Abstract

Ilmenite is an important mineral resource containing Fe and Ti, and titanium concentrate can be obtained after beneficiation. Through the preparation of titanium concentrate oxidized pellets, gas-based shaft furnace reduction experiments, and melting and separation experiments, the phase changes during the roasting process of titanium concentrate oxidized pellets were studied. The effects of different reduction temperatures and atmospheres on the reduction degree and expansion of titanium concentrate pellets were studied, and the reduction melting products were analyzed and evaluated. The research results indicate that the degree of oxidation of titanium concentrate oxidized pellets increases with the increase of roasting temperature. The reduction degree of titanium concentrate pellets also increases with the increase of reduction temperature and H2 content in the reduction atmosphere. The reduction expansion rate of pellets increases with the increase of reduction temperature and CO content in the reduced atmosphere. The phase components in the reduced oxidized titanium concentrate pellets are MgTi2O5, TiO2, and Fe. In the melting products, the recovery rate of iron in molten iron is 98%, the recovery rate in slag TiO2 is 96%, and the grade of titanium in titanium-rich slag is 74%. The efficient comprehensive utilization of iron and titanium in titanium concentrate has been achieved.

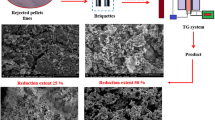

Graphical Abstract

Similar content being viewed by others

References

Levchenko EN, Klyucharev DS, Lalomov AV (2020) Genesis, features of mineral composition, and problems of the development of rare metal-titanium placers in the West Siberian megaprovince. Lithol Min Resour 55:139–151

Ananthapadmanabhan PV, Taylor PR, Zhu W (1999) Synthesis of titanium nitride in a thermal plasma reactor. J Alloy Compd 287(1–2):126–129

Li MH, Geng Y, Liu G, Gao ZY, Rui X, Xiao SJ (2022) Uncovering spatiotemporal evolution of titanium in China: a dynamic material flow analysis. Resour Conserv Recycl 180:106166

Xiao W, Lu XG, Zou XL, Wei XM, Ding WZ (2013) Phase transitions, micro-morphology and its oxidation mechanism in oxidation of ilmenite (FeTiO3) powder. Trans Nonferrous Met Soc China 23:2439–2445

Huang R, Liu PS, Qian X, Zhang JZ (2016) Comprehensive utilization of Panzhihua ilmenite concentrate by vacuum carbothermic reduction. Vacuum 134:20–24

Kang Z, Liao QL, Zhang Z, Zhang Y (2022) Carbon neutrality orientates the reform of the steel industry. Nat Mater 21(10):1094–1098

Yu W, Wen XJ, Chen JG, Kuang JZ, Tang QY, Tian YC, Fu JL, Huang WQ, Qiu TS (2017) Preparation of direct reduced iron and titanium nitride from panzhihua titanomagnetite concentrate through carbothermic reduction-magnetic separation. Minerals 7(11):220

Pan FS, Li K, Tang AT, Wang Y, Zhang J, Guo ZX (2003) Influence of high energy ball milling on the carbothermic reduction of ilmenite. Mater Sci Forum 437–438:105–108

Geng C, Sun TC, Yang HF, Ma YW, Gao EX, Xu CY (2015) Effect of Na2SO4 on the embedding direct reduction of beach titanomagnetite and the separation of titanium and iron by magnetic separation. ISIJ Int 55(12):2543–2549

Lv C, Yang K, Wen SM, Bai SJ, Feng QC (2017) A new technique for preparation of high-grade titanium slag from titanomagnetite concentrate by reduction-melting-magnetic separation processing. JOM 69:1801–1805

Yan ZP, Zhang Y, Zheng SL, Zhang Y, Sun P, Song ZW, Safdar F, Qi T (2022) Preparation of titanium mineral from vanadium titanomagnetite concentrates by hydrogen reduction and acid leaching. Trans Nonferrous Met Soc China 32(9):3099–3109

Li Y, Peng ZH, Wang ZX, Zhu YZ, Xie KQ (2023) Study on the properties of vanadium pellets extracted from vanadium titanium magnetite concentrate by calcium roasting and acid leaching. Minerals 13(3):399

Wu EH, Zhu R, Yang SL, Ma L, Li J, Hou J (2016) Influences of technological parameters on smelting-separation process for metallized pellets of vanadium-bearing titanomagnetite concentrates. J Iron Steel Res Int 23:655–660

Li YY, Yan BJ (2023) A novel approach for pre-concentrating titanium from Ti-bearing blast furnace slag. Sep Sci Technol 58(9):1679–1688

Zhu XF, Zheng SL, Zhang Y, Fang ZGZ, Zhang M, Sun P, Li Q, Zhang Y, Li P, Jin W (2019) Potentially more ecofriendly chemical pathway for production of high-purity TiO2 from titanium slag. ACS Sustain Chem Eng 7(5):4821–4830

Bian ZZ, Ning ZX, Zhao K, Gao R, Li WZ, Lv C, Yuan Y, Li HR (2022) Recovery of vanadium, titanium, and iron from vanadium titanomagnetite concentrate through ammonium sulfate cascade roasting with potassium pyrosulfate. J Sustain Metall 8:1988–2000

Zhang R, Hou Y, Fan G, Huang D, Ding X, Dang J (2022) Gas-based reduction and carbonization of titanium minerals in titanium-bearing blast furnace slag: a combined thermodynamic, experimental and DFT study. Int J Hydrogen Energy 47(12):7586–7599

