Abstract

The potential improvement of DeNOx efficiency enabled by injecting calibrated amounts of NH4NO3 (AN) aqueous solution into lean engine exhausts prior to NH3-SCR converters (Enhanced-SCR) has been investigated by dynamic and steady-state catalytic activity runs over a commercial Fe-zeolite monolith catalyst. The study was performed varying GHSV (35,000–100,000 h−1), temperature (150–550 °C), as well as AN and NO2 feed concentrations. The results demonstrate that already at low temperature (180 °C) the DeNOx activity of the investigated catalyst at Standard-SCR conditions is greatly boosted by the addition of AN: for example, the injection of 250 ppm of NH4NO3 incremented the NO conversion from ∼15 to ∼85 % at GHSV = 50,000 h−1, with feed NO = NH3 = 500 ppm. Furthermore, the dosed NH4NO3 was completely converted, with no undesired release of N2O. We show also that the Enhanced-SCR pathway proceeds through a first step wherein AN rapidly oxidizes NO to NO2, which then goes on to react with NH3 according to the Fast-SCR reaction. Based on this sequential reaction scheme, a simple kinetic model has been developed and successfully fitted to all the collected data.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Due to the tightening emission limits and to the strategies for lower fuel consumption, which reduce the mean temperature of the exhausts and thus of the emission control devices, more effective aftertreatment technologies for diesel vehicles are under investigation. It is a matter of fact that the NH3/urea-SCR plays a major role among the DeNOx technologies [1–4]; nevertheless, it is also well known in literature that the Standard-SCR Reaction (S-SCR) (1) is associated with a lower DeNOx activity in the 200–300 °C temperature range than the Fast-SCR Reaction (F-SCR) (2) [5, 6]:

However, the F-SCR needs a perfect 1:1 stoichiometric NO2/NO ratio to proceed, this constraint requiring an expensive high load noble metal diesel oxidation catalyst (DOC) upstream of the SCR unit. During a typical life cycle, such a noble metal-based DOC is subject to deactivation due to hydrothermal ageing and poisoning [7]. In addition, the high level of variability in the engine exhausts makes it practically impossible to ensure the optimal NO2/NO feed ratio for all possible engine operating conditions.

On this basis, and in order to assist (and possibly reduce) the DOC unit, the potential of dosing aqueous solutions of NH4NO3 to the exhaust gases was addressed since, as previously reported in literature [8–12], this can bring benefits to the DeNOx catalyst performance due to the occurrence of the “Enhanced-SCR” (E-SCR) Reaction (3),

In the low temperature range, Reaction (3) has demonstrated DeNOx performances similar to those of the F-SCR over both V2O5–WO3/TiO2 and Fe-ZSM-5 commercial catalysts, but both fundamental and practical aspects of the E-SCR reactivity are still an open issue.

This work aims at analyzing the effect of NH4NO3 (AN) addition to the SCR reacting system over a commercial Fe-zeolite catalyst for diesel exhaust aftertreatment. In particular, efforts were devoted to identify the key step responsible for the improvement of the DeNOx activity, thus contributing to elucidate the mechanism of the E-SCR reaction. Moreover, the whole set of data herein collected has been used to develop a simple global kinetic model consistent with the E-SCR chemistry.

2 Experimental

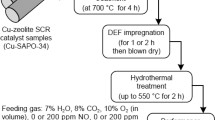

Steady state and transient catalytic activity runs were performed over a commercial washcoated beta-zeolite exchanged with Fe catalyst in the form of a core monolith (7.7 × 7.7 × 65 mm in size), drilled from the original full-size flow-through 400 cpsi (4.3 mil) honeycomb monolith provided by Umicore.

The catalyst sample was placed in a stainless steel sample holder and topped with quartz spheres, before a quartz wool layer, to increase the turbulence and ensure a good mixing of the reactants. The reactor tube (405 mm in length, 15 mm i.d.), containing the sample holder, was inserted in a cylindrical electric oven, whose temperature (up to 575 °C) was remotely controlled by a PID controller (Eurotherm model 2132). The reactor was equipped with three K-type thermocouples: one was used to monitor the inlet gas temperature and two were placed in contact with the top and the bottom of the catalyst.

