Abstract

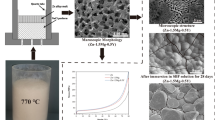

In this study, three-dimensional (3D), biodegradable, porous magnesium (Mg) alloy scaffolds were fabricated using the rapid casting method. The casting models were welded onto a wax rod to produce a casting tree using a stereolithography (SLA) machine with castable wax. The model has a high surface area and porosity. The pore size, strut thickness, and porosity of the 3D porous scaffolds are 1.5 mm, 0.45 mm, and 71.68%, respectively. The relative density and surface area-to-volume ratio are also 3.53 and 5.43, respectively. The pure phase of 45S5 bioglass (BG) nanomaterial was successfully synthesized using the sol–gel method. The 45S5 BG was characterized using transmission electron microscope (TEM), energy-dispersive X-ray analysis (EDX), X-ray diffraction analysis (XRD), Fourier-transform infrared spectroscopy (FTIR), differential thermal analysis (DTA), thermogravimetric (TG) and derivative thermogravimetry (DTG) analyses. To improve the bioactivity and control the degradation rate of Mg alloy scaffolds, the porous surface of the Mg scaffold was coated with 45S5 BG nanomaterials using the electrophoretic deposition (EPD) method. The in vitro degradation test was then performed using simulated body fluid (SBF) for 48 h. The in vitro degradation test results showed that the mass loss percentages of both samples approached each other after 12 h. The uncoated sample lost more mass than the coated sample after 24 and 48 h. The results showed that the coated scaffolds had better bioactivity and greater resistance to degradation.

Similar content being viewed by others

References

A.M. Lopera-Echavarría, D. Medrano-David, A.M. Lema-Perez et al., In vitro evaluation of confinement, bioactivity, and degradation of a putty type bone substitute. Materials Today Communications 26, 102105 (2021). https://doi.org/10.1016/j.mtcomm.2021.102105

D. Zhao, T. Zhu, J. Li et al., Poly(lactic-co-glycolic acid)-based composite bone-substitute materials. Bioactive Mater. 6, 346–360 (2021). https://doi.org/10.1016/j.bioactmat.2020.08.016

H.-Y. Lin, Y.-K. Huang, P.-Y. Hsu et al., Sintering of degradable bone substitutes at room temperature. Ceram. Int. 47, 21714–21720 (2021). https://doi.org/10.1016/j.ceramint.2021.04.185

E. Koç, A. Incesu, A.N. Saud, Comparative study on dry and bio-corrosive wear behavior of Mg-xAl-3Zn Alloys (x = 0.5-1-2-3 wt.%). J. Mater. Eng. Perform. 31, 613–621 (2022). https://doi.org/10.1007/s11665-021-06144-x

Y. Torres, J. Pavón, P. Trueba et al., Design, fabrication and characterization of titanium with graded porosity by using space-holder technique. Proc. Mater. Sci. 4, 115–119 (2014). https://doi.org/10.1016/j.mspro.2014.07.610

X.Z. Lu, C.P. Lai, L.C. Chan, Novel design of a coral-like open-cell porous degradable magnesium implant for orthopaedic application. Mater. Des. 188, 108474 (2020). https://doi.org/10.1016/j.matdes.2020.108474

C.E. Wen, Y. Yamada, K. Shimojima et al., Compressibility of porous magnesium foam: dependency on porosity and pore size. Mater. Lett. 58, 357–360 (2004). https://doi.org/10.1016/S0167-577X(03)00500-7

A. Yánez, M.P. Fiorucci, A. Cuadrado et al., Surface roughness effects on the fatigue behaviour of gyroid cellular structures obtained by additive manufacturing. Int. J. Fatigue 138, 105702 (2020). https://doi.org/10.1016/j.ijfatigue.2020.105702

A. Ataee, Y. Li, D. Fraser et al., Anisotropic Ti-6Al-4V gyroid scaffolds manufactured by electron beam melting (EBM) for bone implant applications. Mater. Des. 137, 345–354 (2018). https://doi.org/10.1016/j.matdes.2017.10.040

K. Heim, F. García-Moreno, J. Banhart, Particle size and fraction required to stabilise aluminium alloy foams created by gas injection. Scripta Mater. 153, 54–58 (2018). https://doi.org/10.1016/j.scriptamat.2018.04.041

N. Wang, E. Maire, X. Chen et al., Compressive performance and deformation mechanism of the dynamic gas injection aluminum foams. Mater. Charact. 147, 11–20 (2019). https://doi.org/10.1016/j.matchar.2018.10.013

