Abstract

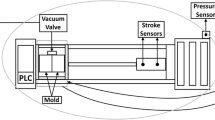

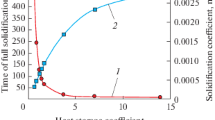

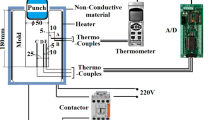

Permanent mold metal casting processes use tempering with oil, water or air as state-of-the-art method for temperature control of certain regions. This approach aims at either creating certain temperature gradients inside the die thus leading to better casting quality or cools down critical hotspots in order to decrease cycle times or increase service life. In order to perform an investigation on the influences of oil tempering on a permanent die and the solidification of the aluminum alloy A356, an experimental setup is used with measurement instrumentation for recording temperatures inside the melt and die as well as recording the movement of the die and the casting, thus enabling a gap width determination and measuring the contact pressure present on an inner core. A thermomechanical simulation of the solidification also is performed representing the processes occurring inside the experimental setup and extending the available data beyond the information locally provided at the experimental measuring positions. This approach allows for an evaluation of the influence of oil tempering on the solidification process, the thermal conditions inside of the casting, die, and core, and describes the behavior of a one-sided cooling of a comparatively large melt volume as well as the influences on a region with two-sided heat extraction affecting a smaller melt volume.

Similar content being viewed by others

References

W. Schneider, D.H. StJohn, A.L. Greer, Solidification Processing of Foundry Alloys: Mechanism of Grain Refinement of Aluminium—Almost All You Need to Know, Aluminium Alloys, vol. 1 (Wiley-VCH, Weinheim, 2008)

J.E. Gruzleski, B.M. Closset, The Treatment of Liquid Aluminum-Silicon Alloys (American Foundrymen’s Society, Schaumburg, 1990)

L. Wang, S. Shivkumar, Influence of Sr content on the modification of Si particles in Al–Si alloys. Metallkunde 86, 441–445 (1995)

M. Di Sabatino, L. Arnberg, Effect of grain refinement and dissolved hydrogen on the fluidity of A356 alloy. Int. J. Cast Met. Res. 18(3), 181–186 (2005)

D. Matisková, Š. Gašpar, L. Mura, Thermal factors of die casting and their impact on the service life of moulds and the quality of castings. Acta Polytech Hung 10(3), 65–78 (2013)

L.Y. Zhang et al., Effect of cooling rate on solidified microstructure and mechanical properties of aluminium-A356 alloy. J. Mater. Process. Technol. 207, 107–111 (2008)

L. Bäckerud, G. Chai, J. Tamminen, Solidification Characteristics of Aluminum Alloys—Volume 2: Foundry Alloys, AFS/Skanaluminium (1990)

D.M. Stefanescu, Thermal analysis—Theory and applications in metalcasting. Int. J. Metalcast. 9(1), 7–22 (2015)

N. Wolff et al., Development of an A356 die casting setup for determining the heat transfer coefficient depending on cooling conditions, gap size, and contact pressure. Materialwissenschaft und Werkstofftechnik 48, Heft 12 (2017)

G. Laschet et al., Multiscale solidification simulation of an axisymmetric A356 component in die casting, in Proceedings of the 6th Decennial International Conference on Solidification Processing (SP17) (Old Windsor, UK, July 2017), pp. 576–580, SS Media, UK, ISBN 978-1-90854929-7

B. Pustal et al., Modellierung des Verzugs eines oberflächennah gekühlten A356 Gussteils mit unterschiedlichen Wärmeübergangs- und Erstarrungsansätzen. Gießerei Special 2, 134–137 (2017)

Acknowledgements

The presented investigations were carried out at RWTH Aachen University within the framework of the Collaborative Research Centre SFB1120-236616214 “Bauteilpräzision durch Beherrschung von Schmelze und Erstarrung in Produktionsprozessen” and funded by the Deutsche Forschungsgemeinschaft e.V. (DFG, German Research Foundation). The sponsorship and support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vossel, T., Wolff, N., Pustal, B. et al. Influence of Die Temperature Control on Solidification and the Casting Process. Inter Metalcast 14, 907–925 (2020). https://doi.org/10.1007/s40962-019-00391-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-019-00391-4