Abstract

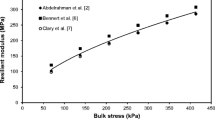

This study aims to assess the long-term performance of fly ash (FA) stabilized reclaimed asphalt pavement (RAP) when utilized as a base course in a full-scale experimental test section. The design mixture for the base course was prepared using an alkali-activated FA-stabilized RAP base (FRB) mixture comprised of 60% RAP, 40% Virgin Aggregate (VA), and 20% FA by weight employing a replacement method. An array of laboratory experiments, including unconfined compressive strength, resilient modulus, and durability tests were performed on FRB mixtures. The test results showed that the alkali activation using the liquid alkaline activator (LAA = Na2SiO3:NaOH) has significantly improved the mechanical strength, stiffness and durability of the mixtures. After that, an experimental test section was designed and constructed on a state highway to evaluate the long-term performance under actual traffic and climatic conditions using horizontal inclinometers and surface profiles. No sign of any distress was observed throughout the monitoring period of 5 years. A comprehensive cost–benefit analysis was performed, which demonstrated that the FRB section could reduce the overall construction cost by approximately 17% while decreasing the total pavement thickness by about 21%. The embodied carbon and global energy potential were calculated for the FRB section and compared the data with equivalent cement-treated base courses. The embodied carbon for the FRB section was estimated to be 30% less than the equivalent cement-treated RAP base for a comparable mechanical strength.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available on request from the authors.

References

Kaza S, Yao L, Bhada-Tata P, Van Woerden F (2018) What a waste 2.0: a global snapshot of solid waste management to 2050. World Bank Publications

Silva RV, De Brito J, Dhir RK (2017) Availability and processing of recycled aggregates within the construction and demolition supply chain: A review. J Clean Prod 143:598–614

Disfani MM, Arulrajah A, Haghighi H, Mohammadinia A, Horpibulsuk S (2014) Flexural beam fatigue strength evaluation of crushed brick as a supplementary material in cement stabilized recycled concrete aggregates. Constr Build Mater 68:667–676

Taha R, Al-Harthy A, Al-Shamsi K, Al-Zubeidi M (2002) Cement stabilization of reclaimed asphalt pavement aggregate for road bases and subbases. J Mater Civ Eng 14(3):239–245

Copeland A (2011) Reclaimed asphalt pavement in asphalt mixtures: State of the practice (No. FHWA-HRT-11-021). Office of Research, Development, and Technology, Federal Highway Administration, USA

Ma F, Sha A, Lin R, Huang Y, Wang C (2016) Greenhouse gas emissions from asphalt pavement construction: a case study in China. Int J Environ Res Public Health 13(3):351

Vidal R, Moliner E, Martínez G, Rubio MC (2013) Life cycle assessment of hot mix asphalt and zeolite-based warm mix asphalt with reclaimed asphalt pavement. Resour Conserv Recycl 74:101–114

Yuan D, Nazarian S, Hoyos LR, Puppala AJ (2010) Cement treated RAP mixes for roadway bases, technical report: FHWA/TX-10/0-6084-1. Washington DC, 122p

Saride S, Avirneni D, Javvadi SCP (2016) Utilization of reclaimed asphalt pavements in Indian low-volume roads. J Mater Civ Eng 28(2):04015107

Avirneni D, Peddinti PR, Saride S (2016) Durability and long term performance of geopolymer stabilized reclaimed asphalt pavement base courses. Constr Build Mater 121:198–209

Hoy M, Horpibulsuk S, Arulrajah A (2016) Strength development of recycled asphalt pavement-fly ash geopolymer as a road construction material. Constr Build Mater 117:209–219

Jallu M, Saride S, Arulrajah A, Challapalli S, Evans R (2021) Effect of curing time on the performance of fly ash geopolymer-stabilized RAP bases. J Mater Civ Eng 33(3):04021001

Puppala AJ, Pedarla A, Chittoori B, Ganne VK, Nazarian S (2017) Long-term durability studies on chemically treated reclaimed asphalt pavement material as a base layer for pavements. Transp Res Rec 2657(1):1–9