O. Andersen, H. Göhler, C. Kostmann et al., Powder metallurgically manufactured cellular metals from carat gold alloys for decorative applications. Met. Powder Rep. 73, 72–79 (2018). https://doi.org/10.1016/j.mprp.2017.06.002

H. Jain, G. Gupta, R. Kumar, D.P. Mondal, Microstructure and compressive deformation behavior of SS foam made through evaporation of urea as space holder. Mater. Chem. Phys. 223, 737–744 (2019). https://doi.org/10.1016/j.matchemphys.2018.11.040

A. Temiz, M. Yaşar, E. Koç, Fabrication of open-pore biodegradable magnesium alloy scaffold via infiltration technique. Inter Metalcast 16, 317–328 (2022). https://doi.org/10.1007/s40962-021-00604-9

G.A. Lara-Rodriguez, I.A. Figueroa, M.A. Suarez et al., A replication-casting device for manufacturing open-cell Mg foams. J. Mater. Process. Technol. 243, 16–22 (2017). https://doi.org/10.1016/j.jmatprotec.2016.11.041

R. Singh, P.D. Lee, R.J. Dashwood, T.C. Lindley, Titanium foams for biomedical applications: a review. Mater. Technol. 25, 127–136 (2010). https://doi.org/10.1179/175355510X12744412709403

Y. Dou, S. Cai, X. Ye et al., 45S5 bioactive glass–ceramic coated AZ31 magnesium alloy with improved corrosion resistance. Surf. Coat. Technol. 228, 154–161 (2013). https://doi.org/10.1016/j.surfcoat.2013.04.022

Y. Yang, C. Michalczyk, F. Singer et al., In vitro study of polycaprolactone/bioactive glass composite coatings on corrosion and bioactivity of pure Mg. Appl. Surf. Sci. 355, 832–841 (2015). https://doi.org/10.1016/j.apsusc.2015.07.053

B. Heublein, R. Rohde, V. Kaese et al., Biocorrosion of magnesium alloys: a new principle in cardiovascular implant technology? Heart 89, 651–656 (2003). https://doi.org/10.1136/heart.89.6.651

Z. Li, X. Gu, S. Lou, Y. Zheng, The development of binary Mg–Ca alloys for use as biodegradable materials within bone. Biomaterials 29, 1329–1344 (2008). https://doi.org/10.1016/j.biomaterials.2007.12.021

A. Abdal-hay, N.A.M. Barakat, J.K. Lim, Hydroxyapatite-doped poly(lactic acid) porous film coating for enhanced bioactivity and corrosion behavior of AZ31 Mg alloy for orthopedic applications. Ceram. Int. 39, 183–195 (2013). https://doi.org/10.1016/j.ceramint.2012.06.008

M. Höhlinger, S. Heise, V. Wagener et al., Developing surface pre-treatments for electrophoretic deposition of biofunctional chitosan-bioactive glass coatings on a WE43 magnesium alloy. Appl. Surf. Sci. 405, 441–448 (2017). https://doi.org/10.1016/j.apsusc.2017.02.049

S. Heise, M. Höhlinger, Y.T. Hernández et al., Electrophoretic deposition and characterization of chitosan/bioactive glass composite coatings on Mg alloy substrates. Electrochim. Acta 232, 456–464 (2017). https://doi.org/10.1016/j.electacta.2017.02.081

Y. Goh, M. Akram, A. Alshemary, R. Hussain, Antibacterial polylactic acid/chitosan nanofibers decorated with bioactive glass. Appl. Surf. Sci. 387, 1–7 (2016). https://doi.org/10.1016/j.apsusc.2016.06.054

Y.-F. Goh, A.Z. Alshemary, M. Akram et al., In-vitro characterization of antibacterial bioactive glass containing ceria. Ceram. Int. 40, 729–737 (2014). https://doi.org/10.1016/j.ceramint.2013.06.062

G. Kaur, O. Pandey, Singh K, et al., A review of bioactive glasses: Their structure, properties, fabrication and apatite formation. J. Biomed. Mater. Res. A 102, 254–274 (2014). https://doi.org/10.1002/jbm.a.34690

B. Garrido, I.G. Cano, S. Dosta, Adhesion improvement and in vitro characterisation of 45S5 bioactive glass coatings obtained by atmospheric plasma spraying. Surf. Coat. Technol. 405, 126560 (2021). https://doi.org/10.1016/j.surfcoat.2020.126560

