Abstract

Large-scale open-pit mining activities have profound impacts on the surrounding landscape and environment. At the cessation of open-pit mining, the rehabilitation of large void spaces can be achieved by pit-lake filling, where the water body provides a confining pressure on surrounding mine surfaces, reducing both the likelihood of slope failure and the need for ongoing slope maintenance. Although pit-lakes present a range of long-term benefits, the geotechnical performance of mines containing soft soils that are susceptible to creep under increasing loads due to pit-lake filling is seldom considered. From a geotechnical standpoint, creep induced failure is commonly associated with slow, downslope movements, prior to critical slope failure events. In this research, time-dependent slope stability analyses based on creep-sensitive materials are presented for an open-cut mine undergoing pit-lake filling. Numerical simulation provides a mechanism for the assessment of materials exhibiting soft soil creep constitutive behaviour under various loading conditions due to pit-lake filling. The response of mine surfaces is investigated for various filling regimes, highlighting location-dependent deformation rates, pore pressures and slope Factors of Safety for a large Australian open-pit brown coal mine. Results are presented for two separate creep-sensitive materials, identifying the ability to achieve final, stable landforms for a range of long-term pit-lake conditions.

Article Highlights

-

Time-dependent creep deformation behaviour is investigated for a large Victorian open-pit brown coal mine undergoing pit-lake rehabilitation.

-

The soft soil creep model is implemented for a large open-pit rehabilitation model, to assess long-lasting creep movements of a specific mine slope.

-

Mine void filling rates are simulated for a range of rehabilitation scenarios over a 5 to 40 year period, identifying the excess pore water pressure distributions in addition to vertical and horizontal deformations rates.

-

The long-term behaviour of 8 cross-section profiles is presented, identifying the effect of pit-lake filling for silt and clay interseam materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Pit-lake filling continues to gain attention as a strategy for long-term open-pit mine rehabilitation. To ensure stability, pit-lakes are formed at the conclusion of mining operations by flooding void spaces, decreasing the risk of slope failure by providing a confining pressure on slopes and mine walls. Filling is commonly controlled by a combination of precipitation, cessation of groundwater depressurisation and runoff from drainage basins (Castro and Moore 2000). In addition to geotechnical advantages, pit-lakes exhibit a range of long-term beneficial environmental qualities, including the creation of aquatic habitats, active and passive recreation areas, and community assets. Although such structures are deemed to reduce the long-term slope stability risk through the restoration of weight-balance, pit-lakes continue to present ongoing challenges (McCullough et al. 2020). Common risks include erosion to the shoreline (McCullough et al. 2019), a reduction in water quality due to acidification (Geller et al. xxxx) and slope failure (McCullough and Lund 2006; Nestler and Stoll 2001), while factors influencing pit-lake performance include climate, regional geology vegetation and regional groundwater flow (Schultze 2012). During active mining, groundwater pressures are often controlled through slope drainage and aquifer depressurisation. Contrastingly, during and after pit-lake filling, dewatering and depressurisation are not used to control groundwater pressures. Instead, capping layers of overburden minimise the infiltration of surface water (Wells et al. 2013).

Pit-lake rehabilitation can achieve mine stability by providing a counterweight to upward pressures from aquifers below the mine surface, preventing floor heave, while also increasing the lateral pressure on mine slopes (Precincts and Regions 2020). During the period of filling prior to achieving the final pit-lake design, drainage boreholes above surface waters may be required for groundwater pressure control and to minimise the risk of ground movements. Further hydrogeological factors impacting stability include surface rebound as aquifers repressurise, scouring and erosion of mine surfaces due to wave effects and increased seismic risks due to pit-lake filling (Schultze et al. 2010).

