Abstract

Insulated Glazed Units (IGUs) are composite elements formed by two or more glass panes held together by structural edge seals, entrapping a gas for thermal and acoustic insulation. There is a wealth of evidence that they are prone to cracking due to an uneven temperature distribution within each glass pane, caused in particular by solar radiation, enhanced by the shielding of contour-frame and cast shadows. The accurate assessment of the temperature field in the glass is the input datum to calculate the thermal strain and the consequent state of stress. An engineered method for calculating the temperature field in the glass panes of multiple IGUs, of arbitrary composition, is developed here. This method considers the various sources of thermal exchange: conduction between the exposed, shadowed and border regions of each pane, convection and radiation with the surrounding environment and between the panes, heat storage. Proper coefficients are defined for multiple reflective phenomena of radiant energy between the various glass layers. The proposed model is applied to explanatory case studies, accounting for the daily variations of the external temperature and solar radiation.

Similar content being viewed by others

Notes

This condition is verified (Lienhard and Lienhard 2019) when the Biot number \(Bi=h s/\lambda \) is lower than 0.1, where s is the thickness, h the convective heat transfer coefficient and \(\lambda \) the thermal conductivity. This is normally the case for architectural glazing.

Nowadays, insulated spacer bars and thermally improved edge seals, designed to considerably reduce heat loss through an IGU, have very low thermal conductivity (Manz 2008).

This models do not apply to double skin façades, for which the heat exchange due to convection is a very complicated phenomenon. In this case, the heat transfer coefficient depends on the type of ventilation (natural or forced), on the temperatures and on the airflow in the cavity (Jiru and Haghighat 2008; Gratia and De Herde 2004; Pasut and De Carli 2012).

This can be evaluated as a function of the external temperature, of view factors from the external surfaces of the fenestration system to both the ground and the sky, and of the fraction of the sky that is clear (ISO15099 2003).

Conduction occurs in solids rather than in liquids and gases, due to the space between molecules. Gas have in general very low thermal conductivity with respect to solids (Lienhard and Lienhard 2019).

Unfortunately, the recorded formulae present a conflicting notation, in particular for what concerns the definition of the coefficients and the summation indexes. Since we have not been able to find background documents for this standard, it is very difficult to reconstruct the hypotheses at the base of the proposed formulations.

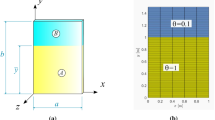

In particular, the time variation of \(T_{ext}(t)\) is approximated with a sinusoidal law, with maximum value of 30\(^{\circ }\)C at 2 PM, and minimum of 10\(^{\circ }\)C at 2 AM, while G(t) is null between 7.30 PM and 4.30 AM, and given by the superposition of two different parabolas in the light hours, with maximum value of 550 W/m\(^2\).

The sky temperature, affected by the diffused solar radiation, scattered but not absorbed by the atmosphere (Lienhard and Lienhard 2019), is commonly evaluated through the energy balance between the earth’s surface and the atmosphere. Several formulas have been proposed (Gliah et al. 2011; Karn et al. 2019) to calculate \(T_{sky}(t)\) as a function of the relevant variables (presence of clouds, atmospheric temperature change with height, the distribution of water vapour in the atmosphere...). Therefore, \(T_{sky}(t)\) does not directly depend on the solar radiance. Although it is slightly lower than \(T_{ext}(t)\), standards often assume (NF DTU 2006) \(T_{sky}(t)=T_{ext}(t)\).

In the graphs of Fig. 18, \(T_{3,2}(t)=(T_{ext}+T_{int})/2=30\,^{\circ }\)C.

For glass with coatings, \(\alpha _k\), \(\tau _k\) and \(r_k\) can take different values on the two sides of a glass element. This makes the expressions governing the heat reflection (2.6) more complicated.

Obviously, the proposed approach allows to calculate also the energy irradiating towards the external and internal environment, corresponding to the heat fluxes \(\Phi _{1,0}\) and \(\Phi _{N+1,N}\), respectively. However, since our aim is to evaluate the energy supplied to the glass plies, these expression are not recorded here.