Before the activity tests, the catalyst was conditioned by heating it up to 550 °C for 5 h in a continuous flow of 10 % (v/v) O2 and 10 % (v/v) H2O, with nitrogen balance (100,000 h−1 GHSV). Typical feed concentrations of NOx (NO2/NOx = 0–0.5) and NH3 during the runs were 500 ppm, with 8 % O2, 5 % H2O (v/v), and balance N2. The five AN feed concentration levels used for the investigation (100, 200, 250, 300, and 350 ppm) were obtained by dosing different aqueous solutions prepared by properly diluting a master 2.5 M solution.

Either liquid water or the AN + H2O solution was metered by a volumetric piston pump (Gilson model 305): the feed rates were around 0.06 ml/min ± 0.0001 for GHSV = 350,000 h−1 or 0.16 ml/min ± 0.0001 for GHSV = 100,000 h−1. Afterwards, the liquid feed was vaporized in a hot pipeline kept at 200 °C, and then mixed with the other gaseous species and fed to the reactor.

Wide ranges of GHSV (35,000–100,000 h−1) and temperature (180–350 °C) have been investigated for each level of AN feed content. The GHSV was calculated as flow rate per total volume of the whole monolith catalyst. For selected levels of AN feed content and GHSV, the investigated temperature range was expanded up to 550 °C.

All the gaseous species (except N2) were continuously monitored at the reactor outlet: NO, NH3, and NO2 by using a UV analyzer (ABB Limas 11HV), while N2O was monitored by a ND-IR analyzer (ABB Uras). AN was not measured; thus, its conversion was calculated from the conversion of the other species according to the stoichiometry of the E-SCR Reaction (3).

3 Results and Discussion

3.1 Effect of NH4NO3 Addition on the SCR Activity

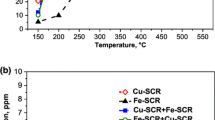

Figure 1 shows the effect of varying the feed content of AN (100, 200, and 250 ppm) on the steady-state NOx conversion measured when feeding 500 ppm of both NH3 and NO, 5 % of H2O, and 8 % of O2 (S-SCR conditions), plotted as a function of temperature. Tests with AN dosing were performed up to 350 °C, and 300 °C in the case of AN = 100 ppm. The curves corresponding to the S-SCR reaction (500 ppm of both NH3 and NO, 5 % of H2O, and 8 % of O2) and to the F-SCR reaction (500 ppm of both NH3 and NOx, with 250 ppm each of NO and NO2, 5 % of H2O, and 8 % of O2) are also displayed for comparison purposes. The GHSV was kept at 50,000 h−1 in all the runs presented in Fig. 1.

The two limiting behaviors for high and low NOx conversion are represented by the F-SCR (black line) and the S-SCR (red line) activities, respectively [13]. At S-SCR conditions, modest NOx conversions were observed below 200 °C, while above 300 °C the DeNOx efficiency was over the 80 %, and did not drop at the highest temperatures since NH3 oxidation was limited over this catalyst.

On the contrary, F-SCR runs showed a superior NOx conversion already at low temperature, and it remained around 90–95 % up to 450 °C. For higher temperatures, partial NO2 decomposition slightly reduced the F-SCR efficiency, which however stayed around 85 %.

Figure 1 shows that adding larger amounts of AN in aqueous solution resulted in a significant growth of DeNOx activity with respect to the S-SCR conditions, increasing both the NH3 (not presented) and the NO conversions towards the upper F-SCR bound. Remarkably, already at low temperature (180 °C), on feeding just 100 ppm of AN, the performance of the catalyst was significantly boosted, with a gain in NO conversion of ∼30 % if compared to the S-SCR case, when no AN was fed to the reactor. The enhancement was even higher when the AN feed concentration was doubled, the NOx conversion being now incremented from approximately 15 % to almost 80 %. Finally, when feeding a stoichiometric amount of AN, corresponding to a concentration of 250 ppm according to Eq. (3), the performance of the Fe-zeolite catalyst was further improved, approaching, though not exactly matching, the NOx conversion activity of the F-SCR reaction. Notably, the DeNOx efficiency was close to 90 % at all the investigated temperatures in this case.

