Highlights

-

The electrochemical techniques utilizing metal-organic frameworks (MOFs)-based catalysts for converting CO2 into chemical species are discussed.

-

The structure–activity relationship of MOF-based catalysts in electrocatalytic CO2 reduction reactions is thoroughly reviewed

-

The challenges and opportunities of large-scale applications of MOF-based materials in electrochemical CO2 reduction reactions are discussed, and possible directions for the future development of MOFs and their derivatives are outlined.

Abstract

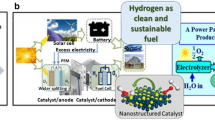

Electrochemically reducing CO2 to more reduced chemical species is a promising way that not only enables the conversion of intermittent energy resources to stable fuels, but also helps to build a closed-loop anthropogenic carbon cycle. Among various electrocatalysts for electrochemical CO2 reduction, multifunctional metal–organic frameworks (MOFs) have been employed as highly efficient and selective heterogeneous electrocatalysts due to their ultrahigh porosity and topologically diverse structures. Up to now, great progress has been achieved in the design and synthesis of highly active and selective MOF-related catalysts for electrochemical CO2 reduction reaction (CO2RR), and their corresponding reaction mechanisms have been thoroughly studied. In this review, we summarize the recent progress of applying MOFs and their derivatives in CO2RR, with a focus on the design strategies for electrocatalysts and electrolyzers. We first discussed the reaction mechanisms for different CO2RR products and introduced the commonly applied electrolyzer configurations in the current CO2RR system. Then, an overview of several categories of products (CO, HCOOH, CH4, CH3OH, and multi-carbon chemicals) generated from MOFs or their derivatives via CO2RR was discussed. Finally, we offer some insights and perspectives for the future development of MOFs and their derivatives in electrochemical CO2 reduction. We aim to provide new insights into this field and further guide future research for large-scale applications.

Similar content being viewed by others

1 Introduction

The overuse of fossil fuels has caused a rapid increase in atmospheric CO2 concentrations and disrupted the natural equilibrium of the carbon cycle, leading the global warming and subsequent consequences such as frequent storms, drought, and rising sea levels [1]. As climate change is getting worse, it is urgent to protect the ecological environment by developing advanced technologies to close the carbon loop. One potential approach is shifting current industries’ energy dependence from fossil fuels to renewable sources such as solar, wind, and thermal [2, 3]. However, unlike the controllable base-load energy in modern power grids, the inherent intermittency of renewable energy sources greatly limits their use or efficiency [4]. To solve the energy fluctuation problem, storing renewable energy in the chemicals form by converting CO2 into chemical feedstocks and fuels is a more promising way, which not only efficiently utilizes renewable energy but also reduces carbon emissions [5, 6].

Electrocatalytic reduction of CO2 to value-added chemicals using renewable electricity provides a practical solution to offset the extra carbon footprint [7,8,9,10,11,12]. However, the high activation barrier to break the symmetrical linear structure and stable C = O bonding (750 kJ mol−1) make the electrochemical process difficult [13,14,15,16,17]. Furthermore, the CO2 reduction reaction (CO2RR) process involves multi-electron/proton transfer processes and generates many different reaction intermediates, which are associated with a number of different reactions pathways and result in a large variety of products [18,19,20,21,22,23,24]. In recent years, efforts have been extensively dedicated to the design of catalysts with high efficiency and selectivity, resulting in noteworthy progress. Metal–organic frameworks (MOFs) are a class of porous coordination polymers consisting of metal ions/clusters coordinated to organic ligands, the open frameworks have high permanent porosity, high crystallinity, and long-range order [25,26,27,28,29,30]. The high surface area, tunable porosity, diversity in inorganic units and organic linkers make them attractive in catalytic reactions especially in the field of electrochemical CO2RR [31,32,33,34,35,36,37]: (1) The remarkably high porosity and surface area of MOFs facilitate the exposure of more active sites and boost rapid mass transport. (2) The electronic structure of MOFs can be precisely modulated via metal ion doping or functionalization of organic ligands, which influences the reaction pathways for CO2 electroreduction. (3) The varied organic linkers and abundant metal ions/clusters make MOFs attractive precursors or templates to fabricate numerous advanced MOF derivatives [such as metal/metal oxide nanoparticles, carbon materials and single-atom catalysts materials (SACs)] [38,39,40,41,42,43,44,45,46,47] as electrocatalysts for selective CO2RR.

There are various methods used for the synthesis of MOFs, including solvothermal, hydrothermal, microwave, and mechanochemical methods. The most common method is solvothermal synthesis, which involves the reaction of metal salts and organic ligands in a solvent at high temperature and pressure. The solvothermal method allows for precise control of the size, shape, and properties of the resulting MOFs. Hydrothermal synthesis is similar to solvothermal synthesis, but the reaction takes place in an aqueous solution instead of an organic solvent. This method is advantageous for the synthesis of water-stable MOFs. Microwave synthesis involves the use of microwave radiation to heat the reaction mixture and promote the formation of MOFs. This method is rapid and efficient and allows for the synthesis of MOFs in minutes rather than hours. Mechanochemical synthesis involves the use of mechanical force to induce chemical reactions between metal ions and ligands. This method is advantageous for the synthesis of MOFs with high thermal stability and is more environmentally friendly than traditional synthesis methods. Overall, the method chosen for the synthesis of MOFs for CO2RR involves a careful balance between catalytic activity, stability, and selectivity, with consideration given to the properties of the metal, ligand, and pore structure.

Primitive MOFs usually have drawbacks including low electrical conductivity, instability and inactive metal nodes due to the blockage of metal centers by organic ligands, which result in poor CO2RR performance. These limitations can be addressed by converting unstable MOFs into MOF derivatives, which can maintain the highly porous structure of the original MOF while also providing improved electrical conductivity and stability. MOF derivatives can be produced through electrochemical/chemistry reduction, surface modification, pyrolysis under specific conditions, and so on, which allow for precise control of material morphology, composition, surface area, and electronic structure of the metal nodes. For example, by controlling decomposition of MOFs under an inert atmosphere at high temperatures or under specific conditions can produce MOF-derived carbon materials or metal/metal oxide nanoparticles, respectively. Notably, MOF precursors with high thermal stability and metal loading can be thermally decomposed under an inert atmosphere to form SACs where isolated metal atoms are embedded in a carbon matrix, greatly enhancing the utilization efficiency of metal atoms. Overall, MOF derivatives largely expands the family of MOF materials and deliver superior performance to the pristine MOFs.

In the past years, MOF-related catalysts in electrochemical CO2RR systems have been thoroughly investigated, it is timely for us to take a systematic review to summarize the recent advances and pertinent challenges in this field (Fig. 1). The review starts with an introduction of the CO2RR reaction mechanisms at the molecular level, as well as a brief summary the electrolyzer structures. Then we discuss how to improve the selectivity and activity in electrochemical CO2RR toward different products from the perspective of materials design strategies such as pore structure modification, central metal atom substitution, and coordination environment adjustments. Finally, this review concludes with some of our insights about the research challenges and future directions, hoping to stimulate continuous innovations for advancing MOF-derived functional materials for electrochemical CO2RR.

2 Mechanism and Electrolyzer Types of Electrocatalytic reduction of CO2

2.1 Mechanism of Electrocatalytic Reduction of CO2

CO2 reduction was first reported by Royer in 1870 when they observed the formation of formic acid in an aqueous medium [48]. Since then, the mechanism of electrochemical CO2RR has been gradually discovered and a number of different possible reaction intermediates are identified, which essentially determine the reaction routes and final products [49, 50]. According to the number of carbon atoms, these products are typically divided into C1, C2, and C3 molecules, such as carbon monoxide (CO), formic acid (HCOOH), methanol (CH3OH), methane (CH4), ethylene (C2H4), acetic acid (CH3COOH), ethanol (CH3CH2OH), n-propanol (CH3CH2CH2OH), and acetone (CH3COCH3). Table 1 shows the corresponding half-reactions for different products as well as their standard reduction potentials versus reversible hydrogen electrodes (RHE) in both acidic and basic conditions [51, 52]. The large variety of possible CO2RR reaction pathways and their similar reduction potentials make the selective reduction to specific products a great challenge. Furthermore, in an aqueous electrolyte, the competition of hydrogen evolution reaction (HER) is a thorny issue that needs to be addressed as well.