J.R. Jones, Review of bioactive glass: From Hench to hybrids. Acta Biomater. 9, 4457–4486 (2013). https://doi.org/10.1016/j.actbio.2012.08.023

M.L. Dittler, I. Unalan, A. Grünewald et al., Bioactive glass (45S5)-based 3D scaffolds coated with magnesium and zinc-loaded hydroxyapatite nanoparticles for tissue engineering applications. Colloids Surf. B 182, 110346 (2019). https://doi.org/10.1016/j.colsurfb.2019.110346

W. Cao, L.L. Hench, Bioactive materials. Ceram. Int. 22, 493–507 (1996). https://doi.org/10.1016/0272-8842(95)00126-3

K. Huang, S. Cai, G. Xu et al., Preparation and characterization of mesoporous 45S5 bioactive glass–ceramic coatings on magnesium alloy for corrosion protection. J. Alloy. Compd. 580, 290–297 (2013). https://doi.org/10.1016/j.jallcom.2013.05.103

M. Alaei, M. Atapour, S. Labbaf, Electrophoretic deposition of chitosan-bioactive glass nanocomposite coatings on AZ91 Mg alloy for biomedical applications. Prog. Org. Coat. 147, 105803 (2020). https://doi.org/10.1016/j.porgcoat.2020.105803

S. Seuss, A.R. Boccaccini, Electrophoretic deposition of biological macromolecules, drugs, and cells. Biomacromol 14, 3355–3369 (2013). https://doi.org/10.1021/bm401021b

T. Kokubo, H. Takadama, How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 27, 2907–2915 (2006). https://doi.org/10.1016/j.biomaterials.2006.01.017

H. Pirayesh, J.A. Nychka, Sol-Gel synthesis of Bioactive Glass-Ceramic 45S5 and its in vitro dissolution and mineralization behavior. J. Am. Ceram. Soc. 96, 1643–1650 (2013). https://doi.org/10.1111/jace.12190

Z. Cai, Z. Liu, X. Hu et al., The effect of porosity on the mechanical properties of 3D-printed triply periodic minimal surface (TPMS) bioscaffold. Bio-des Manuf. 2, 242–255 (2019). https://doi.org/10.1007/s42242-019-00054-7

Y. Jin, H. Kong, X. Zhou et al., Design and characterization of sheet-based gyroid porous structures with bioinspired functional gradients. Materials 13, 3844 (2020). https://doi.org/10.3390/ma13173844

L. Lefebvre, J. Chevalier, L. Gremillard et al., Structural transformations of bioactive glass 45S5 with thermal treatments. Acta Mater. 55, 3305–3313 (2007). https://doi.org/10.1016/j.actamat.2007.01.029

O.P. Filho, G.P. La Torre, L.L. Hench, Effect of crystallization on apatite-layer formation of bioactive glass 45S5. J. Biomed. Mater. Res. 30, 509–514 (1996). https://doi.org/10.1002/(SICI)1097-4636(199604)30:4%3c509::AID-JBM9%3e3.0.CO;2-T

O. Peitl, E. Dutra Zanotto, L.L. Hench, Highly bioactive P2O5–Na2O–CaO–SiO2 glass-ceramics. J. Non-Cryst. Solids 292, 115–126 (2001). https://doi.org/10.1016/S0022-3093(01)00822-5

L.L. Hench, Sol-gel materials for bioceramic applications. Curr. Opin. Solid State Mater. Sci. 2, 604–610 (1997). https://doi.org/10.1016/S1359-0286(97)80053-8

L.L. Hench, D.L. Wheeler, D.C. Greenspan, Molecular control of bioactivity in Sol-Gel glasses. J. Sol-Gel. Sci. Technol. 13, 245–250 (1998). https://doi.org/10.1023/A:1008643303888

Y. Li, S. Cai, G. Xu et al., Synthesis and characterization of a phytic acid/mesoporous 45S5 bioglass composite coating on a magnesium alloy and degradation behavior. RSC Adv. 5, 25708–25716 (2015). https://doi.org/10.1039/C5RA00087D

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Temiz, A., Alshemary, A.Z., Akar, N. et al. Rapid Casting of Biodegradable Porous Magnesium Scaffolds and Electrophoretic Deposition of 45S5 Bioactive Glass Nanoparticles Coatings on Porous Scaffolds: Characterization and In Vitro Bioactivity Analysis. Inter Metalcast 17, 1871–1882 (2023). https://doi.org/10.1007/s40962-022-00903-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-022-00903-9