Abbreviations

- N :

-

Number of glass panel composing the IGU

- i, j :

-

Pedex referred to the considered panel region, \(i,j=1\dots 4\)

- k, l :

-

Pedex referred to the considered glass ply forming the IGU, \(k,l=1\dots N\)

- \(S_i \) :

-

Surface area of the i-th region (m\(^2\))

- \(L_{ij}\) :

-

Lenght of the interface between i-th and j-th regions (m)

- \(s_k \) :

-

Thickness of k-th glass panel, \(k=1\dots N\) (m)

- \(b_k \) :

-

Thickness of k-th spacer, \(k=1\dots N-1\) (m)

- t :

-

Time (s)

- \(T_{i,k}(t) \) :

-

Time-dependent temperature of the i-th region of the k-th glass panel, \(i=1\dots 4\), \(k=1\dots N\) (K)

- \(\Theta _{k}(t) \) :

-

Time-dependent temperature of the gas in the k-th cavity, \(k=1\dots N-1\) (K)

- h :

-

Convective heat transfer coefficient (W/(m\(^2\)K))

- \(\lambda \) :

-

Thermal conductivity (W/(mK))

- \(\rho \) :

-

Density (kg/m\(^3\))

- \(c_P \) :

-

Specific heat (J/(kgK))

- r :

-

Reflectivity (−)

- \(\tau \) :

-

Transmissivity (−)

- \(\alpha \) :

-

Absorptivity (−)

- \(\varepsilon \) :

-

Emissivity (−)

- \(\dot{Q}_{i,k}\) :

-

Heat flow, referred to the i-th region of the k-th glass panel (W)

- \(\dot{\widetilde{Q}}_{k}\) :

-

Heat flow, referred the gas in the k-th cavity (W)

- \(\phi _i\) :

-

Coefficient accounting for the presence of frame and (solar radiation) shadings (−)

- \(\psi _i\) :

-

Coefficient accounting for the presence of the frame (convective heat exchange) (−)

- \(\omega _i\) :

-

Coefficient accounting for the presence of the frame (radiant heat exchange) (−)

- G(t):

-

Density of incident solar radiation (W/m\(^2\))

- \(T_{sky}(t)\) :

-

Radiative sky temperature (K)

- \(_A\) :

-

Referred to the gas in the IGU cavities

- \(_{int}\) :

-

Referred to the internal environment

- \(_{ext}\) :

-

Referred to the external environment

- \(_{conv}\) :

-

Referred to convection heat transfer

- \(_{cond}\) :

-

Referred to conduction heat transfer

- \(_{rad}\) :

-

Referred to heat transfer thorugh radiation

- \(_{stor}\) :

-

Referred to heat storage.

References

Ballarini, R., Pisano, G., Royer-Carfagni, G.: The lower bound for glass strength and its interpretation with generalized weibull statistics for structural applications. J. Eng. Mech. ASCE 142(12), 04016100 (2016)

Bogacki, P., Shampine, L.F.: A 3 (2) pair of Runge-Kutta formulas. Appl. Math. Lett. 2(4), 321–325 (1989)

Bonati, A., Occhiuzzi, A., Pisano, G., Royer-Carfagni, G.: A micro-mechanically motivated model for the strength of heat-treated glass. Glass Struct. Eng. 3(2), 153–166 (2018)

Bonati, A., Pisano, G., Royer Carfagni, G.: Redundancy and robustness of brittle laminated plates. Overlooked aspects in structural glass. Compos. Struct. 227, 111288 (2019)

Chen, H., Wang, Q., Wang, Y., Zhao, H., Sun, J., He, L.: Experimental and numerical study of window glass breakage with varying shaded widths under thermal loading. Fire Technol. 53(1), 43–64 (2017)

Chowdhury, H., Cortie, M.B.: Thermal stresses and cracking in absorptive solar glazing. Constr. Build. Mater. 21(2), 464–468 (2007)

