Abstract

As a result of small pore sizes and property heterogeneities at different scales, flow processes and the related physical mechanisms in shales can be dramatically different from those in conventional gas reservoirs. To accurately capture the “unconventional” flow and transport in shales requires reevaluation of dominant physics controlling flow in shales, as well as innovative hardware technologies to estimate critical material and flow properties. To do so, we need to quantify the current knowledge and identify technology gaps especially as related to the modeling fluid flow in shale gas reservoirs. While fluid flow in shale includes many important aspects, this paper focuses on fluid flow in complex heterogeneous shale matrix. It discusses the recent progress in the areas of multi-scale fluid flow, fracturing fluid imbibition, and stress-dependent shale matrix properties. Future research topics in the related areas are also suggested based on the identified technology gaps.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Unconventional reservoirs have become one of the main sources of oil and gas in the United States and other countries to substitute the depletion of conventional resources. For example, shale gas reserves and production grew rapidly and are becoming the dominant source of natural gas in the US. The dry shale gas production in the United States increased from 0.3 trillion cubic feet in 2000 to 9.6 trillion cubic feet in 2012, or to 40 % of US dry natural gas production (EIA 2014). The rapid development of the unconventional resource is supported by the new technology, including horizontal drilling, hydraulic fracturing, and more importantly a better understanding of the mass transport mechanism in reservoirs at different scales.

In the kingdom of Saudi Arabia, three prospective areas for unconventional gas were found in the Northwest, South Ghawar and condensate-rich shale gas in the Rub’ Al-Khali area (Sayed et al. 2015). Alexeyenko et al. (2012) reported lessons learned from the first shale gas experience in Saudi Arabia and indicated that “…the realm of shale gas development still remains little understood and evolving”.

With the increasing power of computers, numerical modeling has become one of the most useful tools available to reservoir engineers. It has been widely used for interpreting testing data, optimizing design of oil and gas production system including well configurations and spaces, history matches, performance prediction, and the related economic analysis. Considerable success has been achieved by developing and applying numerical models to conventional oil and gas reservoirs, while how to effectively deal with subsurface heterogeneity, scaling issues, and complexity of flow behavior resulting from high non-linearity (e.g., fingering) remain significant challenges. It is also important to note that meaningful and useful model predictions depend on not only reservoir simulators that are used, but also the modeler’s experience, knowledge of the related data and observations, and physical insights into practical problems under consideration. This is mainly because the history match cannot provide unique results and consequently a good history match does not necessarily warrantee a reasonable model prediction. To partially deal with this problem, modeling communities in the areas of high-level nuclear waste management and climate science have often used multiple models with different physical conceptualizations and modeling approaches to match the same data sets and then provide a range of model predictions as a measure of modeling uncertainty.

There is a reason to call shale gas/oil reservoirs ‘unconventional’ in addition to their low permeability; conventional modeling approaches and experiences cannot be directly transferable to them (e.g., Darishchev et al. 2013). Before discussing challenges in modeling flow processes in shale gas reservoirs, it may be worthwhile to discuss what modeling is, although it may sound trivial to experienced modelers. Modeling often simply referrers to application of the existing simulators that, however, is only a part of so-called modeling. In general, modeling includes at least the following four aspects. The first is the constitutive model, or theoretical (or empirical) relationships among parameters and variables of involved physical processes and the corresponding data. For example, the well-known Darcy law is a constitutive model. Obviously, usefulness of a modeling study is eventually determined by how well the used constitutive model captures the key physical mechanisms. Otherwise, predictive capability of the corresponding model study would be very limited. The second aspect corresponds to numerical algorithms and/or soft engineering related issues, including model input/output and visualization of simulation results. Significant progress has been made in this aspect recently. Especially, use of the high performance computing becomes common in the industry and allows for modeling problems with great number of numerical gridblocks. The third aspect is coupling between difficult processes, including thermal, hydraulic, mechanical and chemical (THMC) processes (Fig. 1). Motivated by the available computational powers and the need of projects related to both energy and environment, development and application of THMC modeling capabilities become one of the most active research areas for leading modeling groups in both industry and US national laboratories. The coupled processes are especially relevant to shale gas studies because hydraulic fracturing is apparently a coupled hydro-mechanical process. In addition, hydraulic (or petro-physical) properties (e.g., permeability) of both shale fractures and matrix can be highly stress sensitive, which impacts shale gas flow process in a reservoir. The fourth aspect is model application to engineering problems that is a routine task for reservoir simulation engineers. This includes, but is not limited to, history match and performance (oil/gas recovery) prediction.

In terms of modeling, the “unconventional” part of shale gas studies corresponds to the first aspect discussed above. As long as a valid constitutive model is available for shale gas reservoir, the rest is more or less similar to those for conventional reservoirs. Thus, the focus of this paper is on issues related to the development of constitutive models for shale gas reservoirs.

Figure 2 shows schematically that shale gas flows from shale matrix through fractures to well bore. At the interface between hydraulic fracture and rock matrix, shale gas directly flows from matrix to hydraulic fracture because gas pressure in hydraulic fracture is lower than that in the matrix. It also seems to be a consensus that natural fractures play an important role in shale gas recovery, because they generally can provide a large fracture-matrix surface area available for gas flow. Organic-rich shale matrix contains organic matter, inorganic matter, and microcracks (including laminations).