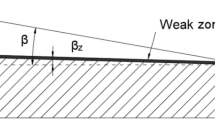

The presence of soft, rate-sensitive creeping soils can have profound implications for the stability of natural and mined slopes. Soils experiencing unrecoverable, continuous creep deformation can lead to an eventual loss of shear strength (Tran et al. 2018). In soil slopes, creep shear strain causes a redistribution of stresses that may lead to near-failure states that are sensitive to additional disturbance (Pusch et al. 2016). Creep often results in a slow and steady downhill movement that results in permanent deformation insufficient to cause shear failure (Ziemer 1977). Contrastingly, many slopes undergo continuous deformation due to creep, causing gradual geometric changes that can lead to a reduction in shear strength, eventually triggering slope failure (Vermeer and Neher 2000a). As a phenomenon, creep has been observed at both the near-surface, exhibiting shallow movement (Asch et al. 1989) and at the deep-seated level (Tran et al. 2018). Long-term time-dependent creep strength was first investigated by Goldstein and Babitskaya (1959), considering the creep failure in response to the application of long-term loads. More recently, a number of soil models have been developed to assess the stability of soft soil slopes and embankments through numerical slope stability analysis. Although numerous slopes containing soft soils exhibiting creep have been investigated (Ghadrdan et al. 2020a, b; Long et al. 2020; Wongchana et al. 2020), the performance of pit-lakes containing soft soils undergoing reloading due to the filling of void spaces has seldom been considered. As soft, creeping soils may be susceptible to further disturbance, the rate of reloading due to the weight of pit-lake water has the potential to bring forth additional deformation and induce failure.

In this research, an open-pit lignite mine within the state of Victoria, Australia, containing a soft interseam susceptible to creep is considered for various potential loading scenarios due to the rate of pit-lake filling. Building on the results of studies characterising the properties of mine soils in the region (Karami and Tolooiyan 2020; Tolooiyan et al. 2020; Tolooiyan et al. 2021; Wen et al. 2020), coupled with previous numerical slope stability analyses of recent open-pit mine batter geometries (Ghadrdan et al. 2020a, b; Dyson and Tolooiyan 2019), this research investigates the response of mine batters to a range of pit-lake filling scenarios based on potential filling rates. As a result, progressive changes in deformation, pore water pressures, plasticity and Factor of Safety (FoS) are investigated to determine the likelihood of soft soil creep mechanisms to impact the stability of large-scale rehabilitated mine slopes under pit-lake filling.

2 Pit lakes and final landforms

Pit-lakes require careful design, especially in relation to long-term stability for periods often in excess of 100 years (Graaf et al. 2019). Predicting future modes of slope instability is a non-trivial task. McCullough and Lund determined that a rebound in groundwater pressures can increase the likelihood of slope failure due to a decrease in the effective stress of mine slope walls (McCullough and Lund 2006). Slopes exposed to fluctuations in the waterfront level induce external water loading, changes in pore pressures and erosion, as can be seen in many embankment dam failures (Johansson 2014), and in some cases, slope failure (Jian et al. 2014; Moregenstern 1963). Sources of natural water level fluctuation include tidal water level changes (Li et al. 1997; Raubenheimer et al. 1999) and wind-induced waves (Bakhtyar et al. 2009). Carter (Carter 2014) noted a range of factors that control the degradation of stability over time, including changes to groundwater pressures, stress conditions and geometry. Erosion and rilling have the potential to damage slope covers and create preferential surface flows, which can negatively impact groundwater pressures, while also allowing surface water to pond.

In many cases, a loss of stability can be linked with rapid drawdown, with an associated reduction in water level. However, a rising level of water, as seen with pit-lake filling, can also be cause for concern. Increases in the water level have been shown to cause stress redistributions due to external loads, which can lead to a loss of shear strength and overall stability, such was the case with the initial filling of the Panama Canal and the Three Gorges Reservoir (Jian et al. 2014; Lane 1966). In assessing slope failure mechanisms, the Finite Element Method (FEM) has been extensively implemented to investigate the influence of water level changes (Lane and Griffiths 2000; Rinaldi et al. 2004; Zhan et al. 2006).

