Abstract

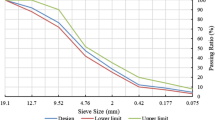

This study investigates the performance of two waste materials, steel slag and construction and demolition waste (CDW), as potential backfill materials for reinforced earth (RE) applications under cyclic loading conditions. Consolidated-undrained cyclic triaxial tests were conducted on the materials to investigate the material behavior. The study also assessed the influence of incorporating geogrids on the cyclic performance of the materials. Both the waste materials exhibited cyclic behavior similar to that of conventional sand, with maximum deviator stress observed in slag, followed by CDW. The presence of slightly higher fines content in slag and CDW resulted in increased excess pore pressure compared to sand. The incorporation of geogrid enhanced the cyclic strength of both slag and CDW. In the first cycle, an improvement of 26% and 20% was observed with the inclusion of geogrid in slag and CDW, respectively, at a frequency of 1 Hz. In addition, the use of geogrid resulted in a reduction in excess pore water pressure generation. At a given frequency, the shear modulus of slag and CDW was found to be higher than that of sand. In the initial loading cycle, the shear modulus of slag was 54% higher, and CDW was 26% higher compared to sand. With the inclusion of geogrid, the dynamic shear modulus of sand, slag and CDW in the first cycle improved by 18%, 28%, and 25%, respectively. Sand exhibited a higher damping ratio compared to slag and CDW. However, the influence of geogrid on the damping ratio was found to be negligible. Furthermore, a 2D numerical investigation was conducted to explore the potential implementation of slag and CDW in practical applications, specifically in RE walls under railway loading. Numerical simulations revealed a significant reduction in wall deflection when slag or CDW was used as backfill compared to conventional material. The peak horizontal facing displacement values were found to reduce by 48% and 32% for slag and CDW, respectively, when compared to the use of sand.

Similar content being viewed by others

Data Availability

The data sets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

United Nations Environment Programme (UNEP (2019) Rising demand for sand calls for resource governance. UNEP, Geneva

Jagan I, Sowjanya PN, Rajesh KN (2023) A review on alternatives to sand replacement and its effect on concrete properties. Mater Today Proc. https://doi.org/10.1016/j.matpr.2023.03.332

Malasavage NE, Jagupilla S, Grubb DG, Wazne M, Coon WP (2012) Geotechnical performance of dredged material—steel slag fines blends: laboratory and field evaluation. J Geotech Geoenviron Eng 138(8):981–991. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000658

Maghool F, Arulrajah A, Suksiripattanapong C, Horpibulsuk S, Mohajerani A (2019) Geotechnical properties of steel slag aggregates: shear strength and stiffness. Soils Found 59(5):1591–1601. https://doi.org/10.1016/j.sandf.2019.03.016

Aliyah F, Kambali I, Setiawan AF, Radzi YM, Rahman AA (2023) Utilization of steel slag from industrial waste for ionizing radiation shielding concrete: a systematic review. Constr Build Mater 382(2023):131360. https://doi.org/10.1016/j.conbuildmat.2023.131360

Wang S, Kim J, Qin T (2024). Mineral carbonation of iron and steel by-products: state-of-the-art techniques and economic, environmental, and health implications. J CO2 Util 81(2024):102707. https://doi.org/10.1016/j.jcou.2024.102707

Yildirim IZ, Prezzi M (2015) Geotechnical properties of fresh and aged basic oxygen furnace steel slag. J Mater Civ Eng 27(12):04015046. https://doi.org/10.1061/(asce)mt.1943-5533.0001310

Mandloi P, Sarkar S, Hegde A (2022) Performance assessment of mechanically stabilised earth walls with sustainable backfills: experimental and numerical approach. Proc Inst Civ Eng Eng Sustain 175(6):302–318. https://doi.org/10.1680/jensu.22.00012

