Abstract

The behaviour of unbound granular materials (UGMs) used in road construction is crucial in determining the longevity and performance of road pavement. Geotechnical analysis can assist engineers in selecting suitable materials and designing road pavements that meet industry standards. This paper presents the results of laboratory geotechnical tests conducted on unbound granular materials (UGMs) collected from three sites (Roses Gap, Rules East, and Polkemmet Road) in Horsham, Victoria, Australia. UGMs were investigated for their mechanical behaviour and suitability as subgrade materials for road pavements. The study utilised laboratory geotechnical tests, including particle size distribution (PSD), Atterberg limits, compaction (Proctor) test, unconfined compressive strength (UCS), California Bearing Ratio (CBR), and repeated load triaxial (RLT) tests, to evaluate the physical and mechanical properties of the UGM samples. The study indicates that UGM samples collected from different locations displayed variations in their geotechnical properties, such as particle size distribution, water absorption, and CBR strength. Roses Gap samples showed weak cohesion properties, and significant vertical displacements after repeated triaxial tests. However, among the samples in this site, samples with higher clay content (RG21) demonstrated the most promise in triaxial tests. Similarly, the Rules East samples were found to be suitable for low-traffic subgrades due to their satisfactory CBR and RLT testing results, albeit with little cohesion from clay content. Out of three locations, Polkemmet samples were identified as potential subgrade applications, with PR12 being the top recommendation overall. It satisfied PSD, CBR, and RLT test conditions due to acceptable particle size in the largest range, highest CBR strength value, and lowest permanent displacement. The study's findings provide useful information for the design of road pavements using these materials and the characterisation of rural materials around the Horsham region for future use in various other contexts.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Australia boasts one of the largest internal trade systems in the world with its extensive road network, spanning over 877,000 km, making it a significant investment and maintenance spender in the transport infrastructure sector [1]. Private transport remains the primary mode of transportation for more than two-thirds of the population, necessitating an expansion and consolidation of roads to keep up with the country's steady economic growth. A crucial aspect of road construction planning involves material preparation, particularly for arterial, collector, and local roads. In Australia's democratic system, state and local governments are responsible for funding and maintaining these roads, providing a financial incentive to ensure they are cost-effective, primarily funded by community taxpayers [2]. This incentivises local governments to explore and use regional land features for growth, such as road development in response to population growth.

Flexible road pavement is a common design approach in Australia, consisting of multiple layers with a surface layer (asphalt, bitumen, concrete) covering a base of granular materials. The base and subgrade of the pavement consist of unconfined granular materials, which serve as a fundamental design element for transferring vehicular traffic loads to the substructure via grain-to-grain mechanisms [3]. The design of flexible pavement is heavily influenced by the bearing capacity characteristics of the subgrade/grade, including aggregate engagement, particle cohesion, and friction, as road survivability is determined by these characteristics [4]. Rigid pavement, a durable and sturdy type of road surface, shares a common feature with its counterpart, flexible pavement: both rely on subbase and subgrade courses, emphasizing the importance of a solid foundation for long-lasting and stable road infrastructure. The use of unbound granular materials (UGMs) in pavement design is crucial in limiting the loss of serviceability of pavement construction caused by traffic load and environmental degradation, designed to withstand the stiffness coefficient of resistance if necessary.

To ensure the quality of UGMs used in road construction several studies [5,6,7,8,9,10,11,12,13,14] have been conducted on soil application, with the aim of utilising local resources. As several local councils require UGMs for developing new roads or maintaining the existing road network due to population and economic growth in the region, sourcing local materials could prove to be a cost-effective option, eliminating the need to source materials from outside and overseas. This would also create new job opportunities in the region, including mines, potential refineries, and construction. Ensuring the safe passage of rural residents to essential services such as medical care, food, and emergency services during extreme weather events is a crucial objective. It is important to note that the materials used in construction must meet local design safety standards, Australian standards, and environmental requirements to obtain stakeholder approval.

To assess the suitability of locally available materials for road construction, a comprehensive analysis must be conducted using various geotechnical laboratory tests. The tests commonly utilised for this purpose include moisture content, particle size distribution, compaction (Proctor), California bearing ratio (CBR), and repeated triaxial tests.

Soil moisture testing can provide insights into the soil profile at different depths. Soil moisture affects various aspects of soil properties, such as specific gravity, permeability, mechanical and chemical properties, soil suction, soil compaction, and the cost of water supply and drying excess water in the soil by different methods [15,16,17,18,19,20]. Thus, investigating and analysing soil moisture results is crucial for geotechnical studies of an area [19]. Determining soil particle size is also crucial for designing pavement performance as it significantly impacts soil's mechanical behaviour [21, 22]. Typically, sieve analysis and hydrometry tests are conducted to determine soil particle size for coarse-grained and fine-grained soils, respectively [23]. Fine-grained soils have more cohesion, while coarse-grained soils have more strength [24]. Soil grading affects the amount of water absorbed by the soil, which can significantly impact pollutants' permeability and soil strength [25]. Furthermore, soil grading affects soil density and suction, which impact the road's resistance and performance [10]. Therefore, soil grading is an important factor when used in the subbase course.

The soil compaction test is a critical geotechnical test that determines the maximum dry density and optimal soil water content for road construction [26, 27]. These parameters are essential because road layers must be compacted close to their maximum dry density, which results in increased resistance to loading and decreased permeability, impacting road stability and performance [28]. Understanding optimal soil water content and maximum dry density is also crucial for estimating the energy, costs, and equipment required for soil compaction and water supply operations in road construction [29]. Additionally, other geotechnical tests, such as CBR and unconfined compressive strength (UCS), are generally conducted on samples prepared under optimal water content and maximum dry density conditions, making soil compaction test results a crucial component of geotechnical investigations.

Flexible pavements comprise a significant portion of the Australian highway system [30], and the CBR test is a critical tool for designing such pavements [31]. The subgrade soil bearing capacity significantly impacts pavement design and determines pavement thickness, with low CBR values resulting in thicker pavements [32]. Therefore, the CBR test is one of the most important tests for geotechnical studies related to road construction. Korkiala-Tanttu [33] introduced a model for unbound materials based on the tests, which is an analytical, nonlinear elastoplastic model that can calculate stresses and deformations in each layer to obtain the total rutting on the surface of the structure.

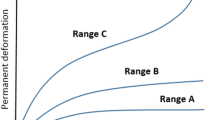

Among the most widely used tests for identifying the suitability of soil samples for road construction, the repeated loading triaxial (RLT) test is considered to be the most important. During this test, cylindrical samples are subjected to vertical cyclic loading (to simulate the loading caused by vehicles moving on the pavement). According to the literature [34, 35], the samples made with optimal water content and maximum dry density performed the most effectively under this cyclic loading condition. One of the important parameters in the design of pavement is permanent/plastic deformation of the subgrade layer. This parameter can show the pavement’s durability and capacity, and the possibility of cracking in pavement over time. Under repeated (cyclic) loading conditions, the test results determine permanent/plastic deformations and the degree of stiffness of UGMs [36]. The term "permanent deformation" refers to the irreversible formation that occurs after loading, and the sample does not return to its original state after unloading. Consequently, repeated triaxial loading test results are extremely critical to understand the behaviour of UGM and design road pavements considering this issue.

