties of a novel Mg–RE–Zn–Y alloy fabricated by rheo-squeeze casting. Mater. Des. 94, 353–359 (2016). https://doi.org/10.1016/j.matdes.2016.01.063

S. Ganguly, A.K. Mondal, S. Sarkar, A. Basu, S. Kumar, C. Blawert, Improved corrosion response of squeeze-cast SiC nanoparticles reinforced AZ91-2.0 Ca-0.3 Sb alloy. Corros. Sci. 166, 108444 (2020). https://doi.org/10.1016/j.corsci.2020.108444

J. Yang, X.F. Yan, C. Wang, Y.X. Luo, High-pressure wear behavior of laser clad MoNiTaTiV high-entropy alloy coating sliding against QBe2.0 beryllium bronze under dry and oil-lubricated conditions. Surf. Coat. Technol. 446, 128757 (2022). https://doi.org/10.1016/j.surfcoat.2022.128757

C. Li, J. Zha, Y.L. Chen, Geometrical shape and dimension errors and surface roughness of stepped holes in a beryllium bronze-aluminum alloy joint produced by forming reamer. Int. J. Adv. Manuf. Technol. 117, 3029 (2021). https://doi.org/10.1007/s00170-021-07863-0

D.C. Kong, C.F. Dong, X.Q. Ni, C. Man, K. Xiao, X.G. Li, Insight into the mechanism of alloying elements (Sn, Be) effect on copper corrosion during long-term degradation in harsh marine environment. Appl. Surf. Sci. 455, 543 (2018). https://doi.org/10.1016/j.apsusc.2018.06.029

Z.B. Xu, Z.Y. Huang, Y.C. Wang, C.X. Lin, X. Xu, Friction and wear behavior of C17200 copper-beryllium alloy in dry and wet environments. J. Mater. Eng. Perform. 30, 7542 (2021). https://doi.org/10.1007/s11665-021-05969-w

M.E. Isametova, N.V. Martyushev, Y.I. Karlina, R.V. Kononenko, V.Y. Skeeba, B.N. Absadykov, Thermal pulse processing of blanks of small-sized parts made of beryllium bronze and 29 NK alloy. Materials 15, 6682 (2022). https://doi.org/10.3390/ma15196682

L.G. Britton, R.J. Willey, Pros and cons of non-sparking tools. Process Saf. Prog. 41, 5 (2022). https://doi.org/10.1002/prs.12347

L. Yu, Z. Wang, J. Wu, X. Meng, X. Lai, Microstructure and properties of vacuum cast Sc-containing Be–Al alloys. Int. J. Metalcast. 13, 201–212 (2019). https://doi.org/10.1007/s40962-018-0249-9

Z.H. Wang, J. Wang, L.B. Yu, J. Wu, M. Wang, B. Su, Numerical simulation and process optimization of vacuum investment casting for Be–Al alloys. Int. J. Metalcast. 13, 74–81 (2019). https://doi.org/10.1007/s40962-018-0228-1

E.A. Elsharkawi, M.F. Ibrahim, A.M. Samuel, H.W. Doty, F.H. Samuel, Understanding the effect of be addition on the microstructure and tensile properties of Al–Si–Mg cast alloys. Int. J. Metalcast. 16, 1777–1795 (2022). https://doi.org/10.1007/s40962-021-00715-3

Z. Wang, J. Li, Y. Zhang, C. Lv, T. Li, J. Zhang et al., Comparison of the mechanical properties and microstructures of QB2.0 and C17200 alloys. Materials 15, 2570 (2022). https://doi.org/10.3390/ma15072570

J. Zuo, Y. Lin, P. Zhong, Y. Liu, Investigation on adhesive wear process of tool coating surface under high-adhesive rate environment in cutting Beryllium-copper C17200 alloy. Mater. Lett. 279, 128488 (2020). https://doi.org/10.1016/j.matlet.2020.128488

S. Ma, L.M. Fu, X.D. Ma, A.D. Shan, Ultra-strong nickel aluminum bronze alloys with ultrafine microstructures by continuous heavy hot rolling. Mater. Charact. 158, 109986 (2019). https://doi.org/10.1016/j.matchar.2019.109986

T. Wilczyńska, G. Mishinsky, R. Wiśniewski, Synthesis of elements and solid structures in atomic-nuclear reactions in dense gases and dense Gas-Metal systems as a result of gamma quanta irradiation. Acta Phys. Pol. A. 139, 438 (2021)

J. Dai, S. Mu, Y. Wang, X. Yang, J. Li, Influence of La and Ce on microstructure and properties of Cu-Cr-Zr Alloy. Adv. Mater. Res. 295, 1168 (2011). https://doi.org/10.4028/www.scientific.net/AMR.295-297.1168

