Abstract

This paper compares the social impact of the steel industry in Belgium, China, and the United States as well as the effects of substituting fossil coal with waste wood following the social Lifecycle Assessment (s-LCA) principles defined by the UNEP/SETAC guidelines. It also aims to be beneficial for practitioners by introducing the s-LCA method and its application to the steel industry. A simplified approach is used by identifying social impacts via the social hotspot database and basing the analysis on national figures for the steel industry. The analysis demonstrates that social risks in the production chain of a Belgian steel mill are mainly situated in the iron ore and coal mining area; for the steel mill in China in the steel-making process itself as well as in coal and limestone mining, whereas the risks are rather equally distributed across the production chain in the United States. As for replacing fossil coal with waste wood, the analysis shows that the effects of this substitution process depend on the location of the steel factory and the previous use of waste wood.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

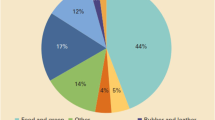

The steel industry is one of the largest industries in the world. In 2020, 1.864 Mt of steel was produced globally [1]. Steel is used in a great variety of applications, affecting nearly every part of everyday life. In 2019 from the 1.839 Mt total consumed steel, around 50 percent was used in building and infrastructure, 16% in mechanical equipment, 12% in automotive, 10% in metal products, 5% in other transport, 3% in electrical equipment, and 2% in domestic appliances [2]. The steel industry is also, with over 6 million employees worldwide, one of the major employers in the world [3].

Furthermore, the steel industry relies on large amounts of raw materials (e.g., iron ore, coal, limestone, etc.), gained in many different countries and under different conditions. The steel-making process, therefore, might include great social benefits (e.g. substantial gain for local communities), but also hold great conflict potential for workers, local communities, and society (e.g. health and safety issues, pollution of air and water, and resource extraction) [4]. Given the size and impact of the steel industry, it is of paramount importance to assess the sustainability of these processes-.

Sustainability is usually separated into three different dimensions, distinguished by different kinds of impacts [5, 6]. First, the environmental dimension deals with the environmental impacts of a product or service (e.g., greenhouse gas emissions, air pollution, and water pollution) based on Life-Cycle Assessment (LCA) methods. The second dimension, the socioeconomic assessment, is based on different forms of Lifecycle Costing (LCC) methods [7, 8] and addresses the economic impact, cost structures, and external costs for society. The third dimension, the social aspect of sustainability, focuses on the social impacts a product or a service induces along its production chain (e.g., association with working conditions, damage for workers and/or local communities, association with armed conflicts, etc.).

Standards for measuring social impacts are still underdeveloped on both theoretical and empirical grounds [9]. By focusing on the steel industry and using the first steps of a social Lifecycle Assessment (s-LCA) this paper demonstrates, how an overview of the most important expected social impacts for specific process chains can be done relatively easily and used to inform decision-makers and consumers. Furthermore, it is demonstrated how production chain changes can influence the expected social impact of a given product.

The next section offers an overview of the existing literature on the social assessment of the steel industry. Subsequently, the basics of the s-LCA approach and the assessment of social impacts using the Social Hotspots Database (SHDB) are introduced. The results section starts with a description of the product system used in the comparison of the steel industry in the three countries Belgium, China, and the United States. Using data from the national level and depicting an “average steel mill” in these countries shows major cross-national differences. Furthermore, it is shown that the effects of substituting fossil coal with waste wood depend on the location of the steel factory and the previous use of waste wood.

Existing Studies on the Steel Industry

Given the size of the steel industry and the constant call for sustainable production processes, it is surprising, that there is still “a lack of studies aiming at understanding social impacts across the value chains of steel products” [10]. There are, to our knowledge, only three studies performing social impact assessment on the steel itself.

