Abstract

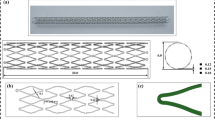

Peripheral Nickel–Titanium (NiTi) stents exploit super-elasticity to treat femoropopliteal artery atherosclerosis. The stent is subject to cyclic loads, which may lead to fatigue fracture and treatment failure. The complexity of the loading conditions and device geometry, coupled with the nonlinear material behavior, may induce multi-axial and non-proportional deformation. Finite element analysis can assess the fatigue risk, by comparing the device state of stress with the material fatigue limit. The most suitable fatigue model is not fully understood for NiTi devices, due to its complex thermo-mechanical behavior. This paper assesses the fatigue behavior of NiTi stents through computational models and experimental validation. Four different strain-based models are considered: the von Mises criterion and three critical plane models (Fatemi–Socie, Brown–Miller, and Smith–Watson–Topper models). Two stents, made of the same material with different cell geometries are manufactured, and their fatigue behavior is experimentally characterized. The comparison between experimental and numerical results highlights an overestimation of the failure risk by the von Mises criterion. On the contrary, the selected critical plane models, even if based on different damage mechanisms, give a better fatigue life estimation. Further investigations on crack propagation mechanisms of NiTi stents are required to properly select the most reliable fatigue model.

Similar content being viewed by others

Abbreviations

- v :

-

Poisson ratio

- \(\alpha\) :

-

Parameter measuring the difference between material responses in tension and compression

- K :

-

Empirical material constant

- S :

-

Empirical material constant

- \(\sigma_{y}\) :

-

Material monotonic yield strength

- \(\sigma_{n,\hbox{max} }\) :

-

Maximum normal stress on the critical plane

- \(\sigma_{\hbox{max} }\) :

-

Maximum normal stress

- \(\sigma_{\text{SAS}}\) :

-

Starting stress value for the forward phase transformation

- \(\sigma_{\text{SSA}}\) :

-

Starting stress value for the reverse phase transformation

- \(\sigma_{\text{FAS}}\) :

-

Final stress value for the forward phase transformation

- \(\sigma_{\text{FSA}}\) :

-

Final stress value for the reverse phase transformation

- \(\varepsilon_{m}^{1}\) :

-

First principal component of the mean strain tensor

- \(\varepsilon_{a}^{\text{VM}}\) :

-

Alternate equivalent strain

- \(\varepsilon_{a}^{1}\) :

-

First principal component of the alternate strain tensor

- \(\varepsilon_{a}^{2}\) :

-

Second principal component of the alternate strain tensor

- \(\varepsilon_{a}^{3}\) :

-

Third principal component of the alternate strain tensor

- \(\varepsilon_{a}\) :

-

Alternate normal strain

- \(\varepsilon_{L}\) :

-

Maximum residual strain

- \(E_{M}\) :

-

Elastic modulus for the austenite phase

- \(E_{A}\) :

-

Elastic modulus for the austenite phase

- \(\Delta L_{m}\) :

-

Mean displacement

- \(\Delta L_{a}\) :

-

Alternate displacement

- \(\frac{{\Delta \varepsilon_{n} }}{2}\) :

-

Normal strain amplitude on the critical plane of maximum shear strain

- \(\frac{{\Delta \gamma_{\hbox{max} } }}{2}\) :

-

Maximum shear strain amplitude on the critical plane of maximum shear strain

- \(\frac{{\Delta \varepsilon_{\hbox{max} } }}{2}\) :

-

Maximum normal strain amplitude on the plane of maximum normal strain

References

MacTaggart JN, Phillips NY, Lomneth CS, Pipinos II, Bowen R, Timothy Baxter B, Johanning J, Matthew Longo G, Desyatova AS, Moulton MJ, Dzenis YA, Kamenskiy AV (2014) Three-dimensional bending, torsion and axial compression of the femoropopliteal artery during limb flexion. J Biomech 47:2249–2256. https://doi.org/10.1016/j.jbiomech.2014.04.053

Nikanorov A, Schillinger M, Zhao H, Minar E, Schwartz LB (2013) Assessment of self-expanding nitinol stent deformation after chronic implantation into the femoropopliteal arteries. EuroIntervention 9:730–737. https://doi.org/10.4244/EIJV9I6A117

Cambiaghi T, Spertino A, Bertoglio L, Chiesa R (2017) Fracture of a supera interwoven nitinol stent after treatment of popliteal artery stenosis. J Endovasc Ther 24(3):447–449. https://doi.org/10.1177/1526602817698655

Adlakha S, Sheikh M, Wu J, Burket MW, Pandya U, Colyer W, Eltahawy E, Cooper CJ (2010) Stent fracture in the coronary and peripheral arteries. J Interv Cardiol 23:411–419. https://doi.org/10.1111/j.1540-8183.2010.00567.x

Pelton AR, Schroeder V, Mitchell MR, Gong XY, Barney M, Robertson SW (2008) Fatigue and durability of Nitinol stents. J Mech Behav Biomed Mater 1:153–164. https://doi.org/10.1016/j.jmbbm.2007.08.001