Several types of pit-lake structures exist based on the desired properties of the final landform, each with a unique set of geotechnical and hydrological characteristics. The design of lake structures is often based on their susceptibility to failure mechanisms (such as rockfalls and slides), hydrological conditions (such as the interaction with ground and surface waters) and water availability. Six viable rehabilitated pit-lake landforms for open-cut mines are presented below:

2.1 Full level pit-lake

Requiring minimal overburden above the water level, a deep lake is formed by filling the pit to the crest of the mine. In this scenario, groundwater is often allowed to recover to the natural level without the requirement of continual dewatering. Mine slopes below the final water level do not require reshaping and are permitted to remain steep. Slopes above the water level are often reshaped to produce shallow slopes, allowing for access and maintenance. Figure 1a indicates the prominent features of a full level pit-lake.

2.2 Full backfilling

Under exceptional circumstances, the mine pit is fully filled with overburn and non-polluting waste material (Fig. 1b). The full backfilling option requires sufficient overburden to fill the void and is rarely an option for deep pits. Groundwater is allowed to recover to natural levels, with landforms surrounding the pit reshaped to control the drainage of surface water.

2.3 Partial pit-lake

In cases where there is insufficient water resources to fill the pit, a partially filled pit provides a final land-use scenario creating a dry landform significantly lower than the mine crest (Fig. 1c). As such, groundwater pumping and mine drainage are required above the water table. Mine slopes above the water surface are reshaped to meet land use requirements.

2.4 Empty void

The mine is partially filled with an engineered impermeable (often clay) liner to inhibit the flow of water into the pit (Fig. 1d). As a result, ongoing groundwater dewatering is required.

3 Soft soil creep constitutive behaviour

Soft clay deposits are complex in nature, often displaying significant signs of anisotropy and rate sensitivity due to underlying sedimentary processes and consolidation history (Burland 1990). In recent years, the time-dependent behaviour of soft soils has been represented using constitutive models such as Soft Soil Creep (SSC) (Vermeer and Neher 2000a). As the name indicates, the model is used to simulate the behaviour of creep (i.e., secondary consolidation) for soft soils such as clay and silt. SSC discerns between primary loading and unloading/reloading behaviour, similar to the Soft Soil (SS) model, however, the SS model does not consider time dependency, as is required when investigating rate-dependent pit-lake filling regimes.

The primary assumption of SSC behaviour is the instantaneous development of elastic strains, while viscoplastic strains will develop over time (Waterman and Broere 2005). As such, viscoplastic behaviour is defined by

where \(\dot{{\upepsilon }_{ij}^{e}}\) and \(\dot{{\upepsilon }_{ij}^{c}}\) are the elastic and creep components, respectively. The creep volumetric strain \({\upepsilon }_{v}^{c}\) is calculated by

where \({\uplambda }^{*}\), \({\upkappa }^{*}\) and \({\upmu }^{*}\) are defined as the modified compression, swelling and creep indices, respectively; τ is time; \({p}^{eq}\) is the stress state, as given in Eq. 3; and \({p}_{p}^{eq}\) is the generalised equivalent pre-consolidation pressure, as given in Eq. 4.

where p and q are stress invariants defined by the current stress state; M is the critical state gradient; \({p}_{0}\) is the initial conditions when the creep volumetric strain and time are equal to zero; and c and ϕ are the cohesion and friction angle shear strength parameters, respectively.

In the case of the modified compression and swelling indices \({\uplambda }^{*}\) and \({\upkappa }^{*}\), parameters are determined based on isotropic compression tests for loading and unloading. The slope of the normal consolidation curve yields the modified compression index, while the slope of the unloading curve provides the modified swelling index. The creep index is obtained by calculating the long-term volumetric strain with respect to log time. The relationship between \({\mu }^{*}, {\uplambda }^{*}\) and \({\upkappa }^{*}\), Cam-Clay parameters and normalised parameters are detailed in Table 1.

The creep strain tensor is defined by Eq. 5, with the critical state line M calculated using the lateral earth pressure \({K}_{0}^{nc}\) from oedometer testing, as shown in Eq. 6. As such, similar to the Modified Cam Clay constitutive model, the bulk modulus is a function of the confinement and modified swelling index (Eq. 7).

where \({E}_{ur}\) and \({\nu }_{ur}\) are the unloading/reloading modulus and Poisson’s ratio, respectively.