Singh and Gupta examined the steel industry in India for the whole lifecycle of steel, from the extraction of raw materials and intermediate products to the steel-making process, the distribution to customers, and finally the end-of-life recycling. The data was taken partly from foreground sources such as interviews with representatives of steel mills and partly from background sources such as nationwide key figures. Categories, subcategories, and metrics were chosen by using the UNEP/SETAC guidelines [11] and identifying the most relevant (sub)categories and best fitting metrics based on interviews with representatives of the steel industry and experts in the field. Social issues that were discovered are skill development, infrastructure, education, health and safety, child labor, and minimum wages [10]. Hosseinijou et al. compared different building materials including steel. They used experts’ judgments to identify potential hotspots and analytical hierarchy processes based on expert interviews to determine the impacts of the hotspots. Identified problems for steel were: contribution to economic progress, pollution level, occupational accidents, waste generation, protection of cultural heritage, and the support of national suppliers [12]. Di Noi et al. compared different raw materials and, among others, “basic metals”. Hotspots were identified using the PSILCA (Product Social Impact Life Cycle Assessment) database and, subsequently, a variety of public datasets (from the World Health Organization, World Bank, etc.) were consulted to determine the severity of an impact. For basic metals, they found the highest social impacts in the categories of freedom of association, health and safety, and corruption [13]. Despite the common topic, these studies point to methodological differences in the analysis of social hotspots: Whereas the first two studies used expert judgment as their main source of data, the third one used various publicly available data.

Other analyses aim for more general social impact assessments. Mancini et al. analyzed in a report for the European Commission mining and manufacturing of basic metals in Europe [14]. They used the s-LCA methodology and the PSILCA database and found corruption, freedom of association, workers’ health and safety, and economic development as the most prevalent risks in the mining sector. In the manufacturing of basic metals, the risk was generally lower, whereas the highest risks were found for health and safety and freedom of association [14].

More literature on social impact assessment is available regarding the raw materials needed for steel production (coal and iron ore) and the mining industry in general. Since s-LCA aims to identify social influences along the whole lifecycle of a product or process, these results are also relevant for the s-LCA of steel. Mancini and Sala reviewed social impact assessments in the worldwide mining sector [15]. As most important social impacts in the mining industry were identified: (1) Economy, income, and security (stimulus to the local economy, but also unfair distribution of the mining benefits and corruptions); (2) Employment and education (job creation, but also child-, forced and compulsory labor); (3) Land use and territorial aspects (land competition and food insecurity); (4) Demography (migration flows and gender imbalances); (5) Environment, health, and safety (injuries, exposure to toxic materials, and water contamination); and (6) Human rights (discrimination, lack of stakeholder inclusion, and impacts on cultural and aesthetic resources). Negative impacts seem to occur more often in the African mining sector (76% of all impacts), whereas studies about Australia report positive impacts in 50 percent of the cases [15].

Azapagic developed a general framework of sustainable development indicators for the mining sector. Among the social factors, he found the following areas as most important: labor practices (employment, labor/management relations, health and safety, training, and diversity); human rights (non-discrimination, freedom of association, child labor, forced labor, disciplinary practice, security practice, and Indigenous rights), society (corruption, political contribution, and competition) and product responsibility [16].

Marimuthu et al. assessed the mining industry’s key challenges in terms of environmental, operational, and social issues [17]. They did this by conducting expert interviews. They revealed a lack of labor and management relations and fair wages as the most critical social challenges [17].

In sum, there are considerable indications that the steel-making process and production exert strong social influences. Nevertheless, social impact assessments in the steel industry are scarce, despite the increasing demand for sustainability by customers and initiatives by the industry itself. The reason for this dearth could be that the evaluation of social impacts is associated with a variety of difficulties regarding its methodological realization and—related to that—a lack of a standardized methodology The disparities in methodology, as well as the variation in countries and environments where these studies are conducted, may explain the differences observed in relation to the identified relevant (and problematic) social indicators.