Similar experiments were run to study the effect of the space velocity (35,000-50,000-75,000-100,000 h−1). In Fig. 2, NOx conversions measured at 200 °C are plotted versus the space velocity for different AN feed contents. Like before, the two reference curves related to the S-SCR and the F-SCR reactions are displayed as well.

As expected, the S-SCR activity was quite adversely affected by the increase of the GHSV, while the F-SCR activity was essentially insensitive, with NOx conversions always above 95 %. As shown before, feeding increasing amounts of AN improved the DeNOx efficiency, bringing it close to the F-SCR curve. Accordingly, also a loss of sensitivity to GHSV was evident when passing from the E-SCR with 100 ppm AN to the E-SCR with 250 ppm AN feed content. It is important to emphasize that neither NO2 nor N2O, i.e., possible AN decomposition products, were detected, during the whole set of E-SCR runs for all AN feed contents.

3.2 Effect of NH4NO3 at High Temperatures

The subsequent step of the work focused on the effect of feeding aqueous solutions of AN at temperatures above 350 °C. A dedicated run was carried out at GHSV equal to 75,000 h−1 with a gas feed composition including 450 ppm of NH3 and 500 ppm of NO (α = NH3/NOx = 0.9) in the presence of 5 % H2O and 8 % O2, and 200 ppm of AN.

Figure 3 shows the steady-state concentrations of ammonia, NO, NO2, and N2O at reactor outlet. Up to 350 °C, the NH3 and NO concentrations resulted in conversions similar to those presented in Fig. 1. At higher temperatures, the NH3 conversion remained constant, while the NO outlet concentration slightly increased due to the onset of NH3 oxidation. The extent of the NH3 oxidation was in line with what is observed over SCR catalysts for mobile applications under typical SCR operating conditions [14], and thus it was not modified by the presence of the AN additive. It is also important to point out that, as mentioned above, the AN was completely converted in the whole temperature range, and no traces of its decomposition products N2O and NO2 were detected. Accordingly, the data in Figs. 1, 2, and 3 point out that, while AN has a very positive influence on the low temperature DeNOx activity of the Fe-zeolite catalyst, it does not show any adverse effect at high temperatures.

The effect of co-feeding NO2 and AN to the Fe-zeolite catalyst was also addressed [15]. It was found that the catalyst was still able to significantly convert NOx, but an increase in the production of N2O was also measured, if compared to the case in which AN alone, and no NO2, was fed together with NO and ammonia. However, the amounts of detected N2O were not very different from those obtained when the NO2 SCR reaction was run on the same catalyst (by feeding NO2 and ammonia in the presence of oxygen and water).

3.3 Reactivity of NH4NO3 with NH3 and with NO: the Enhanced-SCR Mechanism

In order to gain insight into the AN-related catalytic chemistry, the interaction between AN and NH3 was first investigated feeding 500 ppm of NH3 in the presence of 8 % O2 and 5 % H2O. The GHSV was 75,000 h−1. Figure 4a–c shows the results collected at three different temperatures (200-250-350 °C).

From Fig. 4a, it is apparent that at 200 °C there was no reaction (at all AN feed concentrations) between NH3 and AN, as clearly indicated by the NH3 concentration remaining constant and equal to its feed value. Moreover, no AN decomposition products were observed; thus, the build-up of AN onto the catalyst surface was probably occurring. On increasing the temperature up to 250 °C (Fig. 4b), the NH3 concentration remained constant and equal to the feed value, whereas in this case, some NO2 and N2O, i.e., the typical AN decomposition products, were detected: indeed, the reaction between ammonia and NO2 (NO2-SCR) does not proceed at 250 °C, and this results in significant emissions of ammonia and NO2.

As opposite, in the experiment run at 350 °C (Fig. 4c), NH3 was converted as a result of the NO2 SCR activity, since, as shown in Fig. 4b, NO2 is one of the AN decomposition products. Furthermore, some N2O formation was also observed at 350 °C, which is explained by partial AN decomposition. .