Furthermore, rutting, a significant mode of failure in flexible pavement structures, primarily results from the permanent deformation of UGMs utilised in the subbase or base layer [37, 38]. This phenomenon is more prevalent on thin flexible pavements. The repeated load triaxial test (RLT) is recognised as the most feasible approach to replicate the response of aggregate layers under various traffic loads, despite its limitations [38]. This test is widely employed to assess the resistance to permanent deformation and hardness properties of UGM. Korkiala-Tanttu [33] found that it is important to calculate stresses with an elastoplastic material model to avoid tensile stresses in UGM, particularly when asphalt layers are thin. In another study, Gidel et al. [39] introduced a method for modelling the permanent deformation behaviour of UGM through RLT tests, where they assumed a linear correlation between stress levels and permanent axial deformations [39]. Nonetheless, a comprehensive and satisfactory approach to utilise multistage RLT tests to model permanent deformation behaviour has yet to be established. In another study, Li et al. [40] aimed to evaluate the behaviour of granular base material (GBM) under repeated load triaxial testing using the discrete-element method. Both macroscopic and microscopic behaviours were analysed by considering size gradation and aggregate shape in numerical simulations. The simulation results showed good agreement with laboratory tests, and the GBM presented stress-hardening behaviour with increasing volume stress and deviator stress. The microstructure of the GBM remained stable during cyclic loading, and voids within aggregates helped to buffer the change in internal stress.

Alnedawi et al. [11] examined the potential of non-standard unbound granular materials (UGM) in Horsham, located in Victoria, Australia, as pavement aggregates. The findings revealed that UGM performed on par or better than conventional base materials in terms of permanent deformation and modulus of elasticity. This highlights UGM's potential as a sustainable alternative in pavement construction. Additionally, regression models demonstrated improved prediction accuracy for UGM [11]. Previous research undertaken by Sukkar [41] suggested that Horsham has the requisite soil properties for constructing road foundation structures, making it a promising area for road construction. In the area where the UGM industry is situated, there exist multiple quarries and pits that may contain UGM deposits. A collaborating industry partner is interested in evaluating the quality of UGM samples obtained from these sites for their potential use in road construction. In this study, samples of UGM were gathered from several pit locations, and their geotechnical properties were analysed. The objective of this research is to investigate the suitability of UGM for use in road construction. To achieve this objective, an experimental and analytical approach was utilised. Soil samples were collected from three different locations in Western Victoria (Horsham region) and placed in sealed plastic bags.

Geology of Horsham Region

The Horsham region is located in the western part of the state of Victoria in Australia. The Horsham region covers an area of approximately 7500 square kilometres [42] and it is located within the Wimmera–Mallee region, which is characterised by its flat to undulating topography and its semi-arid to sub-humid climate [43]. The geology of this area is dominated by sedimentary rocks, with a mix of sandstone, mudstone, and limestone formations [44, 45]. The region is also home to some volcanic rock formations, including basalt and tuff [46, 47]. The geological features of the Horsham region are part of the larger Murray Basin, which covers an area of over 1 million square kilometres and is a large sedimentary basin that covers a significant portion of southeastern Australia [43, 48]. The sedimentary rocks in the region were formed from the accumulation of sediments that were eroded from the surrounding mountains and deposited in the shallow sea that covered the area during the Permian and Triassic periods [49].

The sediments in the Horsham region were deposited during the Permian and Triassic periods, around 250 to 300 million years ago [49]. Sandstone formations are the most prominent in the region, and they often contain fossils of ancient marine life, such as corals and mollusks [50]. The limestone formations in the region are mostly made up of shell fragments and calcium carbonate deposits from ancient marine organisms [51]. These formations can be found in the form of limestone cliffs and outcrops throughout the region.

Furthermore, the sandstones in this region often contain distinctive red and white layers, which are known as the Red Bluff Sandstone and the White Sandstone, respectively [46]. These sandstone formations are mainly made up of quartz grains, which were transported and deposited by rivers and ocean currents [46]. They also contain occasional layers of shale and siltstone, which were deposited in quieter environments [46]. The limestone formations in the region are relatively small in size but are significant in terms of their geological significance. These limestone formations are rich in fossils, which provide valuable information about the ancient marine life that once inhabited the area [51]. The Horsham region is also known for its groundwater resources, which are stored in porous sandstone and limestone formations. The aquifers in the region are an essential source of water for both agricultural and domestic use, and they play a vital role in supporting the region's economy.

The volcanic rocks in the Horsham region are the result of volcanic activity that occurred in the area around 2 million years ago [48]. The basalt formations are the most common, and they are often found in the form of lava flows and small hills. The tuff formations are the result of volcanic ash and rock fragments that were ejected during explosive volcanic eruptions. These formations can be found in the form of cliffs and outcrops throughout the region [50]. The volcanic rocks in the Horsham region are relatively young and were formed during the Tertiary period, around 2–3 million years ago [48, 51]. The most common volcanic rocks in the region are basalt and tuff. Basalt is a dark, dense, fine-grained volcanic rock that was formed from the solidification of lava flows [48]. Tuff is a lighter, more porous volcanic rock that was formed from the consolidation of volcanic ash and rock fragments that were ejected during explosive volcanic eruptions [48, 52].

Methodology

Materials

Locations of interest (16#) were initially identified around the Horsham region to explore potential gravel quarry creation. Due to the scope of this study and the accessibility of sites, three locations were selected for detailed sampling and investigation (refer to Fig. 1). Rules East and Polkemmet sites were located within 15 kms apart whereas the Roses Gap site is 50 kms away from these two sites. Table 1 presents the texture and soil condition of the target area based on two references [53, 54].

Sample collection was carried out using an auger drilling rig. Boreholes with a diameter of 0.3 m were drilled to a depth of 0.3–1 m (PR11/2 at 1–2 m) at each of the three site locations of interest. The sampling depths were chosen to be a minimum of 300 mm to ensure that the topsoil, which is typically stripped in earthworks, was removed and potential material disturbances were avoided. The extracted samples were transported to Deakin Laboratories for testing, which was conducted according to Australian Standard [55].

In Roses Gap, two boreholes were drilled, and samples were collected, the second borehole was approximately 80 m southwest of the first. Both boreholes were sampled at 0.3 m and 1 m depths. At the second site, located north of Horsham City, Rules East Road, a planned pit drilling operation revealed sedimentary rock at an average depth of 1 m, preventing drilling deeper with the auger. Three samples at depths of 0.3 m, 0.7 m, and 1 m were collected. Samples at depths of 1–2 m were collected from the third site on Polkemmet Road. All the samples were kept in sealed plastic bags and transported back to Deakin University Geotechnical Laboratory for necessary testing (refer to Fig. 2).

Site data were documented, including location, date, temperature, depth, etc., in accordance with Australian Standards for Geotechnical Site Investigations [56]. Nine soil samples collected from three distinct locations were assigned an identification (ID) number as depicted in Fig. 3. Each ID consists of four characters representing the soil sample:

-

The first two characters represent the name of the site.

