Abstract

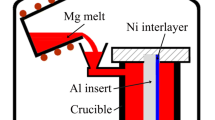

The centrifugal casting process was used to join and investigate the Al/Mg bimetallic interface composed of commercially-pure aluminum and magnesium metals. In the first set of experiments, molten Al was poured into the solid Mg hollow cylinder, and vice-versa in the second group. The formation possibility of the metallurgical interface was examined. The rotation speed was selected as 1200 revolutions per minute (rpm). The preheating temperature in the case of Al casting and Mg casting was 200 °C and 450 °C, respectively. The characterization of bimetals showed that pouring Mg melt into the Al solid part led to a relatively continuous metallurgical bond. When the Al was cast into the Mg, and contrariwise, the interface thickness reached 2–5 mm and 1.6 mm, respectively. The results of energy-dispersive X-ray spectroscopy (EDS) and scanning electron microscopy (SEM) showed that intermetallic compounds multilayer might form at the interface in both cases. Furthermore, microhardness analysis conformed to the intermetallic compound formation with high hardness in the interface.

Similar content being viewed by others

References

S. Emami, M. Divandari, E. Hajjari et al., Comparison between conventional and lost foam compound casting of Al/Mg light metals. Int. J. Cast Met. Res. 26, 43–50 (2013). https://doi.org/10.1179/1743133612Y.0000000037

Z. Jiang, Z. Fan, W. Jiang et al., Interfacial microstructures and mechanical properties of Mg/Al bimetal produced by a novel liquid-liquid compound casting process. J. Mater. Process. Technol. 261, 149–158 (2018). https://doi.org/10.1016/j.jmatprotec.2018.06.013

M. Zamani, M. Divandari, M. Tamizifar, On the characteristics of friction stir welding lap joint of magnesium and aluminum. Iran. J. Mater. Sci. Eng. 15, 64–77 (2018). https://doi.org/10.22068/ijmse.15.1.64

M. Valente, D. Marini, V. Genova et al., Lightweight metallic matrix composites: Development of new composites material reinforced with carbon structures. J. Appl. Biomater. Funct. Mater. (2019). https://doi.org/10.1177/2280800019840294

M. Esmaily, J. Svensson, S. Fajardo et al., Fundamentals and advances in magnesium alloy corrosion. Prog. Mater Sci. 89, 92–193 (2017). https://doi.org/10.1016/j.pmatsci.2017.04.011

T. Zhang, G. Meng, Y. Shao et al., Corrosion of hot extrusion AZ91 magnesium alloy. Part II: effect of rare earth element neodymium (Nd) on the corrosion behavior of extruded alloy. Corrosion Sci. 53, 2934–2942 (2011). https://doi.org/10.1016/j.corsci.2011.05.035

B. Mordike, T. Ebert, Magnesium: properties—applications—potential. Mater. Sci. Eng., A 302, 37–45 (2001). https://doi.org/10.1016/S0921-5093(00)01351-4

E. Hajjari, M. Divandari, S. Razavi et al., Microstructure characteristics and mechanical properties of Al 413/Mg joint in compound casting process. Metall. Mater. Trans. A. 43, 4667–4677 (2012). https://doi.org/10.1007/s11661-012-1296-0

M. Paramsothy, N. Srikanth, M. Gupta, Solidification processed Mg/Al bimetal macrocomposite: Microstructure and mechanical properties. J. Alloy. Compd. 461, 200–208 (2008). https://doi.org/10.1016/j.jallcom.2007.07.050

J. Shangguan, J. Zhao, Y. Shi et al., Effects of Zn interlayer on microstructures and mechanical properties of TC4/AZ91D bimetal via solid-liquid compound casting process. Int. J. Metalcast. (2021). https://doi.org/10.1007/s40962-021-00612-9

S. Li, Z. Zheng, L. Chang et al., A two-step bonding process for preparing 6061/AZ31 bimetal assisted with liquid molten zinc interlayer: the process and microstructure. J. Adhesion Sci. Technol. (2021). https://doi.org/10.1080/01694243.2021.1999713

P. Venkateswaran, A.P. Reynolds, Factors affecting the properties of Friction Stir Welds between aluminum and magnesium alloys. Mater. Sci. Eng., A 545, 26–37 (2012). https://doi.org/10.1016/j.msea.2012.02.069

I. Bhamji, M. Preuss, R. Moat et al., Linear friction welding of aluminium to magnesium. Sci. Technol. Weld. Joining 17, 368–374 (2012). https://doi.org/10.1179/1362171812Y.0000000017