CNR-DT 210: Guide for the Design, Construction and Control of Buildings with Structural Glass Elements. Technical report, National Research Council (Italy)—Advisory Committee on Technical Recommendations for Construction, (2013)

Cuce, E.: Impacts of edge seal material on thermal insulation performance of a thermally resistive photovoltaic glazing (TRPVG): CFD research with experimental validation. J. Energy. Syst. 3(1), 26–35 (2019)

Demain, C., Journée, M., Bertrand, C.: Evaluation of different models to estimate the global solar radiation on inclined surfaces. Renew. Energ. 50, 710–721 (2013)

Drysdale, D.: An Introduction to Fire Dynamics. Wiley, New York (2011)

Edwards, D.K.: Solar absorption by each element in an absorber-coverglass array. Solar Energy 19, 401–402 (1977)

EN 410—Glass in building—Determination of luminous and solar characteristics of glazing. Standard, CEN/TC 129, (2011)

EN 572-1—Glass in building—Basic soda lime silicate glass products. Part 1: Definitions and general physical and mechanical properties. Standard, CEN/TC 129, (2012)

EN 673—Glass in building—Determination of thermal transmittance (U value)—Calculation method. Standard, CEN/TC 129, (2011)

EN ISO 6946—Building components and building elements—Thermal resistance and thermal transmittance—Calculation method. Standard, ISO/TC 163 and CEN/TC 89, (2007)

Evangelisti, L., Guattari, C., Asdrubali, F., de Lieto Vollaro, R.: An experimental investigation of the thermal performance of a building solar shading device. J. Build. Eng. 28, 101089 (2020)

Foraboschi, P.: Analytical modeling to predict thermal shock failure and maximum temperature gradients of a glass panel. Mater. Des. 134, 301–319 (2017)

Galuppi, L.: Practical expressions for the design of DGUs. BAM Approach Eng. Struct. 221, 110993 (2020)

Galuppi, L., Royer-Carfagni, G.: Betti’s Analytical Method for the load sharing in double glazed units. Compos. Struct. 235, 111765 (2020)

Galuppi, L., Maffeis, M., Royer-Carfagni, G.: Enhanced engineered calculation of the temperature distribution in architectural glazing exposed to solar radiation. Glass Struct. Eng. 6, 425–448 (2021)

Gan, G.: Thermal transmittance of multiple glazing: computational fluid dynamics prediction. Appl. Therm. Eng. 21(15), 1583–1592 (2001)

Gao, F., Chen, P., Xia, Y., Zhu, H.-P., Weng, S.: Efficient calculation and monitoring of temperature actions on supertall structures. Eng. Struct. 193, 1–11 (2019)

Gliah, O., Kruczek, B., Gh Etemad, S., Thibault, J.: The effective sky temperature: an enigmatic concept. Heat Mass. Transfer. 47(9), 1171–1180 (2011)

Gratia, E., De Herde, A.: Natural ventilation in a double-skin facade. Energ. Build. 36(2), 137–146 (2004)

Hollands, K.G.T., Wright, J.L., Granqvist, C.G.: Glazings and coatings. In: Solar Energy: The State of the Art, chapter 2. James & James Scientific Publishers, London, UK (2001)

Hunsaker, J.C.: Thermal Stresses. McGraw–Hill Publication in Aeronautical Science, (1957)

ISO 9050—Glass in building—Determination of light transmittance, solar direct transmittance, total solar energy transmittance and ultraviolet transmittance, and related glazing factors. Standard, ISO/TC 160, (2003)

ISO15099—thermal Performance of windows, doors and shading devices—detailed calculation. Standard, ISO/TC 163/SC 2, (2003)

Jiru, T.E., Haghighat, F.: Modeling ventilated double skin façade—a zonal approach. Energ. Build. 40(8), 1567–1576 (2008)

Joshi, A.A., Pagni, P.J.: Fire-induced thermal fields in window glass. I-theory. Fire Saf. J. 22(1), 25–43 (1994)