2.1.1 C1 Pathways

In general, the first step of electrochemical CO2RR is to absorb CO2 molecules onto the catalyst surface and form *CO2−, which can further accept protons and/or electrons to form various intermediates that determine the final products [49, 53]. Figure 2 shows the possible mechanistic pathways of electrochemical CO2 reduction to C1 and C2 products, respectively. For C1 products especially two-electron products, such as CO and HCOOH (or HCOO−), the rate-limiting step is usually identified to be the formation process of *CO2− [49, 52, 54]. The reaction pathway toward CO or HCOO− is typically determined by the absorption configurations of the intermediate on the catalyst surface [55, 56]. Typically, when *CO2− binds to the catalyst surface through two oxygen atoms and forms the *OCHO intermediate, then HCOOH is preferably formed by a proton-coupled electron transfer step. The reaction pathway toward CO is similar, a number of studies, which combines experimental and theoretical evidence, found that *COOH is a key descriptor for CO production [49, 52, 55, 57,58,59,60]. A carbon-bound *COOH intermediate is generated through the initial binding of CO2 to the surface of the catalyst. Subsequently, the concerted proton-electron transfer (CPET) steps are readily triggered by attacking the oxygen atoms and forming H2O, after dehydration, *CO intermediate can be easily desorbed as gaseous CO molecules when the binding energy between the catalyst and the intermediate is relatively low. In contrast, if the binding energy is strong, *CO can get further protonated to two intermediates *CHO or *COH. Then, the *CHO intermediate may be subsequently reduced via the protonation of its carbon atom, resulting in the formation of *CH2O (desorb as HCOH) and *CH3O. And *CH3O can be further reduced via the protonation of its carbon atom or oxygen atom to get CH4 or CH3OH, respectively. On the other hand, *COH also can be further reduced to *C and then hydrogenation to CH4 through the CPET steps [49, 52, 57].

Reproduced with permission from Ref. [48]

Possible mechanistic pathways of CO2 reduction to C1 and C2 products on catalysts.

2.1.2 C2 Pathways

*CO is a crucial intermediate for electrochemical CO2RR to get C2 product, and the reaction pathways of *CO intermediates via multiple CPET or other steps determine the final C2 products. Cu-based materials are the most efficient catalysts explored that show appreciable selectivity and faradaic efficiency for C2 products. On Cu(100) surface, *CO dimerization occurs prior to protonation at low overpotential [61], and is the rate-determining step for the formation of C2H4, CH3CH2OH, and CH3CH2CH2OH [13]. Besides the dimerization of *CO, the C–C bond could be formed by the coupling of other further protonated species. For example, on Cu(100) at high overpotential or on Cu(111) surface, *CO is protonated to *CHO before coupling with CO to form *COCHO, which is a key intermediate for getting C2 products [61, 62]. Another example is that *CH2 intermediate could be generated by the formation of C-H bonds from PECT steps, and it is a pivotal intermediate in the generation of C2H4 and CH3COOH [13, 63]. *CH2 can also be further protonated to *CH3 intermediate, which leads to C2H6 product via *CH3 dimerization. In addition, the reaction pathway for the formation of both C2H4 and CH3CH2OH productions involves CO insertion into *CH2, which is more commonly known as a Fischer–Tropsch-like step [64, 65]. Due to the abundance of intermediates and their protonation possibilities, there are many reaction pathways that form different C2 products, leading to uncontrollable product generation. Significantly, both experiments and density functional theory (DFT) calculations suggest that the rate-determining step in C–C coupling involves a decoupled proton-electron transfer, while whether the C–C coupling is an electrochemical step or a chemical step is still up for debate [66,67,68,69].

2.2 Electrolyzer Types

In the research of electrochemical CO2RR, there are mainly three types of electrolyzers: H-type cells, flow cells, and membrane electrode assembly (MEA) cells. Figure 3a shows a simplified configuration of a traditional H-type cell. The cell is composed of independent cathode and anode chambers, with the characteristics of easy operation, facile assembly, and low cost [13, 70, 71]. The two chambers are separated by an ion-exchange membrane, which allows the flow of ions while preventing the oxidation of the CO2 products by limiting their transport from cathode to anode. Catalysts are usually deposited or coated on conductive but inactive substrates (glassy carbon or carbon paper (CP)) and serve as working electrodes. In an H-type cell, CO2 molecules are commonly bubbled from the bottom of the aqueous electrolyte and saturate the electrolyte, then transferred to the interface of the working electrode where CO2RR takes place. However, the finite CO2 solubility in aqueous electrolyte (only 0.034 M under ambient conditions) results in limited CO2 reduction current densities (less than 100 mA cm−2) [57, 70]. Furthermore, the thick diffusion layer (> 50 μm) leads to poor mass transport between the catalyst surface and bulk electrolyte, resulting in a slow reaction rate [70, 72, 73]. Although H-type cells are hindered by such limitations for practical applications, it provides valuable information for evaluating the intrinsic catalytic performance of the catalysts.

To meet the industrial utilization of the electrochemical CO2RR, flow cells were developed so that CO2 can be efficiently delivered to the cathode continuously. Before introducing flow cells in more detail, it is necessary to learn about the structure and function of gas diffusion electrodes (GDEs). Figure 3b is a schematic of GDEs, which consists of a porous catalyst layer (CL) and a diffusion medium (DM) [74, 75]. The DM typically serves as the gas-permeable and electron-conductive substrate on which the CL is deposited. The substrate not only plays a role in determining the local electronic environment of the catalysts, but also influences the mass transfer of the reactants and products to and from the CL. Most DM consists of two parts, the gas diffusion layer (GDL) and the microporous layer (MPL). The GDL acts as a porous medium, which permits diffusion of both gaseous CO2 to the CL and gaseous products (H2, CO, CH4, C2H4) away from the CL surface [76, 77]. The unique structure of GDEs forms a gas–liquid-solid three-phase interface where the electrochemical CO2RR occurs without solubility limitations [78, 79]. To stabilize the triple-phase interface, MPL composed of carbon black nanoparticles is commonly treated with hydrophobic polytetrafluoroethylene to prevent flooding of electrolytes into GDEs, resulting in efficient mass transport for gaseous CO2.

In flow cells, GDEs are often used for better control of the three-phase interface where the gaseous CO2 feedstock can be directly reduced without mass diffusion limitation. Typical membranes in flow cells include the cation exchange membrane (CEM), anion exchange membrane (AEM), or a bipolar membrane (BPM), the type of membrane affects the applicable electrolyte conditions and the ion transport kinetics. As shown in Fig. 3c, a polymer electrolyte membrane is sandwiched between two electrolyte channels, dividing the cell into two parts: the anodic and cathodic compartments. Both cathode and anode electrolytes are continuously flowed through electrolyte channels by a pump. The anode side typically carries out a complementary oxidation reaction, which is most commonly water oxidation, typically using IrOx nanoparticles on Ti mesh/GDEs [80,81,82]. In the cathode chamber, a GDE sits at the interface of the inbound CO2 and the flowing aqueous electrolyte, which largely improves the mass transport of gas–liquid interface, making it possible to conduct electrochemical CO2RR at industrial-scale current densities [70, 83, 84].

The MEA cell is another emerging class of electrolyzers that has been commonly applied to electrochemical CO2RR. As shown in Fig. 3d, by removing the flowing electrolyte channel between the GDE and membrane, it directly combines GDEs and ion exchange membrane into one unit. Benefiting from the uniqueness of this configuration, the MEA cell could significantly decrease the distance between the cathode and anode and thus boot the mass/electron transfer, resulting in high energy efficiency [85,86,87,88]. In addition, the removal of the flowing liquid electrolyte could relieve GDE flooding and reduce contamination of the cathode catalyst from impurities in electrolyte [89, 90].

3 Using MOFs and their Derivatives as Catalysts for CO2 Electroreduction to Value-Added Chemicals

MOFs are porous crystalline materials synthesized from the coordination bonds of metal ions/clusters and organic ligands, and they possess open frameworks with tunable porous properties. In 2012, a copper rubeanate MOF was first reported as a catalyst for electrochemical CO2RR and was shown to effectively convert CO2 into HCOOH in 0.5 M KHCO3 solution, with an HCOOH selectivity above 98% [91]. Subsequently, Senthil Kumar et al. reported the generation of oxalic acid from CO2RR using Cu3(BTC)2 (BTC = 1,3,5-ben-zenetricarboxylicacid) catalyst in N,N-dimethylformamide, and a high Faradic efficiency (FE) of 51% [92] was achieved. Since then, MOF-related catalysts have received significant attention in electrochemical CO2RR and become a rapidly growing research area. Some of these materials have demonstrated obvious activity, selectivity, and stability for electrochemical CO2RR in various electrolytes. C1 chemicals, such as CO, HCOOH, CH4, and CH3OH, are generally the main products in current MOF-catalyzed CO2RR systems, whereas the desirable C2 products are relatively rare. Thus, this paper mainly focuses on the C1 products produced from MOF-related materials and discusses strategies to enhance their electrocatalytic performance, while state-of-art MOF-related materials for catalyzing CO2 to C2+ are also briefly summarized.

3.1 Carbon Monoxide

CO is a crucial building block for the large-scale production of commodity and specialty chemicals [93]. Among all the products from electrochemical CO2RR, CO is one of the most economically viable products and has a high ratio of molecular weight per electron [94, 95]. As mentioned above, an ideal catalyst that selectively catalyzes the electrochemical reduction of CO2 into CO should possess not only strong adsorption energies of *COOH intermediate but also weak adsorption energies of *CO. However, the binding energies of *COOH and *CO are generally proportionally related and follow the scaling relations, it is hard to alter the reaction pathways individually. Fortunately, the linear relationship can be broken by regulating the intrinsic physical/chemical properties and electrochemical microenvironments of the catalytic materials. Owing to their tunable chemical properties, MOF-related materials are perfect candidates for CO2RR because of their tunable structure and compositions. MOFs also have the advantage of well-defined single-atom sites; this is helpful to elucidate the surface dynamic changes and chemical adsorption of reaction intermediates. So far, a number of MOF-related materials have been extensively explored for the reduction of CO2 to CO (Table 2), we will discuss their structure–activity relationships from the perspective of morphology, conductivity, and the coordination environment of metal center.

