Abstract

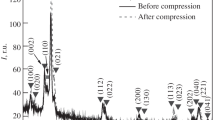

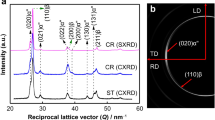

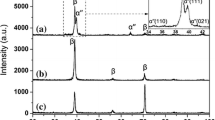

Superelastic alloys based on Ti–Zr–Nb are low-modulus biocompatible alloys for medical applications. We analyzed the regularities of the development of martensitic transformations (MT) β (bcc) → α′′ (orthorhombic lattice) in Ti–(17–19)Zr–(14–15)Nb (at.%) alloys, where α′′-phase arises under the influence of tensile or compressive stress. The crystallographic texture of β-titanium alloys was well studied. However, this is precisely what determines the recoverable strain in the material. Phase analysis using synchrotron radiation showed that the MT begins at 1% deformation, and at 1.5% the martensite lines are clearly distinguishable. The orientational dependences of the formation of domains of the martensite phase were studied using generalized direct pole figures. The main texture components of the cold rolled up to 97% and then recrystallized foils are {221}〈114〉 and {100}〈011〉. Under tensile deformation up to 1.4%, α′′-phase domains with the orientation (100)[001] is formed from β-grains compressed along the normal direction of the foil. With an increase in the degree of deformation to 1.6%, in addition to the main texture component, the second texture component appears. Its orientation depends on the direction of application of the external stress: (001)[110] in tension along the rolling direction and (\(\overline{1 }\)05)[501] in tension in the transverse direction.

Similar content being viewed by others

Data Availability

The data required to reproduce these findings are available to download from [43].

References

Ramezannejad A, Xu W, Xiao WL, Fox K, Liang D, Qian M (2019) New insights into nickel-free superelastic titanium alloys for biomedical applications. Curr Opin Solid State Mater Sci 23(6):100783. https://doi.org/10.1016/J.COSSMS.2019.100783

Miyazaki S, Miyazaki S (2017) My experience with Ti–Ni-based and Ti-based shape memory alloys. Shape Mem Superelast 3(4):279–314. https://doi.org/10.1007/s40830-017-0122-3

Yoneyama T, Miyazaki S (2009) Shape memory alloys for biomedical applications. Woodhead Publishing, England

Nuss S, US Patent no. 7.468.045 (2008)

Nordberg GF, Gerhardsson L, Broberg K, Mumtaz M, Ruiz P, Fowler BA (2007) Interactions in metal toxicology. Handb Toxicol Met, pp 117–145. https://doi.org/10.1016/B978-012369413-3/50062-8

Biocompatibility and tissue reaction to biomaterials. Craig’s Restor Dent Mater, pp 109–133 (2012) https://doi.org/10.1016/B978-0-323-08108-5.10006-4

Köster R, Vieluf D, Kiehn M, Sommerauer M, Kahler J, Baldus S, Meinertz T, Hamm CW (2000) Nickel and molybdenum contact allergies in patients with coronary in-stent restenosis. Lancet 356(9245):1895–1897. https://doi.org/10.1016/S0140-6736(00)03262-1

Kim HY, Hashimoto S, Il KJ, Hosoda H, Miyazaki S (2004) Mechanical properties and shape memory behavior of Ti-Nb alloys. Mater Trans 45(7):2443–2448. https://doi.org/10.2320/matertrans.45.2443

Kim HY, Miyazaki S (2016) Several issues in the development of Ti–Nb-based shape memory alloys. Shape Mem Superelast 2(4):380–390. https://doi.org/10.1007/s40830-016-0087-7

Bedi RS, Beving DE, Zanello LP, Yan Y (2009) Biocompatibility of corrosion-resistant zeolite coatings for titanium alloy biomedical implants. Acta Biomater 5(8):3265–3271. https://doi.org/10.1016/j.actbio.2009.04.019

Kim H-S, Kim W-Y, Lim S-H (2006) Microstructure and elastic modulus of Ti-Nb-Si ternary alloys for biomedical applications. Scr Mater 54(5):887–891. https://doi.org/10.1016/j.scriptamat.2005.11.001

Hao YL, Zhang ZB, Li SJ, Yang R (2012) Microstructure and mechanical behavior of a Ti-24Nb-4Zr-8Sn alloy processed by warm swaging and warm rolling. Acta Mater 60(5):2169–2177. https://doi.org/10.1016/j.actamat.2012.01.003