J. Bae, A.P. Rao, K. Kim et al., Cladding of Mg alloy with Al by twin-roll casting. Scripta Mater. 64, 836–839 (2011). https://doi.org/10.1016/j.scriptamat.2011.01.013

K. Papis, J.F. Löffler, P.J. Uggowitzer, Interface formation between liquid and solid Mg alloys—an approach to continuously metallurgic joining of magnesium parts. Mater. Sci. Eng., A 527, 2274–2279 (2010). https://doi.org/10.1016/j.msea.2009.11.066

Y. Chen, K. Nakata, Friction stir lap joining aluminum and magnesium alloys. Scripta Mater. 58, 433–436 (2008). https://doi.org/10.1016/j.scriptamat.2007.10.033

L. Liu, X. Liu, S. Liu, Microstructure of laser-TIG hybrid welds of dissimilar Mg alloy and Al alloy with Ce as interlayer. Scripta Mater. 55, 383–386 (2006). https://doi.org/10.1016/j.scriptamat.2006.04.025

L.-M. Liu, H.-Y. Wang, Z.-D. Zhang, The analysis of laser weld bonding of Al alloy to Mg alloy. Scripta Mater. 56, 473–476 (2007). https://doi.org/10.1016/j.scriptamat.2006.11.034

G.R. Joshi, V.J. Badheka, Processing of bimetallic steel-copper joint by laser beam welding. Mater. Manuf. Processes 34, 1232–1242 (2019). https://doi.org/10.1080/10426914.2019.1628262

F. Li, Z. Wei, X. Li et al., Investigation on the coupling interaction in electron beam welded Al–Cu bimetallic sheet. Proc. Inst. Mech. Eng. L J. Mater. Des. Appl. 235, 640–652 (2021). https://doi.org/10.1177/1464420720976696

J. Wang, Y. Li, W. Huang, Interface microstructure and diffusion kinetics in diffusion bonded Mg/Al joint. React. Kinet. Catal. Lett. 95, 71–79 (2008). https://doi.org/10.1007/s11144-008-5259-9

M. Mofid, A. Abdollah-Zadeh, F.M. Ghaini, The effect of water cooling during dissimilar friction stir welding of Al alloy to Mg alloy. Mater. Des. 1980–2015(36), 161–167 (2012). https://doi.org/10.1016/j.matdes.2011.11.004

B. Li, Y. Shen, L. Luo et al., Fabrication and anti-oxidation properties of Al/Ti-6Al-4V bimetallic clad-sheet by multi-pass friction stir welding. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 229, 1078–1082 (2015). https://doi.org/10.1177/0954405414535583

D. Dietrich, D. Nickel, M. Krause et al., Formation of intermetallic phases in diffusion-welded joints of aluminium and magnesium alloys. J. Mater. Sci. 46, 357–364 (2011). https://doi.org/10.1007/s10853-010-4841-5

M.R. Mohammad Aliha, Y. Fotouhi, F. Berto, Experimental notched fracture resistance study for the interface of Al–Cu bimetal joints welded by friction stir welding. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 232, 2192–2200 (2018). https://doi.org/10.1177/0954405416688935

T.-F. Kong, L.-C. Chan, T.-C. Lee, Weld diffusion analysis of forming bimetallic components using statistical experimental methods. Mater. Manuf. Process. 24, 422–430 (2009). https://doi.org/10.1080/10426910802714316

E. Hajjari, M. Divandari, S. Razavi et al., Dissimilar joining of Al/Mg light metals by compound casting process. J. Mater. Sci. 46, 6491–6499 (2011). https://doi.org/10.1007/s10853-011-5595-4

M. Akbarifar, M. Divandari, Study of Al/cast iron interface and graphite behavior. J. Mining. Metall. B Metall. 53, 53–59 (2017). https://doi.org/10.2298/JMMB160108027A

M. Akbarifar, M. Divandari, On the interfacial characteristics of compound cast Al/brass bimetals. Int. J. Metalcast. 11, 506–512 (2017). https://doi.org/10.1007/s40962-016-0101-z

G. Zare, M. Divandari, H. Arabi, Investigation on interface of Al/Cu couples in compound casting. Mater. Sci. Technol. 29, 190–196 (2013). https://doi.org/10.1179/1743284712Y.0000000096

A.M. Tavakoli, B. Nami, M. Malekan et al., Influences of coating type on microstructure and strength of aluminum-steel bimetal composite interface. Int. J. Metalcast. (2021). https://doi.org/10.1007/s40962-021-00630-7