Creep-induced slope instability usually occurs when the stress levels are above the critical state line but less than the peak strength. Instability develops as a result of the accumulation of plastic volumetric dialation which leads to a slow softening, finally resulting in failure (Tavenas et al. 1978). There are a range of alternative methods capable of capturing the creep behaviour of soils. A popular method for capturing plasticity inside the yield surface is the bounding surface plasticity method due to its simplicity (Dafalias and Popov 1975). A bounding surface viscoplasticity method has been implemented in several cases to model time-dependent soil behaviour for drained and undrained behaviour during both primary and tertiary creep (Higgins et al. 2013; Mac et al. 2020; Xu and Zhang 2015), nevertheless, the research presented in this study focuses on the use of the Soft Soil Creep model.

4 Site condition and case study

4.1 Location and background

The Latrobe Valley, located in the state of Victoria (Fig. 2), Australia, contains one of the largest brown coal deposits in the world, encompassing more than 43 × 1010 tonnes of brown coal (Spurrier 1986). Three large open-cut mines exist in the region– the Hazelwood, Loy Yang and Yallourn mines, with Yallourn and Loy Yang currently in active use. The Yallourn mine is Australia’s second-largest open pit, containing continuous seams extending in excess of 100 m in depth. The coal seams of the region are particularly sensitive to changes in water content and undergo rapid moisture loss and oxidation (Wen et al. 2020). Victorian Brown Coal (VBC), is a relatively lightweight Intermediate Geotechnical Material (IGM), with a specific gravity of approximately 1.1 g/cm and a moisture content of up to 60% (Moein et al. 2016).

Geotechnical parameters demonstrated in several previous studies (Ghadrdan et al. 2020a, b; Karami and Tolooiyan 2020) highlight the necessary properties to simulate the constitutive behaviour of overburden, VBC and interseam materials (Table 2) as found within the mine, with Fig. 3 denoting the stratigraphy of the Yallourn north-east batter. Similarly, parameters necessary for the Soft Soil Creep constitutive model are presented in Table 3. The Creep Ratio CR (Eq. 8) produces values of 2.7 and 5 for clay and silt, respectively. Values equal to 5 or less are often considered to be creep sensitive.

VBC permeability is highly variable due to the jointed nature of the material in situ. Tolooiyan et al. [2020] observed VBC permeabilities through Lugeon packer tests which vary significantly from permeability tests conducted on small-scale samples within the laboratory (Tolooiyan et al. 2020). A range of large coal joints have been ovserved within the region, through geotechnical and geophysical exploration methods, with one of the primary joints identified in the vicinity included at the crest of the slope geometry provided in Fig. 3 (Tolooiyan et al. 2019). Further details regarding joint interface properties, in addition to the joint characterisation and performance of the joint are found in Ghadrdan et al. (2020c) and Shaghaghi et al. (2020a, b), respectively. The interseam layer underlying the primary layer of excavated coal contains a mixture of localised bands of clay and silt, which can be observed from a range of core samples extracted from the region (Fig. 4). The modified compression index (λ*), swelling index (κ*) and creep index (μ*) for a clay interseam were observed as 0.06, 0.006 and 0.02, respectively, while the values for silt were observed as 0.045, 0.01 and 0.007, respectively.

4.2 Latrobe valley mine filling and water availability

Recent estimates place the volume of water necessary to partially fill the Yallourn mine void, attaining counterweight balance at approximately 1600 GL, with 2800 GL required to completely fill the pit, equivalent to five times the volume of Sydney harbour (Precincts and Regions 2020). Despite such a large magnitude of water, current progressive rehabilitation plans suggest that filling would likely take place over a period of decades, dependent on a number of external factors, including water availability as a function of dam storage, climate change, etc. Table 3 presents a range of filling times for each of the three Latrobe Valley mines, based on various constraints, suggesting a timeline for Yallourn pit filling between 14 and 35 years, as considered by the Victorian Government’s Regional Rehabilitation Strategy (Precincts and Regions 2020).

