Abstract

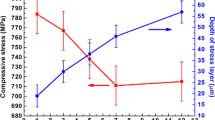

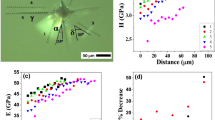

The strength of chemically pre-stressed glass depends on the depth of surface flaws and the value of the pre-stress. So far, some research has been conducted on this topic; however, there were always uncertainties regarding the flaw depth and the pre-stress profile. Consequently, this research characterises the pre-stress profile using experimental methods. The latter include measuring the depth of layer (DoL) and the surface compressive pre-stress (CS) with FSM-7000 h and verifying the achieved DoL with the Na+ and K+ distribution through the thickness obtained from the SEM/EDS analysis. Results demonstrate that the amount of K decreases parabolically (second-order) to a certain value and then remains constant. Based on this observation and some boundary conditions, the equation of the pre-stress profile was obtained for thin chemically pre-stressed aluminosilicate glass (Falcon®) with 8 h and 24 h processing durations in molten salt at 460 °C. A non-strengthened glass (NSG) was also used as a reference for comparison. Then, three artificial laser-induced flaws with accurately controlled depths is tested by means of a clamp bender. The results of the strength tests demonstrated very low deviations in the failure stress. It was shown that even when the depth of the flaw is higher than the DoL, which means that the flaw tip enters the zone with the pre-tensile stress, there is still considerable resistance from the surrounding intact area. Furthermore, it was confirmed that the pre-stress strain energy for 24 h processing is larger than for 8 h, leading to more fragmentation after failure under a similar loading condition. Finally, it was found that the fracture toughness is not constant through the pre-stressed glass thickness, and it is dependent on the pre-stress profile with the peak value at the glass surface.

Similar content being viewed by others

References

ASTM C1499-19: Standard test method for monotonic equibiaxial flexural strength of advanced ceramics at ambient temperature, ASTM International, West Conshohocken, PA (2019). https://doi.org/10.1520/C1499-19

ASTM C158-02 (2017): Standard test methods for strength of glass by flexure (determination of modulus of rupture), ASTM International, West Conshohocken, PA (2017). https://doi.org/10.1520/C0158-02R17

Bartenev, G.: The phenomenon of the hardening of glass. J. Tech. Phys. 18, 383–388 (1948)

Belis, J., Louter, C., Nielsen, J.H., Schneider, J.: Architectural glass. In: Musgraves, J.D., Hu, J., Calvez, L. (eds.) Springer Handbook of Glass, pp. 1781–1819. Springer, Cham (2019). https://doi.org/10.1007/978-3-319-93728-1_52

Bensaid, N., Benbahouche, S., Roumili, F., Sangleboeuf, J.C., Cam, J.B.L., Rouxel, T.: Influence of the normal load of scratching on cracking and mechanical strength of soda-lime-silica glass. J. Non-Cryst. Solids (2018). https://doi.org/10.1016/j.jnoncrysol.2018.01.004

Dix, S., Schuler, C., Kolling, S.: Digital full-field photoelasticity of tempered architectural glass: a review. Opt. Lasers Eng. 153(September 2021), 106998 (2022). https://doi.org/10.1016/j.optlaseng.2022.106998

EN 1288-2: Glass in building—determination of bending strength of glass—part 2: coaxial double ring test on flat specimens with large test surface areas (2000a).

EN 1288-3: Glass in building —determination of the bending strength of glass—part 3: test with specimen supported at two points (Four Point Bending) (2000b).

EN 1288-5: Glass in building—determination of the bending strength of glass—part 5: coaxial double ring test on flat specimens with small test surface areas (2000c).

