Abstract

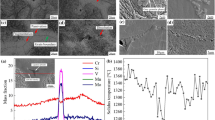

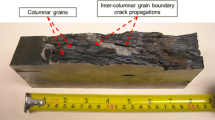

Microstructural characterisation has been carried out on X38CrMoV5-1 steel parts manufactured by gravity investment casting. Optimal heat treatment was applied to the parts: annealing at 780 °C (1 h) and cooling in the furnace; heating at 1020 °C (1 h), cooling in oil and double tempering at 580 °C (2 h). Hillert and Stefansson thermodynamic principles were used to calculate the fraction precipitated of V(C, N) and AlN and the percentages in solution of elements (V, Al, C, N). Calculations showed considerable V precipitation while SEM micrographs showed numerous V(C, N) precipitates of 400 nm average size. Small fraction of mixed (V, Mo)C and (V, Mo, Cr)C precipitates of approximately 5 µm was observed preferentially located close to the initial austenite grain boundaries. A small number of Al2O3 and MnS-type inclusions, with round and rectangular shapes, respectively, were also identified. Abundant pores of up to 165 µm in length and with an average size of 25 µm were located in the interdendritic regions. Comparison of the sizes and fractions of secondary phases (V(C, N), mixed precipitates), defects (pores, inclusions), and their consideration in Griffith’s equation lead to the conclusion that pores are the defects which could cause catastrophic cleavage fracture.

Similar content being viewed by others

References

N. Mebarki, D. Delagnes, P. Lamesle, F. Delmas, C. Levaillant, Relationship between microstructure and mechanical properties of a 5% Cr tempered martensitic tool steel. Mater. Sci. Eng. A 387–389, 171–175 (2004)

W.S. Owen, The effect of silicon on the kinetics of tempering. Trans. ASM 46, 812–829 (1954)

D. Delagnes, P. Lamesle, M.H. Mathon, N. Mebarki, C. Levaillant, Influence of silicon content on the precipitation of secondary carbides and fatigue properties of a 5%Cr tempered martensitic steel. Mater. Sci. Eng. A 394, 435–444 (2005)

D. Mellouli, N. Haddar, A. Köster, H.F. Ayedi, Hardness effect on thermal fatigue damage of hot-working tool steel. Eng. Fail. Anal. 45, 85–95 (2014)

P. Michaud, P.D. Delagnes, P. Lamesle, M.H. Mathon, C. Levaillant, The effect of the addition of alloying elements on carbide precipitation and mechanical properties in 5% chromium martensitic steels. Acta Mater. 55, 4877–4889 (2007)

L. Rancel, M. Gómez, S.F. Medina, Analysis of V(C, N) nanoparticles in a medium carbon bainitic microalloyed steel and their influence on strengthening. Int. J. Mater. Res. 104, 527–534 (2013)

C. Lerchbacher, S. Zinner, H. Leitner, Direct or indirect: influence of type of retained austenite decomposition during tempering on the toughness of a hot-work tool steel. Mater. Sci. Eng. A 564, 163–168 (2013)

I. Souki, D. Delagnes, P. Lours, Influence of heat treatment on the fracture toughness and crack propagation in 5% Cr martensitic steel. Procedia Eng. 10, 631–637 (2011)

S. Pattnaik, D.B. Karunakar, P.K. Jha, Developments in investment casting process—a review. J. Mater. Process. Technol. 212, 2332–2348 (2012)

A. Pastor, Study of the martensitic transformation, optimization of microstructure and preventing brittle fracture in casting parts of high strength steel X38CrMoV5-1. Doctoral thesis, Madrid Complutense University (2015)

J.B. Wiskel, J. Lu, O. Omotoso, D.G. Ivey, H. Henein, Characterization of precipitates in a microalloyed steel using quantitative X-ray diffraction. Metals (2016). https://doi.org/10.3390/met6040090

R.C. Weast, Handbook of Chemistry and Physics, Chap. 12 (CRC Press, Florida, 1973)

M.L. Hillert, I. Staffanson, The regular solution model for stoichiometric phases and ionic melts. Acta Chem. Scand. 24, 3618–3626 (1970)

P.R. Rios, Expression for solubility product of niobium carbonitride in austenite. Mater. Sci. Technol. 4, 324–327 (1988)

H. Adrian, F.B. Pickering, Effect of titanium additions on austenite grain growth kinetics of medium carbon V-Nb steels containing 0.008–.018%N. Mater. Sci. Technol. 7, 176–182 (1991)

E.T. Turkdogan, Causes and effects of nitride and carbonitride precipitation during continuous casting. Iron Steelmak. 16, 61–75 (1989)

L.M. Lifshitz, V.V. Slyozov, The kinetics of precipitation from supersaturated solid solutions. J. Phys. Chem. Solids 19, 35–50 (1961)

A. Pastor, P. Valles, I. Amurrio, S.F. Medina, Heat treatment conditions to prevent failure in die cast X38CrMoV5 steel parts. Eng. Fail. Anal. 56, 520–529 (2015)

X.Z. Zhang, J.F. Knott, Cleavage fracture in bainitic and martensitic steel microstructures. Acta Mater. 47, 3483–3495 (1999)

K. Wallin, T. Saario, K. Torronen, Statistical model for carbide induced brittle fracture in steel. Met. Sci. 18, 13–16 (1984)

A. Studnicki, M. Kondracki, J. Suchoń, J. Szajnar, D. Bartocha, T. Wróbel, Abrasive wear of alloyed cast steels applied for heavy machinery. Arch. Foundry Eng. 15, 99–104 (2015)

T. Gladman, The Physical Metallurgy of Microalloyed Steels (The Institute of Materials, London, 1997)

A. Pastor, P. Valles, W. More, S.F. Medina, Toughness improvement of steel X38CrMov5-1 via alternative manufacturing process and prevention of catastrophic failure in safety parts. Eng. Fail. Anal. 82, 791–801 (2017)

P. Brozzo, G. Buzzichelli, A. Mascanzoni, M. Mirabile, Microstructure and cleavage resistance of low carbon bainitic steels. Met. Sci. 11, 123–129 (1977)

M.J. Roberts, Effect of transformation substructure on the strength and toughness of Fe–Mn alloys. Met. Trans. A 1, 3287–3294 (1970)

J.R. Rice, G.F. Rosengren, Plane strain deformation near a crack tip in a power law hardening material. J. Mech. Phys. Solids 16, 1–12 (1968)

A. Villuendas, J. Jorba, A. Roca, Change on Young’s modulus of hipoeutectoide carbon steels with heat treatment. Rev. Metal. Madrid Extr., 46–52 (2005)

A. Di Schino, C. Guarnaschelli, Effect of microstructure on cleavage resistance of high strength. Mater. Lett. 63, 1968–1972 (2009)

Acknowledgements

The authors want to thank the staff of the Metallic Materials Area of the National Institute for Aerospace Technology (INTA) and of the Physical Metallurgy of the National Centre for Metallurgical Research (CENIM-CSIC).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pastor, A., Valles, P., Jiménez, J.A. et al. Microstructural Analysis of X38CrMov5-1 Steel Parts Manufactured by Casting and Evaluation of Possible Cleavage Failure. Inter Metalcast 14, 384–395 (2020). https://doi.org/10.1007/s40962-019-00356-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-019-00356-7