Karn, A., Chintala, V., Kumar, S.: An investigation into sky temperature estimation, its variation, and significance in heat transfer calculations of solar cookers. Heat Transfer-Asian Res. 48(5), 1830–1856 (2019)

Keski-Rahkonen, O.: Breaking of window glass close to fire. Fire Mater. 12(2), 61–69 (1988)

Keski-Rahkonen, O.: Breaking of window glass close to fire, II: Circular panes. Fire Mater. 15(1), 11–16 (1991)

Lee, Y., Tay, A.A.O.: Finite element thermal analysis of a solar photovoltaic module. Energy Procedia 15, 413–420 (2012)

Li, S., Chen, S.: Field monitoring and prediction on temperature distribution of glass curtain walls of a super high-rise building. Eng. Struct. 250, 113405 (2022)

Lienhard, J.H.I.V., Lienhard, J.H.V.: A Heat Transfer Textbook, 5th edn. Phlogiston Press, Cambridge (2019)

Lu, W., Wang, Y., Chen, H., Jiang, L., Duan, Q., Li, M., Wang, Q., Sun, J.: Investigation of the thermal response and breakage mechanism of point-supported glass facade under wind load. Constr. Build. Mater. 186, 635–643 (2018)

Manz, H.: Numerical simulation of heat transfer by natural convection in cavities of facade elements. Energ. Build. 35(3), 305–311 (2003)

Manz, H.: On minimizing heat transport in architectural glazing. Renew. Energ. 33(1), 119–128 (2008)

Marino, C., Nucara, A., Pietrafesa, M., Polimeni, E.: The effect of the short wave radiation and its reflected components on the mean radiant temperature: modelling and preliminary experimental results. J. Build. Eng. 9, 42–51 (2017)

Mohelníková, J., Altan, H.: Evaluation of optical and thermal properties of window glazing. Wseas Trans. Environ. Develop. 5(1), 86–93 (2009)

N180E—Glass and Thermal Safety. Standard, CEN/TC129/WG8 – Pilkington, (2004)

NF DTU 39 P3 Travaux de bâtiment—Travaux de vitrerie-miroiterie—Partie 3: Mémento calculs des contraintes thermiques. Standard, CSTB, (2006)

Norris, D.J.: Solar radiation on inclined surfaces. Sol Energy 10(2), 72–76 (1966)

Pasut, W., De Carli, M.: Evaluation of various CFD modelling strategies in predicting airflow and temperature in a naturally ventilated double skin façade. Appl. Therm. Eng. 37, 267–274 (2012)

Poláková, M., Schäfer, S., Elstner, M.: Thermal glass stress analysis-design considerations. Chall. Glass Confer. Proc. 6, 725–740 (2018)

Pope, N.D., Bailey, C.G.: Development of a Gaussian glass breakage model within a fire field model. Fire Saf. J. 42(5), 366–376 (2007)

prEN THSTR—Glass in building—Thermal Stress Calculation Method. Standard, CEN/TC129/WG8 - N241E, (2016)

Respondek, Z.: Influence of insulated glass units thickness and weight reduction on their functional properties. Open Eng. 8(1), 455–462 (2018)

Shameri, M.A., Alghoul, M.A., Sopian, K., Zain, M., Fauzi, M., Elayeb, O.: Perspectives of double skin façade systems in buildings and energy saving. Renew. Sust. Energ. Rev. 15(3), 1468–1475 (2011)

Siegel, R.: Net radiation method for transmission through partially transparent plates. nasa report. Technical report, NASA, (1973)

Sincaglia, P.E., Barnett, J.R.: Development of a glass window fracture model for zone-type computer fire codes. J. Fire Protect. Eng. 8(3), 101–117 (1996)

Swinbank, W.C.: Long-wave radiation from clear skies. Q. J. R. Meteor. Soc. 89(381), 339–348 (1963)