A set of steady state and transient runs was then performed in order to address the interaction between NO and AN [11]. Figure 5 shows the step-response run performed with AN = 200 ppm. The experiment was carried out without O2 at 200 °C (the lowest possible temperature to prevent side reactions) at GHSV = 75,000 h−1. Initially, 500 ppm of NO was fed to the reactor, and a steady state was reached after 500 s. At time = 0 s, the piston pump was switched on to feed 5 % of H2O + 200 ppm of AN: the NO outlet concentration dropped immediately to roughly 320 ppm and, at the same time, NO2 was detected, its outlet concentration increasing up to an average value of 180 ppm. This clearly indicates that AN is able to oxidize NO to NO2 quantitatively, according to

When, at time = 1500 s, 500 ppm of NH3 were added to the reactor feed, the NO2 outlet concentration immediately dropped to zero. This indicates that the NO2 produced by Reaction (4) is able to react further with the remaining NO and with NH3 in accordance with the F-SCR Reaction (2).

After a transient, the NH3 and NO outlet concentrations achieved a 1:1 ratio and eventually stabilized around 140 ppm each, in line with the stoichiometry of the Enhanced-SCR Reaction (3).

Based on the results in Fig. 5, it is then possible to outline schematically the mechanism of the Enhanced-SCR Reaction (3) as the sequential combination of the NO oxidation by AN, Reaction (4), and of the Fast-SCR, Reaction (2):

In view of the evidence coming from the dynamic run presented in Fig. 5, a systematic investigation addressing the NO oxidation activity of AN was performed. Five aqueous solutions of AN corresponding to AN feed concentrations of 100-200-250-300-350 ppm were used for this purpose. In Fig. 6a, b, data from steady-state runs performed at 200 °C and 75,000 and 35,000 h−1, respectively, with feeds containing 500 ppm of NO and no O2, are plotted against the AN feed concentration.

The results in Fig. 6 clearly indicate that AN was able to oxidize NO to NO2 quantitatively over the Fe-zeolite catalyst, without formation of undesired by-products at any AN investigated feed concentration level. For instance, in Fig. 6b, 100 ppm of AN reacted quantitatively with 500 ppm of NO producing 100 ppm of NO2 in agreement with Reaction (4). Furthermore, from Fig. 6, it is also evident that the AN oxidizing activity was not affected by the GHSV.

On the other hand, the data in Fig. 6a, b show an increased NOx concentration for AN feed contents in excess of 250 ppm. This result is in conflict with the reacting scheme discussed for Fig. 5, in which it is evident that AN does not change the overall amount of NOx while reacting with NO. Thus, it is possible to assume that, if the NO/AN feed ratio tends to 1, Reaction (4) may come eventually into competition with AN decomposition, which can produce NOx [10, 16] according to the following reactions:

Considering that N2O was actually not detected during the runs presented in Fig. 6, it is most likely that only Reactions (6) and (7) occurred in our experiments.

In order to further investigate Reaction (4), a dedicated run has been carried out by keeping constant the AN feed concentration at 200 ppm while stepwise reducing the NO feed concentration from 500 to 200 ppm. Figure 7 shows the data collected at 200 and 250 °C in the presence of 5 % H2O and 8 % O2, with N2 as balance. The black dashed line represents the theoretical trend for the NO outlet concentration expected from the stoichiometry of Reaction (4), assuming that it proceeds quantitatively. The red and green lines show data from the runs performed at 200 and 250 °C, respectively. From the inspection of Fig. 7, it is evident that, for NO feed concentrations between 500 and 350 ppm, AN reacted quantitatively with NO and was completely converted to NO2, H2O, and N2 according to Reaction (4). Accordingly, the two experimental curves perfectly matched the theoretical dashed line. When the feed NO concentration was further reduced to 300 ppm, however, the AN decomposition via Reactions (6) and (7) started competing with the Reaction (4). The difference between theoretical and experimental outlet NO concentrations increased while approaching NO/AN = 1. We have seen in Fig. 5 that the reaction between NO and AN was almost instantaneous, and this means that at these operating conditions the NO concentration drops rapidly along the monolith length. If the rate of Reaction (4) strongly depends on the NO concentration (positive kinetic order dependence), the low NO concentration at reactor outlet could eventually lead to suitable conditions for the AN decomposition reaction to be kinetically favored. Notably, no evidence of AN decomposition was detected when the AN feed concentration was sub-stoichiometric, i.e., an excess of NO was present.

