Abstract

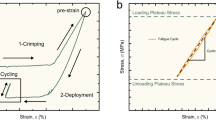

A cumulative energy-based damage model, called total fatigue toughness, is proposed for fatigue life prediction of superelastic NiTi alloys with various deformation responses (i.e., transformation stresses), which also accounts for the effects of mean strain and stress. Mechanical response of superelastic NiTi is highly sensitive to chemical composition, material processing, as well as operating temperature; therefore, significantly different deformation responses may be obtained for seemingly identical NiTi specimens. In this paper, a fatigue damage parameter is proposed that can be used for fatigue life prediction of superelastic NiTi alloys with different mechanical properties such as loading and unloading transformation stresses, modulus of elasticity, and austenite-to-martensite start and finish strains. Moreover, the model is capable of capturing the effects of tensile mean strain and stress on the fatigue behavior. Fatigue life predictions using the proposed damage parameter for specimens with different cyclic stress responses, tested at various strain ratios (R ε = ε min /ε max) are shown to be in very good agreement with the experimentally observed fatigue lives.

Similar content being viewed by others

Abbreviations

- 2N f :

-

Number of reversals to failure

- A → M:

-

Austenite-to-martensite transformation

- E A :

-

Austenite modulus of elasticity

- M → A:

-

Martensite-to-austenite transformation

- N f :

-

Experimental number of cycles to failure

- N f,p :

-

Predicted number of cycles to failure

- R ε :

-

Strain ratio in a cyclic loading (ε min /ε max)

- W d :

-

Dissipated strain-energy-density

- W +e :

-

Tensile austenitic strain-energy-density

- W t :

-

Total strain-energy-density

- ε a :

-

Strain amplitude (i.e., alternating strain)

- ε m :

-

Mean strain

- ε max :

-

Maximum strain

- ε min :

-

Minimum strain

- \(\varepsilon_{\text{f}}^{\text{AM}}\) :

-

A → M finish strain

- \(\varepsilon_{\text{f}}^{\text{MA}}\) :

-

M → A finish strain

- \(\varepsilon_{\text{s}}^{\text{AM}}\) :

-

A → M start strain

- σ a :

-

Stress amplitude (i.e., alternating stress)

- σ m :

-

Mean stress

- σ max :

-

Maximum stress

- σ min :

-

Minimum stress

- \(\sigma_{\text{f}}^{\text{MA}}\) :

-

M → A finish stress (i.e., unloading transformation stress)

- \(\sigma_{\text{s}}^{\text{AM}}\) :

-

A → M start stress (i.e., loading transformation stress)

- \({\varSigma }W_{\text{d}}\) :

-

Cumulative dissipated strain-energy-density

- \({\varSigma}W_{\text{t}}\) :

-

Total fatigue toughness (cumulative total strain-energy-density)

References

Petrini L, Wu W, Dordoni E, Meoli A, Migliavacca F, Pennati G (2012) Fatigue behavior characterization of Nitinol for peripheral stents. Funct Mater Lett 05:1250012. doi:10.1142/S1793604712500129

Johnson R, Padgett JE, Maragakis ME, DesRoches R, Saiidi MS (2008) Large scale testing of nitinol shape memory alloy devices for retrofitting of bridges. Smart Mater Struct 17:035018. doi:10.1088/0964-1726/17/3/035018

Amerinatanzi A, Moghaddam NS, Ibrahim H, Elahinia M (2016) Evaluating a NiTi implant under realistic loads: A simulation study. In: American Society of Mechanical Engineers

Moghaddam NS, Andani MT, Amerinatanzi A, Haberland C, Huff S, Miller M, Elahinia M, Dean D (2016) Metals for bone implants: safety, design, and efficacy. Biomanufacturing Rev 1:1. doi:10.1007/s40898-016-0001-2

Mohd Jani J, Leary M, Subic A, Gibson MA (2014) A review of shape memory alloy research, applications and opportunities. Mater Des 56:1078–1113