Regardless of these differences, a few common steps can be named. First, for every production process theoretically, an almost infinite number of social impacts are perceivable: from various working conditions (e.g., wage policy, social security, health and safety, child and forced labor), to impacts on local communities (e.g., pollution of air and water, land use conflicts, and traffic) to impacts on the wider society (e.g., support or rejection of corruption and illegitimate government, contribution to wealth). Researchers, therefore, need a methodology to choose comparable social impact categories. Second, social impacts vary greatly depending on the region where the process takes place. Third, it is methodologically difficult to measure important indicators of social impacts. In contrast to ecological and socio-economic impacts, there is no general unit in which the impacts can be expressed. Considering these steps and caveats, this article demonstrates, using the first steps of an s-LCA, how a first overview of the most important expected social impacts for a specific production chain can be achieved and used to inform decision-makers and consumers.

Methods

Social Lifecycle Assessment (s-LCA) as a Tool to Measure Social Impacts

Social Life Cycle Assessment (s-LCA) applies life cycle assessment methodological steps while having social impacts as its focus. UNEP-SETAC defines social impacts as the consequences of interactions in the context of an activity (production, consumption, or disposal) and/or endangered by it and/or preventive or reinforcing actions taken by stakeholders (e.g. enforcing safety measures in a plant [11]). The s-LCA follows in principle the ISO 14040 framework and complements the environmental and economic LCA. It can be used to assess the social aspects of products, their actual and potential positive as well as negative impacts along the life cycle, from the extraction of raw materials to the final disposal.

An s-LCA has two main objectives: (a) to enable a comparison of products/services and processes for decision-making and (b) to identify improvement potentials within the system to minimize negative social impacts and maximize positive social impacts. An s-LCA includes the following steps:

Definition of the Goal

Typical goals can be the assessment of changes in social risks and opportunities, provoked by changes in the production process or the comparison of the social impacts of different production processes. In the present study, the goal of the analysis is the assessment of potential social impacts for steel mills situated in Belgium, China, and the United States. Belgium was selected because this analysis is conducted within the H2020 project “Torero” which funds the refitting of an actual steel mill in Ghent, Belgium. China and the United States were added as both countries are major steel producers and reflect different social and economic systems. The comparison, therefore, reflects a wide range of potential impacts of steel mills. Additionally, it is discussed how a change in the production process to become more climate-friendly also changes social impacts.

Definition of the Scope

The scope of a study is defined jointly with the goals. It sets the limits of the study or in other words the function of the product under investigation and the functional units (what is needed to produce a certain amount of the product with a specific function), what process steps are taken into account (and which are not) and the categories and data collected. These elements will be presented in the following paragraphs.

Definition of a Functional Unit

For a comparison of different systems, usually, a functional unit (e.g., one ton of produced crude steel) needs to be defined to account for differences in the product system (e.g., if one of the compared systems needs more coke as input to produce one ton of crude iron than other systems, the social impacts occurring in coke mining should be weighted stronger in this case.) For the present study, no functional unit is defined, as the comparison is based on average national figures. The reason is that the refitting of the steel mill is still ongoing and the actual numbers are not available yet. Regardless, the average values can be used to identify potential hotspots without a comparison of the real performance of steel mills. Hence, it is also not investigated if a steel mill in Belgium, China, or the United States needs more input material to produce one ton of crude steel of a certain quality than a mill in another country.

Definition of the Product System

Every product can be connected to nearly an unlimited number of production processes (most of them relevant to only a small degree for the product in question), therefore, every s-LCA needs to define which process steps are included in the analysis. Furthermore, since local legal and social conditions are very important for a social impact assessment, every process step needs to be connected to a geographic region. The present study compares the steel-making processes and the mining of the three most important raw materials used in steel-making: Iron ore, coal, and limestone. In the second step, the analysis will show, how a change in one of these process steps, namely a substitution of fossil coal by bio coal made out of wood waste, shifts social impacts (see Fig. 1). Limiting assumptions, however, are that the steel-making process takes place entirely in the considered three countries and that the raw materials were produced in the exporting countries.