Yu ZG, Xiao JW, Leng HY, Chou KC (2021) Direct carbothermic reduction of ilmenite concentrates by adding high dosage of Na2CO3 in microwave field. Trans Nonferrous Met Soc China 31(6):1818–1827

Chen DS, Zhao LS, Liu YH, Qi T, Wang JC, Wang LN (2013) A novel process for recovery of iron, titanium, and vanadium from titanomagnetite concentrates: NaOH molten salt roasting and water leaching processes. J Hazard Mater 244–245(15):588–595

Lei Y, Li Y, Peng J, Guo S, Li W, Zhang L, Wan R (2011) Carbothermic reduction of Panzhihua oxidized ilmenite in a microwave field. ISIJ Int 51(3):337–343

Dewan MAR, Zhang GQ, Ostrovski O (2010) Carbothermal reduction of a primary ilmenite concentrate in different gas atmospheres. Metall Mater Trans B 41(1):182–192

Pupyshev AM, Popov IO, Ustinov SM (2012) Research into basic laws of the phase distribution of iron and titanium under conditions of low-temperature reduction of the ilmenite concentrate. Russ J Non-Ferr Met 53:429–432

Lv XD, Chen D, Xin YT, Lv W, Lv XW (2022) Effect of sodium carbonate addition on carbothermic reduction of ilmenite concentrate. Trans Nonferrous Met Soc China 32(3):1010–1018

Choi K, Jeon HS, Lee S, Kim Y, Park H (2022) Gaseous reduction behavior of primary ilmenite at temperatures between 1273 K and 1473 K. Metall and Mater Trans B 53:334–341

Lobo S, Kolbeinsen L, Seim S (2016) Reduction of norwegian and indian ilmenite with carbon monoxide and hydrogen gas blends. Can Metall Q 55(4):455–462

Si XG, Lu XG, Li CW, Li CH, Ding WZ (2012) Phase transformation and reduction kinetics during the hydrogen reduction of ilmenite concentrate. Int J Miner Metall Mater 19(5):384–390

Lu CY, Zou XL, Lu XG, Xie XL, Zheng K, Xiao W, Cheng HW, Li GS (2016) Reductive kinetics of Panzhihua ilmenite with hydrogen. Trans Nonferrous Met Soc China 26:3266–3273

Baysal Z, Kirchner J, Mehne M, Kureti S (2020) Study on the reduction of ilmenite-type FeTiO3 by H2. Int J Hydrogen Energy 46(5):4447–4459

Tang J, Chu MS, Li F, Feng C, Liu ZG, Zhou YS (2020) Development and progress on hydrogen metallurgy. Int J Miner Metall Mater 27:713–723

Dang J, Zhang GH, Chou KC (2015) Kinetics and mechanism of hydrogen reduction of ilmenite powders. J Alloy Compd 619:443–451

Zeng RQ, Wang N, Li W (2023) Gas-based direct reduction of Hongge vanadium titanomagnetite pellets with different MgO additions. JOM 75:2714–2720

Shams A, Moazeni F (2015) Modeling and simulation of the MIDREX shaft furnace: reduction, transition and cooling zones. JOM 67:2681–2689

Li W, Fu GQ, Chu MS, Zhu MY (2017) Reduction behavior and mechanism of Hongge vanadium titanomagnetite pellets by gas mixture of H2 and CO. J Iron Steel Res Int 24:34–42

Zeng RQ, Li W, Wang N, Fu GQ, Chu MS, Zhu MY (2020) Effect of Al2O3 on the gas-based direct reduction behavior of Hongge vanadium titanomagnetite pellet under simulated shaft furnace atmosphere. Powder Technol 376:342–350

Li W, Fu GQ, Chu MS, Zhu MY (2018) Influence of V2O5 content on the gas-based direct reduction of Hongge vanadium titanomagnetite pellets with simulated shaft furnace gases. JOM 70:76–80

Li W, Fu GQ, Chu MS, Zhu MY (2017) Reduction kinetics of Hongge vanadium titanomagnetite-oxidized pellet with simulated shaft furnace gases. Steel Res Int 88(4):1600228

Zhang JL, Schenk J, Liu ZJ, Li KJ (2022) Editorial for special issue on hydrogen metallurgy. Int J Miner Metall Mater 29(10):1817

Zhang JL, Li Y, Liu ZJ, Wang TF, Wang YZ, Li KJ, Wang GL, Xu T, Zhang Y (2022) Isothermal kinetic analysis on reduction of solid/liquid wustite by hydrogen. Int J Miner Metall Mater 29(10):1830–1838

McLellan BC (2009) Potential opportunities and impacts of a hydrogen economy for the Australian minerals industry. Int J Hydrogen Energy 34(9):3571

Yilmaz C, Turek T (2017) Modeling and simulation of the use of direct reduced iron in a blast furnace to reduce carbon dioxide emissions. J Clean Prod 164(15):1519–1530

Acknowledgements

The authors are especially grateful to the Science and Technology Plan Project of Liaoning Province (2022JH24/10200027), the Seventh Batch of Ten Thousand Talents Plan (ZX20220553), and special thanks are due to the instrumental analysis from Analytical and Testing Center, Northeastern University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

The contributing editor for this article was Hongmin Zhu.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shi, Q., Tang, J. & Chu, M. A Novel Process for Direct Reduction of Titanium Concentrate Pellets in a Gas-Based Shaft Furnace. J. Sustain. Metall. 9, 1620–1635 (2023). https://doi.org/10.1007/s40831-023-00752-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-023-00752-8