Vengatesan, K.: Windows Film to Glass: Numerical simulation software for avoiding thermal stress. MS Thesis, IST Tecnico Lisboa, (2017)

Virgone, J., Depecker, P., Krauss, G.: Computer simulation of glass temperatures in fire conditions. Build. Environ. 32(1), 13–23 (1997)

Wang, Y., Hu, J.: Performance of laminated glazing under fire conditions. Compos. Struct. 223, 110903 (2019)

Wang, Q., Zhang, Y., Wang, Y., Sun, J., He, L.: Dynamic three-dimensional stress prediction of window glass under thermal loading. Int. J. Thermal. Sci. 59, 152–160 (2012)

Wang, Q., Chen, H., Wang, Y., Sun, J.: Thermal shock effect on the glass thermal stress response and crack propagation. Procedia Eng. 62, 717–724 (2013)

Wright, J.L.: A correlation to quantify convective heat transfer between vertical window glazings. ASHRAE Trans. 106, 940–946 (1996)

Wright, J.L.: Calculating center-glass performance indices of windows. ASHRAE Trans. 104, 1230–1241 (1998)

Wright, J.L., Kotey, N.A.: Solar absorption by each element in a glazing/shading layer array. ASHRAE Trans. 112, 3–12 (2006)

Wüest, T., Luible, A.: Increased thermal induced climatic load in insulated glass units. J. Facade Des. Eng. 4(3–4), 91–113 (2016)

Xamán, J., Álvarez, G., Lira, L., Estrada, C.: Numerical study of heat transfer by laminar and turbulent natural convection in tall cavities of facade elements. Energ. Build. 37(7), 787–794 (2005)

Yang, Y., Chow, C.L.: Transient temperature fields and thermal stress fields in glazing of different thicknesses exposed to heat radiation. Constr. Build. Mater. 193, 589–603 (2018)

Zhao, H., Wang, Q., Su, Y., Wang, Y., Shao, G., Chen, H., Sun, J.: Experimental investigation on glass cracking for wind load combined with radiant heating. In: Fire Sci Technol 2015, pp. 255–260. Springer (2017)

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors. It was internally supported by Maffeis Engineering SpA, Solagna (Vi), Italy, in collaboration with the University of Parma, Italy.

Author information

Authors and Affiliations

Contributions

This research paper results from a joint collaboration of the involved Authors.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix. Evaluation of the radiant coefficients

Appendix. Evaluation of the radiant coefficients

As indicated in Sect. 2.2.3, when a multiple glazing unit is irradiated by the solar radiation as per (2.8), the energy absorbed by each panel depends upon the coefficients \(\alpha ^*_k\), defined as the ratio between the energy absorbed by the \(k-\)th glass pane and the total energy. Furthermore, to evaluate the amount of energy emitted by the various panels that is absorbed by each panel, as per (2.11), what is needed is the value of the coefficients \({\overline{\varepsilon }}_{lk}\), defined as the part of energy emitted by the \(l-\)th glass element that is absorbed by the \(k-\)th element.

The amount of radiation reflected and transmitted by a multiple glazing, as well as the energy absorbed by each glass pane, can be found by considering the fluxes of radiant energy flowing between the \(i-\)th region of the \(k-\)th glass panel and the adjacent ones, as schematically shown in Fig. 22 where, for clarity, the indexes i are omitted. Let us denote with \(\Phi _{k,k+1}\) the radiant heat flux transmitted by the \(k-\)th to the \((k+1)\)-th glass element (i.e., the transmitted heat flux, from left to right, towards the internal environment), and by \(\Phi _{k,k-1}\) that transmitted by the \(k-\)th to the \((k-1)\)-th glass element (reflected flux, towards the external environment). The heat flux absorbed by the \(k-\)th element is denoted to as \(\Phi _{k,k}\). Each element emits an energy proportional to the fourth power of its temperature, given by the Stefan-Boltzmann law (2.11) and compactly denoted to as \({\mathscr {E}}_k\) in the same Figure.