Identification of the Categories and the Database

The identification of the categories and data relevant to the steel-making process is performed by considering all topics named by the Social Hotspot Database (SHDB). SHDB uses the term “social theme” and has indicators for the themes such as labor rights, human rights, etc. The use of the data from the SHDB is further explained in the next subchapter.

Identifying Social Hotspots Using the “Social Hotspot Database” (SHDB)

Regarding the social impacts of a product or production process, a nearly indefinite number of potential effects is imaginable, which cannot all be investigated by an s-LCA. Therefore, a mode needs to be found to determine a priori, in which social dimensions a critical impact from a product or production process is most likely. These critical dimensions are called social hotspots. One method to do that is to use databases that are designed to reveal critical social impacts of different types of products in—ideally—all countries. The Social Hotspot Database (SHDB), among other databases, provides a possibility to identify such hotspots: It contains country and sector-specific indicator tables to identify hotspots divided into 5 subgroups and 25 social themes (see Table 1) [18].

For each of these social themes, one or more indicators are identified by the SHDB. SHDB compares data from various publicly available data sources and statistical agencies (e.g., World Bank, World Health Organization) and uses this data to determine the characteristic of a specific indicator in a given country and economic sector. This data is categorized into five gradations from a very low risk of occurrence of problems in the observed social theme in the country in the sector to a very high risk of occurrence [18]. Subsequently, all social themes indicating a very high risk of social problems in each production process of a given country are used for further investigation. Vice versa, all themes that are not mentioned have a lower risk.

In a conventional s-LCA, the identified social hotspots are then further examined by using in-depth data (e.g., on-site observation, interviews with experts such as employees’ representatives, and/or use of working records of companies, etc.). Since different process steps usually take place in several countries and potential information providers often might be hesitant to share information (many of the topics are sensitive) this is a time and resource-intensive task. Furthermore, researchers have to be careful regarding the reliability of such data. As for production processes that are not established yet (as is the case in the present example of replacing coal with waste wood in a steel mill), analyses have to rely on more generic data. While the use of generic data does not allow a very fine-grained analysis, it can be still used to understand the potential future social impacts of a new to be developed product or changed production process in advance. Therefore, a simplified approach is proposed by suggesting to end the data extraction with the identification of social hotspots. The next sections will show which kind of information, useful for decision-making and general information, can be derived while needing relatively few resources.

Results

The Social Impact of an Average Steel Mill in Belgium, China, and the United States

As a first step, the main sources for the products of the production process are identified. The product system for the comparison of the steel mills in the present analysis includes the mining of the most important raw materials (iron ore, coal, and limestone [19]) and the processing of these raw materials. Therefore, the product system consists of the mining of these raw materials plus the steel-making process in the steel mill itself—a blast furnace steel mill. A typical steel mill requires around 1370 kg of iron ore, 780 kg of coal, and 270 kg of limestone for the production of 1 metric ton of crude steel [20].

As the present analysis is based on average national figures, the national supply mix of the respective countries is used as an approximation, assuming that the raw materials also have been mined in the countries that export to Belgium, China, or the United States. As for Belgium, the main sources of iron ore are Germany (21% of all imports), the Netherlands (14%), France (11%), the United States (6%), Canada (4%), and Spain (3.5%) [21]. The main importers of coal are the Netherlands (33% of all imports), Norway (30%), Qatar (20%), and Russia (8%) [22]. Limestone is mainly produced in France, Germany, and Belgium [23]. As for China, iron ore stems mostly from Australia (62%) and Brazil (21%) [24]. Coal is mainly produced in China itself [25] and so is limestone [26]. As for the United States, all main sources are domestic [27, 28].