NO conversion in NO + NH4NO3 reaction as a function of NO feed concentration. GHSV = 100,000 h−1, feed: H2O = 5 % (v/v), AN = 200 ppm, O2 = 8 % (v/v), NO = 200–500 ppm. Theoretical value according to Reaction (4)

So far we have shown that the increase of the AN feed content enables to move from the DeNOx activity of the S-SCR reaction to that of the F-SCR reaction: this suggests that adding AN to an NO/NH3 feed mixture is the same as modifying the NO2/NOx feed ratio to the mixture. A few dedicated runs were performed in order to assess this hypothesis.

Figure 8 shows the results of steady-state runs carried out feeding 500 ppm of NH3 and different amounts of NOx, which included the following: 500 ppm of NO for S-SCR, 400 ppm of NO + 100 ppm of NO2 for F-SCR, 500 ppm of NO + 100 ppm of AN for E-SCR, in the presence of 5 % of H2O and 8 % of O2. Like before, the GHSV was 75,000 h−1.

On inspecting Fig. 8, it is evident that the black line, which identifies the run carried out feeding 400 ppm of NO + 100 ppm of NO2, and the green line, which is referred to the run with 500 ppm of NO + 100 ppm of AN in the feed, are completely overlapped, indicating the same DeNOx activity. This result definitely establishes a direct equivalence between NO2 fraction in the NOx feed and the NH4NO3 dose that generates an identical amount of NO2 in the reactor, according to Reaction (4). Based on other similar runs with AN feed concentrations up to 250 ppm (not shown for brevity), it is possible to extend the AN-NO2 equivalence to higher AN feed contents, provided that the AN reacts quantitatively.

3.4 Implications for the F-SCR Mechanism

From the data shown in Fig. 8, a direct equivalence between AN and NO2 is clear. This has some implications also in relation to the catalytic chemistry of the Fast-SCR reaction.

As well known in the literature [17–19], at F-SCR conditions, i.e., when feeding equimolar amounts of NO and NO2, NO2 is adsorbed on the SCR catalyst in the form of nitrate and nitrite surface species. As schematically displayed in Fig. 9a, the nitrites react with NH3 to form highly unstable NH3NO2, which readily decomposes to N2 and H2O; on the other hand, nitrates are reduced by NO to nitrites, which, after reacting with NH3 themselves, eventually decompose to N2 and H2O. In parallel to such a selective Fast-SCR pathway, however, the surface NO3 − species could also react with NH4 +: this reaction can lead to the formation of bulk NH4NO3 and, further, of N2O, i.e., the decomposition product of the latter.

In the case of E-SCR, AN directly forms the nitrates adspecies, which oxidize NO to NO2, being in turn reduced to nitrites. Like before, nitrites then react with NH3 forming N2 and H2O via NH4NO2. The NO2 produced by the NO oxidation step could eventually enter the F-SCR reaction scheme (Fig. 9a). In summary, Fig. 9 emphasizes that E-SCR and F-SCR share the same reaction scheme. It is also worth noticing that, as long as sufficient NO is available to perform the reduction of nitrates, negligible formation of N2O is expected: thus the decomposition route, Reactions (6–7), is an unfavorable reaction pathway for the AN additive in comparison to its reduction by NO, Reaction (4).

3.5 Development of an E-SCR Kinetic Model

A simple kinetic model of E-SCR has been developed, in line with the experimental evidence herein collected. The model takes into account the following three global reactions:

Reaction (4) is the oxidation of NO by AN, Reactions (2) and (1) are the F-SCR and S-SCR, respectively. Notice that the Enhanced-SCR Reaction (3) results from adding Reactions (2) and (4) above, as discussed in previous sections.

For the purposes of kinetic modeling, we assume simple second-order rate equations for Reactions (2) and (4) and a first-order rate equation for Reaction (1). For the sake of simplicity, we also neglect the kinetic dependence on ammonia (zero order), which is acceptable for the experiments discussed in this work, where NH3 was never the limiting reactant.