Different kinds of models are available in the literature for modeling shale gas flow process, shown in Fig. 2. The simplest one is analytical methods. For example, Silin and Kneafsey (2011) and Patzek et al. (2013) developed analytical or semi-analytical solutions for analyzing gas recovery from production wells, based on a key assumption that gas flow resistance in fractures are negligible. With a few parameters, they were able to successfully match production data from a large number of wells in Barnett shale. The most commonly used modeling approach is based on the available reservoir simulators that include multiphase flow, sorption, and gas slip flow (e.g., Darishchev et al. 2013). Recently, a number of researchers have also made an effort to develop models that couple reservoir fluid flow with rock deformation for both hydraulic fracturing and gas recovery processes (e.g., Gan and Elsworth 2016; Kim and Morridis 2014; Perera et al. 2011; Wang et al. 2014). Despite the variations of these modeling approaches, their successful application to a giving problem is eventually determined by how well the key physical mechanisms are captured.

As demonstrated from Fig. 2, gas in place, fracture-matrix surface area and shale-matrix permeability are probably the most important parameters to determine shale gas recovery. Without gas in place, we simply have nothing to recover. The major purpose of horizontal well and hydraulic fracturing technique is to increase fracture-matrix interface area such that shale gas can flow to well bore more easily. In the shale flow path (Fig. 2), the bottle neck is shale matrix because it is where gas is stored and it has the smallest permeability. In addition, the fluid flow process in the shale matrix is not well understood. In this paper, we review related studies on shale gas flow in rock matrix, with a focus on identification of key technology issues and gaps.

It should be noted that because of the complexity of the problem under consideration and space limitation, we only focus on selected technical issues and gaps in this paper. For example, the adsorption may have an important impact on shale gas flow and recovery, but will not be discussed here. The relation between shale fracability and shale minerology is another important research topic that will not be covered here either.

2 Multi-scale fluid flow

Gas transport mechanism in shale is a combination of viscouse flow, slip flow, Knudsen diffusion, and other mechanisms. Gas diffusion is a thermal motion of gas molecules, in which there is a net movement of a substance from a high-concentration region to a low-concentration region, where the diffusive mass flow rate is proportional to the concentration gradient.

Gas flow permeability in shale, as a result of diffusion, is dependent on the pore gas pressure and this pressure dependent permeability can be experimentally measured through pulse-decay permeability tests under different gas pressures (Alnoaimi and Kovscek 2013; Civan et al. 2012). Furthermore, the gas flow in shale is complicated by its pore-structure heterogeneity.

It is a grand challenge to deal with subsurface heterogeneity in modeling flow and transport in oil and gas reservoirs. In conventional reservoirs, the focus has been on heterogeneities above the continuum scale, largely because sub-continuum scale heterogeneities have been well represented by the accepted constitutive models. However, situation is quite different for unconventional shale-gas reservoirs. Significant heterogeneity (or multi-scale behavior) exists for shale below the continuum scale in shale matrix and the role of this heterogeneity in flow process is not yet clear. As a result, an accepted constitutive model to capture sub-continuum scale physics in shale matrix for large-scale modeling is not available to the shale gas community. It is not surprising that the currently available commercial software for shale gas is more or less using the constitutive models developed for conventional reservoirs.

Hu and Ewing (2014) recently reported pore-size distributions of Barnett shale obtained from different laboratory techniques (Fig. 3). While the different techniques do not provide very consistent measurements, they all indicate that there are significant numbers of pores that are smaller than 100 nm (or 0.1 μm). Also, the pore size distributions exhibit more than one peak, an indication of an existence of multiple pore systems in shale.

Observed pore-size distributions for barnette shale samples (Hu and Ewing 2014)

Many observed images of shale including organic matter and inorganic matter have been reported in the literature (e.g., Loucks et al. 2009; Sondergeld et al. 2010; Akkutlu and Ebrahim 2012; Darabi et al. 2012; Yan et al. 2013). Based on these images, Darabi et al. (2012) argued that the organic matter (kerogen) may be locally interconnected at a scale on μm, but are dispersed packets embedded in inorganic matter that provides the core-scale flow paths related to permeability. Akkutlu and Ebrahim (2012) reached the same conclusion and further argued that most of the inorganic pores including micro-fractures have significantly larger dimensions than pores in kerogen and therefore often may not even appear in the small-scale images. They further indicated that the reason for often observed stress dependence of shale matrix permeability is the sensitivity of slit-like pores and micro-fractures (in inorganic matter) to confining stress. However, one cannot completely exclude that organic pores may be globally connected as well and the kerogen packets may have the slit-like shape that is sensitive to confining stress.

Figure 4 summerizes the current understanding of shale pore structure, although some variations exist in the literature (e.g., Akkutlu and Ebrahim 2012; Li et al. 2013; Yan et al. 2013; Sun et al. 2015). Hydraulic fracture is the largest feature artificially created by the hydraulic fracturing process. It is connected with both rock matrix directly and natural fractures that are stimulated by stress disturbance associated with the hydraulic fracturing and by high-pressured fracturing fluid flowing into them. (The connection between hydraulic fracture and rock matrix is not shown in Fig. 4 because it is generally believed that its connection with natural fractures plays a much more important role.) There may be well-connected micro-fractures and other conductive structures (e.g., laminations) that are responsible for the significant portion of the measured core-scale matrix permeability. Note that these small features are really part of the inorganic matter. In Fig. 4, we separate them from the rest of inorganic matter. This separation is useful for discussing the impact of fracturing fluid imbibition on shale gas recovery, as demonstrated later in this paper.

