Abstract

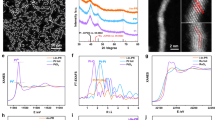

Platinum (Pt) is the state-of-the-art electrocatalyst for anodic hydrogen oxidation reaction (HOR) in proton exchange membrane fuel cells (PEMFCs). However, a critical drawback of PEMFCs is the extreme sensitivity of Pt catalyst to CO (impurity in industrial hydrogen), which markedly damages the device’s performance. Therefore, enhancing the CO-tolerant performance of Pt catalysts is crucial for the commercialization of PEMFCs. Herein, we constructed PtNiW@amorphous WOx core-shell nanowires to improve the CO-tolerance of Pt. Mechanistically, it is demonstrated that the surface amorphous WOx shell can kinetically hinder the accessibility of CO over Pt sites by acting as a selective molecular-sieving layer. Besides, thermodynamically, the electronic effect from the alloying of Ni and W elements could weaken the CO adsorption on Pt sites by downshifting the d-band center. In addition, the oxyphilic W elements can accelerate the dissociation of water to provide more OH species, promoting the oxidation of CO. As a consequence, the as-designed PtNiW@WOx NWs can maintain over 90% HOR current density after 4000 s in 1000 ppm CO/H2, exceeding most of the Pt-based catalysts reported ever.

摘要

铂(Pt)是质子交换膜燃料电池(PEMFCs)阳极氢氧化反应(HOR) 中最先进的电催化剂. 然而, Pt催化剂对CO (工业低成本氢燃料中的杂 质)极度敏感从而中毒, 这会引起器件性能的急剧衰退, 导致器件运行 成本高. 因此, 提高Pt催化剂的CO耐受性对PEMFCs的商业化推广至关 重要. 在此, 我们设计合成了一种独特的PtNiW@WOx核壳纳米线来提 高Pt基催化剂对CO的耐受能力. 机理研究表明, 表面无定形的WOx壳 层可以作为分子围栏, 在动力学上阻碍CO扩散到达Pt位点. 在热力学 上, Ni和W元素合金化产生的电子效应可以使Pt的d带中心降低, 减弱 CO在Pt位点上的化学吸附. 此外, 亲氧W元素可以加速水的解离, 提供 更多OH活性物种, 促进CO的氧化脱附. 因此, 在1000 ppm CO/H2条件 下, 所设计的PtNiW@WOx核壳纳米线催化剂表现出优异的HOR抗CO 中毒性能, 在4000 s后仍能保持超过90%的HOR电流密度, 超过了原始 的PtNi纳米线和目前报道的绝大多数Pt基催化剂.

Similar content being viewed by others

References

Zheng YR, Gao MR, Li HH, et al. Carbon-supported PtCo2Ni2 alloy with enhanced activity and stability for oxygen reduction. Sci China Mater, 2015, 58: 179–185

Wang X, Fang J, Liu X, et al. Converting biomass into efficient oxygen reduction reaction catalysts for proton exchange membrane fuel cells. Sci China Mater, 2020, 63: 524–532

Xiao F, Wang YC, Wu ZP, et al. Recent advances in electrocatalysts for proton exchange membrane fuel cells and alkaline membrane fuel cells. Adv Mater, 2021, 33: 2006292

Gao L, Li X, Yao Z, et al. Unconventional p–d hybridization interaction in PtGa ultrathin nanowires boosts oxygen reduction electrocatalysis. J Am Chem Soc, 2019, 141: 18083–18090

Ma SY, Ma T, Hu Q, et al. Ternary PtRuTe alloy nanofibers as an efficient and durable electrocatalyst for hydrogen oxidation reaction in alkaline media. Sci China Mater, 2022, 65: 3462–3469

DuanMu JW, Gao MR. Advances in bio-inspired electrocatalysts for clean energy future. Nano Res, 2024, 17: 515–533

Zhang G, Qu Z, Tao WQ, et al. Porous flow field for next-generation proton exchange membrane fuel cells: Materials, characterization, design, and challenges. Chem Rev, 2023, 123: 989–1039

Jiao K, Xuan J, Du Q, et al. Designing the next generation of protonexchange membrane fuel cells. Nature, 2021, 595: 361–369

Chaubey R, Sahu S, James OO, et al. A review on development of industrial processes and emerging techniques for production of hydrogen from renewable and sustainable sources. Renew Sustain Energy Rev, 2013, 23: 443–462