If we assume a pseudo homogeneous isothermal plug-flow reactor model with negligible diffusional limitations, pressure drop, and axial dispersion, the mass balance equations for NO, NO2, and AN are, respectively:

with initial conditions:

and

V cat = catalyst volume [cm3]

Q = volumetric flow [cm3/s]

k 4, k 2 = rate constant for Reactions (4) and (2), respectively [cm3/mol/s]

k 1 = rate constant for reaction (1) [s−1]

The estimates of the rate constants k 4, k 2, and k 1 were obtained by global nonlinear regression, fitting the experimental data from all the steady-state catalytic activity runs at six temperature levels (180-200-225-250-300-350 °C). Moreover, for each temperature, runs at four GHSVs and four AN feed concentration levels were considered. Accordingly, the developed kinetic model is able to describe the effects of three operating variables, namely temperature, flow rate, and AN feed content. Due to the considerations introduced in the discussion of Figs. 6 and 7, however, the proposed kinetic model is valid for only NO/AN > 1, since it does not account for AN decomposition.

The plots in Fig. 10 summarize selected kinetic fit results, comparing experimental data and model fit for given temperatures (180–300 °C) and AN feed concentrations (100–250 ppm) as a function of GHSV. From inspection of Fig. 10, it is evident that, in spite of its simplicity, the kinetic model grants a fair agreement with the data. Only for the experiments at 300 °C (Fig. 10d) a systematic underestimation of the NO concentration is evident at low GHSV. This deviation can be explained considering that at these conditions also the NH3 oxidation reaction occurs to some extent, which however was not implemented in the kinetic model for the sake of simplicity.

The accuracy of the kinetic fit is also evident from Fig. 11 where experimental steady-state NO conversions (dots) and model data (solid lines) are plotted versus the AN feed content for three different temperatures.

It is also worth mentioning that the range of model applicability well matches those conditions where AN dosing would be most effective and desirable under real operating conditions, such as AN/NO < 1 and T < 300 °C, i.e., where the S-SCR needs boosting by the NO-oxidizing effect of AN.

4 Conclusions

The data collected in this work clearly indicate that addition of NH4NO3 to the feed stream strongly promotes the NO conversion efficiency at low temperature (up to 250 °C) over the tested commercial Fe-zeolite SCR catalyst. As an example, the injection of 250 ppm of NH4NO3 was responsible for an increase of the NH3 and NOx conversions from ∼20 to ∼90 % at 200 °C and GHSV = 75,000 h−1. Furthermore, the dosed NH4NO3 was completely converted to NO2, N2, and H2O at all tested GHSVs and temperatures, with no undesired formation of N2O, as long as enough NO is present in the feed flow.

By dedicated dynamic runs, we have further demonstrated that the role of AN is to generate NO2 in situ via NO oxidation. Moreover, such a reaction is extremely fast, even at 180 °C, so that the NO2 so formed over the SCR catalyst is essentially equivalent to the NO2 coming from a DOC upstream of the SCR converter. If properly dosed, therefore, NH4NO3 enables to approach the optimal Fast-SCR activity without requiring a noble metal-based DOC (NO2-on-demand).

Data from dedicated runs have also established a direct equivalence between AN and NO2 fed to the reactor. This equivalence implies that the same reaction scheme applies for both Fast-SCR and Enhanced-SCR reactions, which simply differ in their first step. In F-SCR, such a step is the NO2 disproportionation/chemisorption to form nitrates and nitrites adspecies, while the E-SCR reaction pathway is initiated by the dissociation of NH4NO3 into NH3 and HNO3 and the subsequent formation of adsorbed NH4 + and NO3 −.

It is worth highlighting that, based on additional activity tests, the AN additive is efficiently converted also at higher temperatures (above 350 °C) without formation of N2O and NO2, i.e., the typical AN decomposition by-products. Thus, also at high temperature, the E-SCR mechanism is the preferred AN reaction pathway, as long as NO is available.

Contrary to NO, NH3 exhibits no reactivity with AN up to 300 °C at any AN feed content. Moreover, at this temperature, and in the presence of NH3, AN also decomposes to N2O and NO2. Only at 350 °C does NH3 moderately react with AN, but in parallel AN is also thermally decomposed to N2O. Thus, dosing of AN in the absence of NO should be avoided.