The second step was to identify the social hotspots in the steel mill and the three main products needed in the production—iron, coke, and limestone. Table 2 provides an overview of the hotspots in the different countries, processes, stakeholders, and themes. Critical social themes for the whole production process in a Belgian steel mill are especially prevalent in coal mining (mostly because of the use of coal from Qatar and Russia, two countries with a variety of problematic social conditions) and to a smaller degree in iron ore mining (partly caused by ore mining in the United States, a country that has a less developed social system compared to European standards), whereas limestone mining and the work in the steel mill itself are not expected to cause major social problems. In China, high risks of social problems are suspected in all production processes which take place in China (steel production, coal, and limestone mining) whereas production of iron ore outside China (mainly in Australia and Brazil) are not expected to cause major problems. In the United States, social risks are equally distributed among all production steps (except for the risk of severe injuries and fatalities, which is higher for steel-making and iron ore mining). The reason for this is that the United States can produce all the necessary raw materials domestically.

As for the categories, there is a higher risk of unfavorable conditions concerning labor rights and decent work for the Chinese and the US steel-making process (18 identified hotspots in China, 16 in the United States versus 11 in Belgium). Health and safety risks are the lowest in the US steel-making process (4 hotspots in Belgium versus 3 in China, versus 2 in the United States). For human rights violations again, the lowest risk is expected in the United States with 4 identified hotspots versus 6 in Belgium and 9 in China. For an unjust political system, there is a higher risk for the Chinese steel-making process with 5 possible hotspots versus 2 in the Belgian case and none for the US steel-making process. Regarding negative impacts on community aspects, there is a small risk identifiable for the Belgian steel-making process (1 hotspot, caused by lack of access to improved drinking water in Canada) and no risk for the Chinese and the US steel mill.Footnote 1

Another way of reading the results, which is often done in social impact assessments, is to group the identified risks by affected stakeholder category. These stakeholder categories are not provided by SHDB and must be assigned by the researcher. Doing this for the steel-making process using the stakeholder categories as indicated in the UNEP/SETAC guidelines [11] (see column 2 in Table 2), reveals a higher risk for workers in China (21 identified hotspots) followed by the United States (18 hotspots), and Belgium (14 hotspots). Local communities are potentially affected equally negatively in Belgium and China (3 identified hotspots each) and not at all in the United States. Society as a whole can be expected to be most negatively affected in China (14 identified hotspots) followed by Belgium (8 hotspots) and the United States (4 hotspots). Overall, the analysis reveals that steel-making in all three countries has the potential to result in negative social impacts, but the risk is higher in China than in the United States and Belgium.

Assessing the Social Impact of Substituting Fossil Coals with Waste Wood

The analyses presented so far depicted the social impacts of the product system considering the steel mills and the most important raw materials (iron ore, coal, and limestone). Subsequently, the aspect of substituting fossil coal with bio coal produced from waste wood is addressed. The reason for choosing this change is that the present analysis is related to the H2020 project “Torero,” which funds the refitting of an ArcelorMittal steel factory in Ghent, Belgium. The pulverized fossil coal needed in the blast furnace of this steel mill is partially substituted by bio coal produced from wood waste (from construction sites, wood-processing factories, etc.) [29] (Table 3). The question now is what happens with the expected social impacts if fossil coal is substituted by the lower carbon-intensive resource waste wood?

Comparing coal mining with the collection and processing of waste wood (included in the social hotspot database in the sector “wood products”) reveals that the substitution of fossil coal with bio coal produced from waste wood would diminish all identified social hotspots in Belgium (shifting from coal mining in countries as Qatar or Russia to a production step situated in Belgium), whereas for China nearly no change would occur apart from a reduction in the risk “child labor” and for the United States an additional risk with an increased “number of injuries and fatalities” might occur, indicating that the number of injuries and fatalities is higher in the US wood processing industry than in the coal mining industry according to SHDB. So, using less carbon-intensive technologies would lead to a reduction of social impacts in Belgium, but not necessarily in China and the United States. This difference emphasizes the importance of the location where a production step takes place.