3.1.1 Pristine MOFs

Morphology and size are two important characteristics of metal–organic framework (MOF) materials that influence their properties and performance in various applications. In the case of MOFs, the morphology can vary from a crystalline powder to a dense film or even an ordered nanostructured material. The morphology of MOFs can be influenced by several factors such as the synthesis method, the precursor choice, and the reaction conditions. On the other hand, the dimensions of the MOF particles or the size of the pores within the MOF structure determines their adsorption properties. Controlling the morphology and size of MOF material not only maximizes the active sites but also balances both charge and mass transport, resulting in high catalytic activity. For example, Kornienko et al. [96] fabricated a porous thin film of Al2(OH)2TCPP-Co(TCPP-H2 = 4,4′,4″,4‴-(porphyrin-5,10,15,20-tetrayl)tetrabenzoate) MOF and employed it as an electrocatalyst for the efficient and selective reduction of CO2 to CO in aqueous electrolytes, as early as 2015. By optimizing the catalytic linker unit (Fig. 4a) and assembling a porous thin film MOF (Fig. 4b) on a conductive substrate, a three-dimensional (3D) porous working electrode was successfully prepared. As shown in Fig. 4c, when tested in CO2-saturated KHCO3 electrolyte for continuous electrolysis, Al2(OH)2TCPP-Co exhibited good catalytic activity and stability, with a maximum CO FE of over 76% and good stability over 7 h at −0.7 V vs. RHE. The cobalt centers are electrically linked to the electrode and are reduced to the catalytically active Co(I) state (Fig. 4d–f). And the rate-limiting step might be either a CO2 molecule adsorbing onto a Co(I) porphyrin coupled with a one-electron reduction or a one-electron reduction of a Co(I)-CO2 adduct. Thanks to the nanoscopic MOF morphology and thickness, the number of active sites is maximized and both charge and mass transported could be simultaneously balanced, thus improving the electrocatalytic performance. Moreover, Dong et al. [97] also use the same ligand TCPP as a building block to synthesize a 3D highly stable porphyrin-based MOF of PCN-222(Fe) (Zr6O8(OH)4(H2O)4][(TCPP-Fe-(III)-Cl)2). As shown in Fig. 4g, it consists of Zr6 clusters and square planar Fe-TCPP ligands, resulting in a star-shaped network. Thanks to the micromorphology, PCN-222(Fe) extensively exposes the porphyrin active sites, which have a substantial catalytic effect on the electrochemical reduction of CO2. Furthermore, the permanent porosity of PCN-222(Fe) conferred a promising CO2 adsorption ability, which is also advantageous in CO2 electrochemical reduction since the reduction kinetics are closely related to the CO2 concentration. When tested in CO2-saturated 0.5 M KHCO3 aqueous solution at various steady-state potentials from -0.45 to -0.85 V vs. RHE, PCN-222(Fe)/C (PCN-222(Fe) mixed with carbon black) showed excellent catalytic selectivity and activity toward CO. As shown in Fig. 4h, the product distribution in the gas phase was dependent on the applied potentials, and the maximum FE of CO occurs at -0.60 V vs. RHE (91%). In the low overpotential region, the Tafel slope of PCN-222(Fe)/C is 188 mV dec−1, which indicates that a one-electron reduction of CO2 to CO2− radical is a probable rate-limiting step. PCN-222(Fe)/C also showed high structural stability after continuous electrolysis for 10 h, however, the low CO2-to-CO current density (< 10 mA cm−2) limited its large-scale industrial applications.

Reproduced with permission from Ref. [96]. g 3D crystal structure of PCN-222(Fe). h Steady-state current density and the selectivity for each gas product in a potential range from -0.45 to -0.85 V vs. RHE. Reproduced with permission from Ref. [97]

a MOF catalyst allows for the modulation of metal centers, molecular linkers, and functional groups at the molecular level. b Organic building units, in the form of cobalt-metallated TCPP, are assembled into a 3D MOF, Al2(OH)2TCPP-Co with variable inorganic building blocks. c Stability of the MOF catalyst is evaluated through chronoamperometric measurements in combination with faradaic efficiency measurements. d In situ spectroelectrochemical analysis reveals the oxidation state of the cobalt catalytic unit of the MOF under reaction conditions. Upon varying the voltage from 0.2 to -0.7 V vs RHE, the Co(II) Soret band decreases at 422 nm and is accompanied by a C5o(I) Soret band increase at 408 nm. This change is quantified and plotted e to elucidate a formal redox potential of the Co center, which is deemed to be at the peak of the first derivative f of the Co(II) bleach and Co(I) enhancement.

Choosing electron-donating ligands as well as their orientation and bonding arrangements is an efficient strategy to improve the conductivity of MOFs, these functional groups can increase the conductivity of MOFs by creating pathways for the flow of electrons and increasing the density of free electrons in the material [114,115,116]. Owing to the high overlap of d-π conjugation orbitals between the nickel node and the planar Ni-phthalocyanine-substituted X (X: o-phenylenediamine or catechol), Zhang et al. [98] employed Ni-phthalocyanines (NiPc) as the building block for the construction of a porous intrinsically conductive two-dimensional (2D) MOF (NiPc-Ni(NH)4). The 2D NiPc-Ni(NH)4 MOF showed a high electrical conductivity of 2.39 × 10–4 S m−1, and NiPc-Ni(NH)4 nanosheets showed outstanding CO2-to-CO electrocatalytic performance with a high CO selectivity of 96.4% at −0.7 V vs. RHE in CO2-saturated 0.5 M KHCO3 electrolyte. DFT calculations revealed that the active site is Ni-N4 moiety in NiPc. The presence of square planar Ni(NH)4 nodes can efficiently accelerate the proton/electron transport to the active sites, thus accelerating the reaction kinetics during the electrochemical CO2RR. Following the same strategy, Yi et al. [99] employed NiPc as the building block to prepare the phthalocyanine-based MOF (Ni–Pc–NiO4) via the solvothermal synthesis method (Fig. 5a), and then exfoliated the bulk powder into 2D nanosheets through high-frequency sonication at room temperature. A two-contact probe method was applied to test the electrical conductivity of NiPc-NiO nanosheets at room temperature. The 2D NiPc-NiO nanosheets showed good electrical conductivity (4.8 × 10–5 S m−1). Such good electrical conductivity would be beneficial for the electron transfer to the active sites during CO2RR, thereby improving electrochemical activity and energy conversion efficiency. As expected, when tested in CO2-saturated 0.5 M KHCO3 electrolyte, NiPc-NiO nanosheets showed a high CO FE of > 90% in a wide potential range from -0.65 to -1.1 V vs. RHE, reaching the maximum of 98.4% at -0.85 V vs. RHE, surpassing NiPc-OH monomer (Fig. 5b). X-ray absorption spectroscopy (XAS) and X-ray photoelectron spectroscopy (XPS) analysis confirmed that the NiPc sites and NiNO4 nodes in NiPc-NiO4 were well maintained after the CO2RR, demonstrating the superior structural stability of NiPc-NiO4. Theoretical calculations show that the Gibbs free energy of the rate-determining step (RDS) (formation of *COOH intermediate) on NiPC (1.93 eV) is significantly lower than that on the NiO4 node (2.53 eV), revealing that NiPc is the active site for the electrochemical conversion of CO2 to CO (Fig. 5c). Compared to NiO4 node, NiPc showed stronger Van der Waals interaction with CO2 molecules (Fig. 5d) in the more electron-rich environment (Fig. 5e). It is worth noting that the lowest unoccupied molecular orbital (LUMO) energy level of NiPc-NiO4 shifts from −4.22 to −4.62 eV when the CO2 molecule moves from NiPc to NiO4 node (Fig. 5f), revealing the excellent reducibility of NiPc. In addition, another 2D conductive MOF was reported by Majidi et al. [100]. They use a catechol-based linker, tetrahydroxyquinone (THQ), to synthesize the Cu-based 2D conductive MOF (Cu-THQ) nanoflakes, and the product shows good electrical conductivity of 1.5 × 10–7 S cm−1. The presence of the THQ linker in Cu-THQ nanoflakes resulted in a large distance between Cu centers, which not only keeps the Cu center from agglomeration but also ensures the reoxidation of the reduced Cu center during the CO2RR process. When tested in a hybrid electrolyte (1 M C5H14ClNO + 1 M KOH), Cu-THQ showed high CO current densities and low overpotential. DFT calculations revealed that the higher the CO coverage, the lower the free energy for CO adsorption on the Cu surface, resulting in a high CO production rate. Zhong et al. [101] also designed layered 2D conductive MOFs (PcCu-O8-Zn) with bimetallic centers (ZnO4/CuN4) to improve electrocatalytic CO2RR activity (Fig. 5g). They immobilized a mixture of PcCu-O8-Zn and carbon nanotubes (CNTs) onto a carbon paper substrate as the working electrode and tested its CO2RR performance in 0.1 M KHCO3. As shown in Fig. 5h, at −0.7 V vs. RHE, the PcCu-O8-Zn/CNT can effectively reduce CO2 to CO with a FE of 88%. Moreover, such performance could be sustained for over 10 h, demonstrating excellent stability. They conducted a series of operando experiments and theoretical calculation to demonstrate that the synergistic effect of Cu and Zn sites in PcCu-O8-Zn is essential for the high catalytic activity and selectivity toward CO production (Fig. 5i). The ZnO4 units facilitate CO2 reduction, while the CuN4 units promote proton and electron transfer during the reaction process (Fig. 5j).

