Abstract

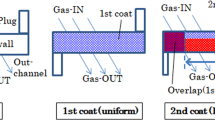

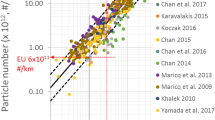

Gasoline particulate filters (GPFs) are an effective means of reducing particle emissions from gasoline direct injection (GDI) engines. This paper explores the filtration efficiency and pressure drop of three GPFs with varying in-wall washcoat volumes through three parameters: particle size, flow rate of gas through the GPF, and amount of soot accumulation. The three GPFs are tested on a custom filtration efficiency test rig with a miniature inverted soot generator used as a particle source at three space velocities of: 32, 000, 97, 000, and 161, 000 h−1. A scanning mobility particle sizer (SMPS) is used to measure the filtration efficiency and amount of soot accumulated on the GPF. The GPFs are loaded with soot until the average filtration efficiency reached > ~ 98%. Results show that the filtration efficiency is a function of particle size, soot loading, and space velocity. With increasing soot loading on the GPF, the filtration efficiencies increase significantly and become less sensitive to mobility diameter. Filtration efficiency is generally found to decrease with increasing space velocity. For clean filters, the GPF without washcoat has the same or higher filtration efficiency than the GPFs with washcoat. At high amounts of soot accumulation, the GPFs with a washcoat have the highest filtration efficiency. The coated filters have a much higher rate of filtration efficiency and pressure drop increase compared to the bare filter. The mechanisms leading to the observed trends in filtration efficiency and pressure drop are also discussed.

Similar content being viewed by others

Data Availability

Electronic data is included as supplementary material.

References

Guan, B., Zhan, R., Lin, H., Huang, Z.: Review of the state-of-the-art of exhaust particulate filter technology in internal combustion engines. J. Environ. Manage. 154, 225–258 (2015)

Johnson, T.V.: Vehicular emissions in review. SAE Int. J. Engines 7(3), 1207–1227 (2014). https://doi.org/10.4271/2014-01-1491

Petasch, J.A.U.: Effect of membranes in exhaust particulate filtration. In 40th International Conference & Expo on Advanced Ceramics & Composites (ICACC 2016), (2013)

Liu, X., Chanko, T., Lambert, C., Maricq, M.: Gasoline particulate filter efficiency and backpressure at very low mileage. SAE Technical Paper 2018–01–1259 (2018). https://doi.org/10.4271/2018-01-1259

Richter, J., Klingmann, R., Spiess, S., Wong, K.: Application of catalyzed gasoline particulate filters to GDI vehicles. SAE Int. J. Engines 5(3), 1361–1370 (2012). https://doi.org/10.4271/2012-01-1244

Zhong, D., He, S., Tandon, P., Moreno, M., and Boger, T.: Measurement and prediction of filtration efficiency evolution of soot loaded diesel particulate filters. SAE Technical Paper2012–01–0363 (2012). https://doi.org/10.4271/2012-01-0363

Boger, T., Rose, D., Nicolin, P., Gunasekaran, N., Glasson, T.: Oxidation of soot (Printex U) in particulate filters operated on gasoline engines. Emission Cont. Sci. Technol. 1, 49–63 (2015)

Adam, F., Olfert, J., Wong, K.F., Kunert, S., Richter, J.M.: Effect of engine-out soot emissions and the frequency of regeneration on gasoline particulate filter efficiency. SAE Technical Paper 2020–01–1431 (2020). https://doi.org/10.4271/2020-01-1431

Chan, T.W., Saffaripour, M., Liu, F., Hendren, J., Thomson, K.A., Kubsh, J., Brezny, R., Rideout, G.: Characterization of real-time particle emissions from a gasoline direct injection vehicle equipped with a catalyzed gasoline particulate filter during filter regeneration. Emiss. Control Sci. Technol. 2(2), 75–88 (2016)