However, whenever a replacement of a material by another material is taking place, it is necessary to consider the current use of this product. Unfortunately, the information on where the waste wood is currently used is only available for BelgiumFootnote 2—as an energy source in thermal power plants. If this source is not available anymore, another energy source needs to produce the necessary thermal energy. In Belgium, the most likely assumption is that this will be gas. A comprehensive analysis of social impacts thus also needs to consider the impact of the substitution product. Results for the Belgian example, again using the national gas mix of Belgium [31], are shown in Table 4: Taking this substitution process into account changes the results fundamentally: Not only would this lead to the reoccurrence of the risks identified in the coal mining process, but also add another risk, i.e., the presence of conflicts (Table 4).

Discussion

The purpose of this paper was to show how relatively easy, with the help of a simplified s-LCA, it is possible to get a first overview of social impacts occurring in a given production process in the steel industry. By comparing different locations and/or process changes, the applied method can help decision-makers in the steel industry to uncover the negative social impacts of their production chains and to adjust accordingly. This endeavor is particularly relevant since process changes aiming at a more environment-friendly production process do not necessarily mean that the new process is also more sustainable concerning social aspects.

Considering the national figures, the analysis based on data from SHDB showed no prevalent expected (negative) social impacts for the steel mill in Belgium. Yet, negative effects can be seen in the supply chain in coal mining (in the categories of labor rights, health and safety, human rights, and governance), iron ore mining (labor rights, health and safety, human rights, and impact on community), and limestone mining (migrant workers). For the steel mill in China, negative impacts can be expected for the steel-making process itself and coal and limestone mining (all categories except for community), whereas fewer negative impacts are expected for iron ore mining (labor rights and governance). For the US steel mill, social impacts can be expected at a similar level in all production process steps. The reason for this is that all processes take place domestically and, therefore, under similar social conditions.

Our results coincide only partly with prior studies on the steel-making process, which identified labor rights, health, and safety [10], health, safety, and community [12], and labor rights, health, safety, and governance [13] as themes with the highest risk of negative social consequences. With regards to the mining sector, almost all social categories were named, most importantly labor rights [14,15,16,17], governance [14,15,16], Health and Safety [14,15,16], Human rights [15, 16], and community impacts [16]. The mining sectors considered in this paper, yield a similar distribution of social risks with an emphasis on labor, human rights, health, and safety.

The differences in the findings can be explained by the fact that the social impact depends on the country where a certain process step takes place. Legal and economic frameworks (labor laws, democratic tradition, social security laws, and wealth distribution) determine how the actual working process and relations to local communities are shaped and, therefore, what social impacts occur. So other than for improvements in environmental performance, which usually require technical changes, improvements in social performance can be reached by either moving process steps into countries with better social conditions or enforcing better social conditions all along the supply chain. This aspect is especially relevant for the mining processes since mining plays a very important role concerning negative social impacts. The first conclusion of this paper points in the direction that, regarding a reduction of negative social impacts, improvement can be achieved under current technical production conditions. As for the social benefits of replacing fossil coal with less climate-invasive materials, such as bio coal from waste wood, the present analysis shows that the impact depends on the locations of the different processes. The substitution process can have positive effects, negative effects, or none. Without going into much detail, the findings indicate that this change per se produces positive effects in Belgium, a positive effect in China, and a negative effect in the United States. However, this statement holds only, if the resources needed in the technical innovative processes either are not needed elsewhere or can be substituted by other low-impact resources. If this is not the case—as shown for the Belgian case, where waste wood is currently used mainly as an energy source in thermal power plants and then potentially replaced by natural gas—the substitution of waste wood diminishes the initial positive effects. A second result derived from these analyses, therefore, is that substitution effects need to be considered from the beginning and at all levels of decision-making to derive a realistic estimation of the occurring social impact effects.

While these results offer solid insights into the social impact of the steel industry and some substitution effects, some limitations need to be mentioned. First, the present results are based on average data for the respective country, assume that the raw materials are produced in the importing countries, and use a simplified production process. Secondly, the effects of the social impacts of different production processes were not weighted according to the proportion in the production process, for example concerning working hours. Third, this article ends with the assessment of potential social hotspots. In s-LCA, the hotspot identification is seen as the anchor guiding the following acquisition of the ‘true’ data for a given production process—which will be possible for the Belgian case once the refitting process in Ghent is completed.