Mahtabi MJ, Shamsaei N, Mitchell MR (2015) Fatigue of Nitinol: The state-of-the-art and ongoing challenges. J Mech Behav Biomed Mater 50:228–254. doi:10.1016/j.jmbbm.2015.06.010

Mahtabi MJ, Shamsaei N, Elahinia MH (2015) Fatigue of shape memory alloys. In: Elahinia MH (ed) Shape memory alloy actuators. John, New York, pp 155–190

Robertson SW, Pelton AR, Ritchie RO (2012) Mechanical fatigue and fracture of Nitinol. Int Mater Rev 57:1–37

Runciman A, Xu D, Pelton AR, Ritchie RO (2011) An equivalent strain/Coffin–Manson approach to multiaxial fatigue and life prediction in superelastic Nitinol medical devices. Biomaterials 32:4987–4993. doi:10.1016/j.biomaterials.2011.03.057

Maletta C, Sgambitterra E, Furgiuele F, Casati R, Tuissi A (2012) Fatigue of pseudoelastic NiTi within the stress-induced transformation regime: a modified Coffin–Manson approach. Smart Mater Struct 21:112001. doi:10.1088/0964-1726/21/11/112001

Kim YS, Miyazaki S (1997) Fatigue properties of Ti-50.9 at% Ni shape memory wires. In: Pelton AR, Hodgson D, Russell SM, Duerig T (ed) Proceedings of the 2nd international conference on shape memory and superelastic technologies (SMST); Pacific Grove, MIAS SMST-97, pp 473–477

Pelton AR, Fino-Decker J, Vien L, Bonsignore C, Saffari P, Launey M, Mitchell MR (2013) Rotary-bending fatigue characteristics of medical-grade Nitinol wire. J Mech Behav Biomed Mater 27:19–32

Tobushi H, Hachisuka T, Yamada S, Lin P-H (1997) Rotating-bending fatigue of a TiNi shape-memory alloy wire. Mech Mater 26:35–42. doi:10.1016/S0167-6636(97)00019-7

Mahtabi MJ, Shamsaei N, Rutherford B (2015) Mean strain effects on the fatigue behavior of superelastic Nitinol alloys: an experimental investigation. Procedia Eng 133:646–654. doi:10.1016/j.proeng.2015.12.645

Moumni Z, Herpen AV, Riberty P (2005) Fatigue analysis of shape memory alloys: energy approach. Smart Mater Struct 14:S287. doi:10.1088/0964-1726/14/5/017

Predki W, Klönne M, Knopik A (2006) Cyclic torsional loading of pseudoelastic NiTi shape memory alloys: damping and fatigue failure. Mater Sci Eng A 417:182–189. doi:10.1016/j.msea.2005.10.037

Jensen DM (2005) Biaxial fatigue behavior of NiTi shape memory alloy. Air Force Institute of Technology

Mahtabi MJ, Shamsaei N (2016) Multiaxial fatigue modeling for Nitinol shape memory alloys under in-phase loading. J Mech Behav Biomed Mater 55:236–249. doi:10.1016/j.jmbbm.2015.10.022

Pelton AR, Schroeder V, Mitchell MR, Gong X-Y, Barney M, Robertson SW (2008) Fatigue and durability of Nitinol stents. J Mech Behav Biomed Mater 1:153–164

Mahtabi MJ, Shamsaei N (2016) A modified energy-based approach for fatigue life prediction of superelastic NiTi in presence of tensile mean strain and stress. Int J Mech Sci 117:321–333. doi:10.1016/j.ijmecsci.2016.08.012

Kan Q, Kang G, Yan W, Dong Y, Yu C (2012) An energy-based fatigue failure model for super-elastic NiTi alloys under pure mechanical cyclic loading. In: Proceedings of SPIE—the international society for optical engineering

Ellyin F, Kujawski D (1993) A multiaxial fatigue criterion including mean-stress effect. In: ASTM special technical publication, vol 1191, pp 55–66

Golos K, Ellyin F (1988) A total strain energy density theory for cumulative fatigue damage. J Press Vessel Technol 110:36–41. doi:10.1115/1.3265565

