Abstract

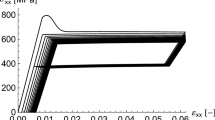

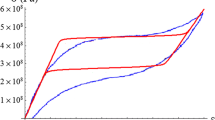

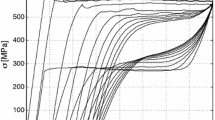

The phenomenon of functional fatigue occurs during cyclic loading of pseudoelastic shape memory alloys. We model this effect by considering an irreversible martensitic volume fraction in addition to the reversible amounts of austenite and martensite based on variational principles. The inclusion of irreversible martensitic volume fractions coincides with experimental observations and enables the model to be easily calibrated without any fitting functions. In our previous studies, we modeled the polycrystalline material structure by static discretization of a relatively large number of randomly chosen grain orientations, which required much numerical effort. In contrast, we now apply a dynamic representation of the orientation distribution function to the modeling of functional fatigue which has proven to be beneficial regarding the numerical performance. To this end, we take into account an averaged grain orientation parameterized by three Euler angles that serve as additional internal variables. This results in an extremely reduced numerical effort. The model derivation is given along with the numerical implementation and computer experiments on the cyclic behavior of shape memory alloys.

Similar content being viewed by others

References

Bolotin VV (1999) Mechanics of fatigue, vol 11. CRC Press, Baco Raton

Suresh S (1998) Fatigue of materials. Cambridge university press, Cambridge

Eggeler G, Hornbogen E, Yawny A, Heckmann A, Wagner MF-X (2004) Structural and functional fatigue of NiTi shape memory alloys. Mater Sci Eng A 378(1):24–33

Otsuka K, Wayman CM (1999) Shape memory materials. Cambridge University Press, Cambridge

Otsuka K, Ren X (2005) Physical metallurgy of Ti–Ni-based shape memory alloys. Prog Mate Sci 50(5):511–678

Wagner MF-X (2005) Ein Beitrag zur strukturellen und funktionalen Ermüdung von Drähten und Federn aus NiTi-Formgedächtnislegierungen. Univ.-Verlag, Europe

Burow J (2010) Herstellung, Eigenschaften und Mikrostruktur von ultrafeinkörnigen NiTi-Formgedächtnislegierungen. urn:nbn:de:hbz:294-29048

Delville R, Malard B, Pilch J, Sittner P, Schryvers D (2011) Transmission electron microscopy investigation of dislocation slip during superelastic cycling of Ni-Ti wires. Int J Plast 27(2):282–297

Miyazaki S, Imai T, Igo Y, Otsuka K (1986) Effect of cyclic deformation on the pseudoelasticity characteristics of Ti–Ni alloys. Metall Trans A 17(1):115–120

Ibarra A, San Juan J, Bocanegra EH, Nó ML (2007) Evolution of microstructure and thermomechanical properties during superelastic compression cycling in Cu–Al–Ni single crystals. Acta Mater 55(14):4789–4798

Morgan NB, Friend CM (2001) A review of shape memory stability in NiTi alloys. J Phys 11(Pr8):325

Wagner MF-X, Nayan N, Ramamurty U (2008) Healing of fatigue damage in NiTi shape memory alloys. J Phys D 41(18):185408

Brinson C (1993) One-dimensional constitutive behavior of shape memory alloys: thermomechanical derivation with non-constant material functions and redefined martensite internal variable. J Intell Mater Syst Struct 4(2):229–242

Lexcellent C, Vivet A, Bouvet C, Calloch S, Blanc P (2002) Experimental and numerical determinations of the initial surface of phase transformation under biaxial loading in some polycrystalline shape-memory alloys. J Mech Phys Solids 50(12):2717–2735

Bouvet C, Calloch S, Lexcellent C (2004) A phenomenological model for pseudoelasticity of shape memory alloys under multiaxial proportional and nonproportional loadings. Eur J Mech A 23(1):37–61

Govindjee S, Miehe C (2001) A multi-variant martensitic phase transformation model: formulation and numerical implementation. Comput Methods Appl Mech Eng 191(3):215–238

Stupkiewicz S, Petryk H (2013) A robust model of pseudoelasticity in shape memory alloys. Int J Numer Methods Eng 93(7):747–769

Stupkiewicz S, Petryk H (2002) Modelling of laminated microstructures in stress-induced martensitic transformations. J Mech Phys Solids 50(11):2303–2331

Stein E, Sagar G (2008) Theory and finite element computation of cyclic martensitic phase transformation at finite strain. Int J Numer Methods Eng 74(1):1–31

Mielke A, Theil F, Levitas VI (2002) A variational formulation of rate-independent phase transformations using an extremum principle. Arch Ration Mech Anal 162(2):137–177

Govindjee S, Hall GJ (2000) A computational model for shape memory alloys. Int J Solids Struct 37(5):735–760

Govindjee S, Kasper EP (1999) Computational aspects of one-dimensional shape memory alloy modeling with phase diagrams. Comput Methods Appl Mech Eng 171(3):309–326

Saint-Sulpice L, Chirani SA, Calloch S (2009) A 3D super-elastic model for shape memory alloys taking into account progressive strain under cyclic loadings. Mech Mater 41(1):12–26