Sarkar S, Hegde A (2022) Strength enhancement of geogrid reinforced marginal backfill materials in triaxial condition. In Geo Congress 2022:467–476. https://doi.org/10.1061/9780784484012.048

Sarkar S, Hegde A (2024) Stress-dilatancy and critical-state behavior of geogrid-reinforced recycled waste materials. J Hazardous Toxic Radioact Waste 28(1):04023042. https://doi.org/10.1061/jhtrbp.hzeng-1257

Secco MP, Bruschi GJ, Vieira CS, Cristelo N (2022) Geomechanical behaviour of recycled construction and demolition waste submitted to accelerated wear. Sustain 14(11):6719. https://doi.org/10.3390/su14116719

Vieira CS, Pereira PM, Lopes MDL (2016) Recycled construction and demolition wastes as filling material for geosynthetic reinforced structures. Interface properties. J Clean Prod 124(2016):299–311. https://doi.org/10.1016/j.jclepro.2016.02.115

Sarkar S, Prakash S, Hegde A (2023) Interaction between biaxial geogrid and solid waste materials: laboratory study and artificial neural network model development. Int J Geosynth Gr Eng 9(6):77. https://doi.org/10.1007/s40891-023-00498-z

Sarkar S, Hegde A (2022) Performance evaluation of geogrid reinforced recycled marginal backfill materials in triaxial test conditions. Int J Geosynth Gr Eng 8(4):48. https://doi.org/10.1007/s40891-022-00395-x

Elgamal A, Zeghal M, Taboada V, Dobry R (1996) Analysis of site liquefaction and lateral spreading using centrifuge testing records. Soils Found 36(2):111–121. https://doi.org/10.3208/sandf.36.2_111

Ghayoomi M, Suprunenko G, Mirshekari M (2017) Cyclic triaxial test to measure strain-dependent shear modulus of unsaturated sand. Int J Geomech 17(9):04017043. https://doi.org/10.1061/(asce)gm.1943-5622.0000917

Li W, Lang L, Wang D, Wu Y, Li F (2018) Investigation on the dynamic shear modulus and damping ratio of steel slag sand mixtures. Constr Build Mater 162(2018):170–180. https://doi.org/10.1016/j.conbuildmat.2017.12.026

Wang L, Xiao X, Ji W et al (2021) Dynamic properties of the mucky clay improved with the steel slag and the rubber particles. Constr Build Mater 294(2021):123489. https://doi.org/10.1016/j.conbuildmat.2021.123489

Wang L, Cao X, Wang Q, Wang B (2020) Dynamic properties of steel slag improved with sand-tyre shreds admixture. Proc Inst Civ Eng Gr Improv 173(3):143–158. https://doi.org/10.1680/jgrim.17.00071

Shafie A, Ghate R (2008) Shear modulus and damping ratio in aggregate-clay mixtures: an experimental study versus ANNs prediction. J Appl Sci 8(18):3068–3082. https://doi.org/10.3923/jas.2008.3068.3082

Bennert T, Papp J, Maher A, Gucunski N (2000) Utilization of construction and demolition debris under traffic-type loading in base and subbase applications. Transp Res Rec 1714(1):33–39. https://doi.org/10.3141/1714-05

Arulrajah A, Piratheepan J, Bo MW, Sivakugan N (2012) Geotechnical characteristics of recycled crushed brick blends for pavement sub-base applications. Can Geotech J 49(7):796–811. https://doi.org/10.1139/T2012-041

Arisha A, Gabr A, El-Badawy S, Shwally S (2016) Using blends of construction and demolition waste materials and recycled clay masonry brick in pavement. Procedia Eng 143(2016):1317–1324. https://doi.org/10.1016/j.proeng.2016.06.148

Saberian M, Li J, Boroujeni M, Law D, Li CQ (2020) Application of demolition wastes mixed with crushed glass and crumb rubber in pavement base/subbase. Resour Conserv Recycl 156(2020):104722. https://doi.org/10.1016/j.resconrec.2020.104722