Fractures exist at different scales in nature. So-called natural fractures can be considered as those that are long enough to be observed with human eye. Micro-fractures or micro-cracks are those fractures that are very small (on a scale of μm) and cannot be observed with the human eye. The existence of micro-cracks in solid bodies has been well recognized in the community of solid mechanics and served as the foundation of fracture mechanics. The organic matter can be connected to micro-fractures directly and to the inorganic matter. Following Akkutlu and Ebrahim (2012) and Darabi et al. (2012), the organic matter, at the core scale, is considered to be isolated packets embeded within the inorganic matter in Fig. 4. The liquid flow depends on not only pore structures, but also the variation of wettability among different parts of pore space. It is generally believed that inorganic mater is water wet (or mixed wet) and organic matter is oil wet, although a recent study indicates that the wettability of kerogen pores may be a function of maturity (Hu et al. 2013). The focus of this section is on gas flow and liquid flow will be discussed in the next two sections.

A number of researchers have developed modeling approaches based on conceptual models of shale pore structures that are similar to Fig. 4 (e.g., Yan et al. 2013; Li et al. 2013; Sun et al. 2015). Yan et al. (2013) reported modeling results from a pore scale in which kerogen pores is further divided into micro-pores and nano-pores. Their results show that desorption does not have a significant effect on production because of the limited pressure drop in kerogen, but diffusion in kerogen does significantly impact production as a result of mass transfer between kerogen and other pore spaces. On the other hand, in a large-scale simulation, Sun et al. (2015) found that kerogen is essentially in equilibrium with inorganic matter for gas flow; however, a very large mass transfer coefficient for gas flow between kerogen and inorganic matter was used in their study. Obviously, the relative importance of multi-scale (or multi-continuum) gas flow behavior is still an unresolved issue.

The current modeling approaches for multi-scale fluid flow are largely adapted from multi-continuum modeling approaches that have been developed for fractured reservoirs for many years (e.g., Warren and Root 1963; Li et al. 2013). Thus, the challenge herein in terms of modeling is the determination of parameter values to characterize mass transfer between different continua (or pore spaces) that will be used for modeling inputs. This is still an issue of active research even for fractured reservoirs (e.g., Zhou et al. 2007). For determining the related parameter values for shale matrix, two complementary approaches may be used. One is the pore-scale model that can capture fairly accurately geometry of pore spaces obtained from imaging process. Then computational fluid dynamics (CFD) tools are employed to simulate the flow process within pores. The advantage of this approach is the capability to simulate the detailed flow behavior that may allow for identification of parts of pore space corresponding to fast and slow flow paths, respectively. However, the model size may be limited by computational power such that the model size cannot be large enough to include all the necessary structures contributing to multi-scale flow (e.g., microcracks and laminations). The other approach is to estimate the mass-transfer parameters from core-scale (or continuum-scale) measurements that can be directly used for reservoir simulations. The limitation is that this approach cannot accurately identify how the continua correspond to different parts of shale pore space.

Most recently, considerable progress has been made in using pressure pulse-decay test data to estimate the mass transfer coefficient between a fast-flow and slow-flow continuum that corresponds to inorganic matter (including microfracture) and organic matter according to Fig. 4 (Liu et al. 2016). The approach is based on an newly developed analytical solution to pressure pulse-decay through a dual-continuum shale sample. It is common that new measurement (or data analysis) techniques of flow and transport parameters and analytical solutions are developed side by side. In principle, the mass transfer coefficient can also be estimated by numerical inversion of pressure pulse-decay test data, which, however, often involves uniqueness issues (e.g., Alnoaimi and Kovscek 2013; Akkutlu and Ebrahim 2012). The preliminary results of Liu et al. (2016) show that Eagle Ford and Barnett shale exhibit considerable dual- or multi-continuum gas flow behavior, but Haynesville shale does not. Nevertheless, their approach can serve as a routine technique to estimate the mass transfer coefficient, given the fact that the pressure pulse-decay test has been widely used in the oil and gas industry laboratories.

In summary, as a result of multi-scale structures, multi-scale fluid flow is common in shale matrix, but has been simply ignored in the currently available commercial simulators for shale gas. The bottleneck of this topic is lack of practical approaches to determine model parameters for multi-scale fluid flow. While important progress has been made, some technical issues remain unsolved in order to provide a complete set of parameter values required by reservoir-scale modeling studies. For example, although the approach of Liu et al. (2016) allows for determining mass transfer coefficient between the two continua for gas flow, practical techniques for estimating porosities for different continua are not available yet. Furthermore, in some cases, multi-scale fluid flow may not be adequately characterized by a dual-continuum system and multi-continuum approaches should be used, which requires an extention of the technique for dual-continuum gas flow to multi-continuum gas flow. On the other hand, how to estimate related model parameter values for multi-scale liquid flow from those for gas flow should be investigated because liquid flow tests are generally more difficult to conduct and the wetability issue further complicates liquid flow behavior. Finally, how to more accurately estimate the related model parameters based on both core-scale laboratory tests and pore-scale models also deserves attentions. Our discussion of multi-scale fluid flow would not be complete without mentioning up-scaling of core-scale fluid parameters to the large-scale ones that can be directly used for reservoir simulations.

3 Spontaneous fracturing fluid imbibition

During hydraulic fracturing and the well shut-in stages, significant amount of fracturing fluids will flow into surrounding shale from hydraulic fractures through imbibition process (Roychaudhuri et al. 2013; Rangel-German and Kovscek 2002). This section focuses on the spontaneous imbibition because it is the major liquid flow mechanism during the relatively long well shut-in stage. The liquid imbibition could cause the loss of gas relative permeability because the liquid may occupy the pores to block gas flow. It also leads to chemically altered zone near fracture-matrix interface. Because chemical composition of fracturing fluids is different from that of original water in shale-gas reservoirs, the original chemical equilibrium between water and solid phases is interrupted by the imbibition of fracturing fluids, which may cause swelling and/or water-weakening of rock at and near fracture surfaces (e.g., Pagels et al. 2013; Lai et al. 2016). Furthermore, temperatures of injected fracturing fluids are generally much lower than the reservoir temperatures, which results in additional disturbance of the reservoir condition especially near the fracture surface. Obviously, actually predicting the imbibition process and its impacts has many practical implications for shale-gas production.