5 Numerical analysis

To consider the behaviour of the North-East batter for a range of potential filling scenarios, Finite Element (FE) models were initially developed, implementing the Hardening Soil (HS) model for VBC and the SSC constitutive model for interseam (Ghadrdan et al. 2020b) within the PLAXIS 2D FE environment (Version 21) (Brinkgreve et al. 2016). Due to the variability of the interseam, two simulation categories were considered – those consisting of a predominantly clay interseam material and those with a predominantly silt interseam. A staged construction procedure was implemented to investigate the time-dependent nature of the filling process consisting of ten filling stages, uniformly distributed between RL -44 and RL -4.. To investigate filling times, a total of ten pit-lake filling stages were used to model the filling process to the crest of the batter. Total filling times range from 5 to 40 years, at increments of 5 years. Each model stage consisted of Fully Coupled Flow Deformation (FCFD) calculations, followed by a Factor of Safety (FoS) stage, to determine the stability and associated failure of the slope at each filling level. For the purposes of the research, a full pit-lake scenario was considered, based on a set of “what if” scenarios for the potential filling rates, commencing from an initial slope excavation surface reached at the end of 2007. The initial study of creep-induced deformations does not incorporate overburden capping layers or reshaping of batters above the water level, due to the lack of public-access data regarding final pit-lake plans. Groundwater levels for the FE model at the commencement and conclusion of filling are shown in Fig. 5.

The FE mesh contains 6243 triangular elements and 50,348 nodes (Fig. 6). To ensure that stress concentrations in the slope do not develop due to the location of the model boundary conditions, the geometry was sufficiently extended from the toe and crest of the slope. Left and right boundaries were horizontally fixed, with the bottom boundary fully fixed. Pore water pressures were controlled such that seepage can occur at vertical boundaries, with no seepage at the bottom of the geometry. To assess depth-dependent trends in deformation and pore water pressures, eight cross-section locations in the mine floor as well as close to the slope toe and crest were chosen, as shown in Fig. 7.

Figures 8, 9, 10 indicate the horizontal (Ux) and vertical deformation (Uy), and excess pore water pressures (Pexcess) for Locations 1 and 5, indicating the behaviour at the toe and bench of the slope when considering a silt interseam and a filling regime of 5 years. The deformation profile for each case is given with respect to the initial deformation of the slope, prior to excavation (as indicated in Ghadrdan et al. 2020b). In each case, continual deformation is observed for each of the ten filling stages, particularly within the upper coal and interseam layers. The slope deformation, and excess porewater pressure profile at the conclusion of the 5 year filling period are given in Figs. 10 and 11. The level of total deformation at the conclusion of filling for each of the eight filling time scenarios (Figs. 12, 13) demonstrates that the rate of deformation is dependent on the rate of filling, with the rate of creep slowing as a result of the time required to reach the final water level. Deformation levels are presented with respect to the excavation stage, such that the filling time can be chosen based on the level of acceptable deformation. The level of creep is location dependent, with vertical deformation dominating in all cases.

To understand the predominant creep behaviour and the rate dependencies due to the filling process, the deformation and pore water pressure was assessed along cross-Sect. 6, slightly below the interseam boundary at an RL of − 42 m. The results for the horizontal and vertical deformation along with their time derivatives, in addition to the excess pore water pressure for each of the filling regimes considered (5–40 years) are shown in Figs. 14 and 15. It is evident that the rate of filling impacts the level of deformation, for both silt and clay interseams. While a longer filling period results in an extended period of creep, inducing larger deformations (Figs. 14a and 15a), it is also evident that the horizontal and vertical deformation rates of change diminish rapidly over short filling periods (Figs. 14b and 15b). In the case of the less creep-sensitive silt interseam, a small rebound in deformations towards the initial slope geometry is most discernable at the conclusion of the 5, 10 and 15 year filling scenarios (Fig. 14c and e). This can be attributed to the negative excess pore water pressure generation close to the crest of the mine, over shorter pit filling periods. This negative pore water pressure acts to keep the slope in tension, reduce the rate of deformation towards the pit void and produce a minor level of deformation towards the initial slope positioning. While this is the case when considering a silt interseam, the behaviour is absent for a clay interseam due to the lack of negative excess pore water pressure (Fig. 15c and e). The salient feature of both analyses is the ongoing (yet diminishing) deformation with time, despite the confining pressure applied to the batter by the pit-lake.