Lambert, C., Chanko, T., Dobson, D., Liu, X., Pakko, J.: Gasoline particle filter development. Emiss. Control Sci. Technol. 3, 105–111 (2017)

Happonen, M., Matilainen, P., Kanniainen, K., Kinnunen, T., Karjalainen, P., Heikkila, J., Ronkko, T., Keskinen, J., Malinen, A., Pirjola, L., Tzamkiozis, T.: The effect of a particle oxidation catalyst (poc®) on particle emissions of a gdi car during transient engine operation. SAE Technical Paper 2013–01–0839 (2013). https://doi.org/10.4271/2013-01-0839

Zhan, R., Eakle, S.T., Weber, P.: Simultaneous reduction of PM, HC, CO and NOx emissions from a GDI engine. SAE Technical Paper 2010–01–0365 (2010). https://doi.org/10.4271/2010-01-0365

Seki, C., Watanabe, T., Mori, T., Furukawa, A., Satoh, N., Imai, Y., Matsuo, Y.: Design of high performance coated GPF with 2D/3D structure analysis. SAE Technical Paper 2019–01–0977 (2019). https://doi.org/10.4271/2019-01-0977

Greiner, R., Prill, T., Iliev, O., van Setten, B., Votsmeier, M.: Tomography based simulation of reactive flow at the microscale: Particulate filters with wall integrated catalyst. Chem. Eng. J. 378, 121919 (2019)

Bissett, E.J.: Mathematical model of the thermal regeneration of a wall-flow monolith diesel particulate filter. Chem. Eng. Sci. 39(7–8), 1233–1244 (1984)

Vlachos, N.D., Konstandopoulos, A.G.: Digital materials methods for DPF development. SAE Technical Paper 2006–01–0260 (2006)

Konstandopoulos, A.G., Vlachos, N.D., Patrianakos, G.: Application of digital material methods to silicon carbide diesel particulate filters. SAE Technical Paper 2007–01–1131 (2007)

Konstandopoulos, A.G., Kostoglou, M., Lorentzou, S., Vlachos, N.: Aspects of multifunctional diesel particulate filters and their efficient simulation. Catal. Today 188(1), 2–13 (2012)

Konstandopoulos, A., Metallinou, R., Dimitrakis, D.: Growth and restructuring phenomena of deposits in particulate filters. SAE Technical Paper 2018–01–1265 (2018). https://doi.org/10.4271/2018-01-1265

Bollerhoff, T., Markomanolakis, I., Koltsakis, G.: Filtration and regeneration modeling for particulate filters with inhomogeneous wall structure. Catal. Today 188, 24–31 (2012)

Plachá, M., Kočí, P., Isoz, M., Svoboda, M., Price, E., Thompsett, D., Kallis, K., Tsolakis, A.: Pore-scale filtration model for coated catalytic filters in automotive exhaust gas aftertreatment. Chem. Eng. Sci. 226, 115854 (2020)

Belot, I., Vidal, D., Votsmeier, M., Hayes, R., Bertrand, F.: Numerical investigation of the impact of washcoat distribution on the filtration performance of gasoline particulate filters. Chem. Eng. Sci. 221, 115656 (2020)

Viswanathan, S., Rothamer, D., Sakai, S., Hageman, M., Foster, D., Fansler, T., Andrie, M.: Effect of particle size distribution on the deep-bed capture efficiency of an exhaust particulate filter. J. Eng. Gas Turbine Power 137(10), 11 (2015). https://doi.org/10.1115/1.4030098

Viswanathan, S., Rothamer, D.A., Foster, D.E., Fansler, T.D., Zelenyuk, A., Stewart, M.L., Bell, D.M.: Evolution of deep-bed filtration of engine exhaust particulates with trapped mass. Int. J. Engine Res. 18(5–6), 543–559 (2016). https://doi.org/10.1177/1468087416675094