-

The third character is the number of boreholes within the site.

-

The fourth character depicts the depth of the sample within that borehole.

In Fig. 3, the location of sample collection, sample number, initial and final IDs, depth of sampling, and mass of soil collected are depicted. However, sample RG11 was inadequate in quantity to carry out all the tests. Despite conducting a particle size distribution test on RG11, which yielded results comparable to RG13, it was concluded that repeating the collection of this sample was unnecessary. Similarly, not all geotechnical tests could be utilised on RE17 and RE11 samples due to their smaller masses. This constraint arose because, based on the desktop study (geology of area), we anticipated a nearly uniform composition of soil layers at various depths, up to 1.0 m, in both RG1 and RE1. However, subsequent soil testing revealed distinct properties in the two layers, contrary to our initial expectations. Another contributing factor was the initially planned smaller number of tests, but upon reviewing results, a decision was made to conduct a more comprehensive study on the soils. Unfortunately, the quantity of soils available for RE17 and RE11 proved insufficient for the expanded testing requirements. Subsequent particle size distribution tests conducted on these two samples revealed identical results. As a result, it was decided to combine these two samples into a single sample, designated RE19, to enhance the accuracy of the geotechnical tests. To achieve this, the soil was fully dehydrated in an oven (at 105 °C for 24 h) and then rehydrated with the appropriate amount of moisture necessary for the different tests. Seven samples of sufficient mass were obtained from the nine collected samples for all geotechnical tests. Figure 4 presents the picture of those seven samples used in the detailed investigation in this study. The moisture content (MC) of a sample was determined using the standard oven drying method [57] using an oven at 105–110 °C for 24 h.

To assess particle size distribution, both dry and wet particle distribution methods were employed. Initially, the samples were sieved mechanically to obtain soils above a size of 75 μm (coarse-grained soils). Subsequently, a hydrometer was utilised to determine the distribution of particles below 75 μm (refer to Fig. 5).

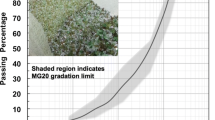

Figure 6 displays the results of sieve analysis and hydrometer tests used to determine the particle size distribution of all soil samples. The classification of the samples and their corresponding Coefficient of Curvature (Cc) and Coefficient of Uniformity (Cu) parameters are presented in Table 2. Austroads [57] guideline recommends that subgrade soil should consist of approximately 70–85% sand, 10–20% silt, and 5–10% clay under standard traffic conditions. The results revealed that soil samples obtained from shallow depths at site Rose Gap (RG) possess coarser granular properties that are suitable for use as subgrade soil. Conversely, samples from the same site taken at a depth of 1000 mm exhibit fine grains that are less appropriate for road construction projects. In contrast, samples from site Rules East (RE) show that both shallow and deep soils have suitable granularity for use in road construction projects. Based on the particle size distribution tests, it is evident that the shallow soil samples from site Polkemmet Road (PR) have a high percentage of fine grains, while the deeper soils (at a depth of 2000 mm) have coarser grading and are more suitable for road construction based on the Austroads [58] guideline. The Cc parameters for soils RG23, RE13, and RE19 range between 1 and 3, indicating that these soils are well-graded. Moreover, the Cu parameter is greater than 4 for all soil samples, indicating the non-uniformity of the soil. In general, non-uniformly graded soils with good grading are stronger in pavement design [59].

Compaction tests are performed to determine the maximum dry density and optimum moisture content of the soil, which are critical parameters for designing and constructing foundations, pavements, and other civil engineering structures. Figure 7 illustrates the initial moisture content (MC) of soil samples obtained from three different sites, PR, RG, and RE. The results indicate that site PR had the highest moisture content, with values of 18.0% and 28.0% at depths of 1000 mm and 2000 mm, respectively. In contrast, samples from the shallow layer (300 mm) of site RG had a lower moisture content, with values of 9.0% and 8.6% for RG13 and RG23, respectively. However, samples extracted from a depth of 1000 mm in site RG had a moisture content of 16.2% and 17.9% for RG11 and RG21, respectively. The results for site RE were slightly different, with surface samples (RE13 and RE17) having higher moisture content compared to sample from a deeper depth (RE11) at 1000 mm.

These findings are relevant to the water supply issue in road construction projects. Water required for soil compaction is a crucial aspect of road construction, and having an appropriate moisture content can significantly reduce project costs. Therefore, the knowledge of soil moisture content in various sites can be helpful in the planning and execution of road construction projects.

In this study, Atterberg tests were carried out on seven soil samples to evaluate their plastic and liquid limits, and the results are presented in Table 3. As depicted in Table 3 and Fig. 8, it is observed that soil samples PR11 and PR12 have higher Atterberg limits, indicating a wider safe interval in their solid and semi-solid phases. Conversely, soil sample RG23 exhibits considerably lower Atterberg limits, indicating its high sensitivity to liquefaction and water addition due to its sandy composition. In conclusion, the Atterberg limit tests suggest that soil samples PR11, PR12, RG13, RG21, RE13, and RE19 are capable of withstanding water absorption before undergoing liquefaction.

Laboratory Testing

This section discusses the geotechnical tests conducted on soil samples obtained from three different sites of the study area i.e., the Horsham region of Western Victoria to determine soil characteristics and mechanical properties.

Compaction (Proctor) Test (CT)

The determination of the optimal moisture content (OMC) and maximum dry density (MDD) of soil samples is a crucial step in assessing their compaction characteristics. In accordance with AS-1289.5.2.1 [60], all soil samples were subjected to at least four compaction tests, with coarse gravel being removed by passing the samples through a 19 mm sieve. A moisture-dry density graph was plotted for each sample, with MDD and OMC being identified by drawing the best curve from four data points at the peak of the graph. Figure 9 provides a schematic diagram and dimensions of the compaction test employed. Each soil sample was compacted using a standard hammer (2.7 kg) in three layers with 25 blows per layer, at a drop height of 300 mm, to achieve the desired compaction.

California Bearing Ratio (CBR) Test

The CBR tests serve the purpose of evaluating the strength of subgrade under standardized forces, which aids in selecting appropriate pavement layer thicknesses and materials. Prior to the test, the samples are compacted to the optimum moisture content (OMC) and maximum dry density (MDD), which are obtained through compaction tests. During the test, an automated penetration piston is used to penetrate the sample to a depth of 12.5 mm, and load and penetration data are recorded for analysis using GDS laboratory equipment. The standard compaction method is employed, consisting of three layers with 25 hammer blows per layer. The weight of each layer is determined based on the MDD and OMC and is used to ensure accurate spacing of the sample in a mould with a diameter of 150 mm and a height of 117 mm after placing the spacer.