Reproduced with permission from Ref. [99]. g Schematic structure of PcCu-O8-Zn (the dashed rectangular indicates the unit cell). h Faradaic efficiency of CO for PcCu-O8-Zn/CNT, PcCu-O8-Cu/CNT, PcZn-O8-Zn/CNT and PcZn-O8-Cu/CNT at different potentials. i Operando surface-enhanced infrared absorption (SEIRA) spectro-electrochemical analysis of PcCu-O8-Zn/CNT in CO2-saturated 0.1 M KHCO3. j Schematic HER and CO2RR reaction process of PcCu-O8-Zn. Reproduced with permission from Ref. [101]

a Illustration of the preparation steps of NiPc-NiO4. Top and side view of their structures with 2 × 2 square grids in AA-stacking mode. b Faradaic efficiencies of CO. c Calculated energy diagrams for CO2-to-CO conversion on two proposed active sites in NiPc-NiO4. d The non-covalent interaction (NCI) between CO2 and NiPc-NiO4 structure. e Mulliken charge of different Ni atoms in NiPc-NiO4. f Energy level of HOMO and LUMO of different Ni atoms in NiPc-NiO4 when introducing CO2.

Ligand engineering can also modulate the coordination environment on metal center, thus boosting the activity of electrochemical CO2RR. By virtue of 1,10-phenanthroline doping, Dou et al. [102] synthesized a ligand-doped product (ZIF-A-LD, ZIF-A: ZIF-8 was activated to generate open Zn sites) with excellent charge transfer ability. Then, the ZIF-A-LD was mixed with carbon black to prepare a working electrode (ZIF-A-LD/CB). When tested in 0.1 M KHCO3, ZIF-A-LD/CB exhibited a higher CO FE compared to pristine ZIF-8. DFT calculations revealed that the charge transfer from the dopant phenanthroline molecule (excellent electron-donating ability) to the adjacent sp2 C sites in the imidazolate enables stronger electrons movement from the active sites to the antibonding orbitals of CO2, which facilitates *COOH formation and boost CO2RR activity. Huang et al. [103] reported a stable MOF (NNU-15), Co(OH)2(H2O)2(Co-TIPP) (TIPP = [5,10,15,20-tetra (4-imidazol-1-yl)phenyl]porphyrin), which contains two OH− coordinated Co ions to mimic the active surface status of the catalysts under alkaline CO2RR conditions (Fig. 6a). It exhibits an outstanding ability to capture and convert the CO2 molecule. When tested in CO2-saturated 0.5 M KHCO3 electrolyte, NNU-15 shows a high FE of 99.2% for CO at -0.6 V vs. RHE (Fig. 6b) and excellent long-term stability of 110 h (Fig. 6c). The NNU-15-CO2 intermediate can be detected during the CO2RR process, demonstrating that the metal catalytic center of MOF can cooperate with OH− to capture and activate the CO2 molecule to form the HCO3−-chelating active center, and thus getting a remarkable activity for CO2 conversion to CO. In another study, Al-attas et al. [104] take a ligand engineering strategy to enhance the efficiency of CO2 conversion to CO for Zn-based MOFs. They prepared two types of Zn-based MOFs with different ligands. As shown in Fig. 6d, one is Zn2(Tz)2Ox, which is assembled from Zn ions and 1,2,4-triazolate ligand (Calgary Framework 20, CALF20), and the other is Zn(MeIm)2 that is assembled from Zn ions and 2-methylimidazolate ligand (zeolitic imidazolate framework-8, ZIF-8). They used a gas-diffusion electrode in a flow electrolyzer (circulated with 1.0 M KOH solution) to assess the activity and selectivity of Zn-based MOFs toward CO2RR. As shown in Fig. 6e, CALF20 shows higher CO FE than ZIF-8 over the whole potential range and the highest FE for CO production is located at −0.97 V vs. RHE with a partial current density of − 32.8 mA cm−2. The difference in the Zn oxidation state between CALF20 and ZIF-8 is confirmed by soft X-ray spectra, indicating that the Zn site in CALF20 exhibited a lower electron density due to the electron-withdrawing character of the triazole ligand. DFT calculations revealed that the C2O2 bridge promotes stronger charge transfer, and the sp2 C sites in azolate are the active sites with low overpotential for CO2RR. More electrons are produced on the adjacent active sites of the azole ligand and facilitated *COOH formation (Fig. 6f), resulting in the high current density and FE toward CO production.

Reproduced with permission from Ref. [103]. d Schematic illustration of the crystal structure of ZIF-8 and CALF20, including the chemical structure of polyhedron zinc nodes. e CO Faradaic efficiencies at different applied potentials for CALF20 and ZIF-8 in 1.0 M KOH. f Calculated free energy diagram for electrochemical reduction of CO2 to CO over CALF20 at U = 0.00 V vs RHE (the dashed lines are simply to guide the eye). Reproduced with permission from Ref. [104]

a 3D frameworks for NNU-15 along the b-axis and 3D frameworks with the open holes in NNU-15. b Faradic efficiencies for CO of TIPP, NNU-16 and NNU-15. c Durability test of NNU-15 at the potential of -0.6 V versus RHE (inset: CO FF at different time).

3.1.2 MOF-Derived Materials

Generally speaking, MOFs are considered to be insulators or poor conductors due to the insulating nature of the organic ligands. The poor conductivity of MOFs is an important limitation for their CO2 catalysis applications. One simple strategy to improve charge transport is mixing MOFs with conductive carbon, but this can result in the loss of mass activities. A more effective way to overcome charge transport is introducing guest redox molecules into the frameworks. For example, Xin et al. [105] introduced cobaltocene into MOF-545-Co to prepare CoCp2@MOF-545-Co through a facile chemical vapor deposition method (Fig. 7a). Compared with MOF-545-Co, CoCp2@MOF-545-Co shows high CO2-to-CO activity and the maximum FE of CO was dramatically increased from 55% (at −0.8 V vs. RHE) to 97% (at −0.7 V vs. RHE) (Fig. 7b). The excellent CO2 reduction performance of CoCp2@MOF-545-Co was demonstrated to originate from the synergy effect of MOF-545-Co and CoCp2. There are several reasons accounting for this consequence. Firstly, in metallocene electron orbits, the participation of d-orbits enlarges the delocalized π-electron from the cyclopentadienyl ring, thus making metallocene a perfect electron-donating or carrying unit. Secondly, the presence of porphyrin ring ligands in MOF-545-Co are ideal charge transfer carriers, and metal in the center of the porphyrin ring might serve as an efficient electron acceptor and active catalysis center. DFT calculations revealed that the introduction of metallocene can create continuous electron transfer channels in MOFs and the strong binding interaction between metalloporphyrin and reactants during the CO2RR process can largely reduce the adsorption energy of CO2. This work shows that the conductivity of MOF materials is a crucial factor that affects the efficiency of electrochemical CO2RR. Furthermore, it could open a new avenue to develop highly selective CO2RR electrocatalysts. In another study, Xin et al. [106] followed the same strategy to enhance the conductivity of MOFs materials. They insert the conducting polypyrrole (PPy) molecule into the channel of MOF-545-Co through a facile in-situ low-temperature polymerization method. As shown in Fig. 7c, in the obtained PPy@MOF-545-Co, the PPy molecule acts like a cable in the MOF channel, it can boost the conductivity of MOFs and facilitate electrons transfer to the active center of Co-TCPP. The charge-transfer resistance of PPy@MOF-545-Co (7.5 Ω) was proved to be much lower than that of MOF-545-Co (12.5 Ω), indicating that it possessed a better electron transfer ability. Subsequently, PPy@MOF-545-Co was applied as the working electrode and its electrocatalytic CO2RR activity was tested using an H-type cell in the CO2-saturated 0.5 M KHCO3 electrolyte. As shown in Fig. 7d, PPy@MOF-545-Co exhibits excellent catalytic activity toward CO with a maximum FE up to 98%, which is much higher than its MOF-545-Co counterpart. The CO partial current density was also remarkably higher than the samples in the controlled experiments. Furthermore, after continuous electrolysis at -0.8 V vs. RHE for 10 h, the chemical structure of PPy@MOF-545-Co remained unchanged, revealing its excellent stability. The charge-transfer resistance of PPy@MOF-545-Co (7.5 Ω) was also lower than that of MOF-545-Co (12.5 Ω), indicating that it possessed a better electron transfer ability. By impregnating guest redox molecules into the framework structure, the charge can transfer directly from the guest molecule to the metalloporphyrin center and the strategy was demonstrated to significantly enhance the charge transfer efficiency.