The complexity of imbibition process in nano-size pores is demonstrated by a recent study by Kelly (2013). Based on a relationship between capillary pressure and water imbibition rate for a capillary tube and using measured rates for flow into nano-size channel, Kelly (2013) was able to estimate capillary pressure as a function of channel size. Her findings can be summarized as follows. First, the commonly used Young–Laplace equation significantly overestimates the estimated capillary pressures. Second, below a certain channel size (e.g., on the order of 100 nm), the capillary pressure, directly contradicting with what is predicted with the Young–Laplace equation, deceases with channel size. Third, there is a considerable variation in relations between capillary pressure and channel size for different fluids. Kelly (2013) attributed these results to forces associated with solid–liquid interactions. Nevertheless, while more studies may be needed to further confirm the findings of Kelly (2013), her results clearly indicate that conventional thinking of the imbibition process may need to be revisited.

A number of researchers have recently reported laboratory experiment results for spontaneous imbibition (Hu and Ewing 2014; Ghanbari et al. 2014; Zhou et al. 2014; Roychaudhuri et al. 2013; Dehghanpour et al. 2013). Based on their experiment observations, Zhou et al. (2014) indicate that the amount of matrix imbibition is positively related to clay content. For shale samples with a similar porosity, relatively large imbibition rates occur in the shale matrix with small TOC. They also found that higher temperatures can reduce the total amount of imbibed fracturing fluid as a result of surface tension reduction. Ghanbari et al. (2014) investigated anisotropy and stress-dependency of imbibition process for shale matrix. They found that imbibition rate is larger along the bedding direction than that in the direction perpendicular to the bedding, which is a direct result of anisotropy of shale matrix permeability. Their results also show that the confining stress can reduce imbibition rate along the bedding direction, but has little effect on the imbibition rate in the direction perpendicular to the bedding. Clearly, micro-structures (micro-fractures and laminations) play an important role in determining liquid flow in shale matrix. This is consistent with a laboratory study reported by Dehghanpour et al. (2013). They also discuss that clay adsorption is a major mechanism for fluid imbibition and that brine intake of all samples under consideration is higher than their oil intake.

In the spontaneous imbibition tests, some researchers investigated solute transport from core samples to the imbibition liquid reservoir (e.g., Sharak et al. 2014; Ghanbari et al. 2014). During the fluid imbibition, fluid flows into a core sample from imbibition fluid reservoir and mixes with high-concentration residual brine within the core. Then, solute, through the imbibed fluid, diffuses back into the reservoir containing the fluid flowing into the core sample. Therefore, observed solute concentration (or electronic conductivity) of the reservoir increases with time (e.g., Sharak et al. 2014; Ghanbari et al. 2014). In general, for a given time a reasonable correlation between the observed concentration increase and cumulative imbibed fluid; this is an indication that solute transport velocity due to diffusion is significantly larger than fluid flow velocity associated with the imbibition. However, the coupling between solute transport (including its source within shale) and fluid imbibition is poorly understood at this point and deserves further research.

The most fundamental physical law to describe fluid flow in pore media is Darcy law. It states that fluid flux is proportional to pressure gradient (without gravitation effects). Recently, some imbibition test results indicate that Darcy law may not be adequate in modeling liquid flow in shale matrix. For example, Fig. 5 shows observed cumulative imbibition as a function of time on a log–log scale for a Barnett shale sample (Hu and Ewing 2014). If the imbibition process follows the Darcy law, the slope should be 0.5 (Liu et al. 2015). As shown in Fig. 5, the slope value clearly deviates from 0.5. Liu (2014) reviewed more evidence of this non-Darcy flow behavior in low-permeability porous media in the literatures of soil sciences and hydrogeology. This is also consistent with a recent study for Pierre shale where the permeability to oil increases with pressure gradient (Wang et al. 2011); Darcy law corresponds to a constant permeability for the single-phase flow. The likely mechanism for this non-Darcy flow is that there is liquid “boundary layer” near the solid–liquid interface, as a result of solid–liquid interaction (Fig. 6). The physical properties of liquid in the boundary layer are different from those without boundary effects. When pore size is big, the relative thickness of the “boundary layer” is very small and thus its impact is negligible for practical applications. However, in shale or other low-permeability media, the pore size is on the order of nano meter and micro meter. In this case, majority of liquid, if not all of them, may be within the “boundary layer”. Consequently, non-Darcy liquid flow behavior occurs. Note that non-Darcy liquid flow referred to here is different from so-called “non-Darcy flow” associated with turbulent flow in high-permeability media.

Observed cumulative imbibition as a function of time for a barnett shale sample (from Hu and Ewing 2014)

To deal with this non-Darcy flow in shale matrix, Liu et al. (2015) developed a phenomenological model for describing liquid flow in shale. It states that liquid flux, unlike the commonly used Darcy law, is proportional to a power function of pressure gradient when the effect of gravitational force can be ignored. The exponent is called unconventional flow index and the proportionality (as a function of liquid content) is called transport parameter. Darcy law is the special case of the new model for the index equal to one. The new model allows the slope in Fig. 5 to be smaller than 0.5 and, thus, is consistent with the related test results. A laboratory workflow to determine these parameters based on spontaneous imbibition test results is also proposed (Liu et al. 2015). However, because the new model is phenomenological in nature, it is not able to show explicit linkages between the model parameters and pore structures including their wettability heterogeneity.