The GDS laboratory equipment's penetration rate was set at 1 mm per minute, in accordance with the relevant standard. To determine soil moisture, two samples were extracted from different depths within the sample (30 mm from both above the sample and at the bottom). The average of the two moisture contents of these two depths was used to determine the final moisture content of the sample. During the test, target compaction of 98% of maximum dry density was assumed. The CBR2.5 and CBR5 values were calculated using the equations specified in AS-1289.6.1.1 [61], with the highest value being reported in accordance with established practice:

where CBR2.5 and CBR5 are CBR values (%) adjusted at 2.5 and 5 mm, and F2.5 and F5 are force (in kN) at penetration of 2.5 mm and 5 mm, respectively.

Unconfined Compressive Strength (UCS) Test

The Unconfined Compressive Strength (UCS) test is used to determine the Unconfined Compressive Strength (UCS) of UGMs, which demonstrates their cohesive properties under zero confining stress. In this study, the UCS test was only used for two samples to confirm the results of CBR tests. The UCS testing method involves compacting a soil sample in a cylindrical mould with three layers and 25 hammer blows at OMC/MDD. The compacted sample, with the size of 100 mm in height and 50 mm in diameter, is then removed from the mould and placed under the piston arm, compressed at a rate of 1 mm per minute until failure occurs. The type of failure, such as shearing along a single plane, double, fracture, foliation, etc., is recorded, and the data are saved in GDS lab software for analysis. The results should indicate the soil's failure envelope or circle, identifying the maximum compressive strength. This method is detailed in AS-5101.4 [62].

Repeated (Cyclic) Loading Triaxial (RLT) Test

The purpose of conducting the repeated load triaxial (RLT) test is to evaluate the permanent deformation (PD) of the unbound granular material (UGM) resulting from cyclic vertical loading over time. The test involves the application of confining pressure, followed by cyclic vertical loading. Moreover, the settlement of the sample is measured during various cycles of vertical loading, as per AS-1289.6.8.1 [63].

The triaxial cell utilised in the RLT testing method contains specimens measuring 50 mm in diameter and 100 mm in height and has a working pressure range of up to 500 kPa. The static confining pressure exerted by the triaxial cell acts as chamber pressure (σ3). This test is conducted to determine the permanent deformation of a specimen without sample saturation and consolidation and with only a cyclic vertical stress stage. The schedule of tests is established based on previous research conducted by Barksdale and Hicks [64], who concluded that 1000 load cycles are sufficient for cohesionless samples. According to the European standard [65], more than 20,000 load cycles may be adequate [66, 67]. In this project, the final number of cycles is 30,000, with 2000 cycles in each stage, and at least 100 cycles are required in each stage, as per the European standard [65]. Therefore, the automated cyclic tests implemented in this project consist of 15 stages, with details presented in Table 4. Additionally, the loading pressure is determined based on the final strength of the samples obtained from the UCS test to ensure they can withstand multiple stages and complete the cyclic triaxial test.

The cyclic triaxial test samples were prepared with a diameter of 50 mm and a height of 100 mm. The compaction process involved compacting each sample into three layers of equal thickness to achieve a target density of 98% of maximum dry density, with the moisture content equal to the optimal moisture content derived from the compaction test. The samples were sealed airtight with a membrane stretcher. Additional details of the methodology can be found in AS-1289.6.8.1 [63].

Results and Discussion

Proctor Compaction Test

Each soil specimen has been subjected to a minimum of four compaction tests. Compaction tests were executed on various samples, and the results are depicted in Table 5 and Fig. 10. The soil collected from site PR revealed high porosity and water absorption ability, leading to a high optimal moisture content. Although the requirement for extra water for compaction may seem like a concern, the soil had a high initial moisture content, implying that only a slight increase in moisture content would suffice to attain the optimal moisture content, making it an ideal material for road construction. For example, PR12 had an initial moisture content of 28.0% and an optimal moisture content of 29.5%, requiring only a 1.5% increase in moisture content. Samples from site RE exhibited high-density values and optimal moisture content of 13.2% and 13.4% for the two samples, respectively, making it an ideal moisture content for soil compaction. As the initial moisture content of these samples was 10.2% and 12.6%, this site is also economically feasible in terms of water supply issues for soil compaction. The compaction test results of the RG site showed that the optimal moisture content of location number 2 samples of this site was very close to the natural moisture content, which is highly beneficial for road construction. Besides, the surface soil of location number 2 (RG23) had the highest maximum dry density among all soil samples, which is valuable. However, the difference between the optimum and natural moisture content of location number 1 on this site is relatively high (about 7%), which may negatively impact the water supply compared to other soil samples. The results shown in Fig. 10 indicate that the RG23 soil is situated within an area characterized by fine sandy soil, whereas the PR12 soil is found in an area with heavy clay content. This distinction can significantly influence their respective mechanical behaviours. Moreover, the soils obtained from the PR region, in general, exhibit a finer texture compared to soils from other regions and possess a higher optimal moisture content. Additionally, the figure includes the zero-air void curve, which represents the condition where the soil contains no air.

To understand the reasons behind the results presented in Table 5, it is needed to consider the properties of soils and how they affect their behaviour under compaction. The particle size distribution of soils is an essential factor that affects their compactibility. Soils with a wide range of particle sizes and a well-graded distribution tend to have better compactibility than soils with a narrow range of particle sizes and a poorly graded distribution. This is because the presence of different particle sizes allows for better interlocking, which increases the soil's resistance to deformation under compaction.

The results of particle size distribution in Fig. 6 show that some soils have a well-graded distribution of particle sizes, such as RG23 and RE13, while others have a poorly graded distribution, such as RG21 and PR11. This difference in particle size distribution can explain why some soils have higher maximum dry densities and lower optimum moisture contents than others, as shown in Table 5. For example, RG23 has a higher maximum dry density and lower optimum moisture content than RG21, likely due to the better interlocking of particles in RG23. The interlocking of particles in RG23 is likely to be more effective, leading to better compactibility and a higher maximum dry density.

Another factor that affects the compaction characteristics of soils is their moisture content. A soil's optimum moisture content is the moisture content at which it achieves its maximum dry density. If the moisture content is too low, the soil will be too dry and resist compaction. If the moisture content is too high, the soil will be too wet and also resist compaction. Therefore, it is important to find the optimum moisture content to achieve maximum compaction.

The optimal moisture content in compaction tests is influenced by various factors including soil type, applied compaction energy, particle size distribution, and soil structure. Clayey soils typically exhibit a higher optimal moisture content compared to sandy and granular soils. For instance, in Fig. 10, samples RR11 and PR12, characterized by higher clay content, demonstrated the highest moisture content at 22.3% and 29.5%, respectively. This can be attributed to the active nature of clay, enabling it to absorb more water and exchange ions. Conversely, soil samples with higher proportions of sand and gravel, such as RG23 and RE13 and RE19, exhibit lower optimal moisture levels of 6.2%, 13.2%, and 13.4%, respectively, as illustrated in Fig. 10 and Table 5. Also, the compaction energy level plays a role in this relationship, with higher energy levels generally associated with lower optimal moisture content. It is worth noting that in this study, all samples underwent compaction under the same energy conditions.

