Abstract

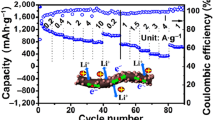

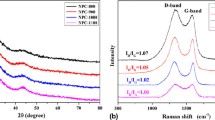

To enhance electrochemical performance of lithium or sodium-ion batteries (LIBs or NIBs), active materials are usually filled in porous conductive particles to produce anode composites. However, it is still challenging to achieve high performance anode composites with high specific capacity, excellent rate performance, high initial Coulombic efficiency (ICE) and long cycle life. Based on these requirements, we design and fabricate activated carbon-coated carbon nanotubes (AC@CNT) with hierarchical structures containing micro- and meso-pores. A new structure of phosphorus/carbon composite (P@AC@CNT) is prepared by confining red P in porous carbon through a vaporization-condensation-conversion method. The micro-pores are filled with P, while the meso-pores remain unoccupied, and the pore openings on the particle surface are sealed by P. Due to the unique structure of P@AC@CNT, it displays a high specific capacity of 1674 mA h g−1 at 0.2 C, ultrahigh ICE of 92.2%, excellent rate performance of 1116 mA h g−1 at 6 C, and significantly enhanced cycle stability for LIBs. The application of P@AC@CNT in NIBs is further explored. This method for the fabrication of the special composites with improved electrochemical performance can be extended to other energy storage applications.

摘要

为了提升锂离子或钠离子电池的电化学性能, 通常的做法是将活性材料填充到多孔导电颗粒中来形成复合材料. 然而, 同时实现电池的高容量、高倍率、高首次库仑效率和长循环寿命等性能仍是一项挑战. 针对这些需求, 我们设计并制备了具有分等级微中孔结构的活性炭包覆碳纳米管材料. 采用蒸发冷凝转化法制备了一种将红磷限制在碳材料孔隙中的新型磷/碳(P/C)复合材料. 在这种复合材料中,碳基的微孔被红磷充斥而介孔被保留. 材料颗粒表面的孔隙被红磷所堵塞. 由于所制备的P/C复合材料这种独特的结构, 其在锂离子电池中以0.2 C倍率充放电时展现了高达1674 mA h g−1的比容量和92.2%的首次库仑效率; 在6 C倍率充放时展现1116 mA h g−1的高容量和优秀的循环稳定性. 另外, 所制备的复合材料在钠离子电池中也展示了卓越的性能. 这种采用特殊结构来改善电化学性能的方法可推广到其他电池或储能应用中.

Similar content being viewed by others

References

Yu HC, Ling C, Bhattacharya J, et al. Designing the next generation high capacity battery electrodes. Energ Environ Sci, 2014, 7: 1760–1768

Wang C, Wang J, Chen H, et al. An interlayer nanostructure of rGO/Sn2Fe-NRs array/rGO with high capacity for lithium ion battery anodes. Sci China Mater, 2016, 59: 927–937

Tarascon JM, Armand M. Issues and challenges facing rechargeable lithium batteries. Nature, 2001, 414: 359–367

Li W, Zeng L, Wu Y, et al. Nanostructured electrode materials for lithium-ion and sodium-ion batteries via electrospinning. Sci China Mater, 2016, 59: 287–321

Liu Z, Zhang Y, Zhao H, et al. Constructing monodispersed MoSe2 anchored on graphene: a superior nanomaterial for sodium storage. Sci China Mater, 2016, 60: 167–177

Yang D, Xu J, Liao XZ, et al. Structure optimization of Prussian blue analogue cathode materials for advanced sodium ion batteries. Chem Commun, 2014, 50: 13377–13380

Wu C, Jiang Y, Kopold P, et al. Peapod-like carbon-encapsulated cobalt chalcogenide nanowires as cycle-stable and high-rate materials for sodium-ion anodes. Adv Mater, 2016, 28: 7276–7283

Li Y, Yan K, Lee HW, et al. Growth of conformal graphene cages on micrometre-sized silicon particles as stable battery anodes. Nat Energ, 2016, 1: 15029

Li W, Yang Z, Li M, et al. Amorphous red phosphorus embedded in highly ordered mesoporous carbon with superior lithium and sodium storage capacity. Nano Lett, 2016, 16: 1546–1553

Che H, Chen S, Xie Y, et al. Electrolyte design strategies and research progress for room-temperature sodium-ion batteries. Energ Environ Sci, 2017, 10: 1075–1101

Wu L, Bresser D, Buchholz D, et al. Unfolding the mechanism of sodium insertion in anatase Tio2 nanoparticles. Adv Energ Mater, 2015, 5: 1401142