The impact of imbibed fracturing fluid on shale gas production is neither simple nor well understood. It is well known and also confirmed by laboratory tests that the presence of fracturing liquid damages reservoirs and impedes gas flow from shale matrix (e.g., Bertoncello et al. 2014). The common practice to deal with this issue is to use relatively long well shut-in time after hydraulic fracturing and flow-back (or cleaning up the fractures). The imbibition process during the shut-in allows fracturing fluid to dissipate away from the interface between fractures and shale matrix and thus increase the gas relative permeability (Bertoncello et al. 2014). On the other hand, it was also reported that “Utica shale wells where flow back was delayed to allow the wells to soak for months produced gas at five times the rate of those where flow back occurred immediately after fracturing” (Rassenfoss 2013). Note that the delay of flow back is expected to cause more reservoir damages, which contradicts with the finding reported by Rassenfoss (2013).

We believe that micro-fractures (and laminations) are the major reason for the above seeming controversy. During hydraulic fracturing and before the flow back, forced imbibition occurs. Liquid flows from the hydraulic fractures and stimulated natural fractures into micro-fractures because of the high permeability of these micro-fractures (Fig. 4). The high fluid pressure would further open up these micro-fractures when the liquid flows into them; micro-fractures are stress-sensitive. Furthermore, relatively dilute fracturing fluid would also dissolve fracture fillings and thus enhances micro-fracture permeability. Eventually, liquid in micro-fractures is adsorbed by water-wet inorganic pores and the gas relative permeability of these micro-fractures becomes high, given the fact that these pores have much larger capillary pressure than that for micro-fractures. Since overall matrix permeability is dominated by micro-fractures, the enhancement of micro-fracture permeability and the availability of the high gas relative permeability definitely help increase the gas production rate. This process may be called stimulation of micro-fractures.

The delay of flow back is necessary to stimulate micro-fractures because it takes time for liquid to flow into micro-fractures within large enough regions near stimulated hydraulic and natural fractures. Note that hydraulic fracturing is a very fast process within the context of liquid flow in low-permeability shale matrix. The forced imbibition during hydraulic fracturing does not have enough time to effectively stimulate micro-fractures. The flow back right after hydraulic fracturing would alter the imbibition process from a forced one to a spontaneous one; the latter is mainly driven by capillarity and cannot help open up the micro-fractures. Also, once high-pressured liquid in micro-fractures is adsorbed into organic pores, the opened micro-fractures may start to close. Even through, they cannot completely return to the state before they are stimulated and the opening-up process can cause further mismatch of asperities and/or shearing that gives rise to permanent enhancement of permeability of micro-fractures (including lamination structures). Nevertheless, our hypothesis is based on a consideration that micro-fractures form a well-connected network and are also directly connected to organic matters (Fig. 4). (The Utica shale does have many small fractures.) Thus, the delay of flow back may not always work when the above condition is not satisfied.

In summary, the complexity of fracturing fluid imbibition results from mixed wettability, strong solid–liquid interaction, and multiple continuum pore structures. At this point, the theory for multiphase flow in shale is not fully established. Some continuum-scale fundamental physical laws for the conventional reservoirs, e.g., Darcy law, may not be valid anymore. For practical applications, at least three aspects in this area deserve more studies. The first is the continuum-scale constitutive model for multiphase flow in shale that is one of the most important inputs into reservoir modeling. While some progress has been made (Liu et al. 2015), more studies are needed along the line, especially the incorporation of the effects of different wettability behavior between the inorganic and organic matters. The second is the coupling between solute transport and imbibition process. The previous experience from studies of fracture hydrology indicates that the interpretation of data related to this coupling should be useful for determining model parameters related to fracture-matrix interaction. The third one is the mechanism of how imbibition affects gas production. Our hypothesis regarding stimulation of micro-fractures (including laminations) needs further evaluation.

4 Stress-dependent properties

Rock mechanics and its coupling with liquid flow play important roles in shale gas flow and production. Hydraulic fracturing, a coupled hydro-mechanical process, is the key technology enabling shale gas production by increasing reservoir contact areas. During the gas production, hydraulic and natural fractures can also be subject to considerable permeability reduction due to pore pressure changes and mechanical property alteration (as a result of fluid and rock interaction). Obviously, rock mechanics and its coupling with flow include many research topics for shale gas studies. In this section, we limit our focus to stress-dependent shale-matrix properties within the context of constitutive model development. Especially, we are interested in the impacts of micro-fractures and TOC, because they are relatively important features for shale matrix.

There are a number of studies in the literature on the stress-dependence of shale-matrix permeability, because permeability is a key parameter in determining shale-gas flow (e.g., Bhandari et al. 2015; Rosen et al. 2014; Sayed et al. 2015). The general conclusions from these permeability studies include that shale matrix permeability is considerably stress-sensitive under typical reservoir conditions, along bedding (horizontal) direction and in the (vertical) direction perpendicular to the bedding.

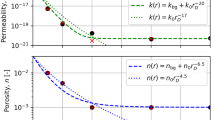

In the shale gas community, the relationship between permeability and effective stress is often empirically represented by;

where k 0 is the permeability at zero effective stress, σ eff is the effective stress, and α M is the stress-sensitive factor. There are other empirical relations in the literature (Zheng et al. 2015). In fact, Eq. (1) can be directly derived from the two-part Hooke’s model (TPHM), a theoretical constitutive model for rock deformation of natural rock (Liu et al. 2009; Zheng et al. 2015).

