Abstract

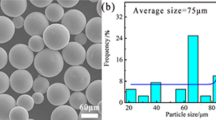

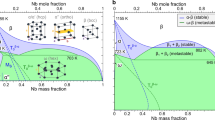

The present study focuses on the anisotropic negative thermal expansion (NTE) behaviors of Ti-rich (Ti54Ni46) and equiatomic Ti–Ni (Ti50Ni50) alloys fabricated by vacuum arc melting and without subsequent plastic deformation. Both alloys exhibit NTE responses in vertical and horizontal directions, and the total strains and CTEs of the NTE stage along the two mutually perpendicular measuring directions are obviously different, indicating obvious anisotropic NTE behavior of the alloys. Besides, the numerical differences between the starting temperature of NTE and austenitic transformation and between the finishing temperature of NTE and austenitic transformation are very small, which indicates that an apparent relationship exists between the NTE behavior and the phase transformation. The microstructure in the vertical cross sections shows obviously preferential orientation characteristics: Ti2Ni phases of both alloys grow along the vertical direction, and B19′ martensite of Ti50Ni50 alloy has distinct preferential orientation, which results from a large temperature gradient between the top and the bottom of the button ingots during solidification. The microstructure with preferential orientation induces the anisotropic NTE behavior of the samples.

Similar content being viewed by others

References

Mavoori H, Jin S (1998) Low-thermal-expansion copper composites via negative CTE metallic elements. JOM 50(6):70–72

Yang X, Cheng X, Li H, Xu J, Sun X (2008) Thermal and electric conductivity of near-zero thermal expansion ZrW2O8/ZrO2 composites. J Ceram Soc Jpn 116(1351):471–474

Mary TA, Evans JSO, Vogt T, Sleight AW (1996) Negative thermal expansion from 0.3 to 1050 Kelvin in ZrW2O8. Science 272(5258):90–92

Chatterji T, Henry PF, Mittal R, Chaplot SL (2008) Negative thermal expansion of ReO3: neutron diffraction experiments and dynamical lattice calculations. Phys Rev B 78(13):134105

Chen J, Nittala K, Forrester JS, Jones JL, Deng J, Yu R, Xing X (2011) The role of spontaneous polarization in the negative thermal expansion of tetragonal PbTiO3-based compounds. J Am Chem Soc 133(29):11114–11117

Kainuma R, Wang JJ, Omori T, Sutou Y, Ishida K (2002) Invar-type effect induced by cold-rolling deformation in shape memory alloys. Appl Phys Lett 80(23):4348–4350

Sutou Y, Omori T, Wang JJ, Kainuma R, Ishida K (2004) Characteristics of Cu–Al–Mn-based shape memory alloys and their applications. Mater Sci Eng A 378(1):278–282

Wang JJ, Omori T, Sutou Y, Kainuma R, Ishida K (2005) Two-way shape memory effect induced by cold-rolling in Ti–Ni and Ti–Ni–Fe alloys. Scripta Mater 52(4):311–316

Monroe JA, Gehring D, Karaman I, Arroyave R, Brown DW, Clausen B (2016) Tailored thermal expansion alloys. Acta Mater 102:333–341

Ahadi A, Matsushita Y, Sawaguchi T, Sun QP, Tsuchiya K (2017) Origin of zero and negative thermal expansion in severely-deformed superelastic NiTi alloy. Acta Mater 124:79–92

Uchil J, Mohanchandra KP, Kumara KG, Mahesh KK, Murali TP (1999) Thermal expansion in various phases of Nitinol using TMA. Phys B Condens Matter 270(3):289–297

Qiu S, Krishnan VB, Padula SA, Noebe RD, Brown DW, Clausen B, Vaidyanathan R (2009) Measurement of the lattice plane strain and phase fraction evolution during heating and cooling in shape memory NiTi. Appl Phys Lett 95(14):141906

Otsuka K, Ren X (2005) Physical metallurgy of Ti–Ni-based shape memory alloys. Prog Mater Sci 50:511–678

Zhao ZX, Ma X, Zeng CY, Cao SS, Ke CB, Zhang XP (2017) Reversible negative thermal expansion response and phase transformation behavior of a Ti-rich Ti54Ni46 alloy prepared by rapid solidification. In Proceedings of International Conference on Martensitic Transformation (ICOMAT) (in press)

Massalski TB, Okamoto H, Subramanian PR, Kacprzak L, Scott WW (eds) (1986) Binary alloy phase diagrams, 2nd edn. American Society for Metals, Metals Park, p 2874

Zhang JX, Sato M, Ishida A (2002) Structure of martensite in sputter-deposited Ti–Ni thin films containing homogeneously distributed Ti2Ni precipitates. Philos Mag A 82(7):1433–1449

Acknowledgements

This study was supported by the National Natural Science Foundation of China under Grant Nos. 51571092 and 51401081, the Key Project Program of Guangdong Provincial Natural Science Foundation under Grant No. S2013020012805.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, ZX., Ma, X., Cao, SS. et al. Anisotropic Negative Thermal Expansion Behavior of the As-Fabricated Ti-Rich and Equiatomic Ti–Ni Alloys Induced by Preferential Grain Orientation. Shap. Mem. Superelasticity 4, 218–223 (2018). https://doi.org/10.1007/s40830-017-0145-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-017-0145-9