California Bearing Ratio (CBR) Test

CBR tests were conducted on all seven soil specimens collected from the site, and the results are presented in Fig. 11. Notably, sample RG23 displayed distinctive behaviour in comparison to the remaining specimens. To validate this peculiarity, another test was conducted on the RG23 samples and results are presented in Fig. 12. It is seen in Fig. 12 that there is no difference in the results of the two tests and findings demonstrate that soil RG23 exhibits divergent behaviour compared with other specimens.

CBR values for both 2.5 mm and 5 mm penetrations have been calculated using Eqs. 1 and 2 and are presented in Table 6 for all samples. The results are expressed as a percentage of the load required to penetrate the soil sample to a depth of 2.5 mm and 5 mm using a standard circular plunger at a rate of 1 mm/min. The highest CBR value indicates the maximum load-bearing capacity of the soil sample. For each sample, the Table 6 shows the CBR values for two depths (CBR2.5 and CBR5) and the highest CBR value was accepted as the CBR of the soil. Looking at the table, it can be seen that the soil samples have varied CBR values. Sample RG23 has the highest CBR values of 26.21 and 28.27 for depths 2.5 mm and 5 mm, respectively, and the highest value of 28.27. This indicates that sample RG23 has a very high load-bearing capacity and is suitable for construction purposes. RG23 is a sandy soil and sandy soils are composed of larger, well-graded particles that tend to interlock more effectively than the smaller particles found in clay soils. This interlocking provides better load-bearing capacity and contributes to higher CBR values. Sandy soils often exhibit higher shear strength compared to clayey soils. The ability of the soil particles to resist shear forces contributes to increased load-bearing capacity, reflected in higher CBR values.

Furthermore, samples RG13 and RG21 have lower CBR values, indicating a relatively weaker load-bearing capacity. However, they still can be used for some construction purposes after proper preparation and reinforcement. Samples RE13, RE19, PR11, and PR12 have moderate to high CBR values. Sample PR12 has the second highest CBR value of 14.84, which is relatively high, indicating that it has a high load-bearing capacity and can be used for construction purposes.

The results obtained indicate that both sites, Rules East (RE) and Polkemmet Road (PR), demonstrated acceptable performance at both low and high soil depths. Notably, samples RE19 and PR12 were found at deeper depths at their respective sites. Sample RG23's CBR behaviour was somewhat unusual, compatible with what was seen in the load-penetration curve. According to variation theory, RG23 had the highest MDD (2.08 g/cm3) and the lowest OMC (6%) among all samples, and its CBR value was accepted as that of well-graded sand.

Unconfined Compressive Strength (UCS) Test

To explore the exceptional behaviour of sample RG23 in the CBR test, additional UCS tests were carried out on samples RG23 and PR12, and the results were compared. The data revealed that RG23 failed at 20 kPa, which was 18 times lower than PR12, indicating exceedingly low cohesive properties of the material under zero confining stress (as depicted in Fig. 13). These findings imply that, despite its good CBR value, RG23's deficient cohesive property renders it unsuitable for use in subgrade layers.

Repeated Loading Triaxial (RLT) Tests

To investigate the performance of different soil samples during repeated traffic loads, replicable with pavement design and construction scenarios, repeated triaxial tests were conducted as described in the methodology section and following the loading plan presented in Table 4. Figure 14a, b illustrates a soil sample before and during a repeated triaxial test. In the test cell, the sample is well-fixed in place so that there is no additional vibration during the loading cycles. Figure 15 also shows a failed sample after 15 stages of cyclic loading. It can be seen from Fig. 15 that the specimen failed along a failure plane which is the weakest plane in shear strength due to vertical cyclic loading. As is evident from Fig. 15, in cyclic tests, there is a failure zone cantered on one surface due to cyclic loading.

The results of cyclic triaxial tests based on cumulative permanent displacement at different loading stages are presented in Fig. 16. Three soil samples with the highest vertical settlement after 15 stages of cyclic loading were RG23, RG21, and RG13, with settlements of 15.17 mm, 2.95 mm, and 1.95 mm, respectively. On the other hand, samples PR12, RE19, RE13, and PR11 had the lowest settlements and showed the most successful performance in the cyclic triaxial test, with 0.68 mm, 0.82 mm, 1.01 mm, and 1.29 mm of permanent displacement, respectively. These findings align with the CBR test results, indicating the complementarity of repeated triaxial and CBR tests in the design of road and pavement construction. Nonetheless, the weak performance of sample RG23, which was previously discussed in the CBR and UCS tests sections, remains a special case of poor behaviour in geotechnical tests.

In Fig. 17, the results of the cyclic triaxial tests for all soil samples are presented based on the number of loading cycles against permanent axial settlement and strain. Figure 17a, b reveals that the cumulative permanent axial settlement and strain increased with an increase in loading cycles. After 30,000 loading cycles, soil RG23 exhibited the most inadequate performance, while soils PR12, RE19, RE13, and PR11 demonstrated the most appropriate performance, consistent with the findings presented in terms of stage number, i.e., Fig. 16. Considering the limit of vertical strain to 1% according to existing guidelines, such as Weng and Wang [68] and Austroads [69], soil RG23, with a strain of 1.5%, is unsuitable for use as a pavement material. As a result, sites PR and RE are the most suitable locations for the samples to be used in road and pavement construction, based on the triaxial test results presented in this section.

Soil Liquefaction

Soil liquefaction is a phenomenon wherein the strength and stiffness of soil are compromised, often occurring during seismic events when there is an accumulation of pore pressure. The California Bearing Ratio (CBR) test is instrumental in assessing the potential for liquefaction, providing valuable information about a soil's ability to withstand vertical loads and maintain stability. Analysing the CBR results for various soil samples reveals distinct liquefaction susceptibilities. Table 7 provides the range of highest CBR values for all soils under investigation, along with a rating or usage classification for each sample according to relevant standards. The highest CBR value, observed in RG23, implies good subgrade/base suitability; however, its unexpectedly low shear strength performance in the Unconfined Compressive Strength (UCS) test raises concerns. This underscores the complexity of soil behaviour, highlighting that a high CBR alone may not guarantee resistance to liquefaction. Conversely, materials from RG13 and RG21, displaying the lowest CBR values, are categorized as "Poor to Fair" for subgrade use, indicating a higher likelihood of susceptibility to liquefaction. The need for additional layers or reinforcement is emphasized for these materials to support heavy traffic loads securely.

Examining the broader spectrum of CBR values across different samples reveals variations in liquefaction potential. Materials falling within the CBR range of 6.45–14.84 are considered "Poor–Fair" or "Fair" for subgrade use. While suitable for lighter traffic loads, these materials may require additional layers or reinforcement when subjected to heavier loads, ensuring stability and minimizing the risk of liquefaction-related issues during seismic events.

Comparison of Results

Table 8 shows the conditions of each sample based on different mechanical tests undertaken in this study. In this table, the green colour indicates the capability of the sample in the intended test to be used in road construction projects as per available Australian standards (detailed explanation of suitability range have been presented in earlier sections), whereas the white colour indicates unsatisfactory performance. The results indicate that samples of site RE for both shallow and deep depths (RE13 and RE19) produce acceptable results for use in road construction. Also, samples of 2000 mm depth at site PR (PR12) are very suitable for road construction. Finally, samples of 1000 mm depth at site PR (PR11) can also be considered as the fourth option among all samples.