The key points of the TPHM include two aspects (Liu et al. 2009). First, in Hooke’s law that states that for elastic deformation stress is proportional to strain, the strain should be true strain, rather than engineering strain. In terms of volumetric strain, the true strain is volume change divided volume at the current stress, while the engineering strain is the volume change divided by the volume at zero stress. The similar strain definitions are applied to strains of other types than volumetric strain. In rock engineering applications, the engineering strain has been exclusively employed. This treatment is practically valid when the mechanical deformation is small, but may not be valid any more when deformation is relatively large. Second, natural rock is always subject to small-scale heterogeneities. To consider the impact of these small-scale heterogeneities on continuum scale (core-scale and above) rock properties, rock mass below the continuum scale can be conceptually divided into two parts, hard and soft. Soft part corresponds to the components of rock subject to large deformation, such as micro-fractures and lamination structures in shale. Because differences between the mechanical properties (e.g., Young’s modulus) of the two parts are generally several orders of magnitude, the interaction of the two parts can be represented by a composite spring system for determining continuum-scale rock properties; they are considered to be connected in a series way (Fig. 7). The TPHM has been comprehensively evaluated by literature data and applied to a number of engineering projects.

The rock mass is represented by a composite spring system (Liu et al. 2009)

Based on the TPHM, Zheng et al. (2015) proposed relationships among porosity, permeability and effective stress. Figure 8 shows consistence between their results and observed rock gas porosity and permeability as a function of effective stress for a shale rock sample. Unlike traditional approaches in which permeability is a function of total porosity, their approach considers permeability as a function of both soft-part porosity and hard-part porosity. The effect of the soft part is demonstrated to roughly follow the cubic law, an indication of fracture-like flow behavior within the soft part. They major conclusions include that below an effective stress of 30 MPa (or 4351 psi), shale-matrix permeability and its stress dependence is dominated by the soft part, or micro-fractures and alike. This point view is generally supported by Rosen et al. (2014) and Bhandari et al. (2015). Micro-fracture (including laminations) is a key factor for determining stress-dependent shale-matrix properties. However, the study of Zheng et al. (2015) does not consider the effect of TOC, because the shale sample, corresponding to Fig. 8, is not an organic-rich shale sample.

Match of the TPHM-based model results with observations (a porosity and b permeability) for a shale gas porosity and permeability (Zheng et al. 2015)

TOC has been demonstrated to have a significant effect on shale matrix properties. Since both clay minerals and TOC have low Young’s modulus, Sone and Zoback (2013) called the combination of these two as “soft component” that is different from the soft part in the TPHM and reported the strong dependence of rock mechanical properties on contents of the “soft component”. This is also supported by the results reported by Lai et al. (2016) who found that mechanical properties are functions of TOC. Nevertheless, the dependence of shale-matrix mechanical properties on TOC is determined by not only TOC, but also TOC’s spatial distribution within shale matrix. It is desirable to incorporate effects of TOC into a constitutive model for coupled deformation and fluid flow. The common approach to estimate the relationship between mineralogy and mechanical properties in the vertical direction is based on an assumption that shale is a perfectly-layered system (e.g., Vernik and Landis 1996). As expected, this is not a satisfactory approximation in many cases. This study provides a more general phenomenological relationship between shale mechanical properties on the content of clay and kerogen.

First, consider two extreme cases, the relationships of Reuss and Voigt, respectively, which bound the observed relationship between shale mechanical properties on the content of clay and Kerogen (Sone and Zoback 2013). If the volume fractions χ i and bulk moduli K i of the various mineral components of the rock are known, the methods of Reuss and Voigt can be used to provide estimates of effective modulus K. The Reuss effective modulus is the weighted harmonic mean of the individual moduli:

The Voigt effective modulus is the weighted mean of the individual moduli:

The Reuss effective modulus is accurate when the stress is normal to the layering and Voigt effective modulus is when the stress is along the layering direction. It is very likely that the real distributions of the mineral components, with respect to the given stress direction, should be between the two extreme cases. Thus, we propose the following empirical relationship to capture this reasoning:

The above relationship is reduced to the Reuss’s result for l = −1and Voigt’s result for l = 1. Thus the l value should be between −1 and 1(except zero).

Sone and Zoback (2013) reported shale mechanical properties, as functions of volumetric fraction of clay plus kerogen, for shale formations including Barnett, Haynesville and Eagle Ford. Figure 9 shows Young’s modulus data (corresponding to the vertical direction), as compared with results calculated from Eq. (5) that should apply to effective Young’s modulus as well. Obviously, Eq. (5) with l = −0.5 better fits the data from different shale formations than the Reuss’s formulation (corresponding to Eq. (5) with l = −1).

Some clay minerals in shale matrix swell after adsorbing liquid water from fracturing fluid. When the swelling is involved, the traditional Biot effective stress formulation does not apply any longer and the effective stress should include an additional term called internal swelling stress (Liu and Rutqvist 2010). The internal swelling stress concept has been verified by experimental observations and widely accepted in the coal geology community. It can be also applied here to deal with the swelling in shale.

The coupling of mechanical deformation and fluid flow touches on many research areas. This section has been limited to a small number of factors related to shale matrix. To develop a model capability to capture this coupling, there are some issues that need further investigations. For example, a constitutive model for stress-dependent shale-matrix mechanical and hydraulic properties is required for modeling studies. It should include the impacts of micro-fractures, TOC, and clay swelling. Any constitutive model would include parameters whose values need to be determined from measurements. A workflow is also required to estimate parameter values for the constitutive model using laboratory measurements. Of cause, the usefulness of a constitutive model has to be demonstrated by a reservoir simulator that incorporates the developed constitutive model.

5 Conclusions

This study provides a comprehensive review on development of the constitutive models and/or measurement of the related model parameters; the development also serves as a means to integrate data, physics and reservoir simulations.