Reproduced with permission from Ref. [105]. c Schematic presentation for the advantages of PPy in the channel of MOF-545-Co for electrocatalytic CO2RR. d FECO of PPy@MOF-545-Co and contrastive samples measured under different voltages. Reproduced with permission from Ref. [106]

a Comparison of MCp2@MOF and MOF in electrocatalytic CO2RR. b Electrocatalytic CO2RR performances of CoCp2@MOF-545-Co and comparative samples.

3.1.3 MOF-Derived Single-Atom Catalysts Materials

Recently, single-atom catalysts have been demonstrated to show excellent catalytic performance for various reactions due to their controllable properties and high atom utilization efficiency. Particularly, MOFs are ideal sacrificial templates to fabricate SACs because of the uniformly dispersed metal sites and abundant heteroatoms to immobilize the single metal site, resulting in a number of catalysts with high selectivity and remarkable activity for CO2RR. For instance, Gong et al. [107] employ MgNi-MOF-74 as precursors to produce NiSA-Nx-C SACs (x is N coordination numbers) (Fig. 8a). The presence of Mg2+ in MgNi-MOF-74 can regulate and control the interatomic distance between adjacent Ni atoms, while N atoms from pyrolyzed polypyrrole (PPy) serve as anchoring sites to stabilize the Ni atoms. By controlling the pyrolysis temperature, they prepared three single-atom Ni catalysts with different N coordination numbers. Among them, NiSA-N2-C (Fig. 8b) exhibits the highest selectivity for CO and the maximum FE is 98% at −0.8 V vs. RHE in CO2-saturated 0.5 M KHCO3 (Fig. 8c). This work not only provides a strategy for the fabrication of SACs, but also opens an avenue to enhance the activity of SACs for CO2RR by controlling the metal coordination environment. Similarly, Chen et al. [108] report an amination strategy to regulate the electronic structure of SACs. As shown in Fig. 8d, they successful synthesized Ni–N4/C–NH2 SACs by a two-step method. A gas-tight H-type cell containing CO2-saturated 0.5 M KHCO3 electrolyte was used to evaluate the electrocatalytic activity of Ni–N4/C–NH2 and a maximum CO FE of 96.2% was achieved. Although the CO FE is slightly lower than that of Ni–N4/C (98.1%), the CO partial current density of Ni–N4/C–NH2 is found to be significantly enhanced, which is 2.5 times that of Ni–N4/C at −1.0 V vs. RHE (Fig. 8e). In order to meet requirements for industrial CO2-to-CO production, they applied a gas-fed flow cell equipped with a GDE to solve the mass transfer limitation caused by low solubility of CO2 in aqueous electrolysis. As shown in Fig. 8f, Ni–N4/C–NH2 achieves a remarkable CO partial current density of 447.6 mA cm−2 at −1.0 V vs. RHE, which is 7.0 times that in an H-type cell and is much larger than that of Ni–N4/C (250 mA cm−2), suggesting that amination treatment can indeed boost catalytic activity. DFT calculations revealed that the electronic structure of M–N/C catalysts are regulated by amino-modification (Fig. 8g), which enhances the adsorption energies of the reaction intermediates and accelerates the charge transfer rate, thus promoting the CO2 activation and transformation process. Moreover, phthalocyanine-based MOFs can also be used as catalyst regulators to modify the electronic structure of metal center and enhance the CO2RR to CO. For example, Lin et al. [109] took a synergistic catalysis strategy to boost the CO2RR activity by anchoring Fe–N sites into CoPc (CoPc©Fe–N–C) through a sequential pyrolysis and post-impregnation method (Fig. 8h). CoPc©Fe–N–C shows CO FE of above 90% over the measured potential range of -0.13 to -0.84 V vs. RHE, exceeding its counterpart. Significantly, CO current density reaches 275.6 ± 27.0 mA cm−2 at −0.84 V vs. RHE, which is sufficient to satisfy industrial requirements. The strong interaction between CoPc and Fe–N-C also reduces the *CO poisoning and accelerates desorption of CO. DFT calculations revealed that the adsorption energy of *CO and *H on CoPc©Fe–N–C is lower than that of Fe–N–C, while the *COOH formation energy does not change much (Fig. 8i), demonstrating unprecedented synergistic catalysis effect toward CO2RR.

Reproduced with permission from Ref. [107]. d Schematic of the synthesis process for Ni–N4/C–NH2. e CO partial current density of Ni–N4/C and Ni–N4/C–NH2. f Electrocatalytic activity of Ni–N4/C–NH2 in the flow cell. g Projected DOS of Ni 3d in Ni–N4/C–NH2 and Ni–N4/C. Reproduced with permission from Ref. [108]. h Schematic illustration for the preparation of CoPc©Fe–N-C. The image on the far right is the calculated electron density difference of the CoPc©Fe–N-C structure. (Blue and yellow contours present electron depletion and electron accumulation, respectively. The isosurface level is set to be 0.0006 e Bohr-3). i Calculated free energy diagram for the CO2RR to CO at U = -0.7 V versus RHE on the Fe site in CoPc©Fe–N-C, Fe site in Fe–N-C, Co site in CoPc©N–C, and Zn site in CoPc©Zn-N–C, respectively. Reproduced with permission from Ref. [109]

a Illustration showing the host–guest cooperative protection strategy for the fabrication of NiSA-Nx-C catalysts for electrocatalytic CO2 reduction. b EXAFS fitting and optimized model for NiSA-N2-C. c FEs of CO at different applied potentials in the CO2-saturated 0.5 M KHCO3 electrolyte.

3.2 Formate/Formic acid

HCOOH/HCOO− is not only a hydrogen storage chemical with high energy density, but is also widely applied in the green synthesis of a range of petrochemicals in modern energy systems [117,118,119]. Moreover, among all kinds of products from CO2RR, HCOOH possesses the highest profit per mole of electrons, exhibiting good economic prospects in large-scale industrial production [75]. To date, there are many MOF-related catalysts showing remarkable activity and selectivity for the production of HCOOH by CO2RR. Several representative examples are shown in Table 3, we will discuss their structure–activity relationships from the perspective of metal composition, such as In, Sn, and Bi.

3.2.1 In-based MOF

Among the numerous catalyst materials that were studied, In-based catalysts were found to be selective toward the production of HCOOH. Recently, with the marriage of biomimetic and catalytic technology, a new revolution has emerged in structure design of In-based catalysts, which has significantly promoted the development of the CO2RR field. For example, by mimicking the active [NiS4] sites of formate dehydrogenase and CO-dehydrogenase, Zhou et al. [120] prepared a crystalline enzyme-mimicking three-dimensional In-based MOF, (Me2NH2+){InIII-[Ni(C2S2(C6H4COO)2)2]} 3DMF 1.5H2O (In-MOF 1, DMF = N,N-dimethylformamide), with excellent chemical and thermal stabilities. Compared to the isomorphic MOF, (Me2NH2+) [InIII-(TTFTB)]·0.7C2H5OH·DMF (In-MOF 2, TTFTB = tetrathiafulvalene-tetrabenzoate), In-MOF 1 exhibited higher HCOOH selectivity during CO2RR and the FE increased from 54.7% to 89.6% (-1.3 V vs. RHE) (Fig. 9a), demonstrating that the presence of unsaturated [NiS4] sites in MOFs can significantly enhance the CO2RR activity (Fig. 9b). DFT calculations further revealed that the formation energy of *HCOO intermediate on In-MOF 1 is much lower than that of In-MOF 2 (Fig. 9c), the introduced unsaturated [NiS4] sites are proved to be the absorption and catalytic site for CO2-to-HCOOH. Another In-based MOF was reported by Zhu et al. [121]. They constructed a stable 3D In-MOF (V11), {(Me2NH2) [In(BCP)]·2DMF}n (H4BCP = isophthalic acid) consisting two types of channels (1.6 and 1.2 nm diameter) (Fig. 9d). Subsequently, methylene blue molecules were introduced into the framework of V11 and then converted to carbon nanoparticles (CPs), forming V11-supported CPs (CPs@V11) (Fig. 9e). When tested in CO2-saturated 0.5 M KHCO3 electrolyte, the catalytic performance of CPs@V11 (methylene blue mass load of 10%) was significantly improved and the highest FEHCOOH is 90.1% at −0.84 V vs. RHE. In addition, it also exhibited higher HCOOH partial current density than that of pure V11 at the same potential (Fig. 9f), obviously, the introduction of CPs via pyrolysis of MB greatly enhances the catalytic activity of the MOF. In-situ Fourier Transform infrared spectroscopy (FT-IR) spectra at different potentials showed that there are obvious absorption peaks of *HCOO intermediate at 1394 cm−1, which gradually increase with decreasing potential (Fig. 9g). The introduced CPs not only improves electrochemical active surface area (ECSA) but also increases the conductivity, thus facilitating charge transfer (Fig. 9h) and enhancing the catalytic performance of the MOFs in terms of activity and selectivity. In addition, Qiu et al. [122] also synthesized an efficient In-based electrocatalyst (In2O3-x@C nanocorn) for converting CO2 to HCOOH through a two-step process involving In MOF preparation and carbonization. When tested in 1 M KOH electrolyte, such electrocatalyst exhibited excellent catalytic activity and stability, due to its unique nanocorn structure, high concentration of active sites, and favorable electronic transfer properties. The operando experiments have confirmed that In3+ species as the catalytic active sites for the production of HCOOH. Furthermore, DFT calculations have revealed that the presence of oxygen vacancies creates an electron-rich environment for the In3+ active sites, leading not only to an enhancement of the reducing power at the active sites but also to a reduction in the energy barrier for electron transfer.