Hoy M, Rachan R, Horpibulsuk S, Arulrajah A, Mirzababaei M (2017) Effect of wetting–drying cycles on compressive strength and microstructure of recycled asphalt pavement–fly ash geopolymer. Constr Build Mater 144:624–634

Chakravarthi S, Boyina A, Singh AK, Shankar S (2019) Evaluation of cement treated reclaimed asphalt pavement and recycled concrete pavement bases. Int J Pavement Res Technol 12:581–588

Arshad M (2020) Laboratory investigations on the mechanical properties of cement treated RAP-natural aggregate blends used in base/subbase layers of pavements. Constr Build Mater 254:119234

Kasu SR, Manupati K, Muppireddy AR (2020) Investigations on design and durability characteristics of cement treated reclaimed asphalt for base and subbase layers. Constr Build Mater 252:119102

Palomo A, Grutzeck MW, Blanco MT (1999) Alkali-activated fly ashes: a cement for the future. Cem Concr Res 29(8):1323–1329

Davidovits J (1991) Geopolymers: inorganic polymeric new materials. J Therm Anal Calorim 37(8):1633–1656

Hoyos LR, Puppala AJ, Ordonez CA (2011) Characterization of cement-fiber-treated reclaimed asphalt pavement aggregates: preliminary investigation. J Mater Civ Eng 23(7):977–989

IRC:37 (2012) Guidelines for the design of flexible pavements. Indian Code of Practice, New Delhi, India

AASHTO (American Association of State Highway and Transportation Officials) (1993) Guidelines for design of pavement structures, vol 1. Washington, DC

Jallu M, Arulrajah A, Saride S, Evans R (2020) Flexural fatigue behavior of fly ash geopolymer stabilized-geogrid reinforced RAP bases. Constr Build Mater 254:119263

Austroads (2006) Guide to pavement technology. Part 4D: stabilised materials. AGPT04D/06, Sydney

Puppala AJ, Hoyos LR, Potturi AK (2011) Resilient moduli response of moderately cement-treated reclaimed asphalt pavement aggregates. J Mater Civ Eng 23(7):990–998

Saride S, Jallu M (2020) Effect of fly ash geopolymer on layer coefficients of reclaimed asphalt pavement bases. J Transp Eng Part B: Pavements 146(3):04020033

Puppala AJ, Saride S, Williammee R (2012) Sustainable reuse of limestone quarry fines and RAP in pavement base/subbase layers. J Mater Civ Eng 24(4):418–429

Freire A, Neves J, Roque A, Martins I, Antunes M (2019) Feasibility study of milled and crushed reclaimed asphalt pavement for application in unbound granular layers. Road Mater Pavement Des 22:150–215

ASTM (American Society for Testing and Materials) D2487 (2011) Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International, West Conshohocken, PA

AASHTO M145-91 (2009) Classification of soils and soil-aggregate mixtures for highway construction purposes. Washington, DC

ASTM C618 (2012a) Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. ASTM International, West Conshohocken, PA

Saride S, Avirneni D, Javvadi SCP, Puppala AJ, Hoyos LR (2015) Evaluation of fly ash treated reclaimed asphalt pavement for base/subbase applications. Indian Geotech J 45:401–411

ASTM D1633 (2007) Standard Test Methods for compressive strength of molded soil-cement cylinders. ASTM International, West Conshohocken, PA

JTG/T F20-2015 (2012) Technical specifications for construction of highway road bases. Ministry of Communications of the People’s Republic of China

CCANZ (Cement and Concrete Association of New Zealand) (2008) Road recycling and construction using cement stabilization. Technical Rep. Wellington, New Zealand, p 1–12

SAPEM (South African Pavement Engineering Manual) (2014) South African pavement engineering manual. Technical Rep. South African National Roads Agency Society Limited, Pretoria

DOH, D (2000) S204/2000 Standard of soil cement base. Department of Highways, Thailand

