Abstract

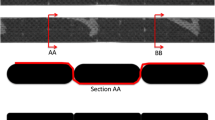

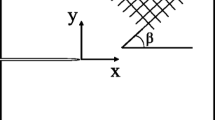

Part II of this two part paper is concerned with the need to understand the multiaxial response of textile composite materials as compared to the uniaxial response seen in part I. In this paper, a test methodology is introduced to create a a dynamic multiaxial stress state on composite plates. Shock loading of plain woven textile composite materials is studied using a novel technique to induce damage initiation at the crown of the sample, where a biaixal state of stress is present. Both fiberglass and carbon fiber materials are tested at different shock strengths to understand if the failure mode changes at increased shock strengths. The results show the influence of both rate and the multiaxial stress state on the failure strains.

Similar content being viewed by others

References

Chen Y, Clausen AH, Hopperstad OS, Langseth M (2009) Stressstrain behavior of aluminum alloys at a wide range of strain rates. Int J Solids Struct 46(21):3825–3835

Oosterkamp L, Ivankovic A, Venizelos G (2000) High strain rate properties of selected aluminium alloys. Mater Sci Eng 278(12):225–235

Smerd R, Winkler S, Salisbury C, Worswick M, Lloyd D, Finn M (2005) High strain rate tensile testing of automotive aluminum alloy sheet. Int J Impact Eng 32(14):541–560

Zhang X, Li H, Li H, Gao H, Gao Z, Liu Y, Liu B (2008) Dynamic property evaluation of aluminum alloy 2519a by split Hopkinson pressure bar. Trans Nonferrous Met Soc China 18(1):1–5

Broomhead P, Grieve RJ (1982) The effect of strain rate on the strain to fracture of sheet steel under biaxial tensile stress conditions. J Eng Mater Technol 104:101–106

Pickett AK, Pyttel T, Payen F, Lauro F, Petrinic N, Werner H, Christlein J (2004) Failure prediction for advanced crashworthiness of transportation vehicles. Int J Impact Eng 30(7):853–872

Grolleau V, Gary G, Mohr D (2008) Biaxial testing of sheet materials at high strain rates using viscoelastic bars. Exp Mech 48:293–306

Ramezani M, Ripin ZM (2010) Combined experimental and numerical analysis of bulge test at high strain rates using split Hopkinson pressure bar apparatus. J Mater Process Technol 210(8):1061–1069

Stoffel M, Schmidt R, Weichert D (2001) Shock wave-loaded plates. Int J Solids Struct 38(4243):7659–7680

Mouritz AP (1995) The effect of underwater explosion shock loading on the fatigue behaviour of grp laminates. Composites 26(1):3–9

Mouritz AP (1995) The damage to stitched fGRPg laminates by underwater explosion shock loading. Compos Sci Technol 55(4):365–374

LeBlanc J, Shukla A (2010) Dynamic response and damage evolution in composite materials subjected to underwater explosive loading: an experimental and computational study. Compos Struct 92(10):2421–2430

LeBlanc J, Shukla A (2011) Dynamic response of curved composite panels to underwater explosive loading: experimental and computational comparisons. Compos Struct 93(11):3072–3081

Schiffer A, Tagarielli VL (2015) The response of circular composite plates to underwater blast: experiments and modeling. J Fluids Struct 52:130–144

Tekalur S, Shivakumar K, Shukla A (2008) Mechanical behavior and damage evolution in e-glass vinyl ester and carbon composites subjected to static and blast loads. Compos B 39(1):57–65

Tekalur S, Bogdanovich A, Shukla A (2009) Shock loading response of sandwich panels with 3-d woven e-glass composite skins and stitched foam core. Compos Sci Technol 69(6):736–753

Wang E, Gardner N, Shukla A (2009) The blast resistance of sandwich composites with stepwise graded cores. Int J Solids Struct 46(1819):3492–3502

Jackson M, Shukla A (2011) Performance of sandwich composites subjected to sequential impact and air blast loading. Compos B 42(2):155–166

LeBlanc J, Shukla A, Rousseau C, Bogdanovich A (2007) Shock loading of three-dimensional woven composite materials. Compos Struct 79(3):344–355

Tekalur S, Shukla A, Shivakumar K (2008) Blast resistance of polyurea based layered composite materials. Compos Struct 84(3):271–281

Pankow M, Justusson B, Salvi A, Waas AM, Yen CF, Ghiorse S (2011) Shock response of 3D woven composites: an experimental investigation. Compos Struct 93(5):1337–1346

Pankow M, Waas AM, Yen CF, Ghiorse S (2011) Shock loading of 3d woven composites: a validated finite element investigation. Compos Struct 93(5):1347–1362

Justusson B, Pankow M, Heinrich C, Rudolph M, Waas AM (2013) Use of a shock tube to determine the bi-axial yield of aluminum alloy under high rates. Int J Impact Eng 58:55–65

Rathakrishnan E (2010) Applied Gas Dynamics. Wiley, Hoboken

Lang E, Chou TW (1998) The effect of strain gage size on measurement errors in textile composite materials. Compos Sci Technol 58(34):539–548

Acknowledgements

The authors would like to thank the Army Research Laboratories, Aberdeen proving ground, for their continued financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Justusson, B., Marek, J., Waas, A. et al. Dynamic Characterization of Textile Composites Part II: Bi-axial Tension. J. dynamic behavior mater. 4, 268–281 (2018). https://doi.org/10.1007/s40870-018-0165-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-018-0165-3