Gas process in shale is related to diffusion due to its nano pore sizes, where shale matrix (including micro-fractures and the alike) has multi-scale heterogeneity that results in multi-scale flow process. While numerical schemes based on the multi-continuum concept adapted from fracture reservoir models are available for simulating multi-scale flow, the current technology gap is to determine the related parameters, including mass transfer coefficients between two different continua and volumetric fractions of the continua, at scales that are relevant to reservoir simulations.

Fracturing fluid imbibition impacts shale gas production owing to a variety of mechanisms. Considerable amount of experimental work on spontaneous imbibition into shale matrix has been reported in the literature. However, several key technique issues remain unsolved. These include the relationship between liquid flux and pressure gradient, incorporation of the impact of mixed wettability into a constitute model for multiphase flow, coupling between tracer transport and imbibition, and mechanism of enhancement of gas production with delayed flow back. Regarding the last issue, we also postulate that the stimulation of micro-fractures contributes to the gas production-rate enhancement; this needs further investigation.

The importance of the coupled hydro-mechanical processes to gas flow in shale matrix, partially demonstrated by the strong stress-sensitivity of shale-matrix permeability, has been well known in the shale gas community. However, a well-accepted continuum-scale constitutive model (or relationships among mechanical properties, flow properties, and deformation) has not been available to incorporate effects of micro-fractures, TOC and clay swelling. The future research should focus on the development of such a constitutive model that can be used for large-scale simulations of the coupled processes and on workflow to estimate the related parameter values with test results.

References

Akkutlu IY, Ebrahim F (2012) Multiscale gas transport in shales with local kerogen heterogeneities. SPEJ 1002–1011

Alexeyenko AV, Adebiyi IA, Bartko KM, Faraj O, Campo C (2012) First shale gas experience in Saudi Arabia: Lessons learned. Paper (SPE 163320) presented at the SPE Kuwait international petroleum conference and exhibition held in Kuwait city, Kuwait

Alnoaimi KR, Kovscek AR (2013) Experimental and numerical analysis of gas transport in shale including the role of sorption. Paper (SPE 166375) presented at the SPE annual technical conference and exhibition held in New Orleans, Louisiana, USA

Bertoncello A, Wallace J, Blyton C, Honarpour M, Kabir CS (2014) Imbibition and water blockage in unconventional reservoirs: water-management implications during flowback and early production. SPE Reserv Eval Eng 497–506

Bhandari AR, Flemings PB, Polito PJ, Cronin MB, Bryant SL (2015) Anisotropy and stress dependence of permeability in the barnett shale. Trans Porous Med

Civan F, Rai CS, Hondergeld CH (2012) Determining shale permeability to gas by simultaneous analysis of various pressure tests. SPEJ 717–726

Darabi H, Ettehad A, Javadpour F (2012) Gas flow in ultra-tight shale strata. J Fluid Mech 710:641–658

Darishchev A, de Nancy ENSG, Lemouzy P, Rouvroy P (2013) On simulation of flow in tight and shale gas reservoirs. Paper (SPE 163990) presented at the SPE middle east unconventional resources conference and exhibition held in Muscat, Oman, pp 28–30

Dehghanpour H, Lan Q, Saeed Y, Fei H, Qj Z (2013) Spontaneous imbibition of brine and oil in gas shales: effect of water adsorption and resulting micro-fractures. Energy Fuels 27:3039–3049

EIA (2014) Annual Energy Outlook 2014 with Projections to 2040, Technical Report. US Energy Information Administration

Gan Q, Elsworth D (2016) A continuum model for coupled stress and fluid flow in discrete fracture network. Geomech Geophys Geo-Energy Geo-Resour (2016) 2:43–61 doi:10.1007/s40948-015-0020-0

Ghanbari E, Xu M, Dehghanpour H, Bearinger D (2014) Advances in understanding liquid flow in gas shales. Paper (SPE 171653) presented at the SPE/CSUR unconventional resources conference-Canada held in Calgary, Alberta, Canada

Hu QH, Ewing RP (2014) Integrated experimental and modeling approaches to studying the fracture-matrix interaction in gas recovery from barnett shale. Report 09122-12. University of Texas at Arlington

Hu Y, Devegowda D, Strolo A, Ho TA, Phan A, Civan F, Sigal R (2013) A pore-scale study describing the dynamics of slickwater distribution in shale gas formations following hydraulic fracturing. Paper (SPE 164552) presented at the SPE North America unconventional resources conference and exhibition held in woodlands, Texas, USA

Kelly S (2013) Experimental investigation of the influence of molecular surface interactions on imbibition in shale nano-pore proxies. Paper (SPE 167635) presented at the SPE annual technical conference and exhibition held in New Orleans, Louisiana, USA

Kim J, Morridis GJ (2014) Gas flow tightly coupled to elastoplastic geomechanics for tight- and shale-gas reservoirs: Material failure and enhanced permeability. SPE J 1110–1125

Lai BT, Li H, Zhang JL, Jacobi D, Georgi D (2016) Water-content effects on dynamic elastic properties of organic-rich shale. SPEJ (SPE 175040)

Li N, Ran Q, Li J, Yuan J, Wang C, Wu YS (2013) A multiple-continuum model for simulation of gas production from shale gas reservoirs. Paper (165991) presented at the reservoir characterization and simulation conference and exhibition held in Abu Dhabi, UAE

Liu HH (2014) Non-Darcian flow in low permeability media: key issues related to geological disposal of high-level nuclear waste in shale formations. Hydrogeol J 22(7):1525–1534