Lu C, Chen J, Gu C, Wang J, Cai Y, Zhang T (2021) Resilient and permanent deformation behaviors of construction and demolition wastes in unbound pavement base and subbase applications. Transp Geotech 28(2021):100541. https://doi.org/10.1016/j.trgeo.2021.100541

Esparza LA, Ossa A, Botero E (2020) Evaluation of the complex dynamic modulus of asphaltic concretes manufactured with construction and demolition waste (CDW) aggregates. Environ Sci Pollut Res 27(2020):11575–11586. https://doi.org/10.1007/s11356-020-07727-2

Maheshwari BK, Singh HP, Saran S (2012) Effects of reinforcement on liquefaction resistance of solani sand. J Geotech Geoenviron Eng 138(7):831–840. https://doi.org/10.1061/(asce)gt.1943-5606.0000645

Yu Z, Woodward PK, Laghrouche O, Connolly DP (2019) True triaxial testing of geogrid for high speed railways. Transp Geotech 20(2019):100247. https://doi.org/10.1016/j.trgeo.2019.100247

Kim UJ, Kim DS (2020) Load sharing characteristics of rigid facing walls with geogrid reinforced railway subgrade during and after construction. Geotext Geomembr 48(6):940–949. https://doi.org/10.1016/j.geotexmem.2020.08.002

ASTM D2487 (2020). Standard practice for classification of soils for engineering purposes (unified soil classification system). ASTM Int West Conshohocken, PA

ASTM D854 (2014) Standard test methods for specific gravity of soil solids by water pycnometer. ASTM Int West Conshohocken, PA

ASTM D4254 (2006): Standard test methods for minimum index density and unit weight of soils and calculation of relative density. ASTM Int West Conshohocken, PA

ASTM D2434 (2000) Standard test method for permeability of granular soils (constant head). ASTM Int West Conshohocken, PA

ASTM D6637 (2014) Standard test method for determining tensile properties of geogrids by the single or multi-rib tensile method. ASTM Int West Conshohocken, PA

Castro G, Poulos SJ (1977) Factors affecting liquefaction and cyclic mobility. ASCE J Geotech Eng Div 103(6):501–516. https://doi.org/10.1061/ajgeb6.0000433

Gobbi S, d’Avila MPS, Lenti L, Semblat JF, Reiffsteck P (2022) Liquefaction assessment of silty sands: experimental characterization and numerical calibration. Soil Dyn Earthq Eng 159(2022):107349. https://doi.org/10.1016/j.soildyn.2022.107349

Mao X, Fahey M (2003) Behaviour of calcareous soils in undrained cyclic simple shear. Geotechnique 53(8):715–727. https://doi.org/10.1680/geot.2003.53.8.715

Yao CR, Wang B, Liu ZQ, Fan H, Sun FH, Chang XH (2019) Evaluation of liquefaction potential in saturated sand under different drainage boundary conditions—an energy approach. J Mar Sci Eng 7(11):411. https://doi.org/10.3390/jmse7110411

Banerjee R, Chattaraj R, Parulekar YM, Sengupta A (2021) Numerical prediction of undrained cyclic triaxial experiments on saturated Kasai river sand using two constitutive models of liquefaction. Bull Eng Geol Environ 80(2021):8565–8582. https://doi.org/10.1007/s10064-021-02449-2

Yang ZX, Pan K (2017) Flow deformation and cyclic resistance of saturated loose sand considering initial static shear effect. Soil Dyn Earthq Eng 92:68–78

Sitharam TG (2003) Discrete element modelling of cyclic behaviour of granular materials. Geotech Geol Eng 21:297–329

Sitharam TG, Dinesh SV (2003) Numerical simulation of liquefaction behaviour of granular materials using discrete element method. J Earth Syst Sci 112:479–484

