Abstract

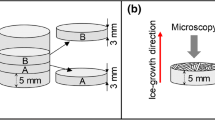

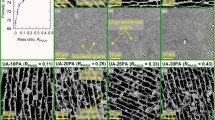

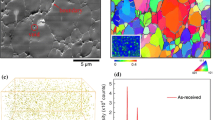

The central focus of this study is to investigate the influence of microstructure and direction of impact (relative to the growth direction of ice crystals) on the impact behavior of ice-templated sintered alumina materials and understand the relationship between dynamic compressive strength and impact response. All materials were fabricated using alumina suspensions of the same solid loading but at three different freezing front velocity (FFV) regimes; very-high FFV, moderately-high FFV, and low FFV. Lamella wall thickness, pore size, and pore aspect ratio decreased, and wall connectivity increased with FFV. Materials also exhibited a structural gradient along the growth direction of ice crystals. As the templated microstructure became finer with FFV, the impact resistance of the materials increased, and radius of damage crater, depth-of-penetration, and mass loss decreased. Materials also exhibited radial cracking, and the materials fabricated at very-high FFV showed a greater propensity for radial cracking for impact along the growth direction. The impact process evolved in three phases; penetration phase, dwell phase and rebound phase. Analysis of high-speed videos revealed that modifying the microstructure affected not only the impact resistance but also the duration of these phases. Variation in microstructure caused a change in the mechanism of damage evolution during impact. Dynamic compressive strength increased with FFV, and the results revealed a direct relationship between impact response and strength. For both impact and dynamic compression, energy absorption per unit volume increased with FFV, further reinforcing the relationship between impact behavior and the dynamic compressive response of ice-templated materials.

Similar content being viewed by others

References

Reid S (1993) Deformation mechanisms in impact energy absorbing components and materials. In: Lee WB (ed) Advances in engineering plastics and applications. Elsevier, pp 19–26

Magness LS Jr (1994) High strain rate deformation behaviors of kinetic energy penetrator materials during ballistic impact. Mech Mater 17:147–154

Shim VPW, Yap KY (1997) Modelling impact deformation of foam-plate sandwich systems. Int J Impact Eng 19:615–636

Raiser G, Clifton RJ (1993) High strain rate deformation and damage in ceramic materials. J Eng Mater Technol 115:292–299

Holmquist TJ, Johnson GR (2005) Characterization and evaluation of silicon carbide for high-velocity impact. J Appl Phys 97:1–12

LaSalvia JC, Normandia MJ, Miller HT, MacKenzie DE (2005) Sphere impact induced damage in ceramics: I. Armor-grade SiC and TiB2. Ceram Eng Sci Proc 26:171–181

LaSalvia JC, McCauley JW (2010) Inelastic deformation mechanisms and damage in structural ceramics subjected to high-velocity impact. Int J Appl Ceram Technol 7:595–605

Anderson CE, Behner T, Holmquist TJ, Orphal DL (2011) Penetration response of silicon carbide as a function of impact velocity. Int J Impact Eng 38:892–899

Subhash G, Maiti S, Geubelle PH, Ghosh D (2008) Recent advances in dynamic indentation fracture, impact damage and fragmentation of ceramics. J Am Ceram Soc 91:2777–2791

Chen W, Rajendran AM, Song B, Nie X (2007) Dynamic fracture of ceramics in armor applications. J Am Ceram Soc 90:1005–1018

LaSalvia JC, Normandia MJ, Miller HT, MacKenzie DE (2005) Sphere impact induced damage in ceramics: I. Armor-Grade SiC and TiB2. In: Swab JJ (ed) Advances in ceramic armor. Proceedings of the 29th international conference on advanced ceramics and composites, vol 26. Cocoa Beach, FL, pp 170–181, 2005

Iyer KA (2007) Relationships between multiaxial stress states and internal fracture patterns in sphere-impacted silicon carbide. Int J Fract 146:1–18

Normandia MJ (2004) Impact response and analysis of several silicon carbides. Int J Appl Ceram Technol 1:226–234

National Research Council (2011) Opportunities in protection materials science and technology for future army applications. National Academies Press

Silva MV, Stainer D, Al-Qureshi HA, Montedo ORK, Hotza D (2014) Alumina-based ceramics for armor application: mechanical characterization and ballistic testing. J Ceram 2014:1–6

Garcia-Avilaa M, Portanova M, Rabiei A (2014) Ballistic performance of a composite metal foam-ceramic armor system. Procedia Mater Sci 4:151–156