Liu HH, Rutqvist J (2010) A new coal-permeability model: internal swelling stress and fracture-matrix interaction. Transp Porous Media 82(1):157–171

Liu HH, Rutqvist J, Berryman JG (2009) On the relationship between stress and elastic strain for porous and fractured rock. Int J Rock Mech Min Sci 46(2):289–296

Liu HH, Lai B, Chen JH (2015) Unconventional spontaneous imbibition into shale matrix: theory and a methodology to determine relevant parameters. Transp Porous Media. doi:10.1007/s11242-015-0580-z

Liu HH, Lai B, Chen JH, Georgi D (2016) Pulse-decay permeability tests for gas flow in a dual-continuum system: late-time behavior. Research Report. J Petrol Sci Eng 147:292–301

Loucks RG, Reed RM, Ruppel SC, Jarvie DM (2009) Morphology, genesis, and distribution of nanometer-scale pores in siliceous mudstones of the Mississippian barnett shale. J Sediment Res 79:848–861

Pagels M, Willberg DM, Edelman E, Zagorski W, Frantz J (2013) Quantifying fracturing fluid damage on reservoir rock to optimize production. Paper URTeC 1578948 presented at the unconventional resources technology conference held in Denver, Colorado, USA

Patzek TW, Male F, Marder M (2013) Gas production in the barnett shale obeys a simply scaling theory. PNAS 110(49):19731–19736

Perera MSA, Ranjith PG, Airey D (2011) Numerical simulation of gas flow through porous sandstone and its experimental validation. Fuel 90(2):547–554

Rangel-German ER, Kovscek AR (2002) Experimental and analytical study of multi-dimensional imbibition in fractured porous media. J Petrol Sci Eng 36(1–2):45–60

Rassenfoss S (2013) In search of the waterless fracture. JPT 46–54

Rosen R, Mickelson W, Sharf-Aldin M, Kurtoglu B, Kosanke T, PaiAngle M, Patterson R, Mir F, Narasimhan S, Amini A (2014) Impact of experimental studies on unconventional reservoir mechanics. Paper (SPE 168965) presented at unconventional resources conference-USA held in the woodlands, Texas, USA

Roychaudhuri R, Tsotsis TT, Jessen K (2013) An experimental investigation of spontaneous imbibition in gas shales. J Petrol Sci Eng 111:87–97

Sayed MA, Al-Muntasheri GA, Liang F, (2015) Required understanding for the development of shale reservoirs in the Middle East in light of developments in North America. Paper (SPE-172939) presented at the SPE Middle East unconventional resources conference and exhibition held in Muscat, Oman

Sharak AZ, Noel M, Dehghanpour H, Bearinger D (2014) Understanding the origin of flowback salts: a laboratory and field study. Paper (171647) presented at the Canadian unconventional resources conference held in Calgary, Alberta, Canada

Silin D, Kneafsey TJ (2011) Gas shale: from nanometer-scale observations to well modeling. Paper (CSUG/SPE 149489) presented at the Canadian unconventional resources conference held in Calgary, Alberta, Canada

Sondergeld CH, Ambrose RJ, Rai CS, Moncrieff J (2010) Microstructural studies of gas shale. Paper (SPE Paper 131771) presented at society of petroleum engineers unconventional gas conference, Pittsburgh, Pennsylvania

Sone H, Zoback D (2013) Mechanical properties of shale-gas reservoir rocks—Part 1: static and dynamic properties and anisotropy. Geophysics 75(5):D381–D392

Sun H, Chawathe A, Hotelf H, Shi X, Li L (2015) Understanding shale gas flow behavior using numerical simulation. SPE J 142–154

Vernik L, Landis C (1996) Elastic anisotropy of source rocks: implication for HC generation and primary migration. AAPG Bull 80:531–544

Wang D, Butler R, Liu H, Ahmed S (2011) Flow-rate behavior and imbibition in shale. SPE Reserv Eval Eng 505–512

Wang X, Winterfeld P, Ma X, Ye D, Miao J, Wang Y, Wang C, Wu YS (2014) Simulation of coupled hydraulic fracturing propagation and gas well performance in shale gas reservoirs. Paper (SPE-168967) presented at the SPE unconventional resources conference-USA held in the woodlands, Texas, USA

Warren JE, Root PJ (1963) The behavior of naturally fractured reservoirs. SPEJ 3:245–255

Yan B, Alfi M, Wang Y, Killough JE, (2013) A new approach for the simulation of fluid flow in unconventional reservoirs through multiple permeability modeling. Paper (SPE 166173) presented at the SPE annual technical conference and exhibition held in New Orleans, Louisiana, USA

Zheng J, Zheng L, Liu HH, Ju Y (2015) On the relationships among permeability, porosity, and effective stress for low-permeability sedimentary rock. Int J Rock Mech Min Sci (in review)

Zhou Q, Liu HH, Molz FJ, Bodvarsson GS (2007) Field-scale effective matrix diffusion coefficient for fractured rock: results from literature survey. J Contam Hydrol 93:161–187

Zhou Z, Hoffman B, Bearinger D, Li X (2014) Experimental and numerical study on spontaneous imbibition of fracturing fluids in shale gas formation. Paper (SPE 171600) presented at the Canadian unconventional resources conference held in Calgary, Alberta, Canada

Acknowledgments

The authors from Aramco Research Center (Houston) thank the management of the center and Saudi Aramco for their permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, H.H., Ranjith, P.G., Georgi, D. et al. Some key technical issues in modelling of gas transport process in shales: a review. Geomech. Geophys. Geo-energ. Geo-resour. 2, 231–243 (2016). https://doi.org/10.1007/s40948-016-0031-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40948-016-0031-5