The sandy nature of soil RG23 renders it unsuitable for pavement construction, as demonstrated by its poor performance in Atterberg tests, UCS, and repeated triaxial tests. Meanwhile, samples RG13 and RG21 performed inadequately in CBR tests but may be considered for use on low-traffic roads with caution. Specifically, they may be suitable for roads with less than 30 vehicles per day and no more than 15% heavy vehicles, particularly those without subgrade, subbase, or base layers and instead only a layer of gravel is laid over this surface. Such roads are intended to provide access to farmers during wet weather. Using locally sourced such materials, despite their low strength and high permanent settlement, can provide a more cost-effective option compared with transporting high CBR gravels hundreds or thousands of kilometres away. However, further research should be conducted to determine soil permeability and hydraulic conductivity during the rainy seasons. Additionally, static triaxial/direct shear tests should be conducted if these materials are used on thick pavements, and low-cost additives or recycled materials may be added to slightly increase their strength and efficiency. The optimal composition ratio of these soil samples should be analysed to maximise their strength, and numerical analysis should be performed to determine the maximum safe thickness for these soil samples.

Implications of Results

The implications of this study’s results are significant for road pavement design and construction. The study provides information on the mechanical properties and suitability of different unbound granular materials (UGMs) for subgrade applications, which is essential for selecting the appropriate soil for meeting industry standards and stakeholder demands. The study's findings suggest that different UGM samples have different mechanical properties, and their suitability for subgrade applications depends on their particle size, clay content, sand content, and CBR strength value.

The study's results suggest that the Roses Gap (RG13/RG21/RG23) UGM samples are not suitable for subgrade applications due to their poor cohesion properties and significant vertical displacement after loading cycles. RG21, with a higher clay content, was the most practical choice for subgrade among the Roses Gap samples. The Rules East (RE13 and RE19) UGM samples exhibited similar mechanical properties and could be used in low-traffic subgrades, but their low cohesion from clay content made them unsuitable as a sole choice in road pavement design.

The Polkemmet Road samples (PR11 and PR12) were both suitable for subgrade applications, with PR12 being the top recommendation due to its acceptable particle sizing, large range of particle sizes, and high CBR strength value. However, PR11, with a high fine particle content, was not recommended due to restricted water circulation within the particles resulting in slow drainage.

The study's findings have several practical applications in the field of road pavement design and construction. For example, the knowledge gained from this study can be used to select the appropriate soil for subgrade construction in road pavements, which is critical for ensuring the long-term performance and safety of road infrastructure.

The study's results can also be used to optimise the design of road pavements, especially in rural areas where the availability of suitable materials is limited. By understanding the mechanical properties of different UGMs, road designers can select the most suitable materials for subgrade construction, which can help reduce the costs associated with road pavement construction and maintenance.

Furthermore, the study's results can be used to improve the sustainability of road pavement construction. By selecting suitable UGMs, road designers can reduce the environmental impact of road construction by minimising the use of non-renewable resources and reducing waste.

Limitations of the Study

Notwithstanding the progress achieved in this investigation, there are some limitations to the present study. Potential limitations are:

-

Limited sample size: The study only investigated UGMs from a specific point of interest of an industry partner. The findings may not be generalizable to other areas with different soil characteristics, which limits the applicability of the results.

-

Limited testing methods: The study only performed a few geotechnical tests (PSD, CT, CBR, UCS, RLT) to evaluate the mechanical properties of the UGMs. Other important tests, such as permeability or shear strength, were not performed.

-

Limited consideration of environmental factors: The study did not take into account potential environmental factors that could impact the longevity and mechanical behaviour of pavement structures. Factors such as climate, precipitation, and freeze–thaw cycles could affect the performance of the UGMs and should be considered.

Future Topics and Opportunities

This study provides an overview of the suitability of unbound granular materials (UGM) collected from three distinct locations in the Horsham region for potential use in road construction and pavement projects. It represents a pioneering study that investigates these sites through comprehensive geotechnical testing, with significant opportunities identified for further research. Several practical and relevant topics that could be explored in greater depth are discussed below.

-

The impact of wetting and drying cycles on pavement material performance: Wet and dry cycles caused by precipitation events are among the most significant factors affecting pavement materials, leading to potential cracking and reduced performance. This study aims to assess the performance of the introduced materials under different wetting and drying conditions.

-

Numerical simulation of large-scale road paving using the introduced materials: To evaluate the performance of pavements utilizing the introduced materials under various loads and identify optimal designs, it is possible to use engineering software to model different pavement scenarios and assess their performance.

-

Additive incorporation to improve material performance and reduce costs associated with water supply and compaction equipment: The addition of various additives to existing materials can eliminate some of their drawbacks and lower project costs. For example, reducing the amount of water and energy required for compaction can result in cost savings. This project aims to evaluate existing additives and recommend optimal additions through experimental testing.

-

Experimental assessment of UGM water retention behaviour under infiltration: UGMs used in permeable pavements are prone to significant infiltration over their useful life, and their mechanical properties can be affected by changes in humidity. However, there is limited evidence regarding the impact of infiltration on the load capacity and storage behaviour of UGMs. The purpose of this study is to investigate this issue through experimental testing.

Summary and Conclusion

The subgrade or base of a road pavement plays a crucial role in determining the longevity and mechanical behaviour of the pavement structure. Therefore, it is necessary to investigate the performance of unbound granular materials (UGMs) used in such layers to choose suitable soil mechanical behaviours that satisfy the demands of stakeholders and industry standards. Here are the most important results:

-

Samples from the Rules East (RE13, RE19) and Roses Gap (RG13, RG21, RG23) regions in the Horsham area of western Victoria, Australia, exhibit high sand content and poor cohesion properties. However, they can be used as fine particle fillers in coarse gravel materials.

-

Among the Roses Gap samples, RG21, with higher clay content, showed the most promising results. It demonstrates good water absorption performance and may have potential for certain applications.

-

RG13 and RG21 lack the cohesive strength required for high-traffic volume roads and are not recommended for such use. However, they may be suitable for low-traffic volume roads, such as local access roads for farmers (less than 30 vehicles per day, no more than 15% heavy vehicles), although further investigation is recommended.

-

RE13 and RE19 samples have similar mechanical properties and can be used to a certain degree in low-traffic subgrades. However, their limited cohesion from clay content makes them unsuitable as the sole choice in road pavement design.

-

Soils from deeper depths at the RE19 location exhibit better performance in terms of permanent deformation compared to soils from shallow depths at RE13.

-

The Polkemmet samples PR11 and PR12 are potential choices for subgrade applications. PR11, with high fine particle content, is not recommended due to restricted water circulation and slow drainage. On the other hand, PR12, with coarser particles, is the top recommendation overall, satisfying PSD, CBR, and RLT test conditions with acceptable particle size, high CBR strength value, and low permanent displacement.