Shabani B, Hafttananian M, Khamani S, et al. Poisoning of proton exchange membrane fuel cells by contaminants and impurities: Review of mechanisms, effects, and mitigation strategies. J Power Sources, 2019, 427: 21–48

Zhou Y, Xie Z, Jiang J, et al. Lattice-confined Ru clusters with high CO tolerance and activity for the hydrogen oxidation reaction. Nat Catal, 2020, 3: 454–462

Wang T, Li LY, Chen LN, et al. High CO-tolerant Ru-based catalysts by constructing an oxide blocking layer. J Am Chem Soc, 2022, 144: 9292–9301

Liu Z, Jackson G, Eichhorn B. PtSn intermetallic, core–shell, and alloy nanoparticles as CO-tolerant electrocatalysts for H2 oxidation. Angew Chem Int Ed, 2010, 49: 3173–3176

Lee H, Park S, Kim H. Preparation of CO-tolerant PtRuNi/C ternary electrocatalyst having a composition gradient shell. Chem Eng J, 2021, 414: 128792

Chen G, Chen W, Lu R, et al. Near-atomic-scale superfine alloy clusters for ultrastable acidic hydrogen electrocatalysis. J Am Chem Soc, 2023, 145: 22069–22078

Gao FY, Gao MR. Nickel-based anode catalysts for efficient and affordable anion-exchange membrane fuel cells. Acc Chem Res, 2023, 56: 1445–1457

Yang Z, Lai W, He B, et al. Tailoring interfacial chemistry of defective carbon-supported Ru catalyst toward efficient and CO-tolerant alkaline hydrogen oxidation reaction. Adv Energy Mater, 2023, 13: 2300881

Blyholder G. Molecular orbital view of chemisorbed carbon monoxide. J Phys Chem, 1964, 68: 2772–2777

Zhang ZC, Tian XC, Zhang BW, et al. Engineering phase and surface composition of Pt 3 Co nanocatalysts: A strategy for enhancing CO tolerance. Nano Energy, 2017, 34: 224–232

Zhan C, Xu Y, Bu L, et al. Subnanometer high-entropy alloy nanowires enable remarkable hydrogen oxidation catalysis. Nat Commun, 2021, 12: 6261

Shi G, Yano H, Tryk DA, et al. Highly active, CO-tolerant, and robust hydrogen anode catalysts: Pt–M (M = Fe, Co, Ni) alloys with stabilized Pt-skin layers. ACS Catal, 2017, 7: 267–274

Men Y, Wu D, Hu Y, et al. Understanding alkaline hydrogen oxidation reaction on PdNiRuIrRh high-entropy-alloy by machine learning potential. Angew Chem Int Ed, 2023, 62: e202217976

Cheng H, Xia J, Wang M, et al. Surface anion promotes Pt electrocatalysts with high CO tolerance in fuel-cell performance. J Am Chem Soc, 2022, 144: 22018–22025

Yang Y, Gao F, Zhang X, et al. Suppressing electron back-donation for a highly CO-tolerant fuel cell anode catalyst via cobalt modulation. Angew Chem Int Ed, 2022, 61: e202208040

Ma M, Li G, Yan W, et al. Single-atom molybdenum engineered platinum nanocatalyst for boosted alkaline hydrogen oxidation. Adv Energy Mater, 2022, 12: 2103336

Wang P, Yang Y, Zheng W, et al. V–O species-doped carbon frameworks loaded with Ru nanoparticles as highly efficient and CO-tolerant catalysts for alkaline hydrogen oxidation. J Am Chem Soc, 2023, 145: 27867–27876

Zhang XB, Xia L, Zhao G, et al. Fast and durable alkaline hydrogen oxidation reaction at the electron-deficient ruthenium-ruthenium oxide interface. Adv Mater, 2023, 35: 2208821

Yang G, Yang Y, Qu H, et al. Engineering Ru–RuO2 interface with regulated hydroxyl adsorption towards efficient and CO-tolerant hydrogen oxidation reaction. Mater Today Phys, 2024, 40: 101312

Liu Z, Hu JE, Wang Q, et al. PtMo alloy and MoOx@Pt core-shell nanoparticles as highly CO-tolerant electrocatalysts. J Am Chem Soc, 2009, 131: 6924–6925

Hsieh YC, Zhang Y, Su D, et al. Ordered bilayer ruthenium–platinum core-shell nanoparticles as carbon monoxide-tolerant fuel cell catalysts. Nat Commun, 2013, 4: 2466