Reproduced with permission from Ref. [120]. d The view of the two types of 1D channels in V11. e Illustration of the preparation process of CPs@V11. f The comparison of the FE HCOO- and the j HCOO- for various samples. g Potential-dependent in situ FTIR spectra of CPs@V11. h Nyquist plots for the samples in CO2-saturated 0.5 M KHCO3 electrolyte. Reproduced with permission from Ref. [121]

a Plots of FEHCOO– for In-MOF 1 and In-MOF 2 versus applied potential. b Crystal structure of In-MOF 1 viewed along the a-axis, showing three rhombic pores and a two-fold interpenetrated framework (hydrogen atoms have been removed for clarity), and structures of ligands [Ni(C2S2(C6H4COOH)2)2] and H4TTFTB with different conformations. c Proposed reaction paths for the formation of HCOOH on the [NiS4] and [In(COO)4].– sites.

3.2.2 Sn-based MOF

Sn-based MOFs are another class of catalysts with excellent HCOOH selectivity. Geng et al. [123] prepared Sn-doped ZIF8 catalysts via an ion-exchange strategy, the method can efficiently integrate Sn into the node of ZIF-8 while preserving the whole framework structure. When tested in CO2-saturated 0.5 M KHCO3, Sn-doped ZIF8 showed high HCOOH activity and selectivity of 74% FE at −1.1 V vs. RHE. And the spatially separated Sn atoms are proposed to be responsible for the superior CO2RR activity of Sn-doped ZIF8. Similarly, Deng et al. [124] also replaces the Zn metal nodes in ZIF8 by Sn doping, and then follows a solvent-assisted linker exchange (SALE) process to obtain the Sn-N6-MOF catalyst (Fig. 10a). When tested in CO2-saturated 0.5 M KHCO3, such catalyst achieved excellent selectivity for HCOOH with FEHCOOH up to 85.1% at −1.23 V vs. RHE. In-situ Raman spectra indicate the organic ligands in MOF are gradually lost during the CO2RR (Fig. 10b). Furthermore, ex-situ 119Sn Mössbauer results demonstrated the presence of zero-valence Sn metal after continuous electrolysis for 1 h at −1.23 V vs. RHE (Fig. 10c). A series of experiments results have revealed that Sn-N6-MOF catalyst undergoes in-situ structural reconstruction during the CO2RR process and then generates Sn nanoclusters, which are the real active sites for producing HCOOH (Fig. 10d). In a previous study, Wu et al. [125] also discovered that Sn(101) crystal plane is more favorable for the formation of HCOOH (Fig. 10e). They synthesized a Sn-MOF (Sn3O(1,4-BDC)2) precursor to prepare a series of Sn(101)/SnO2/C composites via the calcination and acidic etching processes (Fig. 10f). The Sn(101)/SnO2/C-500 (500 is the carbonization temperature) exhibits high selectivity toward HCOOH and achieved a FEHCOOH up to 93.3% at −0.8 V vs. RHE (Fig. 10g). However, the FEHCOOH of such catalyst is gradually reduced from 93.3% to 72.8% after continuous electrolysis for 13 h at −0.8 V vs. RHE.

Reproduced with permission from Ref. [124]. e Calculated free-energy diagrams for HCOO−,CO formation. f Schematic illustration showing the preparation of Sn(101)/SnO2/C catalysts. g Electrocatalytic property of Sn(101)/SnO2/C-500. Reproduced with permission from Ref. [125]

a Diagram of the synthetic procedures for Sn-N6-MOF. b In-situ Raman spectra measured with varying the acquiring time at -1.23 V vs. RHE in CO2-saturated 0.5 M KHCO3 aqueous. c Room temperature 119 Sn Mössbauer spectra acquired after maintained at -1.23 V vs. RHE in CO2-saturated 0.5 M KHCO3 aqueous for 1 h. d Proposed reaction pathway for the formation of HCOOH over Sn-N6-MOF.

3.2.3 Bi-based MOF

Bi is also a promising electrocatalyst for CO2RR to produce formate in aqueous solutions because of its large overpotential for HER in the aqueous electrolyte (Bi is situated at the bottom corner point of the volcano plot), low toxicity, and good stability [138, 139]. Therefore, Bi-based MOFs have drawn tremendous attention as catalysts for CO2 reduction to HCOOH [140]. Zhang et al. [126] synthesized a Bi-MOF (Bi-BTC-D) by the hydrothermal method and evaluated its CO2RR performance in the CO2-saturated 0.5 M KHCO3 electrolyte. Electrochemical experiments showed HCOOH selectivity with a maximum FE of 95.5% at -0.86 V vs. RHE. DFT calculations revealed that BTC ligands in MOF structure can effectively regulate the catalytic activity of the Bi atoms. Li et al. [127] also use the same ligand (H3BTC) to construct a helical rod-based 2D Bi-MOF (CAU-17) with permanent crystallographic-independent channels (Fig. 11a), and it exhibits high CO2-to-HCOOH activity in the H-cell. Such catalyst achieves an excellent FE of 92.2% at −0.9 V vs. RHE (Fig. 11b, c). It is worth noting that the type of catholyte significantly affects the selectivity of HCOOH (Fig. 11d). When SO42− was added in the catholyte, the accumulated negative charges on the electrode surface can generate a potential difference in the electric double layer and facilitates the transport of polar water molecules instead of nonpolar CO2 molecules, leading to the dominating competitive HER. Operando XAS (Fig. 11e) and DFT calculations were also conducted to explore the origin of the high HCOOH selectivity on the Bi-MOF, and the results showed that the highly accessible Bi3+ and the unique channels played vital roles in the enhancement of CO2 adsorption and HCOOH conversion. Nevertheless, the maximum HCOOH partial current density is only 15 mA cm−1 at −1.1 V vs. RHE, which is far from meeting the requirements for industrial applications (Fig. 11c). Yang et al. [128] also synthesized a Bi-MOF (CAU-17) with claviform shape and then spray on CP as the precursor, following an in-situ electroreduction process to fabricate leafy Bi nanosheets (Bi NSs) (Fig. 11f). Electrochemical experiments, which were conducted in a flow cell reactor, revealed that Bi NSs are excellent catalyst with high HCOOH activity and selectivity in both 1 M KHCO3 or KOH electrolytes. The maximum FE of Bi NSs is up to 98% at the potential of −0.48 V vs. RHE (total current density up to 133 mA cm−2) (Fig. 11g). Significantly, the HCOOH partial current density reaches 374 mA cm−2 at −1.51 V vs. RHE in 1 M KHCO3. The outstanding performance may be associated with the hybrid Bi/Bi-O species on the surface of Bi NSs. DFT calculations also confirm that O atoms of the Bi-O surface may be beneficial to reduce the free energy barrier for *OCHO formation (Fig. 11h).

Reproduced with permission from Ref. [127]. f Schematic illustration of the preparation procedure of Bi NSs. (purple, gray, orange, and yellow balls represent Bi, C, O, and H, respectively). g FEs and cathodic energetic efficiency (CEEs) of formic acid over two electrocatalysts in 1 M KOH. h Gibbs free energy profiles for CO2 electroreduction to HCOOH on Bi NPs and Bi NSs. Reproduced with permission from Ref. [128]

a Schematic depiction of the formation of Bi-MOF. Bi-O polyhedra shown in the MOF crystal structure are indicated in purple. b HCOOH FEs, c HCOOH partial current densities of Bi-MOF, Bi sheets, bulk Bi2O3, and carbon paper electrodes within a potential window of −0.6 to −1.1 V in CO2-saturated 0.1 M KHCO3 solution. d HCOOH FEs and HCOOH partial current densities of Bi-MOF in various electrolytes. e Comparison of Bi L3-edge X-ray absorption fine structure (XAFS) of Bi-MOF along with those for Bi metal and Bi2O3 as reference standards and represent their respective XANES and Fourier transform of EXAFS spectrum as a function of electrochemical bias and with electroreduction time under in-situ electrochemical CO2 reduction conditions.