When the solar radiation is considered, the heat fluxes are strongly related one another by the absorptivity, transmissivity and reflectivity coefficients \(\alpha _k\), \(\tau _k\) and \(r_k\) of the glass panesFootnote 10. For each glass panel, one can write the system of equations (Wright 1998; Hollands et al. 2001; Edwards 1977)

On the other hand, to evaluate the flows due to the energy emitted by the glass panels (2.12), one has consider that the aborptivity of the \(k-\)th glass pael coincides with its emissivity \(\varepsilon _k\), while the reflectivity is \(1-\varepsilon _k\), being null the transmissivity. Hence, in this case system (A.1) reduces to

This kind of problem is usually solved by means of various numerical methods, which can be based on the “net radiation” (Siegel 1973), recursive (Edwards 1977), matrix (Wright and Kotey 2006) and “ray tracings” (Wright 1998) approaches. Here, in order to evaluate \(\alpha ^*_k\) and \({\overline{\varepsilon }}_{kl}\), the problem is split in two different parts, by considering separately the effects of the energies from the solar radiation and from the glass panel themselves.

1.1 Solar radiation

Consider the case where the front surface of the fenestration (panel \(k=1\)) is irradiated by the energy \({\mathscr {E}}\), representative of the contribution by the sun. The relevant heat fluxes can be evaluated by posing \(\Phi _{0,1}={\mathscr {E}}\) and \({\mathscr {E}}_k=0\) in (A.1), and by solving this system of equations by assuming that the heat coming from the internal environment is null (\(\Phi _{N+1,N}=0\)).

Let us define the overall reflectivity coefficients of the multiple glazing \(r^*\) as the ratio between the total reflected energy and the total energy, and analogously define the overall transmissivity coefficient \(\tau ^*\). Furthermore, with reference to Fig. 22, denote as \(\alpha ^*_k\) the part of the total energy absorbed by the \(k-\)th glass ply, \(k=1 \dots N\), i.e.,

These coefficients can be analytically calculated by solving (A.1). Consider, first, the simplest case of a double glazing, with glass panels characterized by the same thermal properties (\(\alpha _k=\alpha \), \(\tau _k=\tau \) and \(r_k=r\), for \(k=1,2\)). The relevant coefficients read

A graphical interpretation of these results is given in Fig. 23.

Figure 24 shows the coefficients \(\alpha _1^*\) and \(\alpha _2^*\), evaluated as per (A.4), plotted as a function of \(\alpha \) and r. As expected, for given values of \(\alpha \) and r, one finds that \(\alpha _1^*>\alpha _2^*\): the energy absorbed by the front panel is higher than that absorbed by the back panel. Furthermore, while \(\alpha _1^*\) monotonically increases as \(\alpha \) increases, \(\alpha _2^*\) shows a strong decrease for high values of \(\alpha \) and r, due to the decrease of \(\tau =1-\alpha -r\). Notice that, when \(\tau =0\), no thermal energy is transmitted to the second panel, and \(\alpha _2^*=0\).

For two glass elements with different thermal properties, it can be calculated that the overall coefficients take the form

In case of three glass elements, all with the same thermal properties, one finds

Figure 25 shows the tridimensional plot of \(\alpha _1^*\), \(\alpha _2^*\) and \(\alpha _3^*\), as given by (A.6).

It is clear that \(\alpha _1^*>\alpha _2^*>\alpha _3^*\). Notice as well that \(\alpha _2^*\) and \(\alpha _3^*\) are strongly affected by the reflectivity and the transmissivity. In particular, when \(\tau =1-\alpha -r=0\), no thermal energy is transmitted to the second and the third panels, and \(\alpha _2^*=\alpha _3^*=0\).

Finally, for a unit composed of four glass panels, one has

where \(f(\tau ,r)=(1+r-r^2+r\tau ^2-r^3)(1-r-r^2-r\tau ^2+r^3)\).