Dong Z, Nan Y, Tang T, et al. Synergistically mitigating electron back-donation by single-atomic Fe–N–C and alloying to boost CO-tolerance of Pt in hydrogen oxidation. ACS Catal, 2023, 13: 7822–7830

Yang Z, Chen C, Zhao Y, et al. Pt single atoms on CrN nanoparticles deliver outstanding activity and CO tolerance in the hydrogen oxidation reaction. Adv Mater, 2023, 35: 2208799

Wang S, Fu L, Huang H, et al. Local oxidation induced amorphization of 1.5-nm-thick Pt-Ru nanowires enables superactive and CO-tolerant hydrogen oxidation in alkaline media. Adv Funct Mater, 2023, 33: 2304125

Tian X, Ren R, Wei F, et al. Metal-support interaction boosts the stability of Ni-based electrocatalysts for alkaline hydrogen oxidation. Nat Commun, 2024, 15: 76

Igarashi H, Fujino T, Zhu Y, et al. CO tolerance of Pt alloy electrocatalysts for polymer electrolyte fuel cells and the detoxification mechanism. Phys Chem Chem Phys, 2001, 3: 306–314

Dai Y, Liu Y, Chen S. Pt–W bimetallic alloys as CO-tolerant PEMFC anode catalysts. Electrochim Acta, 2013, 89: 744–748

Wang X, Li Y, Wang Y, et al. Proton exchange membrane fuel cells powered with both CO and H2. Proc Natl Acad Sci USA, 2021, 118: e2107332118

Yang X, Wang Y, Wang X, et al. CO-tolerant PEMFC anodes enabled by synergistic catalysis between iridium single-atom sites and nanoparticles. Angew Chem Int Ed, 2021, 60: 26177–26183

Yao Z, Yuan Y, Cheng T, et al. Anomalous size effect of Pt ultrathin nanowires on oxygen reduction reaction. Nano Lett, 2021, 21: 9354–9360

Wang Y, Yuan Y, Huang H. Recent advances in Pt-based ultrathin nanowires: Synthesis and electrocatalytic applications. Chin J Chem, 2021, 39: 1389–1396

Gao L, Sun T, Tan X, et al. Trace doping of early transition metal enabled efficient and durable oxygen reduction catalysis on Pt-based ultrathin nanowires. Appl Catal B-Environ, 2022, 303: 120918

Wang L, Xu N, Wang WH, et al. Revealing the link between structural relaxation and dynamic heterogeneity in glass-forming liquids. Phys Rev Lett, 2018, 120: 125502

Yu X, Tian H, Fu Z, et al. Strengthening the hydrogen spillover effect via the phase transformation of W18O49 for boosted hydrogen oxidation reaction. ACS Catal, 2023, 13: 2834–2846

Peng L, Tian H, Cui X, et al. Dual synergetic catalytic effects boost hydrogen electric oxidation performance of Pd/W18O49. Nano Res, 2021, 14: 2441–2450

Wang X, Zhao L, Li X, et al. Atomic-precision Pt6 nanoclusters for enhanced hydrogen electro-oxidation. Nat Commun, 2022, 13: 1596

Shi G, Yano H, Tryk DA, et al. Effect of core-alloy composition and particle size of stabilized Pt skin/PtCo alloy nanocatalysts on the CO-tolerant hydrogen oxidation electrocatalysis. Electrochim Acta, 2019, 328: 135056

Uchida H, Izumi K, Watanabe M. Temperature dependence of CO-tolerant hydrogen oxidation reaction activity at Pt, Pt−Co, and Pt−Ru electrodes. J Phys Chem B, 2006, 110: 21924–21930

Zheng JH, Li G, Zhang JM, et al. General strategy for evaluating the d-band center shift and ethanol oxidation reaction pathway towards Pt-based electrocatalysts. Sci China Chem, 2023, 66: 279–288

Chang X, Vijay S, Zhao Y, et al. Understanding the complementarities of surface-enhanced infrared and Raman spectroscopies in CO adsorption and electrochemical reduction. Nat Commun, 2022, 13: 2656

Wei X, Yin Z, Lyu K, et al. Highly selective reduction of CO2 to C2+ hydrocarbons at copper/polyaniline interfaces. ACS Catal, 2020, 10: 4103–4111