Kaufmann C, Cronin D, Worswick M, Pageau G, Beth A (2003) Influence of material properties on the ballistic performance of ceramics for personal body armor. Shock Vib 10:51–58

David NV, Gao XL, Zheng JQ (2009) Ballistic resistant body armor: contemporary and prospective materials and related protection mechanisms. Appl Mech Rev 62:050802-1

Marx J, Rabiei A (2017) Overview of composite metal foams and their properties and performance. Adv Eng Mater 19:1600776

Mohan K, Hon YT, Idapalapati S, Seow HP (2005) Failure of sandwich beams consisting of alumina face sheet and aluminum foam core in bending. Mater Sci Eng A 409:292–301

Gama BA, Bogetti TA, Fink BK, Yu C-J, Claar TD, Eifert HH, Gillespie JW Jr (2001) Aluminum foam integral armor: a new dimension in armor design. Compos Struct 3–4:381–395

Gibson LJ, Ashby MF (1999) Cellular solids structure and properties. Cambridge University Press, Cambridge

Tan YM, Cervantes O, Nam SW, Molitoris JD, Hooper JP (2016) Dynamic fragmentation of cellular, ice-templated alumina scaffolds. J Appl Phys 119:024901–24911

Xu X, Liu J, Gu W, Liu X, Cao T (2018) Shock wave attenuation characteristics of aluminum foam sandwich panels subjected to blast loading. Shock Vib 2018:1–10

Shen J, Ren X-J (2013) Experimental investigation on transmission of stress waves in sandwich samples made of foam concrete. Def Technol 9:110–114

Ghosh D, Kang H, Banda M, Kamaha V (2017) Influence of anisotropic grains (platelets) on the microstructure and uniaxial compressive response of ice-templated sintered alumina scaffolds. Acta Mater 125:1–14

Deville S (2013) Ice-templating, freeze casting: beyond materials processing. J Mater Res 28:2202–2219

Ghosh D, Dhavale N, Banda M, Kang H (2016) A comparison of microstructure and uniaxial compressive response of ice-templated alumina scaffolds fabricated from two different particle sizes. Ceram Int 42:16138–16147

Deville S (2010) Freeze-casting of porous biomaterials: structure, properties and opportunities. Materials 3:1913–1927

Banda M, Ghosh D (2020) Effects of temperature and platelets on lamella wall microstructure, structural stability, and compressive strength in ice-templated ceramics. Materialia 9:1–16

Porter MM, Imperio R, Wen M, Meyers MA, McKittrick J (2014) Bioinspired scaffolds with varying pore architectures and mechanical properties. Adv Funct Mater 24:1978–1987

Ghosh D, Banda M, Akurati S, Kang H, Fakharizadeh VO (2017) On the brittle fracture characteristics of lamella walls of ice-templated sintered alumina scaffolds and effects of platelets. Scr Mater 138:139–144

Anderson C, Walker J (2005) An analytical model for dwell and interface defeat. Int J Impact Eng 31:1119–1132

Banda M, Ghosh D (2018) Effects of porosity and strain rate on the uniaxial compressive response of ice-templated sintered macroporous alumina. Acta Mater 149:79–192

Ghosh D, Banda M, John JE, Terrones DA (2018) Dynamic strength enhancement and strain rate sensitivity in ice-templated ceramics processed with and without anisometric particles. Scr Mater 154:236–240

Akurati S, Ghosh D, Banda M, Terrones DA (2019) Direct observation of failure in ice-templated ceramics under dynamic and quasistatic compressive loading conditions. J Dyn Behav Mater 5:463–483

Chen Z, Wang X, Atkinson A, Brandon N (2016) Spherical indentation of porous ceramics: cracking and toughness. J Eur Ceram Soc 36:3473–3480

Acknowledgements

This work was partially supported by the Thomas F. and Kate Miller Jeffress Memorial Trust, Bank of America, Trustee. D.G. also acknowledges National Science Foundation supported S-STEM Grant (#1833896) and Virginia Space Grant Consortium (VSGC) for undergraduate scholarship opportunities to D.A.T.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Akurati, S., Terrones, D.A. & Ghosh, D. Role of Microstructure on Impact Response and Damage Morphology of Ice-Templated Porous Ceramics. J. dynamic behavior mater. 7, 2–20 (2021). https://doi.org/10.1007/s40870-020-00272-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-020-00272-6