Abstract

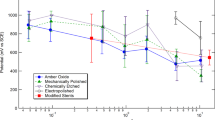

The effects of reductions in Nitinol inclusion size and area fraction on corrosion resistance have yet to be elucidated, particularly for very high microstructural purity Nitinol. Therefore, the objective of this study was to determine the impact of various Nitinol microstructural purities on pitting resistance and nickel ion release. Generic heart valve frames were manufactured with different vacuum arc remelting methods (VAR, H.P. VAR, and VAR/EBR) and surface finishes (thermal oxide, chemical etch, electropolish). Frames were subjected to pitting corrosion testing and 60-day immersion in a simulated physiological environment. Microstructural analysis found the maximum inclusion length for VAR/EBR tubing was 2 times smaller than H.P. VAR and 8 times smaller than standard VAR tubing. Despite these differences, pitting corrosion resistance was similar between microcleanliness groups for any of the surface finishes tested. In addition, the nickel release profiles for chemically etched and electropolished heart valve frames were similar for all microstructural purities further demonstrating that reduction in inclusion size did not impact corrosion resistance. Electropolished surfaces possessed better pitting and ion release performance compared to thermal oxide surfaces. These results indicate that the localized and uniform corrosion performance is maintained in higher microstructural purity VAR-based Nitinol for different surface finishes.

Similar content being viewed by others

References

Leon MB, Smith CR, Mack M, Miller DC, Moses JW, Svensson LG, Tuzcu EM, Webb JG, Fontana GP, Makkar RR (2010) Transcatheter aortic-valve implantation for aortic stenosis in patients who cannot undergo surgery. N Engl J Med 363(17):1597–1607

Pelton AR, Pelton SM, Ulmer J, Niedermaier D, Plaskonka-Weissenburger K, Mitchell MR, Saffari P (2017) The use of next generation Nitinol for medical implants. In: Chakfé N, Meichelboeck W (ed) European symposium on vascular biomaterials. Strasbourg, pp 35–44

Launey M, Robertson SW, Vien L, Senthilnathan K, Chintapalli P, Pelton AR (2014) Influence of microstructural purity on the bending fatigue behavior of VAR-melted superelastic Nitinol. J Mech Behav Biomed Mater 34:181–186

Robertson SW, Launey M, Shelley O, Ong I, Vien L, Senthilnathan K, Saffari P, Schlegel S, Pelton AR (2015) A statistical approach to understand the role of inclusions on the fatigue resistance of superelastic Nitinol wire and tubing. J Mech Behav Biomed Mater 51:119–131

Pelton AR, Pelton SM, Jörn T, Ulmer J, Niedermaier D, Plaskonka K, Lepage WS, Saffari P, Mitchell MR (2019) The quest for fatigue-resistant nitinol for medical implants. In: Mitchell MR, Woods TO, Jerina KL (eds) Fourth symposium on fatigue and fracture of metallic medical materials and devices. ASTM International, West Conshohocken, pp 1–30

Shabalovskaya S, Anderegg J, Van Humbeeck J (2008) Recent observations of particulates in Nitinol. Mater Sci Eng A 481:431–436

Neelakantan L, Monchev B, Frotscher M, Eggeler G (2012) The influence of secondary phase carbide particles on the passivity behaviour of NiTi shape memory alloys. Mater Corros 63(11):979–984

Schroeder V (2009) Evolution of the passive film on mechanically damaged Nitinol. J Biomed Mater Res Part A 90(1):1–17

Bai Z, Rotermund HH (2011) The intrinsically high pitting corrosion resistance of mechanically polished nitinol in simulated physiological solutions. J Biomed Mater Res B Appl Biomater 99(1):1–13

Pound BG (2018) Pit initiation on nitinol in simulated physiological solutions. J Biomed Mater Res Part B 106(4):1605–1610

Wohlschlögel M, Steegmüller R, Schüßler A (2014) Effect of inclusion size and distribution on the corrosion behavior of medical-device grade nitinol tubing. J Mater Eng Perform 23(7):2635–2640