This study contains important test results that will be useful in making recommendations regarding the application of such materials in the design of road pavements. The study will also be beneficial in characterizing rural materials around Horsham for future use in various other contexts, including land/road development and pavement (subgrade) construction.

Despite the progress made in this investigation on unbound granular materials (UGMs) for road construction, there are notable limitations. The study's sample size is restricted to a specific industry partner's point of interest, potentially limiting the generalizability of findings to areas with different soil characteristics. The testing methods employed, while comprehensive, did not include crucial assessments such as permeability or shear strength. Furthermore, environmental factors impacting pavement longevity were not considered. Future research opportunities lie in exploring the impact of wetting and drying cycles on pavement materials, conducting numerical simulations for large-scale road paving using UGMs, incorporating additives to enhance material performance and reduce costs, and experimentally assessing UGM water retention behaviour under infiltration. These avenues aim to address the study's limitations and contribute valuable insights to the field of road construction and pavement projects.

Data Availability

The datasets generated and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Hughes C (2020) Australia: length of roads by state 2018|Statista [Internet]. Statista. https://www.statista.com/statistics/1030909/australia-length-of-roads-by-state/

Aulich C (1999) From convergence to divergence: reforming Australian local government. Aust J Public Adm 58(3):12–23

Taha R, Al-Harthy A, Al-Shamsi K, Al-Zubeidi M (2002) Cement stabilization of reclaimed asphalt pavement aggregate for road bases and subbases. J Mater Civ Eng 14(3):239–245

Abu-Farsakh MY, Chen Q, Hanandeh S (2019) Accelerated load testing of geosynthetic base reinforced/stabilized unpaved and pavement test sections (No. FHWA/LA. 18/603). Louisiana. Department of Transportation and Development

Hill AR, Dawson AR, Mundy M (2001) Utilisation of aggregate materials in road construction and bulk fill. Resour Conserv Rec 32(3–4):305–320

Caicedo B, Coronado O, Fleureau JM, Correia AG (2009) Resilient behaviour of nonstandard unbound granular materials. Road Mater Pavement Des 10(2):287–312

Araya AA, Huurman M, Molenaar AA, Houben LJ (2012) Investigation of the resilient behaviour of granular base materials with simple test apparatus. Mater Struct 45:695–705

Rahman MS, Erlingsson S (2015) A model for predicting permanent deformation of unbound granular materials. Road Mater Pavement Des 16(3):653–673

Falla GC, Leischner S, Blasl A, Erlingsson S (2017) Characterization of unbound granular materials within a mechanistic design framework for low volume roads. Trans Geot 13:2–12

Alnedawi A, Nepal KP, Al-Ameri R (2018) Mechanistic behaviour of open and dense graded unbound granular materials under traffic loads. Geomate J 14(45):124–129

Alnedawi A, Kafle B, Ullah S, Kerr W (2021) Investigation of non-standard unbound granular materials under cyclic loads: experimental and regression analyses. Int J Pavement Eng. https://doi.org/10.1080/10298436.2021.1877291

Huhtala M (2020) COST 337—unbound granular materials for road pavements. In: Bearing capacity of roads, railways and airfields, pp 1023–1030

Sangsefidi E, Larkin TJ, Wilson DJ (2021) The effect of weathering on the engineering properties of laboratory compacted unbound granular materials (UGMs). Const and Build Mat 276:122242

Leischner S, Spanier T, Falla GC (2022) Effective experimental characterization of the non-linear elastic deformation behaviour of unbound granular materials. In: Eleventh international conference on the bearing capacity of roads, railways and airfields, vol 2, pp 435–444

Defossez P, Richard G, Boizard H, O’Sullivan MF (2003) Modeling change in soil compaction due to agricultural traffic as function of soil water content. Geoderma 116(1–2):89–105

Shaxson F, Barber R (2003) Optimizing soil moisture for plant production: the significance of soil porosity. UN-FAO, Rome

Ray RL, Jacobs JM, de Alba P (2010) Impacts of unsaturated zone soil moisture and groundwater table on slope instability. J geotech Geoenviron Eng 136(10):1448–1458

Greco R, Guida A, Damiano E, Olivares L (2010) Soil water content and suction monitoring in model slopes for shallow flowslides early warning applications. Phys Chem Earth Parts A/B/C 35(3–5):127–136

Sl SU, Singh DN, Baghini MS (2014) A critical review of soil moisture measurement. Measurement 54:92–105

Garg A, Bordoloi S, Ni J, Cai W, Maddibiona PG, Mei G, Poulsen TG, Lin P (2019) Influence of biochar addition on gas permeability in unsaturated soil. Géotech Lett 9(1):66–71

Xiao Y, Tutumluer E, Qian Y, Siekmeier JA (2012) Gradation effects influencing mechanical properties of aggregate base–granular subbase materials in Minnesota. Trans Res Rec 2267(1):14–26

Jibon M, Mishra D, Kassem E (2020) Laboratory characterization of fine-grained soils for Pavement ME Design implementation in Idaho. Trans Geotech 25:100395

Wen B, Aydin A, Duzgoren-Aydin NS (2002) A comparative study of particle size analyses by sieve-hydrometer and laser diffraction methods. Geotech Test J 25(4):434–442

Park TW, Kim HJ, Tanvir MT, Lee JB, Moon SG (2018) Influence of coarse particles on the physical properties and quick undrained shear strength of fine-grained soils. Geomech Eng 14(1):99–105

Salimnezhad A, Soltani-Jigheh H, Soorki AA (2021) Effects of oil contamination and bioremediation on geotechnical properties of highly plastic clayey soil. J Rock Mech Geotech Eng 13(3):653–670

Poon CS, Chan D (2006) Feasible use of recycled concrete aggregates and crushed clay brick as unbound road sub-base. Constr Build Mater 20(8):578–585

Baghbani A, Nguyen MD, Alnedawi A, Milne N, Baumgartl T, Abuel-Naga H (2023) Improving soil stability with alum sludge: an AI-enabled approach for accurate prediction of California Bearing Ratio. Appl Sci 13(8):4934

Nguyen MD, Baghbani A, Alnedawi A, Ullah S, Kafle B, Thomas M, Milne NA (2023) Investigation on the suitability of aluminium-based water treatment sludge as a sustainable soil replacement for road construction. Transp Eng 12:100175

Lu Y, Xu C, Baghbani A (2023) Initial state of excavated soil and rock (ESR) to influence the stabilisation with cement. Constr Build Mater 400:132879

Qiao Y, Dawson AR, Parry T, Flintsch G, Wang W (2020) Flexible pavements and climate change: a comprehensive review and implications. Sustainability 12(3):1057

Plati C, Tsakoumaki M (2023) A critical comparison of correlations for rapid estimation of subgrade stiffness in pavement design and construction. Constr Mater 3(1):127–142

Oloo SY, Fredlund DG, Gan JK (1997) Bearing capacity of unpaved roads. Can Geotech J 34(3):398–407

Korkiala-Tanttu L (2005) A new material model for permanent deformations in pavements. In: Proceedings of the international conferences on the bearing capacity of roads, railways and airfields