Kim HY, Sasaki T, Okutsu K, Kim JI, Inamura T, Hosoda H, Miyazaki S (2006) Texture and shape memory behavior of Ti-22Nb-6Ta alloy. Acta Mater 54(2):423–433. https://doi.org/10.1016/j.actamat.2005.09.014

Sun F, Nowak S, Gloriant T, Laheurte P, Eberhardt A, Prima F (2010) Influence of a short thermal treatment on the superelastic properties of a titanium-based alloy. Scr Mater 63(11):1053–1056. https://doi.org/10.1016/j.scriptamat.2010.07.042

Zhang J, Sun F, Hao Y, Gozdecki N, Lebrun E, Vermaut P, Portier R, Gloriant T, Laheurte P, Prima F (2013) Influence of equiatomic Zr/Nb substitution on superelastic behavior of Ti-Nb-Zr alloy. Mater Sci Eng A 563:78–85. https://doi.org/10.1016/j.msea.2012.11.045

Miyazaki S, Kim HY, Hosoda H (2006) Development and characterization of Ni-free Ti-base shape memory and superelastic alloys. Mater Sci Eng A 438–440:18–24. https://doi.org/10.1016/j.msea.2006.02.054

Ramarolahy A, Castany P, Prima F, Laheurte P, Péron I, Gloriant T (2012) Microstructure and mechanical behavior of superelastic Ti-24Nb-0.5O and Ti-24Nb-0.5N biomedical alloys. J Mech Behav Biomed Mater 9:83–90. https://doi.org/10.1016/j.jmbbm.2012.01.017

Fukui Y, Inamura T, Hosoda H, Wakashima K, Miyazaki S (2004) Mechanical properties of a Ti-Nb-Al shape memory alloy. Mater Trans 45(4):1077–1082. https://doi.org/10.2320/matertrans.45.1077

Kim HY, Fu J, Tobe H, Il KJ, Miyazaki S (2015) Crystal structure, transformation strain, and superelastic property of Ti–Nb–Zr and Ti–Nb–Ta Alloys. Shape Mem Superelast 1(2):107–116. https://doi.org/10.1007/s40830-015-0022-3

Fu J, Yamamoto A, Kim HY, Hosoda H, Miyazaki S (2015) Novel Ti-base superelastic alloys with large recovery strain and excellent biocompatibility. Acta Biomater 17:56–67. https://doi.org/10.1016/J.ACTBIO.2015.02.001

Cai S, Daymond MR, Ren Y, Schaffer JE (2013) Evolution of lattice strain and phase transformation of β III Ti alloy during room temperature cyclic tension. Acta Mater 61(18):6830–6842. https://doi.org/10.1016/J.ACTAMAT.2013.07.062

Kim HY, Ikehara Y, Kim JI, Hosoda H, Miyazaki S (2006) Martensitic transformation, shape memory effect and superelasticity of Ti-Nb binary alloys. Acta Mater 54(9):2419–2429. https://doi.org/10.1016/j.actamat.2006.01.019

Inamura T, Shimizu R, Kim HY, Miyazaki S, Hosoda H (2016) Optimum rolling ratio for obtaining {001}〈110 〉 recrystallization texture in Ti-Nb-Al biomedical shape memory alloy. Mater Sci Eng C 61(April):499–505. https://doi.org/10.1016/j.msec.2015.12.086

Zaripova MM, Isaenkova MG, Perlovich YA, Osintsev AV, Fesenko VA (2019) Influence of crystallographic texture and phase composition on the effect of superelastiñity of foils from alloys based on Ti-Nb. Chelyabinsk Phys Math J. https://doi.org/10.24411/2500-0101-2019-14109

Zaripova MM, Isaenkova MG, Fesenko VA, Osintsev AV (2021) The influence of the crystallographic texture and phase composition of Ti-Nb-Zr alloys with shape memory and superelasticity on their functional properties. IOP Conf Ser Mater Sci Eng 1121(1):012032. https://doi.org/10.1088/1757-899x/1121/1/012032

Isaenkova MG, Perlovich YA, Fesenko VA, Zaripova MM (2019) Orientation dependence of functional properties of alloys with shape memory effect and superelasticity. Chelyabinsk Phys Math J. https://doi.org/10.24411/2500-0101-2019-14209

Kim HY, Miyazaki S (2018) Chapter 4—Thermomechanical treatment and microstructure control. In: Kim HY, Miyazaki S (eds) Ni-free Ti-based shape memory alloys. Butterworth-Heinemann, Oxford, pp 111–145