Figure 16 presents the FoS distributions for both materials. Although both materials exhibit continual deformation, due to the rate of movement coupled with the confining pressure of the pit-lake, an increase in the FoS is observed for both cases. Only minimal changes in the shape of the failure are observed throughout the filling process, with the typical slope failure surface given in Fig. 17.

6 Conclusion

Creeping and rate-sensitive soft soils are challenging materials for large-scale slope design. In the case of mine pit rehabilitation, the rate of filling is often constrained by a number of factors such as water availability. Although this is a primary factor in current pit-lake rehabilitation, the rate at which soft soils are loaded can also impact the behaviour of the mine slope. Results of numerical analyses using the Soft Soil Creep constitutive model present a set of scenarios based on mine filling rates for an Australian open-pit mine. Although continual deformation is noted throughout the filling period, with the rate of creep controlled by the speed of filling, the Factor of Safety remained unhindered by the loading process, indicating that based on the limited factors considered in this study, large-scale slope failure mechanisms as a result of changes to the water level are unlikely. Although the results highlight the behaviour of sensitive clays within pit-lakes, a number of additional factors for future consideration may provide further insight into their performance for mine rehabilitation scenarios. The angle of mine slopes above the final water level are commonly reduced to minimise failure and allow for long-term access and maintenance. Impermeable liners are also commonly implemented to produce a barrier inhibiting the infiltration of water, controlling groundwater pressures. Given the interplay between soft soil rate creep and rate sensitivity with respect to mine rehabilitation, the performance of partial pit-lake scenarios and final water levels, when combined with rate sensitive materials, presents a compelling case for future investigation.

Data availability

Specific data can be provided on request by the corresponding author.

References

Van Asch TWJ, Deimel MS, Haak WJC, Simon J (1989) The viscous creep component in shallow clayey soil and the influence of tree load on creep rates. Earth Surf Proc Land 14(6):557–564

Bakhtyar R, Barry DA, Li L, Jeng DS, Yeganeh-Bakhtiary A (2009) Modeling sediment transport in the swash zone: a review. Ocean Eng 36(9):767–783

Brinkgreve R, Kumarswamy S, Swolfs W, Waterman D, Chesaru A, Bonnier P (2016) PLAXIS 2016. PLAXIS bv, the Netherlands

Burland JB (1990) On the compressibility and shear strength of natural clays. Géotechnique 40(3):329–378

Carter T (2014) Guidelines for use of the scaled span method for surface crown pillar stability assessment. Ontario Ministry of Northern Development and Mines, Ontario. 1–34

Castro J, Moore J (2000) Pit lakes: their characteristics and the potential for their remediation. Environ Geol 39(11):1254–1260

Dafalias Y, Popov E (1975) A model of nonlinearly hardening materials for complex loading. Acta Mech 21(3):173–192

Dyson AP, Tolooiyan A (2019) Prediction and classification for finite element slope stability analysis by random field comparison. Comput Geotech 109:117–129

Dyson AP, Tolooiyan A (2020) Comparative approaches to probabilistic finite element methods for slope stability analysis. Simulat Modell Pract Theory 100:102061

Geller W, Schultze M, Kleinmann R, Wolkersdorfer C (2012) Acidic pit lakes the legacy of coal and metal surface mines. Environmental Science and Engineering/Environmental Science, Springer, Berlin, Heidelberg, 525 pp

Ghadrdan M, Dyson AP, Shaghaghi T, Tolooiyan A (2020a) Slope stability analysis using deterministic and probabilistic approaches for poorly defined stratigraphies. Geomech Geophys Geo 7(1):4