S. Han, H. Huh, Evaluation of a cast-joining process of dual-metal crankshafts with nodular cast iron and forged steel for medium speed diesel engines. Int. J. Adv. Manuf. Technol. 63, 319–327 (2012). https://doi.org/10.1007/s00170-012-3909-6

W. Jiang, F. Guan, G. Li et al., Processing of Al/Cu bimetal via a novel compound casting method. Mater. Manuf. Processes 34, 1016–1025 (2019). https://doi.org/10.1080/10426914.2019.1615084

S. Emami, M. Divandari, H. Arabi et al., Effect of melt-to-solid insert volume ratio on Mg/Al dissimilar metals bonding. J. Mater. Eng. Perform. 22, 123–130 (2013). https://doi.org/10.1007/s11665-012-0243-y

G. Xu, A.A. Luo, Y. Chen et al., Interfacial phenomena in magnesium/aluminum bi-metallic castings. Mater. Sci. Eng., A 595, 154–158 (2014). https://doi.org/10.1016/j.msea.2013.11.093

Q. Hu, Z. Jiang, W. Jiang et al., Interface characteristics of Mg/Al bimetal produced by a novel liquid-liquid compound casting process with an Al interlayer. Int. J. Adv. Manuf. Technol. 101, 1125–1132 (2019). https://doi.org/10.1007/s00170-018-2990-x

M. Gholami, M. Divandari, Interfacial phases and defects characteristics of Al/Cu-Zn bimetal produced via centrifugal casting process. Iran. J. Mater. Sci. Eng. 15, 52–61 (2018). https://doi.org/10.22068/ijmse.15.4.52

Hoeschl, M., Wagener, W.,Wolf, J. BMW's magnesium-aluminium composite crankcase, state-of-the-art light metal casting and manufacturing. SAE Technical Paper, 2006. Doi: https://doi.org/10.4271/2006-01-0069

K. Matsugi, M. Konishi, O. Yanagisawa et al., Erratum to “Joining of spheroidal graphite cast iron to stainless steel by impact-electric current discharge joining.” J. Mater. Process. Technol. 166, 313–320 (2005). https://doi.org/10.1016/j.jmatprotec.2004.10.006

H. Zhang, Y. Chen, A.A. Luo, Improved interfacial bonding in magnesium/aluminum overcasting systems by aluminum surface treatments. Metall. and Mater. Trans. B. 45, 2495–2503 (2014). https://doi.org/10.1007/s11663-014-0140-x

T. Noguchi, N. Horikawa, H. Nagate et al., Application of flow and solidification simulation in cast-in insertion processing. Int. J. Cast Met. Res. 18, 214–220 (2005). https://doi.org/10.1179/136404605225022955

Smith, W. F. Structure and properties of engineering alloys. McGraw-Hill Book Co., xiv+ 512, 23 x 16 cm, illustrated(16. 95) (1981).

Avedesian, M. M.,Baker, H. ASM specialty handbook: magnesium and magnesium alloys; ASM international, 1999.

Davis, J. R. Aluminum and aluminum alloys; ASM international, 1993.

F. Calvo, A. Ureng, J.G. De Salazar et al., Special features of the formation of the diffusion bonded joints between copper and aluminium. J. Mater. Sci. 23, 2273–2280 (1988). https://doi.org/10.1007/BF01115800

M. Akbarifar, M. Divandari, S.M.A. Boutorabi et al., Characteristic investigation of the as-received samples: nano-oxides in Al–5Mg–Be Melt. Int. J. Metalcast. (2022). https://doi.org/10.1007/s40962-022-00773-1

S. Feliu Jr., C. Maffiotte, A. Samaniego et al., Effect of naturally formed oxide films and other variables in the early stages of Mg-alloy corrosion in NaCl solution. Electrochim. Acta 56, 4554–4565 (2011). https://doi.org/10.1016/j.electacta.2011.02.077

R.K. Tayal, S. Kumar, V. Singh et al., Experimental investigation and evaluation of joint strength of A356/Mg bimetallic fabricated using compound casting process. Int. J. Metalcast. 13, 686–699 (2019). https://doi.org/10.1007/s40962-018-0288-2

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sarvari, M., Ghaemi Khiavi, S., Divandari, M. et al. Dissimilar Joining of Al/Mg Light Metals by Centrifugal Compound Casting Process. Inter Metalcast 17, 998–1007 (2023). https://doi.org/10.1007/s40962-022-00832-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-022-00832-7