Tuissi A, Rondelli G, Bassani P (2015) Plasma arc melting (PAM) and corrosion resistance of pure NiTi shape memory alloys. Shape Memory Superelasticity 1(1):50–57

Sun F, Jordan L, Albin V, Lair V, Ringuedé A, Prima F (2020) On the high sensitivity of corrosion resistance of NiTi stents with respect to inclusions: an experimental evidence. ACS Omega 5(6):3073–3079

Clarke B, Carroll W, Rochev Y, Hynes M, Bradley D, Plumley D (2006) Influence of nitinol wire surface treatment on oxide thickness and composition and its subsequent effect on corrosion resistance and nickel ion release. J Biomed Mater Res Part A 79(1):61–70

Trepanier C, Tabrizian M, Yahia LH, Bilodeau L, Piron DL (1998) Effect of modification of oxide layer on NiTi stent corrosion resistance. J Biomed Mater Res 43(4):433–440

Nagaraja S, Chandrasekar V, Ormonde D, Hickey H, Lipschultz K, Chao C, Vilendrer K, Pelton AR (2018) The impact of fatigue testing and surface processing on nickel release in nitinol stents. Shape Memory Superelasticity 4(4):462–471

Sullivan SL, Dreher M, Zheng J, Chen L, Madamba D, Miyashiro K, Trépanier C, Nagaraja S (2015) Effects of oxide layer composition and radial compression on nickel release in nitinol stents. Shape Memory Superelasticity 1(3):319–327

Thierry B, Tabrizian M, Trepanier C, Savadogo O, Yahia LH (2000) Effect of surface treatment and sterilization processes on the corrosion behavior of NiTi shape memory alloy. J Biomed Mater Res 51(4):685–693

Zhu L, Trepanier C, Fino JM, Pelton A (2004) Oxidation of nitinol and its effect on corrosion resistance. In: Proceedings of ASM materials & processes for medical devices conferenced, pp 156–161

Belohlavek J, Belohlavkova S, Hlubocky J, Mrazek V, Linhart A, Podzimek S (2013) Severe allergic dermatitis after closure of foramen ovale with Amplatzer occluder. Ann Thorac Surg 96(3):e57–e59

Honari G, Ellis SG, Wilkoff BL, Aronica MA, Svensson LG, Taylor JS (2008) Hypersensitivity reactions associated with endovascular devices. Contact Dermatitis 59(1):7–22

Rigatelli G, Cardaioli P, Giordan M, Aggio S, Chinaglia M, Braggion G, Roncon L (2007) Nickel allergy in interatrial shunt device-based closure patients. Congenit Heart Dis 2(6):416–420

Rabkin DG, Whitehead KJ, Michaels AD, Powell DL, Karwande S (2009) Unusual presentation of nickel allergy requiring explantation of an Amplatzer atrial septal occluder device. Clin Cardiol 32(8):55–57

Slavin L, Tobis JM, Rangarajan K, Dao C, Krivokapich J, Liebeskind DS (2007) Five-year experience with percutaneous closure of patent foramen ovale. Am J Cardiol 99(9):1316–1320

Khodaverdian RA, Jones KW (2009) Metal allergy to Amplatzer occluder device presented as severe bronchospasm. Ann Thorac Surg 88(6):2021–2022

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the journal Shape Memory and Superelasticity on Cardiovascular Nitinol Medical Devices. The issue was organized by Dr. Srinidhi Nagaraja, G.RAU, Inc. and Dr. Harshad M. Paranjape, Confluent Medical Technologies, Inc.

Rights and permissions

About this article

Cite this article

Nagaraja, S., Sena, G., Stafford, P. et al. Effects of Nitinol Microstructural Purity on Localized and Uniform Corrosion Susceptibility. Shap. Mem. Superelasticity 8, 118–128 (2022). https://doi.org/10.1007/s40830-022-00366-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-022-00366-1