Thanks to the tunable porosity and well-defined architectures, MOFs are particularly appealing with regard to fabricating versatile carbon hybrid nanostructures with well-defined compositions and morphologies. CAU-17, which is an ideal sacrificial template to fabricate various metal/carbon hybrids catalysts, has been widely used in CO2RR. For example, Deng et al. [129] construct carbon-nanorods-encapsulated bismuth oxides catalysts (Bi@C and Bi2O3@C) via the carbonization of CAU-17 in Ar and air atmosphere, respectively (Fig. 12a). The Bi2O3@C-800 shows a high FEHCOOH of 92% at −0.9 V vs. RHE (Fig. 12b) in CO2-saturated 0.5 M KHCO3 electrolyte using an H-type reactor. However, the HCOOH partial current density is only 7.5 mA cm−2, which was attributed to the low solubility of CO2 in aqueous electrolytes. When they employ a flow cell configuration using 1 M KOH electrolyte, the HCOOH FE of Bi2O3@C-800 stays above 93% at −0.3 to −1.1 V vs. RHE and the HCOOH partial current density is significantly enhanced (Fig. 12c). The presence of crystalline Bi-O structure in the Bi2O3@C-800 is proved to be beneficial for promoting the reaction kinetics (Fig. 12d). The carbon matrix can significantly reduce the charge transfer resistance, which can promote the formation of *CO2− intermediates. Therefore, the synergistic effect of Bi2O3 nanoparticles and carbon matrix is beneficial to improve the activity and selectivity for CO2-to-HCOOH. Ying et al. [130] prepared the CAU-17 fiber with a larger accessible surface area and abundant active catalytic sites via morphology engineering. Then, they calcined the fiber-shaped MOFs in an inert gas atmosphere to prepare Bi/C hybrids (CAU-17-fiber-x, x is the calcination temperature) for catalyzing CO2 to HCOOH (Fig. 12e). The CAU-17-fiber-400 gets the highest CO2-to-formate FE (96.4%), with a high partial current density (20.4 mA cm−2) at −0.9 V vs. RHE in CO2-saturated 0.1 M KHCO3 aqueous electrolyte using H-type cell (Fig. 12f). In the Bi/C hybrids, Bi nanoparticles (NPs) were encapsulated inside the CAU-17 derived porous fiber-shaped carbon framework, such a novel structure brought many unique benefits, such as larger accessible surface area and higher Bi content, thus improving the activity of CO2RR. Wang et al. [131] used another H3BTC ligand to prepare a Bi-based bimetallic MOF (BiIn-MOF), which was then calcined to obtain MOF-derived Bi/In bimetallic oxide nanoparticles/carbon (BiInO-x@C, x representative the ratio of Bi/In) in Ar atmosphere at 600 °C (Fig. 12g). Benefiting from the synergistic effect of bimetallic components, BiInO-0.67@C exhibits excellent activity and selectivity for the electroreduction of CO2 to formate. They also applied in-situ FT-IR to reveal the catalyst mechanism of BiInO-0.67@C. As shown in Fig. 12h, the peak at 1430 cm−1 is attributed to the symmetric stretching mode of OCO in the *HCOO species of the dioxygen bridge, indicating that the *HCOO pathway is the preferred route to produce formate on the catalyst.

Reproduced with permission from Ref. [129]. e Schematic representation of preparation of CAU-17-derived electrocatalysts. f CAU-17-fiber series at various potentials in CO2-saturated electrolyte based on a 2,500 s experiment. Reproduced with permission from Ref. [130]. g Schematic diagram of the preparation process of the BiInO-x@C catalyst. h In situ FT-IR spectra of BiInO -0.67@C at 1200 − 2200 cm−1. Reproduced with permission from Ref. [131]

a Schematic illustration of the preparation procedure of Bi@C and Bi2O3@C catalysts. b FE of formate for various Bi-based composites in all potentials range. c FE and partial current density of HCOOH for Bi2O3@C-800 in all potentials range. d Tafel plots.

In addition to carbon-based materials, MOFs can also be used to prepare ultrathin metallene materials. As demonstrated by Cao et al. [132], ultrathin Bi-based metal–organic layers could serve as a pre-catalyst to produce atomically thin bismuthene (Bi-ene) following in-situ electrochemical reconstruction (Fig. 13a). The as-obtained Bi-ene shows an average thickness of 1.28–1.45 nm (Fig. 13b) and exposes more active sites due to the two-dimensional nature. As a result, Bi-ene could deliver a FEHCOOH close to 100% at a wide potential range in both KHCO3 and KOH electrolytes. Notably, the total current density can reach 200 mA cm−2 at −0.75 V vs. RHE in 1 M KOH (Fig. 13c). In-situ ATR-IR spectroscopy and DFT analysis confirmed that HCOOH is generated through the *HCOO intermediate on Bi-ene. Furthermore, Yuan et al. [133] prepared a Bi-1,3,5-tris(4-carboxy-phenyl) benzene (Bi-BTB) and discovered that the bismuth-carboxylate MOFs can be in-situ transformed to Bi2O2CO3 in an HCO3− electrolyte. Bi-BTB exhibits an outstanding CO2-to-HCOOH performance (Fig. 13d). After electrolysis, the crystalline phase of Bi-BTB disappeared from the X-ray diffraction (XRD), while the peaks intensities of a new crystalline phase of Bi2O2CO3 dramatically increase, indicating that the true catalytic species are Bi2O2CO3 (Fig. 13e). Since Bi3+ ion and carboxylate belong to intermediate acid and hard base, Bi-BTB is not stable. Therefore, in the presence of HCO3−, the Bi–O bonds in Bi-BTB can be broken, resulting in the structural evolution from Bi-BTB to Bi2O2CO3 (Fig. 13f). A Tafel slope of 119 mV dec−1 for Bi2O2CO3 indicate that the initial electron transfer step is the RDS for the CO2RR (Fig. 13g). This work shows a good example of surface reconstruction and gives a strong signal that careful evaluation is required to distinguish the real reactive sites for different MOF electrocatalysts.

Reproduced with permission from Ref. [132]. d FE of production and the current densities of HCOOH with Bi-BTB at different working potentials in CO2-saturated 0.5 M KHCO3 electrolyte. e The changes of XRD patterns for various samples. f Electrochemical cell for the electrolysis experiments and proposed mechanism for the formation of MOF-derived Bi2O2CO3. g Tafel plot for MOF-derived Bi2O2CO3 in CO2-saturated 0.5 M KHCO3 electrolyte. Reproduced with permission from Ref. [133]

a Synthesis and characterizations of Bi-MOLs and Bi-ene. b Atomic force microscopy images of Bi-ene. c Chronopotentiometric curves at 100 and 200 mA cm.−2 in 1.0 M KHCO3 and KOH.

3.3 Methane

Among all products derived from CO2RR, CH4 has attracted significant attentions because of its high values of mass heat (56 kJ g−1), good compatibility with current energy infrastructure [141,142,143]. Furthermore, the CO2RR reaction for CH4 formation is thermodynamically more favored than the reaction for both CO and HCOOH. However, as a deepest reduction product, the formation of CH4 involves eight electrons and sluggish kinetics, resulting in high overpotential and low selectivity. Therefore, it is extremely attractive to design catalysts with high activity and selectivity for CO2 reduction to CH4. To date, a number of MOF-related catalysts have been proved to be capable of promoting CO2RR toward CH4 (Table 4).

Generally, Cu-based catalysts show the best catalytic activity for the selective production of CH4 in the CO2RR system. For example, Kim et al. [144] prepared highly isolated Cu nanoparticles (Cu NPs) clusters with an average size of 30–50 nm for CO2-to-CH4, which were synthesized from Cu-MOF-74 precursor via an electroreduction process (Fig. 14a). When tested in 0.1 M KHCO3, the as-obtained Cu NPs clusters exhibited good catalytic activity toward CH4. As shown in Fig. 14b, the maximum FE of CH4 is approximately 50% at −1.3 V vs. RHE, while only 35% is achieved by commercial Cu NPs at the same conditions. It should be also noted that Cu NPs show the highest activity for CH4 at −1.3 V vs. RHE, and the CH4 partial current densities on Cu NPs are 2.3 times that of the commercial Cu NPs. It is believed that the activity difference is attributed to the extent of aggregation of Cu particles at nanoscales and MOF-derived Cu NPs are found to be less aggregated. Yang et al. [145] employed adenine and acetic acid ligands to fabricate Cu-ade MOF with different thicknesses (Cu-ade nanosheets (s-Cu-ade), nanoplates (p-Cu-ade) and nanocuboids (c-Cu-ade)). Figure 14c shows the molecular structure of the Cu-ade monomer, where stable MOFs were formed by the bonding of N with C and Cu. Electrochemical measurements demonstrated that s-Cu-ade has the best CO2 reduction performance in CO2-saturated 0.1 M KHCO3 electrolyte and the maximum FE of CH4 is over 50% at -1.6 V vs. RHE (Fig. 14d). It worth noting that the CO2 electroreduction process can induce the structure evolution of the Cu-MOF to form Cu nanoparticles functionalized by the nitrogen containing ligands (Fig. 14e, f). The presence of N-containing functional groups would activate the protons to obtain COH* or CHO* intermediate [153,154,155,156], which are critical intermediates for further hydrogenation to form CH4, thus boosting the conversion of CO2 to CH4 (Fig. 14g).