Kumar SS, Krishna AM, Dey A (2017) Evaluation of dynamic properties of sandy soil at high cyclic strains. Soil Dyn Earthq Eng 99(2017):157–167. https://doi.org/10.1016/j.soildyn.2017.05.016

Zhu Z, Zhang F, Peng Q, Dupla JC, Canou J, Cumunel G, Foerster E (2021) Effect of the loading frequency on the sand liquefaction behaviour in cyclic triaxial tests. Soil Dyn Earthq Eng 147(2021):106779. https://doi.org/10.1016/j.soildyn.2021.106779

Akosah S, Zhou L, Chen JF, Korli Lawer A (2023) Experimental investigation on cyclic behavior of geogrid-reinforced coral sand from the South China Sea. Mar Georesources Geotechnol 2023:1–14. https://doi.org/10.1080/1064119X.2023.2214933

Kokusho T (1980) Cyclic triaxial test of dynamic soil properties for wide strain range. Chem Pharm Bull 20(2):45–60. https://doi.org/10.3208/sandf1972.20.2_45

Seed HB, Wong RT, Idriss IM, Tokimatsu K (1986) Moduli and damping factors for dynamic analyses of cohesionless soils. J Geotech Eng 112(11):1016–1032. https://doi.org/10.1061/(ASCE)0733-9410(1986)112:11(1016)

Okur DV, Ansal A (2007) Stiffness degradation of natural fine grained soils during cyclic loading. Soil Dyn Earthq Eng 27(9):843–854. https://doi.org/10.1016/j.soildyn.2007.01.005

Lanzo G, Vucetic M, Doroudian M (1997) Reduction of shear modulus at small strains in simple shear. J Geotech Geoenviron Eng 123(11):1035–1042. https://doi.org/10.1061/(ASCE)1090-0241(1997)123:11(1035)

Vucetic M, Mortezaie A (2015) Cyclic secant shear modulus versus pore water pressure in sands at small cyclic strains. Soil Dyn Earthq Eng 70(2015):60–72. https://doi.org/10.1016/j.soildyn.2014.12.001

ASTM D3999 (2003) Standard test methods for the determination of the modulus and damping properties of soils using the cyclic triaxial apparatus. ASTM Int West Conshohocken, PA

Qi Y, Indraratna B, Heitor A, Vinod JS (2018) Effect of rubber crumbs on the cyclic behavior of steel furnace slag and coal wash mixtures. J Geotech Geoenviron Eng 144(2):04017107. https://doi.org/10.1061/(asce)gt.1943-5606.0001827

Payeur JB, Corfdir A, Bourgeois E (2015) Dynamic behavior of a mechanically stabilized earth wall under harmonic loading: experimental characterization and 3D finite elements model. Comput Geotech 65(2015):199–211. https://doi.org/10.1016/j.compgeo.2014.12.001

Mandloi P, Hegde A (2022) Performance evaluation of reinforced earth walls with sustainable backfills subjected to railway loading. Front Built Environ 8(2022):1048079. https://doi.org/10.3389/fbuil.2022.1048079

Wichtmann T, Triantafyllidis T (2009) On the correlation of “static” and “dynamic” stiffness moduli of non-cohesive soils. Bautechnik 86(S1):28–39. https://doi.org/10.1002/bate.200910039

Acknowledgements

The authors would like to thank and acknowledge Indian Institute of Technology Patna and Department of Higher Education (Govt. of India) for providing the funding for the present research work for which no specific grant number has been allotted.

Author information

Authors and Affiliations

Contributions

Sanjana Sarkar: conceptualization, experimental investigation, formal analysis, writing—original draft. Amarnath Hegde: conceptualization, formal analysis, supervision, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sarkar, S., Hegde, A. Performance Evaluation of Steel Slag and Construction and Demolition Waste as Reinforced Earth Backfill Materials Under Cyclic Loading Conditions. Int. J. of Geosynth. and Ground Eng. 10, 38 (2024). https://doi.org/10.1007/s40891-024-00549-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-024-00549-z