Liu S, Feng J, Bian X, et al. A controlled red phosphorus@Ni-P core@shell nanostructure as an ultralong cycle-life and superior high-rate anode for sodium-ion batteries. Energ Environ Sci, 2017, 10: 1222–1233

Zhu J, Chen C, Lu Y, et al. Nitrogen-doped carbon nanofibers derived from polyacrylonitrile for use as anode material in sodiumion batteries. Carbon, 2015, 94: 189–195

Xu J, Wang M, Wickramaratne NP, et al. High-performance sodium ion batteries based on a 3D anode from nitrogen-doped graphene foams. Adv Mater, 2015, 27: 2042–2048

Tang K, Fu L, White RJ, et al. Hollow carbon nanospheres with superior rate capability for sodium-based batteries. Adv Energ Mater, 2012, 2: 873–877

Jache B, Adelhelm P. Use of graphite as a highly reversible electrode with superior cycle life for sodium-ion batteries by making use of co-intercalation phenomena. Angew Chem Int Ed, 2014, 53: 10169–10173

Wu L, Buchholz D, Bresser D, et al. Anatase TiO2 nanoparticles for high power sodium-ion anodes. J Power Sources, 2014, 251: 379–385

He M, Yuan L, Hu X, et al. A SnO2@carbon nanocluster anode material with superior cyclability and rate capability for lithiumion batteries. Nanoscale, 2013, 5: 3298–3305

Ni W, Cheng J, Shi L, et al. Integration of Sn/C yolk–shell nanostructures into free-standing conductive networks as hierarchical composite 3D electrodes and the Li-ion insertion/ extraction properties in a gel-type lithium-ion battery thereof. J Mater Chem A, 2014, 2: 19122–19130

Zhu Y, Han X, Xu Y, et al. Electrospun Sb/C fibers for a stable and fast sodium-ion battery anode. ACS Nano, 2013, 7: 6378–6386

Liu Y, Zhang N, Jiao L, et al. Tin nanodots encapsulated in porous nitrogen-doped carbon nanofibers as a free-standing anode for advanced sodium-ion batteries. Adv Mater, 2015, 27: 6702–6707

David L, Bhandavat R, Singh G. MoS2/graphene composite paper for sodium-ion battery electrodes. ACS Nano, 2014, 8: 1759–1770

Nagao M, Hayashi A, Tatsumisago M. High-capacity Li2S-nanocarbon composite electrode for all-solid-state rechargeable lithium batteries. J Mater Chem, 2012, 22: 10015–10020

Kwon HT, Kim JH, Jeon KJ, et al. CoxP compounds: electrochemical conversion/partial recombination reaction and partially disproportionated nanocomposite for Li-ion battery anodes. RSC Adv, 2014, 4: 43227–43234

Sun J, Lee HW, Pasta M, et al. Carbothermic reduction synthesis of red phosphorus-filled 3D carbon material as a high-capacity anode for sodium ion batteries. Energ Storage Mater, 2016, 4: 130–136

Zhu Y, Wen Y, Fan X, et al. Red phosphorus-single-walled carbon nanotube composite as a superior anode for sodium ion batteries. ACS Nano, 2015, 9: 3254–3264

Li W, Hu S, Luo X, et al. Confined amorphous red phosphorus in MOF-derived N-doped microporous carbon as a superior anode for sodium-ion battery. Adv Mater, 2017, 29: 1605820

Ramireddy T, Xing T, Rahman MM, et al. Phosphorus-carbon nanocomposite anodes for lithium-ion and sodium-ion batteries. J Mater Chem A, 2015, 3: 5572–5584

Yu Z, Song J, Gordin ML, et al. Phosphorus-graphene nanosheet hybrids as lithium-ion anode with exceptional high-temperature cycling stability. Adv Sci, 2015, 2: 1400020

Yuan D, Cheng J, Qu G, et al. Amorphous red phosphorous embedded in carbon nanotubes scaffold as promising anode materials for lithium-ion batteries. J Power Sources, 2016, 301: 131–137

Wang L, He X, Li J, et al. Nano-structured phosphorus composite as high-capacity anode materials for lithium batteries. Angew Chem Int Ed, 2012, 51: 9034–9037

Pei L, Zhao Q, Chen C, et al. Phosphorus nanoparticles encapsulated in graphene scrolls as a high-performance anode for sodium-ion batteries. ChemElectroChem, 2016, 2: 1652–1655

Yabuuchi N, Matsuura Y, Ishikawa T, et al. Phosphorus electrodes in sodium cells: small volume expansion by sodiation and the surface-stabilization mechanism in aprotic solvent. ChemElectroChem, 2014, 1: 580–589