Glaesemann, G.S., Jakus, K., Ritter, J.E.: Strength variability of indented soda-lime glass. J. Am. Ceram. Soc. 70(6), 441–444 (1987). https://doi.org/10.1111/j.1151-2916.1987.tb05665.x

Gy, R.: Ion exchange for glass strengthening. Mater. Sci. Eng. b: Solid-State Mater. Adv. Technol. 149(2), 159–165 (2008). https://doi.org/10.1016/j.mseb.2007.11.029

Jiang, L., Guo, X., Li, X., Li, L., Zhang, G., Yan, Y.: Different K + -Na + inter-diffusion kinetics between the air side and tin side of an ion-exchanged float Aluminosilicate glass. Appl. Surf. Sci. 265, 889–894 (2013). https://doi.org/10.1016/j.apsusc.2012.11.143

Karlsson, S., Jonson, B., Stålhandske, C.: The technology of chemical glass strengthening—a review. Glass Technol. 51(2), 41–54 (2010)

Kistler, S.S.: Stresses in glass produced by nonuniform exchange of monovalent ions. J. Am. Ceram. Soc. 45(2), 59–68 (1962). https://doi.org/10.1111/j.1151-2916.1962.tb11081.x

Laurs, M., Schaaf, B., Di Biase, P.., Feldmann, M.: Determination of prestress profiles in chemically toughened glass by means of photoelasticity. In: GPD Glass Performance Days, pp. 145–49 (2019)

Lee, E.H., Rogers, T.G., Woo, T.C.: Residual stresses in a glass plate cooled symmetrically from both surfaces. J. Am. Ceram. Soc. 48(9), 480–487 (1965). https://doi.org/10.1111/j.1151-2916.1965.tb14805.x

Macrelli, G.: Chemically strengthened glass by ion exchange: strength evaluation. Int. J. Appl. Glas. Sci. 9(2), 156–166 (2018). https://doi.org/10.1111/ijag.12291

Macrelli, G., Özben, N., Kayaalp, A.C., Ersundu, M.Ç., Sökmen, İ: Stress in ion exchanged soda-lime silicate and sodium aluminosilicate glasses: experimental and theoretical comparison. Int. J. Appl. Glas. Sci. 11(4), 730–742 (2020). https://doi.org/10.1111/ijag.15787

Maniatis, I., Nehring, G., Siebert, G.: Studies on determining the bending strength of thin glass. Proc. Inst. Civ. Eng. Struct. Build. 169(6), 393–402 (2016). https://doi.org/10.1680/jstbu.14.00003

Moayedi, E., Wondraczek, L.: Quantitative analysis of scratch-induced microabrasion on silica glass. J. Non-Cryst. Solids (2017). https://doi.org/10.1016/j.jnoncrysol.2017.05.003

Nategh, S., Missinne, J., Vijverman, P., Van Steenberge, G., Belis, J.: Effect of ultrashort laser-induced surface flaws on architectural glass strength. Constr. Build. Mater. 295, 123590 (2021a). https://doi.org/10.1016/j.conbuildmat.2021.123590

Nategh, S., Symoens, E., Missinne, J., Belis, J.: Effect of loading rate, surface flaw length and orientation on strength of laser-modified architectural glass. In: IABSE Congress: Structural Engineering for Future Societal Needs, pp. 1581–88 (2021b). https://doi.org/10.2749/ghent.2021b.1581

Neugebauer, J.: Determination of bending tensile strength of thin glass. In: Challenging Glass Conference Proceedings—Challenging Glass 5: Conference on Architectural and Structural Applications of Glass, CGC 2016, no. June: 419–28 (2016)

Nielsen, J.H.: Remaining stress-state and strain-energy in tempered glass fragments. Glass Struct. Eng. 2(1), 45–56 (2017). https://doi.org/10.1007/s40940-016-0036-z

Nielsen, J.H., Olesen, J.F., Stang, H.: Characterization of the residual stress state in commercially fully toughened glass. J. Mater. Civ. Eng. 22(2), 179–185 (2010). https://doi.org/10.1061/(asce)0899-1561(2010)22:2(179)

Nielsen, J.H., Thiele, K., Schneider, J., Meyland, M.J.: Compressive zone depth of thermally tempered glass. Constr. Build. Mater. 310(July), 125238 (2021). https://doi.org/10.1016/j.conbuildmat.2021.125238

Nordberg, M.E., Mochel, E.L., Garfinkel, H.M., Olcott, J.S.: Strengthening by Ion exchange. J. Am. Ceram. Soc. 47(5), 215–219 (1964). https://doi.org/10.1111/j.1151-2916.1964.tb14399.x