Ghadrdan M, Shaghaghi T, Tolooiyan A (2020b) Sensitivity of the stability assessment of a deep excavation to the material characterisations and analysis methods. Geomech Geophys Geo 6(4):59

Ghadrdan M, Shaghaghi T, Tolooiyan A (2020c) Sensitivity of the stability assessment of a deep excavation to the material characterisations and analysis methods. Geomech Geophys Geo 6(4):1–14

Goldstein M, Babitskaya S (1959) Methods of determining the long term strength of soils. Osn Fund I Mekh Gruntov 4:4–11

Graaf P de , Desjardins M, Tsheko P 2019 Geotechnical risk management for open pit mine closure: a sub-arctic and semi-arid case study. Proceedings of the 13th International conference on mine closure: Australian centre for geomechanics, p. 211–234.

Higgins W, Chakraborty T, Basu D (2013) A high strain-rate constitutive model for sand and its application in finite-element analysis of tunnels subjected to blast. Int J Numer Anal Meth Geomech 37(15):2590–2610

Jian W, Xu Q, Yang H, Wang F (2014) Mechanism and failure process of Qianjiangping landslide in the three Gorges Reservoir China. Environ Earth Sci 72(8):2999–3013

Johansson J (2014) Impact of water-level variations on slope stability: Luleå tekniska universitet

Karami M, Tolooiyan A (2020) Investigating the elastoplasticity of an Australian soft rock based on laboratory test results. Eng Geol 276:105762

Lane P, Griffiths D (2000) Assessment of stability of slopes under drawdown conditions. J Geotech Geoenviron Eng 126(5):443–450

Lane K (1966) Stability of reservoir slopes. The 8th US Symposium on Rock Mechanics (USRMS): American rock mechanics Association

Li L, Barry DA, Pattiaratchi CB (1997) Numerical modelling of tide-induced beach water table fluctuations. Coast Eng 30(1):105–123

Long M, Grimstad G, Trafford A (2020) Prediction of embankment settlement on Swedish peat using the soft soil creep model. Proceed Institut Civil Eng–Geotech Eng. https://doi.org/10.1680/jgeen.20.00141

Mac TN, Shahbodagh B, Khalili N (2020) Modelling of creep rupture in clay using the bounding surface viscoplasticity theory. J Mater Eng Struct 7(4):677–84

McCullough CD, Lund MA (2006) Opportunities for sustainable mining pit lakes in Australia. Mine Water Environ 25(4):220–226

McCullough CD, Schultze M, Vandenberg J (2020) Realizing beneficial end uses from abandoned pit lakes. Minerals 10(2):133

McCullough CD, van Rooijen A, van Maren DS (2019) Process-based erosion modelling for shoreline rehabilitation design of a coal mine pit lake. In: Fourie AB, Tibbett M, editors. Proceedings of the 13th International conference on mine closure. Perth: Australian centre for geomechanics, p. 75–88

Moein F, Xue J, Dent B, Mackay R (2016) Review of the historical data characterizing Latrobe Valley brown coal consolidation behaviour. Geol Soci, London, Eng Geol Special Publicat 27(1):217–226

Moregenstern N (1963) Stability charts for earth slopes during rapid drawdown. Geotechnique 13(2):121–131

Nestler P, Stoll RD (2001) Stabilisation of bank slopes that are prone to liquefaction in ecologically sensitive areas. Waste Manage 21(2):153–159

Pusch R, Knutsson S, Xiaodong L, Yang T (2016) Creep can strengthen clay : a matter of long-term slope stability

Raubenheimer B, Guza RT, Elgar S (1999) Tidal water table fluctuations in a sandy ocean beach. Water Resour Res 35(8):2313–2320

Rinaldi M, Casagli N, Dapporto S, Gargini A (2004) Monitoring and modelling of pore water pressure changes and riverbank stability during flow events. Earth Surf Proc Land 29(2):237–254

Schultze M, Pokrandt K-H, Hille W (2010) Pit lakes of the central German lignite mining district: creation, morphometry and water quality aspects. Limnologica 40(2):148–155