Abeyaratne R, Kim S-J (1997) Cyclic effects in shape-memory alloys: a one-dimensional continuum model. Int J Solids Struct 34(25):3273–3289

Abeyaratne R, Kim S-J, Knowles JK (1994) A one-dimensional continuum model for shape-memory alloys. Int J Solids Struct 31(16):2229–2249

Auricchio F, Reali A, Stefanelli U (2007) A three-dimensional model describing stress-induced solid phase transformation with permanent inelasticity. Int J Plast 23(2):207–226

Auricchio F, Petrini L (2004) A three-dimensional model describing stress-temperature induced solid phase transformations: solution algorithm and boundary value problems. Int J Numer Methods Eng 61(6):807–836

Hartl DJ, Chatzigeorgiou G, Lagoudas DC (2010) Three-dimensional modeling and numerical analysis of rate-dependent irrecoverable deformation in shape memory alloys. Int J Plast 26(10):1485–1507

Lagoudas DC, Hartl D, Chemisky Y, Machado L, Popov P (2012) Constitutive model for the numerical analysis of phase transformation in polycrystalline shape memory alloys. Int J Plast 32:155–183

Bo Z, Lagoudas DC (1999) Thermomechanical modeling of polycrystalline SMAs under cyclic loading, part III: evolution of plastic strains and two-way shape memory effect. Int J Eng Sci 37(9):1175–1203

Lagoudas DC, Entchev PB (2004) Modeling of transformation-induced plasticity and its effect on the behavior of porous shape memory alloys. part I: constitutive model for fully dense SMAs. Mech Mater 36(9):865–892

Lagoudas DC (2008) Shape memory alloys: modeling and engineering applications. Springer, New York

Tanaka K, Nishimura F, Hayashi T, Tobushi H, Lexcellent C (1995) Phenomenological analysis on subloops and cyclic behavior in shape memory alloys under mechanical and/or thermal loads. Mech Mater 19(4):281–292

Lexcellent C, Bourbon G (1996) Thermodynamical model of cyclic behaviour of Ti–Ni and Cu–Zn–Al shape memory alloys under isothermal undulated tensile tests. Mech Mater 24(1):59–73

Bartel T, Osman M, Menzel A (2016) A phenomenological model for the simulation of functional fatigue in shape memory alloy wires. Meccanica 52:973

Waimann J, Junker P, Hackl K (2016) A coupled dissipation functional for modeling the functional fatigue in polycrystalline shape memory alloys. Eur J Mech A 55:110–121

Junker P (2014) A novel approach to representative orientation distribution functions for modeling and simulation of polycrystalline shape memory alloys. Int J Numer Methods Eng 98(11):799–818

Simon T, Kröger A, Somsen C, Dlouhy A, Eggeler G (2010) On the multiplication of dislocations during martensitic transformations in NiTi shape memory alloys. Acta Mater 58(5):1850–1860

Krooß P, Niendorf T, Kadletz PM, Somsen C, Gutmann MJ, Chumlyakov YI, Schmahl WW, Eggeler G, Maier HJ (2015) Functional fatigue and tension-compression asymmetry in [001]-oriented Co49Ni21Ga30 high-temperature shape memory alloy single crystals. Shape Memory Superelast 1(1):6–17

Carstensen C, Hackl K, Mielke A (2002) Non-convex potentials and microstructures in finite–strain plasticity. Proc R Soc Lond A 458(2018):299–317

Hackl K, Fischer FD (2008) On the relation between the principle of maximum dissipation and inelastic evolution given by dissipation potentials. Proc R Soc A 464(2089):117–132

Junker P, Makowski J, Hackl K (2014) The principle of the minimum of the dissipation potential for non-isothermal processes. Contin Mech Thermodyn 26(3):259–268

Junker P, Hackl K (2015) A variational growth approach to topology optimization. Struct Multidiscip Optim 52(2):293–304

Günther C, Junker P, Hackl K (2015) A variational viscosity-limit approach to the evolution of microstructures in finite crystal plasticity. Proc R Soc A 471:20150110

Huo Y, Müller I (1993) Nonequilibrium thermodynamics of pseudoelasticity. Contin Mech Thermodyn 5(3):163–204

Junker P, Jaeger S, Kastner O, Eggeler G, Hackl K (2015) Variational prediction of the mechanical behavior of shape memory alloys based on thermal experiments. J Mech Phys Solids 80:86–102

Junker P (2014) An accurate, fast and stable material model for shape memory alloys. Smart Mater Struct 23(11):115010

Hackl K (1999) On the representation of anisotropic elastic materials by symmetric irreducible tensors. Contin Mech Thermodyn 11(6):353–369

Mehrabadi MM, Cowin SC (1990) Eigentensors of linear anisotropic elastic materials. Q J Mech Appl Math 43(1):15–41

Author information

Authors and Affiliations

Corresponding author

Additional information

Submitted to Shape Memory and Superelasticity— Invited Special Issue Contribution [2016].

Rights and permissions

About this article

Cite this article

Waimann, J., Junker, P. & Hackl, K. Modeling the Cyclic Behavior of Shape Memory Alloys. Shap. Mem. Superelasticity 3, 124–138 (2017). https://doi.org/10.1007/s40830-017-0105-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-017-0105-4