The kinetic analysis of the data herein collected has shown that a simple sequential model, accounting for NO oxidation by NH4NO3 followed by Fast-SCR, as well as for S-SCR (Reactions (4), (2), and (1)), can well describe the behavior of the overall E-SCR reacting system in the presence of the ammonium nitrate under conditions where AN dosing is most desirable/effective (i.e., AN/NO < 1 and T < 300). In order to have a full description of both SCR and E-SCR reacting systems, then, the sub-model developed in this work, accounting specifically for the reactivity of AN with NO, could be simply appended to an existing NH3-SCR kinetic model.

References

Forzatti, P., Lietti, L., Tronconi, E.: Encyclopedia of Catalysis, pp. 298–343. Wiley, New York (2003)

Nova, I., Beretta, A., Groppi, G., Lietti, L., Tronconi, E., Forzatti, P.: In: Cybulski, A., Moulijn, J.A. (eds.) Structured Catalysts and Reactors, pp. 171–214 Second ed. Taylor and Francis, Boca Raton (2006)

Johnson, T.: Platin. Met. Rev. 52, 23–37 (2008)

Rahkamaa-Tolonen, K., Maunula, T., Lomma, M., Huuhtanen, M., Keiski, R.L.: Catal. Today 100, 217–222 (2005)

Kato, A., Matsuda, S., Kamo, T., Nakajima, F., Kuroda, H., Narita, T.: J. Phys. Chem. 85, 4099–4102 (1981)

Koebel, M., Elsener, M., Kleemann, M.: Catal. Today 59, 335–345 (2000)

Winkler, A., Ferri, D., Hauert, R.: Catal. Today 155, 140–146 (2010)

Forzatti, P., Nova, I., Tronconi, E.: Apparatus and process for reducing the content of nitrogen oxides in the exhaust gases of combustion systems. European Patent EP 2 144 691 B1 (2008)

Forzatti, P., Nova, I., Tronconi, E.: Angew. Chem. Int. Ed. 48, 8366–8368 (2009)

Forzatti, P., Nova, I., Tronconi, E.: Ind. Eng. Chem. Res. 49, 10386–10391 (2010)

Forzatti, P., Nova, I., Tronconi, E., Kustov, A., Thøgersen, J.R.: Catal. Today 184, 153–159 (2012)

Forzatti, P., Nova, I., Tronconi, E.: SAE Technical Paper 2010-01-1181 (2010)

Iwasaki, M., Shinjoh, H.: Appl. Catal. A Gen. 390, 71–77 (2011)

Colombo, M., Nova, I., Tronconi, E.: Catal. Today 151, 223–230 (2010)

Marchitti, F., Nova, I., Forzatti, P., Tronconi, E., Adelberg, S., Strots, V.: A system simulation study of the Enhanced-SCR reaction”, Top Catal, accepted for publication

Ciardelli, C., Nova, I., Tronconi, E., Chatterjee, D., Bandl-Konrad, B., Weibel, M., Krutzsch, B.: Appl. Catal. B Environ. 70, 80–90 (2007)

Colombo, M., Nova, I., Tronconi, E.: Catal. Today 197, 243–255 (2012)

Yeom, Y.H., Henao, J., Li, M.J., Sachtler, W.M.H., Weitz, E.: J. Catal. 231, 181–193 (2005)

Savara, A., Li, M.-J., Sachtler, W.M.H., Weitz, E.: Appl. Catal. B Environ. 81, 251–257 (2008)

Acknowledgments

The financial support of European CO2RE—CO2 REduction for long distance transport (SCP1-GA-2012-284909) is gratefully acknowledged. The authors thank Dr. Stephan Eckhoff, Umicore, for supplying the Fe-zeolite SCR catalyst, and Vadim Strots and Stephan Adelberg, IAV GmbH, for many useful discussions and critical suggestions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Marchitti, F., Hemings, E.B., Nova, I. et al. Enhancing the Low-T NH3-SCR Activity of a Commercial Fe-Zeolite Catalyst by NH4NO3 Dosing: an Experimental and Modeling Study. Emiss. Control Sci. Technol. 2, 1–9 (2016). https://doi.org/10.1007/s40825-015-0030-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40825-015-0030-y