Gall K, Tyber J, Brice V, Frick CP, Maier HJ, Morgan N (2005) Tensile deformation of NiTi wires. J Biomed Mater Res A 75A:810–823. doi:10.1002/jbm.a.30464

Bagheri A, Mahtabi MJ, Shamsaei N (2016) Fatigue behavior and cyclic deformation of additive manufactured NiTi, Submitted publication

Pelton AR, Dicello J, Miyazaki S (2000) Optimisation of processing and properties of medical grade Nitinol wire. Minim Invasive Ther Allied Technol 9:107–118

Saedi S, Turabi AS, Taheri Andani M, Haberland C, Karaca H, Elahinia M (2016) The influence of heat treatment on the thermomechanical response of Ni-rich NiTi alloys manufactured by selective laser melting. J Alloy Compd 677:204–210. doi:10.1016/j.jallcom.2016.03.161

Shaw JA, Kyriakides S (1995) Thermomechanical aspects of NiTi. J Mech Phys Solids 43:1243–1281. doi:10.1016/0022-5096(95)00024-D

Mohd Jani J, Leary M, Subic A (2016) Designing shape memory alloy linear actuators: A review. J Intell Mater Syst Struct. doi:10.1177/1045389X16679296

Frenzel J, George EP, Dlouhy A, Somsen C, Wagner MF-X, Eggeler G (2010) Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater 58:3444–3458. doi:10.1016/j.actamat.2010.02.019

Otsuka K, Ren X (2005) Physical metallurgy of Ti–Ni-based shape memory alloys. Prog Mater Sci 50:511–678. doi:10.1016/j.pmatsci.2004.10.001

Halford GR (1966) The energy required for fatigue (plastic strain hysteresis energy required for fatigue in ferrous and nonferrous metals). J Mater 1:3–18

Morrow J (1965) Cyclic plastic strain energy and fatigue of metals. In: Lazan B (ed) Internal friction, damping, and cyclic plasticity. ASTM International, West Conshohocken, PA, pp 45–87. doi:10.1520/STP43764S

Nip KH, Gardner L, Davies CM, Elghazouli AY (2010) Extremely low cycle fatigue tests on structural carbon steel and stainless steel. J Constr Steel Res 66:96–110. doi:10.1016/j.jcsr.2009.08.004

Lefebvre D, Ellyin F (1984) Cyclic response and inelastic strain energy in low cycle fatigue. Int J Fatigue 6:9–15. doi:10.1016/0142-1123(84)90003-3

Shrestha R, Simsiriwong J, Shamsaei N, Moser RD (2016) Cyclic deformation and fatigue behavior of polyether ether ketone (PEEK). Int J Fatigue 82(3):411–427. doi:10.1016/j.ijfatigue.2015.08.022

Yang B, Liaw PK, Morrison M, Liu CT, Buchanan RA, Huang JY, Kuo RC, Huang JG, Fielden DE (2005) Temperature evolution during fatigue damage. Intermetallics 13:419–428. doi:10.1016/j.intermet.2004.07.032

Gloanec A-L, Cerracchio P, Reynier B, Van Herpen A, Riberty P (2010) Fatigue crack initiation and propagation of a TiNi shape memory alloy. Scr Mater 62:786–789. doi:10.1016/j.scriptamat.2010.02.001

Smith KN, Watson P, Topper TH (1970) A stress–strain parameter for the fatigue of metals. J Mater 5:767–778

Acknowledgements

Nima Shamsaei’s contributions were partially supported by the National Science Foundation under Grant No. 1660446. Experiments were performed at the Center for Advanced Vehicular Systems at the Mississippi State University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mahtabi, M.J., Shamsaei, N. Fatigue Modeling for Superelastic NiTi Considering Cyclic Deformation and Load Ratio Effects. Shap. Mem. Superelasticity 3, 250–263 (2017). https://doi.org/10.1007/s40830-017-0115-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-017-0115-2