In sum, this paper can be seen as a guideline for how to easily assess potential social hotspots when comparing different production sites and changes along the production chain in the steel industry. The analysis, contributing to the qualitative assessments of product systems at the macro-economy level, shows that the social impacts vary, even for identical processes, due to the geographic location of the production processes. Furthermore, it shows that production changes towards more environment-friendly processes do not necessarily imply that negative social impacts are reduced as well. Our paper stops at the assessment of different effects. At the end of the day, economic and political leaders would have to decide in which direction the processes should be changed. Regardless, considerations about becoming less climate-damaging, therefore, should always be accompanied by an analysis of the social impacts induced by the proposed changes, thereby also raising the acceptance of these new technologies.

Notes

Note that the number of examined indicators is different for different categories, so a cross-category comparison cannot be done with the absolute numbers.

This information derives from the project partners of the H2020 project “Torero”, which demonstrates the possibility of substituting coke with bio coal produced from waste wood. In other countries/under other conditions waste wood might be used for other purposes, for example, to construct particleboards [30]. This would change the social impact of the process chain.

References

World Steel Association (2021) Global crude steel output decreases by 0.9% in 2020. https://www.worldsteel.org/media-centre/press-releases/2021/Global-crude-steel-output-decreases-by-0.9--in-2020.html

World Steel Association (2023) Steel markets. https://worldsteel.org/steel-topics/steel-markets/

World Steel Association (2021) People are proud to work in steel. https://www.worldsteel.org/about-steel/steel-industry-facts/people-proud-steel.html

Kaltenegger I, Schwarzinger S (2018) The challenge of quantification: social life cycle assessment (s-LCA) for advanced biofuel from waste wood integrated in the steel industry. https://www.fruitrop.com/en/content/download/44031/725043/file/Thema%204%20taille%20mini.pdf#page=104

Finkbeiner M, Schau EM, Lehmann A et al (2010) Towards life cycle sustainability assessment. Sustainability 2:3309–3322. https://doi.org/10.3390/su2103309

Neugebauer S, Forin S, Finkbeiner M (2016) From life cycle costing to economic life cycle assessment—introducing an economic impact pathway. Sustainability 8:428. https://doi.org/10.3390/su8050428

Rödger J-M, Kjaer LL, Pagoropulous A (2018) Life cycle costing: an introduction. In: Hauschild MZ, Rosenbaum RK, Olsen SI (eds) Life cycle assessment: theory and practice. Springer, Cham, pp 373–399

Moreau V, Weidema BP (2015) The computational structure of environmental life cycle costing. Int J Life Cycle Assess 20:1359–1363. https://doi.org/10.1007/s11367-015-0952-1

Rawhouser H, Cummings M, Newbert SL (2019) Social impact measurement: current approaches and future directions for social entrepreneurship research. Entrep Theory Pract 43:82–115. https://doi.org/10.1177/1042258717727718

Singh RK, Gupta U (2018) Social life cycle assessment in Indian steel sector: a case study. Int J Life Cycle Assess 23:921–939. https://doi.org/10.1007/s11367-017-1427-3

UNEP/SETAC (2009) Guidelines for social life cycle assessment of products: Social and socio-economic LCA guidelines complementing environmental LCA and Life Cycle Costing, contributing to the full assessment of goods and services within the context of sustainable development

Hosseinijou SA, Mansour S, Shirazi MA (2014) Social life cycle assessment for material selection: a case study of building materials. Int J Life Cycle Assess 19:620–645. https://doi.org/10.1007/s11367-013-0658-1

Di Noi C, Ciroth A, Mancini L et al (2020) Can S-LCA methodology support responsible sourcing of raw materials in EU policy context? Int J Life Cycle Assess 25:332–349. https://doi.org/10.1007/s11367-019-01678-8

