Abstract

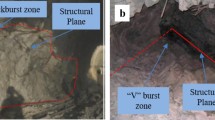

Segmental lining is a new supporting structure for mine tunnels, but the applicability of the existing protective coal pillar design method to this structure is uncertain. In this paper, based on TBM-inclined tunnels in Xinjie Coalmine, China, a 1:35 scale 2D physical model with a 4 m width and 1.8 m height was constructed to simulate the complete engineering process. The effects of coal mining on the safety of segmental linings were assessed to determine the optimal size of the coal pillar under inclined tunnels. The results indicate that a reasonable pillar width can maintain the inclined tunnel and its segmental lining stable under deep mining activities. During the coal excavation process, the tangential force around the lining will gradually increase; the left shoulder, crown, and right shoulder of the lining are the positions where the highest forces are expected, which are two or three times those of other positions; and the maximum displacement of the tunnel in the vertical direction is approximately triple that in the horizontal direction. Mining-induced rock bursts are the key factor in lining instability, especially under excessive amplitudes and high-frequency vibrations, which promote segment cracking. For the Xinjie Coalmine, damage to the tunnel lining can be initiated when the coal pillar width below the pair of tunnels reaches 120 m, and visible cracks appear when the pillar width is below 100 m. Thus, it is recommended that the optimum pillar width for mining should be set at 120 m.

Similar content being viewed by others

References

Boldt H, Henneke J (1981) Tunnel boring under coal mining conditions. In: 1981 Rapid Excavation and Tunneling Conference, pp 722–737

Cai M, Kaiser PK, Tasaka Y, Maejima T, Morioka H, Minami M (2004) Generalized crack initiation and crack damage stress thresholds of brittle rock masses near underground excavations. Int J Rock Mech Min 41:833–847

Chu B, Hsu S, Chang Y, Lin Y (2007) Mechanical behavior of a twin-tunnel in multi-layered formations. Tunn Undergr Sp Tech 22:351–362

Chu ZF, Wu ZJ, Liu QS, Liu BG, Sun JL (2021) Analytical solution for lined circular tunnels in deep viscoelastic burgers rock considering the longitudinal discontinuous excavation and sequential installation of liners. J Eng Mech 147(4):04021009

Donnelly C, Rammage G, Donghi M (2014) Alternative excavation methods in undeground coal mining. 14th Coal Operators’ Conference, University of Wollongong, The Australasian Institute of Mining and Metallurgy & Mine Managers Association of Australia. pp 216–223

Eberhardt E, Stead D, Stimpson B, Read RS (1998) Identifying crack initiation and propagation thresholds in brittle rock. Can Geotech J 35:222–233

Gao M, Zhang Z, Qiu Z et al (2018) The mechanism of hysteretic ground settlement caused by shield tunneling in mixed-face conditions. Geomech Geophys Geo-energ Geo-resour 4:51–61

Handewith HJ (1983) TBM tunnels in the Western Hemisphere; an overview. Tunnel Technol Newsl 41:1–8

He M, Gong W, Zhai H, Zhang H (2010) Physical modeling of deep ground excavation in geologically horizontal strata based on infrared thermography. Tunn Undergr Sp Tech 25(4):366–376

He M, Xie H, Peng S, Jiang Y (2005) Study on rock mechanics in deep mining engineering. Chin J Rock Mech Eng 24:2803–2813

Huang F, Zhu H, Xu Q, Cai Y, Zhuang X (2013) The effect of weak interlayer on the failure pattern of rock mass around tunnel—scaled model tests and numerical analysis. Tunn Undergr Sp Tech 35:207–218

Kulatilake PHSW, Wu Q, Yu Z, Jiang F (2013) Investigation of stability of a tunnel in a deep coal mine in China. Int J Min Sci Techno 23:579–589

Lei M, Peng L, Shi C (2015) Model test to investigate the failure mechanisms and lining stress characteristics of shallow buried tunnels under unsymmetrical loading. Tunn Undergr Sp Tech 46:64–75

Li LF, Li G, Gong WL, Wang J, Deng HL (2019) Energy evolution pattern and roof control strategy in non-pillar mining method of goaf-side entry retaining by roof cutting—a case study. Sustainability 11(24):7029

Li SC et al (2015) Model test study on surrounding rock deformation and failure mechanisms of deep roadways with thick top coal. Tunn Undergr Sp Tech 47:52–63

Murphy G (1950) Similitude in engineering. Ronald Press Co, New York

Ren W, Guo C, Peng Z, Wang Y (2010) Model experimental research on deformation and subsidence characteristics of ground and wall rock due to mining under thick overlying terrane. Int J Rock Mech Min 47:614–624

Shi XM, Liu BG, Tannant D, Qi Y (2017) Influence of consolidation settlement on the stability of inclined TBM tunnels in a coal mine. Tunn Undergr Sp Tech 69:64–71

Shi XM, Liu BG, Xiang YY, Qi Y (2018) A method for selecting similar materials for rocks in scaled physical modeling tests. J Min Sci 54(6):938–948

Sinha S, Walton G (2019) Numerical analyses of pillar behavior with variation in yield criterion, dilatancy, rock heterogeneity and length to width ratio. J Rock Mech Geotech 11(1):46–60

Sun H, Liu XL, Zhang SG, Nawnit K (2020) Experimental investigation of acoustic emission and infrared radiation thermography of dynamic fracturing process of hard-rock pillar in extremely steep and thick coal seams. Eng Fract Mech 226:106845

Tang ZG, He C, Lin G (2005) Study on mechanical behavior of segment of shield tunnel of metro with model test. Chin J Geotech Eng 27(1):85–89

Wang Y, Liu BG, Qi Y (2018) A risk evaluation method with an improved scale for tunnel engineering. Arab J Sci Eng 43(4):2053–2067

White SB (1978) The use of a tunnel boring machine on a coal mine decline In: Australian Tunnelling Conference, 3rd Sydney, NSW, pp 66–70

Xu T, Yang T, Chen C et al (2015) Mining induced strata movement and roof behavior in underground coal mine. Geomech Geophys Geo-energ Geo-resour 1:79–89

Yu B (2016) Behaviors of overlying strata in extra-thick coal seams using top-coal caving method. J Rock Mech Geotech 8(2):238–247

Zhang JF, Jiang FX, Zhu ST, Zhang L (2016) Width design for gobs and isolated coal pillars based on overall burst-instability prevention in coal mines. J Rock Mech Geotech 8(4):551–558

Zhang ZX, Xu Y, Kulatilake PHSW, Huang X (2012) Physical model test and numerical analysis on the behavior of stratified rock masses during underground excavation. Int J Rock Mech Min 49:134–147

Zhao J, Zhang Y (2017) Studies on rock failure of layered rock in underground mining-face and control techniques. Geomech Geophys Geo-Energy Geo-Resour 3:405–414

Zhu Z, Li Y, Xie J, Liu B (2015) The effect of principal stress orientation on tunnel stability. Tunn Undergr Sp Tech 49:279–286

Acknowledgements

The study was sponsored by the Chinese National Science and Technology Support Program (No. 2013BAB10B06) and the Open Fund of State Key Laboratory of Water Resource Protection and Utilization in Coal Mining (Grant No. GJNY-18-73.2). These supports are greatly acknowledged and appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qi, Y., Liu, B., Tannant, D. et al. Protective coal pillar design for segmental lining-supported TBM mine tunnels using physical model tests. Geomech. Geophys. Geo-energ. Geo-resour. 7, 21 (2021). https://doi.org/10.1007/s40948-021-00221-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-021-00221-0