AASHTO T307-99 (2003) Standard method of test for determining the resilient modulus of soils and aggregate materials. Standard specifications for transportation materials and methods of sampling and testing

ASTM D559 (2003) Standard test methods for wetting and drying compacted soil-cement mixtures. ASTM International, West Conshohocken, PA

ASTM D1557 (2012b) Standard test methods for laboratory compaction characteristics of soil using modified effort. ASTM International, West Conshohocken, PA

Cheng TW, Chiu JP (2003) Fire-resistant geopolymer produced by granulated blast furnace slag. Miner Eng 16(3):205–210

Mohammed BS, Haruna S, Wahab MMA, Liew MS, Haruna A (2019) Mechanical and microstructural properties of high calcium fly ash one-part geopolymer cement made with granular activator. Heliyon 5(9)

Koksal F, Gencel O, Kaya M (2015) Combined effect of silica fume and expanded vermiculite on properties of lightweight mortars at ambient and elevated temperatures. Constr Build Mater 88:175–187

Asphalt Institute (1982) Research and development of the Asphalt Institute's thickness design manual. Asphalt Institute

Season and Crop Coverage Report (2016–2019). Directorate of Economics and Statistics, Vijayawada (Report No: 2018/05/SCR-2016-17-28-05-18). Government of Andhra Pradesh

Haas R, Hudson WR (2015) Pavement asset management. Wiley

Blaszczynski T, Król M (2015) Usage of green concrete technology in civil engineering. Procedia Eng 122:296–301

Wang F, Xie J, Wu S, Li J, Barbieri DM, Zhang L (2021) Life cycle energy consumption by roads and associated interpretative analysis of sustainable policies. Renew Sustain Energy Rev 141:110823

Davidovits J (2015) False values on CO2 emission for geopolymer cement/concrete published in scientific papers. Technical paper 24:1–9

Boustead I (2005) Eco-profiles of the European Plastics Industry: sodium hydroxide. Plast Eur 3:13

Fawer M, Concannon M, Rieber W (1999) Life cycle inventories for the production of sodium silicates. Int J Life Cycle Assess 4:207–212

Sreedhar S, Jichkar P, Biligiri KP (2016) Investigation of carbon footprints of highway construction materials in India. Transp Res Procedia 17:291–300

Praticò FG, Perri G, De Rose M, Vaiana R (2023) Comparing bio-binders, rubberised asphalts, and traditional pavement technologies. Constr Build Mater 400:132813

White P, Golden JS, Biligiri KP, Kaloush K (2010) Modeling climate change impacts of pavement production and construction. Resour Conserv Recycl 54(11):776–782

Wirtgen Group (2012) Wirtgen cold recycling manual

Poltue T, Suddeepong A, Horpibulsuk S, Samingthong W, Arulrajah A, Rashid ASA (2020) Strength development of recycled concrete aggregate stabilized with fly ash-rice husk ash based geopolymer as pavement base material. Road Mater Pavement Des 21(8):2344–2355

Mohammadinia A, Arulrajah A, Sanjayan J, Disfani MM, Bo MW, Darmawan S (2015) Laboratory evaluation of the use of cement-treated construction and demolition materials in pavement base and subbase applications. J Mater Civ Eng 27(6):04014186

Acknowledgements

This research was supported by the Technology Systems Development Program of the Department of Science and Technology [DST/TSG/STS/2013/40] and funded by the Government of India. We sincerely thank and acknowledge Dr. Vinay Kumar, Dr. Mypati Vamsi Navya Krishna, and Dr. B. Ramu for their assistance during the construction and field monitoring visits.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors reported no potential conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jallu, M., Saride, S. Performance of Alkali-Activated Fly Ash Stabilized High Percentage RAP Aggregates as a Pavement Base Course: Laboratory and Field Perspectives. Int. J. of Geosynth. and Ground Eng. 10, 15 (2024). https://doi.org/10.1007/s40891-024-00523-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-024-00523-9