Hasan M, Schmahl WW, Hackl K, Heinen R, Frenzel J, Gollerthan S, Eggeler G, Wagner M, Khalil-Allafi J, Baruj A (2008) Hard X-ray studies of stress-induced phase transformations of superelastic NiTi shape memory alloys under uniaxial load. Mater Sci Eng A 481–482:414–419. https://doi.org/10.1016/J.MSEA.2007.02.156

Zheng QS, Liu Y (2002) A Prediction of the detwinning anisotropy in textured NiTi shape memory alloy. Philosoph Mag. https://doi.org/10.1080/01418610208243195

Yang Y, Castany P, Cornen M, Prima F, Li SJ, Hao YL, Gloriant T (2015) Characterization of the martensitic transformation in the superelastic Ti-24Nb-4Zr-8Sn alloy by in situ synchrotron X-ray diffraction and dynamic mechanical analysis. Acta Mater 88:25–33. https://doi.org/10.1016/j.actamat.2015.01.039

Svetogorov RD, Sulyanov SN (2018) High-resolution powder diffraction at the XSA beamline of the Kurchatov Synchrotron Radiation Source. In: IX National crystal chemical conference, Suzdal, conference proceedings 81.

Svetogorov RD, Dionis—diffraction open integration software. Certificate of registration № 2018660965.

Perlovich YA, Isaenkova MG (2015) Strukturnaya neodnorodnost’ teksturirovannykh metallicheskikh materialov (Structural heterogeneity of textured metal materials). National Research Nuclear University MEPhI, Moscow, 398, In Russ.

Perlovich Y, Isaenkova M, Bunge HJ (2001) The fullest description of the structure of textured metal materials with generalized pole figures: the example of rolled Zr alloys. Mater Sci Forum 378–381:180–185. https://doi.org/10.4028/www.scientific.net/MSF.378-381.180

Perlovich Y, Isaenkova M (2002) Distribution of c- and a-dislocations in tubes of Zr alloys. Metall Mater Trans A. https://doi.org/10.1007/s11661-002-0156-8

Perlovich Yu, Isaenkova M (2005) Distribution of dislocation density in tubes from Zr-based alloys by X-ray data. Solid State Phenom 105:89–94. https://doi.org/10.4028/3-908451-09-4.89

Perlovich Yu, Isaenkova M (1997) Features of the phase transformations in sheets, tubes and welding seams of the alloy Zr-2.5%Nb. Text Microstruct 30:55–70. https://doi.org/10.1155/TSM.30.55

Fesenko V, Perlovich Y, Isaenkova M (2015) The increased shape memory effect in rolled Ti-48%Ni-2%Fe single crystals. Mater Today Proc 2:S751–S754. https://doi.org/10.1016/J.MATPR.2015.07.391

Perlovich Y, Isaenkova M (2011) Non-uniform strain hardening of crystallites within different regions of texture maxima: evidences and mechanisms. Mater Sci Forum 702–703:681–684. https://doi.org/10.4028/www.scientific.net/MSF.702-703.681

Perlovich Yu, Isaenkova M, Fesenko V (2008) Three laws of substructure anisotropy of textured metal materials, revealed by X-ray method of generalized pole figures. Mater Proces Text Ceram Trans 200:539–546. https://doi.org/10.1002/9780470444214.ch20

Perlovich Y, Isaenkova M, Bunge HJ, Fesenko V (2000) Distribution of residual microstresses in rolled textured metal materials. Mater Sci Forum 347–349:291–296. https://doi.org/10.4028/www.scientific.net/MSF.347-349.291

MTEX Toolbox (Electronic resource). https://mtex-toolbox.github.io/index.html. Accessed 19 Nov 2021

Zaripova M (2021) Phase and texture analysis data Mendeley Data, V1. https://doi.org/10.17632/2vmgssbt7f.1

Acknowledgements

The work was carried out with the financial support of the Russian Federation represented by the Ministry of Science and Higher Education of the Russian Federation (Agreement No. 075-15-2021-1352).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zaripova, M., Fesenko, V., Krymskaya, O. et al. Change in the Crystallographic Texture of the Martensitic Phase in Superelastic Ti–Zr–Nb Alloys with Increasing Tensile Strain. Shap. Mem. Superelasticity 8, 188–199 (2022). https://doi.org/10.1007/s40830-022-00383-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-022-00383-0