Abstract

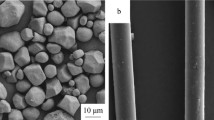

Molten titanium easily reacts with not only oxygen, carbon, and nitrogen but also the ceramic mold to form an α-case on the casting surface. However, the brittle α-case must be removed by chemical milling because it weakens the mechanical properties of the casting. The aim of this study is to evaluate and suppress the formation of the α-case by including TiO2 in the mold. Titanium powder was added into the alumina mold in order to facilitate the formation of TiO2 by the oxidation of titanium during mold firing. Another way to include TiO2 in the mold was to simply add TiO2 into the alumina mold. Optical microscopy and the micro-Vickers hardness test were used to characterize the α-case. The composition and morphology of the molds were confirmed using X-ray diffraction and field emission scanning electron microscopy. The mold with added titanium (Al2O3 + Ti) was effective in controlling the α-case. However, the interfacial reactions of the mold with the added TiO2 (Al2O3 + TiO2) exhibited distinct differences in α-case formation compared to the Ti-added mold (Al2O3 + Ti), while having almost identical compositions.

Similar content being viewed by others

References

P.R. Beeley, R.F. Smart, Investment Casting, 1st edn. (Institute of Materials, London, 1995), pp. 23–24

S.Y. Sung, B.J. Choi, B.S. Han, H.J. Oh, Y.J. Kim, J. Mater. Sci. Technol. 24, 70 (2008)

K.F. Lin, C.C. Lin, J. Mater. Sci. 34, 5899 (1999)

M.G. Kim, S.Y. Sung, Y.J. Kim, Mater. Trans. 45, 536 (2004)

I. Barin, G. Platzki, Thermochemical Data of Pure Substances, 3rd edn. (VCH Publishers, New York, 1995)

S. Jones, P.M. Marquis, Br. Ceram. Trans. 94, 68 (1995)

V.V. Tavgen, E.V. Shinkareva, E.V. Karpinchik, YuG Zonov, Sov. Powder Metall. Metal Ceram. 31, 193 (1992)

J. Zhu, A. Kamiya, T. Yamada, W. Shi, K. Naganuma, K. Mukai, Mater. Sci. Eng., A 327, 117 (2002)

N. Sobczak, M. Singh, R. Asthana, Curr. Opin. Solid State Mater. Sci. 9, 241 (2005)

J.P. Kuang, R.A. Harding, J. Campbell, J. Mater. Sci. Technol. 16, 1007 (2000)

C. Frueh, D.R. Poirier, M.C. Maguire, Metall. Mater. Trans. B 28, 919 (1997)

K.S. Chan, M. Koike, B.W. Johnson, T. Okabe, Metall. Mater. Trans. A 39, 171 (2008)

W.J. Boettinger, M.E. Williams, S.R. Coriell, U.R. Kattner, B.A. Mueller, Metall. Mater. Trans. B 31, 1419 (2000)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, S., Kim, YJ. Evaluation of the α-Case with TiO2 in Mold for Titanium Investment Casting. Inter Metalcast 11, 71–76 (2017). https://doi.org/10.1007/s40962-016-0093-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-016-0093-8