Sane, A.J.I.T.Y., Cooper, A.R.: Stress buildup and relaxation during ion exchange strengthening of glass. J. Am. Ceram. Soc. 70(2), 86–89 (1987). https://doi.org/10.1111/j.1151-2916.1987.tb04934.x

Santos, F.O., Louter, C., Correia, J. R.: Exploring thin glass strength test methodologies. In: Challenging Glass 6: Conference on Architectural and Structural Applications of Glass, CGC 2018—Proceedings (2018). https://doi.org/10.7480/cgc.6.2192

Schneider, J., Schula, S., Weinhold, W.P.: Characterisation of the scratch resistance of annealed and tempered architectural glass. Thin Solid Films 520(12), 4190–4198 (2012). https://doi.org/10.1016/j.tsf.2011.04.104

Schwind, G., von Blücher, F., Drass, M., Schneider, J.: Double ring bending tests on heat pretreated soda-lime silicate glass. Glass Struct. Eng. 5(3), 429–443 (2020). https://doi.org/10.1007/s40940-020-00129-3

Seaman, J.H., Lezzi, P.J., Blanchet, T.A., Tomozawa, M.: Degradation of Ion-exchange strengthened glasses due to surface stress relaxation. J. Non-Cryst. Solids 403, 113–123 (2014). https://doi.org/10.1016/j.jnoncrysol.2014.07.016

Tada, H., Paris, P.C., Irwin, G.R.: The Stress Analysis of Cracks Handbook, 3rd edn. ASME Press, New York (2010). https://doi.org/10.1115/1.801535

Terakado, N., Sasaki, R., Takahashi, Y., Fujiwara, T., Orihara, S., Orihara, Y.: A novel method for stress evaluation in chemically strengthened glass based on Micro-Raman spectroscopy. Commun. Phys. 3(1), 1–7 (2020). https://doi.org/10.1038/s42005-020-0305-7

Tyagi, V., Varshneya, A.K.: Measurement of progressive stress buildup during ion exchange in alkali Aluminosilicate glass. J. Non-Cryst. Solids 238(3), 186–192 (1998). https://doi.org/10.1016/S0022-3093(98)00691-7

Varshneya, A.K., Macrelli, G., Yoshida, S., Kim, S.H., Ogrinc, A.L., Mauro, J.C.: Indentation and abrasion in glass products: lessons learned and yet to be learned. Int. J. Appl. Glass Sci. (2021). https://doi.org/10.1111/ijag.16549

Wang, Z., Suo, T., Manes, A.: Effect of chemical strengthening residual stress on the flexural performance and fracture behavior of aluminosilicate glass. Eng. Fract. Mech. 258(November), 108104 (2021). https://doi.org/10.1016/j.engfracmech.2021.108104

Zaccaria, M., Dubru, M., Lucca, N., Šikyňová, A.: Chemically strengthened glass for architectural applications. Ce/papers 4(6), 135–144 (2021). https://doi.org/10.1002/cepa.1626

Zaccaria, M., Overend, M.: Nondestructive safety evaluation of thermally tempered glass. J. Mater. Civ. Eng. 32(4), 04020043 (2020). https://doi.org/10.1061/(asce)mt.1943-5533.0003086

Zaccaria, M., Peters, T., Ebert, J., Lucca, N., Schneider, J., Louter, C.: The clamp bender: a new testing equipment for thin glass. Glass Struct. Eng. 7(2), 173–186 (2022). https://doi.org/10.1007/s40940-022-00188-8

Acknowledgements

The authors gratefully acknowledge the support of AGC in providing thin glass samples and the strength testing setup for this study. Furthermore, the authors would like to acknowledge the support of technicians in the Cleanroom (associated imec laboratory at Ghent University) and Magnel-Vandepitte laboratory, Department of Structural Engineering and Building Materials of Ghent University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nategh, S., Zaccaria, M., Missinne, J. et al. Experimental strength characterisation of thin chemically pre-stressed glass based on laser-induced flaws. Glass Struct Eng 7, 471–486 (2022). https://doi.org/10.1007/s40940-022-00205-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40940-022-00205-w