1.2 Energy emitted by the glass plies

Consider now the energy emitted by a single glass panel, that is proportional to the fourth power of its temperature according to (2.11). The energy absorbed by the different glass panes can be evaluated by assuming that the heat coming from both the external and the internal environment are null, i.e., by setting \(\Phi _{0,1}=\Phi _{N+1,N}=0\) in (A.2). Solving (A.1), the energy absorbed by the \(k-\)th glass paneFootnote 11 can be found in the form

As discussed in Sect. 2.2.3, due to reflection phenomena (Fig. 4), the \(k-\)th glass absorbs a part of the energy emitted by itself, denoted as \({\overline{\varepsilon }}_{kk}\ne 0\). Obviously, for a single glazing (\(N=1\)), one has that \({\overline{\varepsilon }}_{11}=0\), since in this case there are no reflection phenomena. For a double glazing (\(N=2\)), reflections play a decisive role, as schematically shown in Fig. 4. The relevant coefficients read

For the case of a double glazing where glass panels have the same thermal properties (\(\varepsilon _k=\varepsilon \) for \(k=1,2\)), Eq. (A.9) can be simplified in the form

Figure 5a shows the coefficients \({\overline{\varepsilon }}_{11}={\overline{\varepsilon }}_{22}\) and \({\overline{\varepsilon }}_{12}={\overline{\varepsilon }}_{12}\), evaluated as per (A.10), plotted as a function of \(\varepsilon \). In general, coefficients \({\overline{\varepsilon }}_{11}\) and \({\overline{\varepsilon }}_{22}\), accounting for the “self-reflection”, i.e., the phenomenon for which a glass panel absorb a part of the energy emitted by itself as shown in Fig. 4, are lower than those accounting for the energy exchange between adjacent panels. It may be also noticed that, when \(\varepsilon \rightarrow 1\), the reflected part is negligible, and hence \({\overline{\varepsilon }}_{12}={\overline{\varepsilon }}_{12}\rightarrow 1\) and \({\overline{\varepsilon }}_{11}={\overline{\varepsilon }}_{22}\rightarrow 0\), i.e., all the energy emitted by panel 1 is absorbed by panel 2, and viceversa.

In case of three glass elements, all with the same thermal properties, one obtains

Figure 5b is the counterpart of Fig. 5a for a triple glazing, showing \({\overline{\varepsilon }}_{lk}\), evaluated as per (A.11), as a function of \(\varepsilon \). Observe that, due to the symmetry of the problem, the role of the external elements (\(k=1\) and \(k=3\)) is the same: this provides \({\overline{\varepsilon }}_{k1}={\overline{\varepsilon }}_{k3}\) and \({\overline{\varepsilon }}_{1k}={\overline{\varepsilon }}_{3k}\). Furthermore, it may be verified that \({\overline{\varepsilon }}_{kl}={\overline{\varepsilon }}_{lk}\), \(k,l=1 \dots N\): the heat interchange between two surfaces is symmetrical. These relations hold also for the case of a glazing fenestration composed by four glass panels, for which the relevant coefficients are

Both in the case \(N=3\) [Eq. (A.11)] and \(N=4\) [Eq. (A.12)], notice that the coefficients \({\overline{\varepsilon }}_{11}={\overline{\varepsilon }}_{NN}\), accounting for the self-reflection of the external panes, are in general lower than those accounting for the thermal energy exchange between adjacent panels. On the other hand, the heat exchange between not adjacent panes is null, due to the null transmissivity of the interposed panel. The “self-reflection” coefficient of inner panels, i.e., \({\overline{\varepsilon }}_{kk}\,,\ k=2\dots N-1\), takes quite high values, since it accounts for the energy reflection on both sides.

Rights and permissions

About this article

Cite this article

Galuppi, L., Maffeis, M. & Royer-Carfagni, G. Engineered calculation of the uneven in-plane temperatures in Insulating Glass Units for structural design. Glass Struct Eng 7, 71–99 (2022). https://doi.org/10.1007/s40940-022-00169-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40940-022-00169-x