Mojet BL, Ebbesen SD, Lefferts L. Light at the interface: The potential of attenuated total reflection infrared spectroscopy for understanding heterogeneous catalysis in water. Chem Soc Rev, 2010, 39: 4643

Nørskov JK, Abild-Pedersen F, Studt F, et al. Density functional theory in surface chemistry and catalysis. Proc Natl Acad Sci USA, 2011, 108: 937–943

Lambert DK. Vibrational Stark effect of adsorbates at electrochemical interfaces. Electrochim Acta, 1996, 41: 623–630

Lambert DK. Vibrational Stark effect of CO on Ni(100), and CO in the aqueous double layer: Experiment, theory, and models. J Chem Phys, 1988, 89: 3847–3860

Wu ZZ, Zhang XL, Yang PP, et al. Gerhardtite as a precursor to an efficient CO-to-acetate electroreduction catalyst. J Am Chem Soc, 2023, 145: 24338–24348

Chen S, Liu N, Zhong J, et al. Engineering support and distribution of palladium and tin on MXene with modulation of the d-band center for CO-resilient methanol oxidation. Angew Chem Int Ed, 2022, 61: e202209693

Gao L, Yang Z, Sun T, et al. Autocatalytic surface reduction-assisted synthesis of PtW ultrathin alloy nanowires for highly efficient hydrogen evolution reaction. Adv Energy Mater, 2022, 12: 2103943

Acknowledgements

This work was supported by the National Natural Science Foundation of China (22322902, U22A20396, 22102052, 22309050, and 22211540385), the National Key Research and Development Program of China (2021YFA1502000), the Science and Technology Innovation Program of Hunan Province (2021RC3065), Jiebang Guashuai Project of Changsha City (kq2301009), Shenzhen Science and Technology Program (JCYJ20210324120800002, JCYJ20220818100012025, and JCYJ20230807122007015), and China Postdoctoral Science Foundation (2023T160205).

Author information

Authors and Affiliations

Contributions

Author contributions Huang H provided guidance and revised the manuscript. Sun T and Lai W performed and analyzed the HAADF-STEM characterizations. Liu W designed this work, carried out the experiments, analyzed the results, and wrote this paper. Yang F carried out the DFT simulations. Huang C, Du J and Ye J conducted the in-situ FTIR. Zeng Y performed the XPS analyses. Gao L carried out the XRD measurements. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest The authors declare that they have no conflict of interest.

Additional information

Supplementary information Supporting data are available in the online version of the paper.

Wei Liu received his Bachelor’s degree from Hunan Institute of Technology in 2021. Currently, he is pursuing a Master’s degree at Hunan University, focusing on the control of synthesis and application of precious metal nanocrystals.

Fongrong Yang completed her BS degree at Hunan University in 2021. She is currently pursuing a Master’s degree at Hunan University. Her research focuses on controlling the synthesis of precious metal nanocrystals assistented by DFT.

Tulai Sun is an associate researcher at Zhejiang University of Technology. He received his PhD degree in materials science and engineering from Zhejiang University and then worked as a postdoctoral fellow at the Center for Electron Microscopy, Zhejiang University. His research primarily revolves around the development of electron microscopy techniques and their applications in understanding the structure-activity relationships of functional materials.

Wenchuan Lai obtained his PhD degree from Sichuan University in 2020. Then he joined Hongwen Huang’s group as a post-doctoral fellow at Hunan University. Now, he is an associate professor at Nanjing Normal University. His research is focused on the chemistry and applications of graphene, nanotechnology as well as polymer nanocomposites.

Hongwen Huang is now a full professor at Hunan University. He received his Bachelor’s degree in materials science and engineering from the South China University of Technology in 2009 and his PhD degree in materials science and engineering from Zhejiang University in 2015. From 2012 to 2014, he studied at Georgia Institute of Technology under the supervision of Prof. Younan Xia. After graduation, he worked at the University of Science and Technology of China as a postdoctoral fellow from 2015 to 2017 and joined Hunan University in 2017. His research interests include the controlled growth of nanocrystals and their applications in energy-related electrocatalysis.

Rights and permissions

About this article

Cite this article

Liu, W., Yang, F., Sun, T. et al. Ultrathin PtNiW@WOx core-shell nanowires for enhanced CO-tolerant hydrogen oxidation: three-in-one catalyst design. Sci. China Mater. 67, 1866–1875 (2024). https://doi.org/10.1007/s40843-023-2804-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-023-2804-9