Abstract

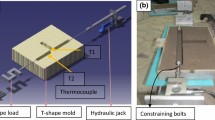

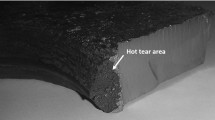

Hot cracking is a serious problem in casting of many alloys such as high-strength steels, austenitic stainless steels and aluminum alloys. In this study, the problem of hot tear during the casting of stainless steel CF3M (316L) cast in silica sand mold cored by CO2 was investigated. To do this, an in situ casting experiment using a T-shape mold equipped with K-type and B-type thermocouples, load cell, linear variable differential transformer and data acquisition system is used to characterize and quantify the hot tearing of CF3M during solidification along with simulation. Recorded thermal stress/force and displacement data are used for casting simulation and thermo-physical properties calculations. Simulation is carried out using casting simulation software, and thermo-physical properties were calculated using J-mat pro V8 software. Visco-plastic constitutive model was used to predict the hot tear; visco-plastic parameters play an important role to evaluate plastic strain. These parameters were derived from experimental and simulation data, and it is revealed that it is an accumulated plastic strain. Validation of developed model is part of future work. This study also focused on the effect of superheat on the hot tearing susceptibility of stainless steel alloy. Results have revealed that with increasing degree of superheat, the hot tearing susceptibility increases.

Similar content being viewed by others

References

H.F. Bishop, C.G. Ackerlind, W.S. Pellini, Metallurgy and mechanics of hot tearing. AFS Trans. 60, 818–833 (1952)

G. Brian, Thomas2 modeling of stress, distortion and hot tearing ASM handbook, Volume 15: casting ASM handbook committee, p. 449–461 doi: 10.1361/asmhba0005238

J. Campbell, Castings (Butterworth-Heinemann, Oxford, 1991)

T.W. Clyne, G.J. Davies, A quantitative solidification test for castings and an evaluation of cracking in aluminium–magnesium alloys. Br. Foundrym. 68, 238 (1975)

D.G. Eskin, Suyitno, L. Katgerman, Mechanical properties in the semi-solid state and hot tearing of aluminum alloys. Prog. Mater. Sci. 49, 629–711 (2004)

J.C. Hamaker, W.P. Wood, Influence of phosphorus on hot tear resistance of plain and alloy gray iron. AFS Trans. 60, 501–510 (1952)

J.V. Eeghem, A.D. Sy, A contribution to understanding the mechanism of hot tearing of cast steel. AFS Trans. 73, 282–291 (1965)

S.A. Metz, M.C. Flemings, A fundamental study of hot tearing. AFS Trans. 78, 453–460 (1970)

Y.F. Guven, J.D. Hunt, Hot-tearing in aluminum copper alloys. Cast Metals 1, 104–111 (1988)

S. Instone, D. StJohn, J. Grandfield, New apparatus for characterizing tensile strength development and hot cracking in the mushy zone. Int. J. Cast Metals Res. 12(6), 441–456 (2000)

D. Viano, D. Stjohn, J. Grandfield, C. Cáceres, Hot tearing in Aluminuium-Copper alloys, Light Metals, Edited by Halvor Kvande TMS (Metals and Materials Society, The minerals, 2005)

A. Roger, Stainless steel an introduction to their metallurgy and corrosion resistance. Dairy food Environ. Sanit. 20(7), 506–517 (2000)

C. Monroe, C. Beckermann, Deformation during casting of steel: mold and material properties, in Proceedings of the 61st SFSA Technical and Operating Conference, Paper No. 5.6 (Steel Founders’ Society of America, Chicago 2007)

C. Monroe, C. Beckermann, Simulation of hot tearing and distortion during casting of steel: comparison with experiments in Proceedings of the SFSA Technical and Operating Conference, Steel Founders’ Society of America (2006)

Y. Motoyama, H. Takahashi, Y. Inoue, K. Shinji, M. Yoshida, Development of a device for dynamical measurement of the load on casting and the contraction of the casting in a sand mold during cooling. J. Mater. Process. Technol. 212(6), 1399–1405 (2012)

Y. Motoyama, H. Takahashi, Y. Inoue, K. Shinji, M. Yoshida, Dynamic measurements of the load on castings and the contraction of the castings during cooling in sand molds. J. Mater. Process. Technol. 213(2), 238–244 (2013)

N.N. Prokhorov, Resistance to hot tearing of cast metals during solidification. Rus. Cast, Prod. 2, 172–175 (1962)

I.I. Novikov, Goryachelomkost tsvetnykh metallov i splavov (Hot Shortness of Nonferrous Metals and Alloys) (Nauka, Moscow, 1966)

L. Katgerman, A mathematical model for hot cracking of aluminum alloys during DC casting. J. Metals. 34, 46–49 (1982)

M. Rappaz, J.-M. Drezet, M. Gremaud, A new hot tearing criterion. Metall. Mater. Trans. A 30A, 449 (1999)

A. Stangeland, A. Mo, M. M’Hamdi, D. Viano, C. Davidson, Thermal strain in the mushy zone related to hot tearing. Metall. Mater. Trans. A 37A, 705 (2006)

T. Suzuki, K.H. Tacke, K. Wunnenberg, K. Schwerdtfeger, Creep properties of steel at continuous casting temperatures. Ironmak. Steelmak. 15(2), 90–100 (1988)

Peter J. Wray, Effect of carbon content on the plastic flow of plain carbon steels at elevated temperatures. Metall. Trans. A 13A(1), 125–134 (1982)

P.F. Kozlowski, B.G. Thomas, J.A. Azzi, H. Wang, Simple constitutive equations for steel at high temperatures. Metall. Trans. A 23A, 903–918 (1992)

C. Li, B.G. Thomas, Thermomechanical finite-element model of shell behavior in continuous casting of steel. Metall. Mater. Trans. B 35B, 1151–1172 (2004)

S. Koric, B.G. Thomas, Efficient thermo-mechanical model for solidification processes. Int. J. Numer. Methods Eng. 66, 1955–1989 (2006)

S. Koric, L.C. Hibbeler, B.G. Thomas, Explicit coupled thermo-mechanical finite element model of steel solidification. Int. J. Numer. Methods Eng. 78, 1–31 (2009)

A.K. Gupta, V.K. Anirudh, S.K. Singh, Constitutive models to predict flow stress in austenitic stainless steel 316 at elevated temperatures. Mater. Des. 43, 410–418 (2013)

C.E. Bates, S.K. Trikha, Improved method of hot tear testing and method to reduce hot tear. Trans. AFS V10, 173–180 (1994)

D. Bhiogade, S. Randiwe, A. M. Kuthe, Investigation of characteristics of CO2 mold for stainless steel casting, in Proceedings of the 63rd Indian Foundry Congress 27feb-1st March 2015, Delhi, India

D. Bhiogade, S. Randiwe, A. M. Kuthe, Critical analysis of rapid prototyping assisted investment casting for medical implants, in Proceedings of the 72nd World Foundry Congress 21–25th May 2016, Nagoya, Japan

W.I. Pumphrey, P.H. Jennings, A consideration of the nature of brittleness at temperature above the solidus in castings and welds in aluminum alloys. J. Inst. Metals 75, 235 (1948)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Bhiogade, D.S., Randiwe, S.M., Kuthe, A.M. et al. Study of hot tearing in stainless steel CF3M during casting using simulation and experimental method. Inter Metalcast 12, 331–342 (2018). https://doi.org/10.1007/s40962-017-0170-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-017-0170-7