Runciman A, Xu D, Pelton AR, Ritchie RO (2011) An equivalent strain/Coffin-Manson approach to multiaxial fatigue and life prediction in superelastic Nitinol medical devices. Biomaterials 32:4987–4993. https://doi.org/10.1016/j.biomaterials.2011.03.057

Robertson SW, Pelton AR, Ritchie RO (2012) Mechanical fatigue and fracture of Nitinol. Int Mater Rev 57:1–37. https://doi.org/10.1179/1743280411Y.0000000009

Suresh S (1998) Fatigue of materials. Cambridge University Press, Cambridge. https://doi.org/10.1017/CBO9780511806575

Petrini L, Dordoni E, Allegretti D, Pott D, Kütting M, Migliavacca F, Pennati G (2017) Simplified multistage computational approach to assess the fatigue behavior of a Niti transcatheter aortic valve during in vitro tests: a proof-of-concept study. J Med Device 11:21009. https://doi.org/10.1115/1.4035791

Harvey SM (2011) Nitinol stent fatigue in a peripheral human artery subjected to pulsatile and articulation loading. J Mater Eng Perform 20:697–705. https://doi.org/10.1007/s11665-011-9881-8

Gokgol C, Diehm N, Nezami FR, Buchler P (2015) Nitinol stent oversizing in patients undergoing popliteal artery revascularization: a finite element study. Ann Biomed Eng 43:2868–2880. https://doi.org/10.1007/s10439-015-1358-8

Fatemi A, Shamsaei N (2011) Multiaxial fatigue: an overview and some approximation models for life estimation. Int J Fatigue 33:948–958. https://doi.org/10.1016/j.ijfatigue.2011.01.003

Mahtabi MJ, Shamsaei N (2015) Multiaxial fatigue modeling for Nitinol shape memory alloys under in-phase loading. J Mech Behav Biomed Mater 55:236–249. https://doi.org/10.1016/j.jmbbm.2015.10.022

Mahtabi MJ, Shamsaei N, Mitchell MR (2015) Fatigue of Nitinol: the state-of-the-art and ongoing challenges. J Mech Behav Biomed Mater 50:228–254. https://doi.org/10.1016/j.jmbbm.2015.06.010

Arrigoni M, Auricchio F, Cacciafesta V, Petrini L, Pietrabissa R (2001) Mechanical characterisation of orthodontic superelastic Ni-Ti wires. Strain 11:577–582. https://doi.org/10.1051/jp4:2001896

Pelton AR, Fino-Decker J, Vien L, Bonsignore C, Saffari P, Launey M, Mitchell MR (2013) Rotary-bending fatigue characteristics of medical-grade Nitinol wire. J Mech Behav Biomed Mater 27:19–32. https://doi.org/10.1016/j.jmbbm.2013.06.003

Mahtabi MJ, Shamsaei N, Rutherford B (2015) Mean strain effects on the fatigue behavior of superelastic Nitinol alloys: an experimental investigation. Procedia Eng 133:646–654. https://doi.org/10.1016/j.proeng.2015.12.645

Shamsaei N, Fatemi A (2009) Effect of hardness on multiaxial fatigue behaviour and some simple approximations for steels. Fatigue Fract Eng Mater Struct 32:631–646. https://doi.org/10.1111/j.1460-2695.2009.01369.x

Brown MW, Miller KJ (2006) A theory for fatigue failure under multiaxial stress–strain conditions. Arch Proc Inst Mech Eng 187:745–755. https://doi.org/10.1243/PIME_PROC_1973_187_161_02

Kandil FA, Brown MW, Miller KJ (1982) Biaxial low-cycle fatigue failure of 316 stainless steel at elevated temperatures. In: Proceedings of the international conference on mechanical behaviour and nuclear applications of stainless steel at elevated temperatures. Metals Society (Book 280), London

Socie DF, Waill LA, Dittmer DF (1985) Biaxial fatigue of Inconel 718 including mean stress effects. Multiaxial Fatigue. https://doi.org/10.1520/STP36238S

Socie D (1987) Multiaxial fatigue damage models. J Eng Mater Technol 109:293. https://doi.org/10.1115/1.3225980

Auricchio F, Constantinescu A, Menna C, Scalet G (2016) A shakedown analysis of high cycle fatigue of shape memory alloys. Int J Fatigue 87:112–123. https://doi.org/10.1016/j.ijfatigue.2016.01.017

Acknowledgements

We acknowledge Medtronic-Invatec for the experimental samples produced in its laboratory and Mr. Carlo Guala, MEng for his technical support provided within the project ‘‘RT3S—Real Time Simulation for Safe Vascular Stenting’’ funded by the European Commission under the 7th Framework Programme, GA FP7-2009-ICT-4-248801. A mention to Eng. Jennifer Frattolin, from the Department of Mechanical Engineering at the McGill University, Montreal, Canada, is also due for his help in revising the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Allegretti, D., Berti, F., Migliavacca, F. et al. Fatigue Assessment of Nickel–Titanium Peripheral Stents: Comparison of Multi-Axial Fatigue Models. Shap. Mem. Superelasticity 4, 186–196 (2018). https://doi.org/10.1007/s40830-018-0150-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-018-0150-7