Blengini G, Ciroth A, Eisfeldt F et al (2018) Social assessment of raw materials supply chains: a life-cycle-based analysis. EUR, scientific and technical research series. Publications Office of the European Union, Luxembourg

Mancini L, Sala S (2018) Social impact assessment in the mining sector: review and comparison of indicators frameworks. Resour Policy 57:98–111. https://doi.org/10.1016/j.resourpol.2018.02.002

Azapagic A (2004) Developing a framework for sustainable development indicators for the mining and minerals industry. J Clean Prod 12:639–662. https://doi.org/10.1016/S0959-6526(03)00075-1

Marimuthu R, Sankaranarayanan B, Ali SM et al (2021) Assessment of key socio-economic and environmental challenges in the mining industry: implications for resource policies in emerging economies. Sustain Prod Consum 27:814–830. https://doi.org/10.1016/j.spc.2021.02.005

Benoit-Norris C, Cavan DA, Norris G (2012) Identifying social impacts in product supply chains: overview and application of the social hotspot database. Sustainability 4:1946–1965. https://doi.org/10.3390/su4091946

EUROFER (2020) Raw materials. https://www.eurofer.eu/issues/environment/raw-materials/

World Steel Association (2023) Fact sheet-steel and raw materials. https://worldsteel.org/wp-content/uploads/Fact-sheet-raw-materials-2023.pdf. Accessed 11 Apr 2023

Worldbank (2018) Belgium ores and metal imports by country. https://wits.worldbank.org/CountryProfile/en/Country/BEL/Year/2018/TradeFlow/Import/Partner/by-country/Product/OresMtls

Eurostat (2018) Discover the world of energy trade. https://ec.europa.eu/eurostat/de/web/products-eurostat-news/-/wdn-20200706-1

European Commission (2018) Competitiveness of the European cement and lime sectors: final report. Publications Office of the European Union, Luxembourg

Statista (2021) Breakdown of iron ore import volume to China in 2019, by major country of origin. https://www.statista.com/statistics/1070171/china-iron-ore-import-share-by-country/

Xie S (2020) China becomes net coke importer in July, a 20 years first. https://www.mysteel.net/article/5018104-06/China-becomes-net-coke-importer-in-July--a-20-year-first.html

Ministry of Natural Ressources (2018) China mineral resources, Beijing

U.S. Energy Administration Information (2021) Quarterly coal report. https://www.eia.gov/coal/production/quarterly/

National Minerals Information Center (2021) Mineral industry surveys. https://d9-wret.s3.us-west-2.amazonaws.com/assets/palladium/production/s3fs-public/media/files/mis-202110-feore.pdf

ArcelorMittal (2021) TORrefying wood with ethanol as a renewable output: large-scale demonstration. https://www.torero.eu/. Accessed 07 Jul 2021

Kamke FA (2004) Solid wood products|wood-based composites and panel products. In: Burley J (ed) Encyclopedia of forest sciences. Elsevier, Oxford, pp 1338–1345

Eurostat (2020) Energy trade 2019. https://ec.europa.eu/eurostat/cache/infographs/energy_trade/entrade.html?geo=BE&year=2019&language=EN&trade=imp&siec=G3000&filter=all&fuel=gas&unit. Accessed 08 Oct 2021

Funding

Open access funding provided by University of Graz. This study was funded by HORIZON EUROPE Framework Programme, 745810.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editors for this article were M. Akbar Rhamdhani and Veena Sahajwalla.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hadler, M., Brenner-Fliesser, M. & Kaltenegger, I. The Social Impact of the Steel Industry in Belgium, China, and the United States: A Social Lifecycle Assessment (s-LCA)-Based Assessment of the Replacement of Fossil Coal with Waste Wood. J. Sustain. Metall. 9, 1499–1511 (2023). https://doi.org/10.1007/s40831-023-00742-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-023-00742-w