F. Cao, G. Dong, Y. Jiang, P. Xiao, T. Wang, S. Liang, Effect of La addition on microstructures and properties of TiB2(-TiB) Cu hybrid composites prepared by in situ reaction. Mater. Sci. Eng. A. 789, 139605 (2020). https://doi.org/10.1016/j.msea.2020.139605

F. Cao, X. Zhang, Y. Jiang et al., Effect of different rare earths on microstructures and tensile strength of in situ hybrid reinforced (TiB2p+TiBw)/Cu composites. Mater. Charact. 184, 111624 (2022). https://doi.org/10.1016/j.matchar.2021.111624

P. Hu, H. Song, Y. Chen, F. Chen, S. Zhang, Mechanisms for refining precipitation and improving strengthening of annealed Cu-2Ag alloy via La modification. J. Alloys Compd. 883, 160912 (2021). https://doi.org/10.1016/j.jallcom.2021.160912

W.J. Gao, S.M. Xing, Y. Wang, Effect of lanthanum addition on microstructure and hardness of brass alloys produced by rheological squeeze casting. J. Rare Earths 40, 1953–1962 (2022). https://doi.org/10.1016/j.jre.2021.12.010

W. Zhang, Z. Zhao, J. Fang, P. He, Z. Chao, D. Gong et al., Evolution and strengthening mechanism of metastable precipitates in Cu-2.0 wt% Be alloy. J. Alloys Compd. 857, 157601 (2021). https://doi.org/10.1016/j.jallcom.2020.157601

D. Zhu, Q. Zeng, Y. Liu, C. Li, L. Lu, T. Han et al., Effects of hot-rolling on secondary electron yield properties of Cu-2.7 Be alloy. J. Alloys Compd. 919, 165780 (2022). https://doi.org/10.1016/j.jallcom.2022.165780

J.S. Gaffney, N.A. Marley, The periodic table of the elements. General Chem. Eng. (2018). https://doi.org/10.1016/B978-0-12-810425-5.00002-3

A. Ohno, Solidification the separation theory and its practical applications (Springer Science Business Media, 2012). https://doi.org/10.1007/978-3-642-95537-2

J.A. Dantzig, M. Rappaz, Solidification: Revised & Expanded (EPFL Press, 2016)

S.H. Davis, Theory of solidification (Cambridge University Press, Cambridge, 2001)

M.C. Flemings, Behavior of metal alloys in the semisolid state. Metall. Trans. A 22, 957–981 (1991). https://doi.org/10.1007/BF02661090

R. Asthana, A. Kumar, N.B. Dahotre, Materials processing and manufacturing science (Elsevier, 2006). https://doi.org/10.1016/B978-075067716-5/50004-2

L. Yang, F. Zhang, M. Yan, M. Zhang, Microstructure and mechanical properties of multiphase layer formed during thermo-diffusing of titanium into the surface of C17200 copper–beryllium alloy. Appl. Surf. Sci. 292, 225–230 (2014). https://doi.org/10.1016/j.apsusc.2013.11.121

C.H. Sha, Z.F. Zhou, Z.H. Xie, P. Munroe, High entropy alloy FeMnNiCoCr coatings: Enhanced hardness and damage-tolerance through a dual-phase structure and nanotwins. Surf. Coat. Technol. 385, 125435 (2020). https://doi.org/10.1016/j.surfcoat.2020.125435

L. Chen, X. Ren, W. Zhou, Z. Tong, S. Adu-Gyamfi et al., Evolution of microstructure and grain refinement mechanism of pure nickel induced by laser shock peening. Mater. Sci. Eng. A. 728, 20 (2018). https://doi.org/10.1016/j.msea.2018.04.105

H. Herrmann, H. Bucksch, Clausius-Clapeyron equation. Dict. Geotech. Eng. Wörterbuch GeoTechnik (2014). https://doi.org/10.1007/978-3-642-41714-6_32107

A. Zhilyaev, A. Pshenichnyuk, Percolation mechanism of deformation processes in ultrafine-grained polycrystals, in Superplasticity and Grain Boundaries in Ultrafine-Grained Materials. (Elsevier, 2011)

A. Paul, T. Laurila, S. Divinski, Chapter 1-defects, driving forces and definitions of diffusion coefficients in solids, in Handbook Solid State Diffusion. (Elsevier, 2017)

B.L. Bramfitt, The effect of carbide and nitride additions on the heterogeneous nucleation behavior of liquid iron. Metall. Trans. 1, 1987 (1970). https://doi.org/10.1007/BF02642799

Acknowledgements

This study was financially supported by the Fundamental Research Funds for the Central Universities (No. 2020YJS146 and No. 2020YJS155).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, W., Xing, S., Shan, A. et al. Microstructure and Hardness Properties of Beryllium Bronze with Lanthanum Addition Fabricated by Rheological Squeeze Casting Process. Inter Metalcast 18, 147–158 (2024). https://doi.org/10.1007/s40962-023-01003-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-01003-y