Schultze M (2012) The filling and remediation of pit lakes in former open cast lignite mines. Master's thesis, Braunschweig Technical University

Shaghaghi T, Ghadrdan M, Tolooiyan A (2020) Effect of rock mass permeability and rock fracture leak-off coefficient on the pore water pressure distribution in a fractured slope. Simul Modell Pract Theory 105:102167

Shaghaghi T, Ghadrdan M, Tolooiyan A (2020) Design and optimisation of drainage systems for fractured slopes using the XFEM and FEM. Simul Modell Pract Theory 103:102110

Spurrier PL (1986) Brown coal: victoria’s vital resource. Energy 11(11–12):1251–1257

Tavenas F, Leroueil S, Rochelle PL, Roy M (1978) Creep behaviour of an undisturbed lightly overconsolidated clay. Can Geotech J 15(3):402–423

Tolooiyan A, Dyson AP, Karami M, Shaghaghi T, Ghadrdan M (2019) Application of ground penetrating radar (GPR) to detect joints in organic soft rock. Geotech Test J 42(2):257–274

Tolooiyan A, Dyson AP, Karami M, Shaghaghi T, Ghadrdan M (2020) Investigation of an Australian soft rock permeability variation. Bull Eng Geol Env 79(6):3087–3104

Tolooiyan A, Dyson AP, Karami M, Shaghaghi T, Ghadrdan M, Tang Z (2021) Maximising the efficiency of Menard pressuremeter testing in cohesive materials by a cookie-cutter drilling technique. Eng Geol 287:106096

Tran TTT, Hazarika H, Indrawan IGB, Karnawati D (2018) Prediction of time to soil failure based on creep strength reduction approach. Geotech Geol Eng 36(4):2749–2760

Vermeer P, Neher H (2019) A soft soil model that accounts for creep. Beyond 2000a in computational geotechnics: Routledge, p. 249–61

Vermeer P, Neher H (1999) A soft soil model that accounts for creep. Beyond 2000b in computational geotechnics. 249–261

Victorian state government DoJ, Precincts and Regions. Latrobe Valley Regional Rehabilitation Strategy (2020)

Waterman D, Broere W (2005) Practical application of the soft soil creep model-Part III. Plaxis Bullletin, 17

Wells PJ, Anderson J, Trott S, Browett C (2013) Mine design with rehabilitation in mind: for tailings and water. Sustainable engineering society (SENG) 2013 conference: Looking back looking forward: engineers Australia, p. 199

Wen J, Tang Z, Dyson AP, Tolooiyan A (2020) The mechanical behaviour of pre-existing transverse cracks in lignite under uniaxial compression. Geomech Geophys Geo 7(1):6

Wongchana P, Jitsangiam P, Thongmunee S, Tanchaisawat T (2020) Modelling of creep behavior of claystone in Mae Moh Open-Pit mine using the soft soil creep model. Springer, Berlin, pp 349–355

Xu T, Zhang L (2015) Numerical implementation of a bounding surface plasticity model for sand under high strain-rate loadings in LS-DYNA. Comput Geotech 66:203–218

Zhan TL, Zhang W, Chen Y (2006) Influence of reservoir level change on slope stability of a silty soil bank. Unsaturated Soils p. 463–472

Ziemer RR (1977) Measurement of soil creep by inclinometer. US dept Agric, Forest service, Engineering tech report ETR-7100–4, Washington, DC 10 p

Acknowledgements

The authors wish to thank Dr. Mojtaba Karami for providing the results of geotechnical laboratory tests on coal, and interseam samples and Dr. Mohsen Ghadrdan for the development and calibration of an initial soft soil creep slope stability model for an active open-pit mining.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions. None.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Dyson, A.P., Moghadam, M.S., Zad, A. et al. The role of creep deformation in pit lake slope stability. Geomech. Geophys. Geo-energ. Geo-resour. 8, 138 (2022). https://doi.org/10.1007/s40948-022-00451-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-022-00451-w