Li W, Yang Z, Jiang Y, et al. Crystalline red phosphorus incorporated with porous carbon nanofibers as flexible electrode for high performance lithium-ion batteries. Carbon, 2014, 78: 455–462

Sun J, Zheng G, Lee HW, et al. Formation of stable phosphoruscarbon bond for enhanced performance in black phosphorus nanoparticle-graphite composite battery anodes. Nano Lett, 2014, 14: 4573–4580

Xin S, Gu L, Zhao NH, et al. Smaller sulfur molecules promise better lithium-sulfur batteries. J Am Chem Soc, 2012, 134: 18510–18513

Zhang X, Jin J, Yan P, et al. Structure and electrochemical performance of graphene/porous carbon coated carbon nanotube composite for supercapacitors. Mater Lett, 2015, 160: 190–193

Raymundo-Piñero E, Azaïs P, Cacciaguerra T, et al. KOH and NaOH activation mechanisms of multiwalled carbon nanotubes with different structural organisation. Carbon, 2005, 43: 786–795

Zhu Y, Murali S, Stoller MD, et al. Carbon-based supercapacitors produced by activation of graphene. Science, 2011, 332: 1537–1541

Wang Y, Tian L, Yao Z, et al. Enhanced reversibility of red phosphorus/active carbon composite as anode for lithium ion batteries. Electrochim Acta, 2015, 163: 71–76

Gogotsi Y, Portet C, Osswald S, et al. Importance of pore size in high-pressure hydrogen storage by porous carbons. Int J Hydrogen Energ, 2009, 34: 6314–6319

Ji J, Ji H, Zhang LL, et al. Graphene-encapsulated Si on ultrathingraphite foam as anode for high capacity lithium-ion batteries. Adv Mater, 2013, 25: 4673–4677

Qian J, Qiao D, Ai X, et al. Reversible 3-Li storage reactions of amorphous phosphorus as high capacity and cycling-stable anodes for Li-ion batteries. Chem Commun, 2012, 48: 8931–8933

Palomares V, Serras P, Villaluenga I, et al. Na-ion batteries, recent advances and present challenges to become low cost energy storage systems. Energ Environ Sci, 2012, 5: 5884–5901

Zhu C, Mu X, van Aken PA, et al. Single-layered ultrasmall nanoplates of MoS2 embedded in carbon nanofibers with excellent electrochemical performance for lithium and sodium storage. Angew Chem Int Ed, 2014, 53: 2152–2156

Zhou X, Wan LJ, Guo YG. Synthesis of MoS2 nanosheet-graphene nanosheet hybrid materials for stable lithium storage. Chem Commun, 2013, 49: 1838

Li W, Li M, Wang M, et al. Electrospinning with partially carbonization in air: Highly porous carbon nanofibers optimized for high-performance flexible lithium-ion batteries. Nano Energ, 2015, 13: 693–701

Yan Y, Yin YX, Guo YG, et al. A sandwich-like hierarchically porous carbon/graphene composite as a high-performance anode material for sodium-ion batteries. Adv Energ Mater, 2014, 4: 1301584

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (91648109), the National Key Research and Development Program of China (2017YFB0307001), the Priority Academic Program Development of Jiangsu Higher Education Institutions, and 333 project of Jiangsu Province.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Jiang Xu received his PhD degree from the State Key Laboratory of Metastable Materials Science and Technology, Yanshan University in 2015. He is now a Research Associate in Prof. Jianning Ding’s group at Changzhou University. His interest involves the design, synthesis, and characterizations of materials for various applications including supercapacitors, Li-ion or Na-ion batteries, etc.

Ningyi Yuan received her PhD degree from Shanghai Institute of Microsystem and Information Technology, Chinese Academy Sciences in 2003. Since 2007, she has been a professor at Changzhou University. Her current research is focused on organic solar cells, silicon nanowire solar cells, Li-ion batteries, Li-S battery, etc.

Jianning Ding received his PhD degree from Tsinghua University in 2001. After working as a research fellow in City University of Hong Kong from 2002 to 2003, he joined Jiangsu University and became a professor in 2003. Then he joined Changzhou University in 2007. His main interests focus on micro/nano devices, new energy and materials, etc.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Xu, J., Ding, J., Zhu, W. et al. Nano-structured red phosphorus/porous carbon as a superior anode for lithium and sodium-ion batteries. Sci. China Mater. 61, 371–381 (2018). https://doi.org/10.1007/s40843-017-9152-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-017-9152-9