Parreira AB, Gonçalves RF (2000) The influence of moisture content and soil suction on the resilient modulus of a lateritic subgrade soil. In: ISRM Int Sym. OnePetro

Kumar A, George V (2018) Effect of soil parameters on resilient modulus using cyclic tri-axial tests on lateritic subgrade soils from Dakshina Kannada, India. Geotech Geol Eng 36(6):3987–4000

Uzan J (1999) Granular material characterization for mechanistic pavement design. J Transp Eng 125(2):108–113

Nagabhushana MN, Tiwari D, Jain PK (2013) Rutting in flexible pavement: an approach of evaluation with accelerated pavement testing facility. Procedia Soc Behav Sci 104:149–157

Erlingsson S, Rahman MS (2013) Evaluation of permanent deformation characteristics of unbound granular materials by means of multistage repeated load triaxial tests. Transp Res Rec 2369(1):11–19

Gidel GP, Hornych JJ, Chauvin D, Breysse A, Denis A (2001) New approach for investigating the permanent deformation behaviour of unbound granular material using the repeated load triaxial apparatus. Bridges Roads Lab Liaison Bull 233:5–21

Li J, Zhang J, Zhang A, Peng J (2022) Evaluation on deformation behaviour of granular base material during repeated load triaxial testing by discrete-element method. Int J Geomech 22(11):04022210

Sukkar F (2011) The stabilization of urban pavements founded on expansive clay subgrades in Victoria, Australia. Doctoral dissertation, Swinburne University of Technology

Hutley N, Dean A, Hart N, Daley J (2022) Uninsurable nation: Australia's most climate-vulnerable places.

Herczeg AL, Dogramaci SS, Leaney FWJ (2001) Origin of dissolved salts in a large, semi-arid groundwater system: Murray Basin, Australia. Mar Freshe Res 52(1):41–52

Moore DH, Maher S (1998) Lessons from a case study of a geophysical interpretation in Western Victoria. Exp Geophys 29(3–4):524–530

Lisitsin VA, González-Álvarez I, Porwal A (2013) Regional prospectivity analysis for hydrothermal-remobilised nickel mineral systems in western Victoria, Australia. Ore Geol Rev 52:100–112

Jaireth S, Hoatson DM, Miezitis Y (2014) Geological setting and resources of the major rare-earth-element deposits in Australia. Ore Geol Rev 62:72–128

Moore DH, VandenBerg AHM, Willman CE, Magart APM (1998) Palaeozoic geology and resources of Victoria. AGSO J Aust Geol Geophys 17:107–122

Bowler JM, Kotsonis A, Lawrence CR (2006) Environmental evolution of the Mallee region, western Murray Basin. Proc R Soc Victoria 118(2):161–210

King L (1959) Denudational and tectonic relief in South-Eastern Australia. S Afr J Geol 62(1):113–138

Bednarik RG (2010) Discriminating between cupules and other rock markings. Mysterious cup marks. BAR Int Ser 2073:41–51

Miranda JA, Wallace MW, McLaren S (2009) Tectonism and eustasy across a Late Miocene strandplain: the Loxton-Parilla Sands, Murray Basin, southeaster Australia. Sediment Geol 219(1–4):24–43

GOV V (1982) Victoria Geological Map. Retrieved from Geological Survey of Victoria: http://earthresources.efirst.com.au/product.asp?pID=254&cID=31&c=17563

Geological Survey of Victoria (1982) Victoria 1:2500000 geological map. Geological Survey of Victoria (depi.vic.gov.au/vro)

VSIS (2014) Soil texture. Retrieved from Victorian Resources Online: https://vro.agriculture.vic.gov.au/dpi/vro/vrosite.nsf/pages/soil_soil-texture

AS1726.5.5.4 (2017) Sample handling and Management - Geotechnical Site Investigation. SAI Global. Retrieved from https://www.saiglobal.com/

AS-1726 (2017) Geotechnical site investigations. Australian Standard NSW: SAI Gloal. Retrieved 2022, from https://www.saiglobal.com

AS-1289.2.1.1 (2005) Soil moisture content tests, determination of the moisture content of a soil, Oven drying method (standard method). Standards Australia (AS)

Austroads (2019) Guide to pavement technology part 4D. Retrieved from Austroads: https://austroads.com.au/__data/assets/pdf_file/0033/179673/AGPT04D-19_Guide_to_Pavement_Technology_Part_4D_Stabilised_Materials.pdf

Nikolaides A (2014) Highway engineering: pavements, materials and control of quality. CRC Press

AS-1289.5.2.1 (2017) Soil compaction and density tests, determination of the dry density/moisture content relation of a soil using MOdified compactive effort. Standards Austrlia (AS)

AS-1289.6.1.1 (2014) Determination of the California bearing ratio of a soil, Standard laboratory method for a remoulded specimen. Standards Australia (AS).

AS-5101.4 (2008) Unconfined Compressive strength of compacted materials. Retrieved from SAI global: www.siaglobal.com

AS-1289.6.8.1 (1995) Soil strength and consolidation tests, determination of the resilient modulus and permanent deformation of granular unbound pavement materials. Standards Australia (AS)

Barksdale RD, Hicks RG (1972) Evaluation of materials for granular base courses. In: Proc 3rd Int Conf on Materials Technology (Rio de Janeiro)

EN 13286-7 (2004) Unbound and hydraulically bound mixtures—part 7: cyclic load triaxial testfor unbound mixtures. Comite Europeen de Normalisation

Young MA, Baladi GY (1977) Repeated load triaxial testing state of the art RR-477. Michigan Department of Transportation

Kaluder J (2019) Cyclic load triaxial test procedures for soils in transportation engineering. IOP Conf Ser Mater Sci Eng 566(1):012013

Weng X, Wang W (2011) Influence of differential settlement on pavement structure of widened roads based on large-scale model test. J Rock Mech Geotech Eng 3(1):90–96

Austroads (2019) RD-PV-D1 Pavement Design. Austroads Publication, Cham

Austroads (2018) Guide to Pavement Technology Part 4A Granular Base and Subbase Materials. Austroads Pub, pp 1–64

Bowles JE (1992) Engineering properties of soils and their measurement. McGraw-Hill, Inc.

Acknowledgements

The authors express their gratitude to Horsham Rural City Council for providing the financial support and opportunity to work on a project investigating unbound granular materials for road pavements. They also thank the project support team, field staff, and Deakin University laboratory staff for their crucial contributions.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions. Partial financial support was received from Horsham Rural City Council for research leading to these results.

Author information

Authors and Affiliations

Contributions

Conceptualization: BK; Methodology: BK, RP; Formal analysis and investigation: AB, RP; Writing—original draft: BK, AB; Writing—review and editing: BK, AB, RP, KS; Funding acquisition: BK; Resources: BK, KS; Supervision: BK.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kafle, B., Baghbani, A., Pempeit, R. et al. Investigating the Mechanical Behaviour of Unbound Granular Material (UGM) for Road Pavement Construction Applications: A Western Victoria Case Study. Int. J. of Geosynth. and Ground Eng. 10, 29 (2024). https://doi.org/10.1007/s40891-024-00543-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-024-00543-5