Viswanathan, S., Sakai, S. S., Hageman, M., Foster, D. E., Fansler, T., Andrie, M., Rothamer, D. A.: Effect of particle size distribution on the deep-bed capture efficiency of an exhaust particulate filter. In ASME 2014 Internal Combustion Engine Division Fall Technical Conference. American Society of Mechanical Engineers Digital Collection (2014). https://doi.org/10.1115/1.4030098

Gong, J., Rutland, C.J.: based heterogeneous multiscale filtration model. Environ. Sci. Technol. 49(8), 4963–4970 (2015). https://doi.org/10.1021/acs.est.5b00329

Sheppard, J., Yang, P., Strzelec, A.: Modeling and experimentation of GDI-sized particulate filtration and pressure-drop behavior in uncoated commercial DPF substrates. SAE Technical Paper 2019–01–0052 (2019). https://doi.org/10.4271/2019-01-0052

Porter, Q., Strzelec, A.: Benchtop Investigation of filtration efficiency and pressure drop behavior of commercial high porosity gasoline particulate filters. SAE Technical Paper 2019–01–0054 (2019). https://doi.org/10.4271/2019-01-0054

Yang, P., Pate, M., Strzelec, A.: Gasoline particulate filter substrate heterogeneity effects on its performance. SAE Int. J. Engines 13(1), 49–62 (2020). https://doi.org/10.4271/03-13-01-0004

Viswanathan, S., Rothamer, D., Zelenyuk, A., Stewart, M., Bell, D.: Experimental investigation of the effect of inlet particle properties on the capture efficiency in an exhaust particulate filter. J. Aerosol Sci. 113, 250–264 (2017). https://doi.org/10.1016/j.jaerosci.2017.08.002

Olfert, J., Rogak, S.: Universal relations between soot effective density and primary particle size for common combustion sources. Aerosol Sci. Tech. 53(5), 485–492 (2019)

Belot, I., Sun, Y., Vidal, D., Votsmeier, M., Causse, P., Trochu, F., Bertrand, F.: A 3D additive manufacturing approach for the validation of a numerical wall-scale model of catalytic particulate filters. Chem. Eng. J. 405, 126653 (2021). https://doi.org/10.1016/j.cej.2020.126653

Kuwabara, S.: The forces experienced by randomly distributed parallel circular cylinders or spheres in a viscous flow at small Reynolds numbers. J. Phys. Soc. Jpn. 14(4), 527–532 (1959). https://doi.org/10.1143/JPSJ.14.527

Konstandopoulos, A.G., Kostoglou, M., Vlachos, N.: The multiscale nature of diesel particulate filter simulation. Int. J. Veh. Des. 41(1–4), 256–284 (2006)

Yang, P., Strzelec, A.: Numerical study of pore size and distribution effects on gasoline particulate filter performance. SAE Int. J. Engines 12(5) (2019). https://doi.org/10.4271/03-12-05-0032

Konstandopoulos, A., Skaperdas, E., Masoudi, M.: Microstructural properties of soot deposits in diesel particulate traps. SAE Technical Paper 2002–01–1015 (2002). https://doi.org/10.4271/2002-01-1015

Koltsakis, G., Konstantinou, A., Haralampous, O., Samaras, Z.: Measurement and intra-layer modeling of soot density and permeability in wall-flow filters. SAE Technical Paper 2006–01–0261 (2006). https://doi.org/10.4271/2006-01-0261

Funding

Funding for this project was provided by the Natural Science and Engineering Research Council of Canada (NSERC) and Umicore AG & Co. Support was provided by the China Scholarship Council (No. 201906340207) for the visit of Xiangxiao Kong to the University of Alberta.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kong, X., Chen, K., Greiner, R. et al. Particle Size-Dependent Filtration Efficiency and Pressure Drop of Gasoline Particle Filters with Varying Washcoat Volumes. Emiss. Control Sci. Technol. 7, 105–116 (2021). https://doi.org/10.1007/s40825-021-00193-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40825-021-00193-3