Reproduced with permission from Ref. [144]. c Molecular structure of the Cu-ade monomer. d FE of CH4 and C2H4 for the s-Cu-ade MOF. e N 1s scan XPS patterns of the initial and cathodized Cu-ade MOFs. f XRD pattern of the cathodized s-Cu-ade MOF. g Proposed Cu-ade MOF evolution. Reproduced with permission from Ref. [145]

a Schematic illustration of the hydrothermal synthesis of Cu-MOF-74 and preparation of Cu NPs from Cu-MOF-74 by electroreduction. b Faradaic efficiencies for C1 and C2 hydrocarbons production and partial current density for CH4 production on Cu NP electrodes at the applied potential.

As discussed above, achieving high hydrocarbon selectivity remains a great challenge. Fortunately, the synergistic strategy that combines Cu2O with Cu MOFs seems to be an effective way to enhance hydrocarbon selectivity, which has been confirmed by recent studies. For instance, Tan et al. [146] prepared an all-in-one hybrid Cu2O@Cu-MOF by time-resolved controllable restructuration. Briefly, the surface of Cu2O spheres can be oxidized to Cu2+ in the mixed alcohol solution at 80 °C, and then Cu2+ can further coordinate with H3BTC to form Cu-MOFs on the surface of Cu2O, resulting in Cu2O@Cu-MOF (Fig. 15a). When tested in CO2-saturated 0.1 M KHCO3 solution, Cu2O@Cu-MOF showed considerable FECH4, which was significantly higher than that of both Cu2O and Cu-MOF, and the maximum FE was up to 63.2% at −1.71 V vs. RHE (Fig. 15b). Due to the porous nature of the framework, Cu2O@Cu-MOF exhibited considerable adsorption capacity of CO2 molecules (Fig. 15c), which significantly enlarge the local CO2 concentration on the active sites of the electrode, while the intrinsic catalytic activity of Cu2O can be maintained well simultaneously. Moreover, the Cu2O core embedded in the Cu-MOF accelerates charge transfer. On the contrary, Yi et al. [147] fabricated Cu2O(111) quantum dots with an average size of 3.5 nm on a porous conductive Cu-MOFs (CuHHTP) via an electroreduction process (Fig. 15d). Linear sweep voltammetry (LSV) tests are conducted in both Ar and CO2-saturated 0.1 M KCl + 0.1 M KHCO3 mixture solution. As shown in Fig. 15e, compared with pristine Cu-MOFs, the Cu2O(111)@CuHHTP shows larger current densities at same conditions, implying that Cu2O(111) quantum dots have high electrocatalysis activity for the CO2RR. Notably, Cu2O(111)@CuHHTP achieved high selectivity of 73% at -1.4 V vs. RHE toward CH4 with partial current density up to -10.8 mA cm−2 (Fig. 15f). The superior electrochemical performance was attributed to the following two reasons: 1) Due to the strong charge delocalization between Cu2+ and HHTP, Cu-MOFs shows excellent electronic conductivity (5.1 × 10–5 S m−1) and serves as a conductive substrate, which can accelerate the electron transfer to Cu2O(111) during the CO2RR process. 2) During electroreduction, Cu-O4 nodes in Cu-MOFs were partially reduced to Cu2O, thus exposing a number of hydroxyl groups of the uncoordinated HHTP ligand. The hydroxyl-rich environment was assumed to stabilize the *CO intermediate by hydrogen bonding (Fig. 15g) and improves the selectivity toward CH4 [157,158,159].

Reproduced with permission from Ref. [146]. d Illustration of the solvothermal synthesis of CuHHTP and preparation of Cu2O@CuHHTP via electrochemical treatment of CuHHTP at the applied potential of -1.2 V vs. RHE for 30 min. e LSV curves of CuHHTP and Cu2O@CuHHTP in 0.1 M KCl/0.1 M KHCO3 electrolyte under Ar and CO2. f Comparison of CH4 FE between Cu2O@CuHHTP, Cu2O on conductive carbon black(Cu2O@CCB), and commercial Cu2O. g Proposed mechanism of Cu2O@CuHHTP for the formation of CH4. Reproduced with permission from Ref. [147]

a Schematic illustration of the process to synthesize Cu2O@Cu-MOF. b FEs of CH4 and C2H4 and the ratio of CH4 to C2H4 for Cu2O@Cu-MOF, Cu-MOF, and Cu2O at − 1.71 V versus RHE in CO2-saturated 0.1 M KHCO3 solution. c CO2 adsorption curves of Cu2O@Cu-MOF, Cu-MOF, and Cu2O.

Apart from Cu2O, many other Cu(I)-based catalysts have also been demonstrated to be active for the selective reduction of CO2 to CH4. For example, Zhu et al. [148] prepared a Cu-MOF, Cu4ZnCl4(btdd)3 (Cu4II-MFU-4 l, H2btdd = bis(1H-1,2,3-triazolo-[4,5-b],[4′,5′-i])dibenzo-[1, 4]-dioxin), by an ion exchange process that uses Cu(II) ions to replace outer sphere Zn(II) ions in Zn5Cl4(btdd)3 (MFU-4 l) cluster (Fig. 16a). When tested in CO2-saturated 0.5 M NaHCO3 solution, Cu4II-MFU-4 l showed obvious electrocatalytic CO2RR activity and achieved a high CH4 FE of 92% at -1.2 V vs. RHE (Fig. 16b), while MFU-4 l only yielded minor CO product at the same condition. After long-term electrolysis, the Cu(II) ions were found to be reduced to Cu(I) ions (Cu4Zn-(btdd)3) with the trigonal pyramidal Cu(I)N3 sites, indicating that the Cu(I)N3 sites is the actual active centers for the CO2RR (Fig. 16c). Figure 16d shows the conversion process from Cu(II) to Cu(I) ions during the electrocatalysis. Moreover, in situ experiments and DFT calculations revealed that the synergistic interactions between Cu(I)N3 sites and adjacent aromatic hydrogen atoms can stabilize the key CO2-to-CH4 intermediates via hydrogen bonding. In order to understand the effect of intrinsic cuprophilic interactions inside the Cu(I) catalysts, Zhang et al. [149] used 2-(5-(3-(5-(pyridin-2-yl)-1H-,2,4-triazol-3-yl)phenyl)-1H-1,2,4-triazol-3-yl) pyridine (H2bptb) and Cu(I) ions to construct two MOFs (NNU-32 and NNU-33(S) (S = sulfate radical)). Then they transformed NNU-33(S) into NNU-33(H) (H = hydroxyl) through an anion exchange process in 1 M KOH solution (Fig. 16e). After structural transformation, NNU-33(H) showed enhanced cuprophilic interactions and expanded interlayer distances. The electrocatalytic CO2RR performance was tested in 1 M KOH solution using a flow cell and the results showed that NNU-33(H) exhibited a high FECH4 value of 82.17% at -0.9 V vs. RHE (Fig. 16f). Significantly, the current density is up to 391.79 mA cm−2 at -0.9 V vs. RHE, which is sufficient to satisfy the requirements of industrial applications. The XAS, in situ Raman, XPS, and in situ FTIR were performed to confirm the structural stability of NNU-33(H) and those results suggested that the properties of NNU-33(H) are stable during CO2RR. The distances of Cu(I)-Cu(I) in both NNU-32 and NNU-33(H) are a little larger than twice the covalent radius of Cu but significantly shorter than twice its van der Waals radius, suggesting the existence of cuprophilic interactions in the crystal. Moreover, the distances of Cu ions in NNU-33(H) are shorter than that NNU-32, illustrating stronger cuprophilic interactions in NNU-33(H), which may be the key factor that influences the CH4 selectivity. DFT calculations revealed the fourth hydrogenation step (*H2COOH → *OCH2) is the potential determining step (PDS) (Fig. 16g). Significantly, the free energy of the PDS process is increased significantly from 0.74 to 1.11 eV after removing the Cu(I)-Cu(I) interaction, confirming that the internal Cu-Cu interaction plays an essential role in the CO2RR process. However, the durability of NNU-33(H) still needs to be improved (Fig. 16h).

Reproduced with permission from Ref. [148]. e Structures of {Cu8} clusters and unit cell in NNU-33(S) and NNU-33(H), respectively. f Electrocatalytic performances of NNU-33(H) FE of H2, CO, CH4, and C2H4 products. g Calculated free energy diagram and the corresponding intermediates for CO2 electrocatalytic reduction to CH4 on the Cu8 model catalyst. h Current profile and FEs of CH4 at a constant voltage of -0.9 V vs RHE. Reproduced with permission from Ref. [149]

a Structures of local coordination environments, metal transformation process, and Cu4II-MFU-4 l (3D channel surface highlighted in yellow). b FE and TOF by Cu4II-MFU-4 l. c Cu K-edge EXAFS spectra and fitting for CuN3C at -1.2 V under CO2. d Illustration of the conversion from Cu(II) to Cu(I) ions and the formation of intermediates during the electrocatalysis.

As discussed before, reasonable regulation of the Cu coordination environment in MOFs is a common method to modulate the selectivity of electroreduction catalysis, this is also applicable for the CO2-to-CH4 process using MOF-based electrocatalysts. For example, Zhang et al. [150] employed the highly conjugated organic ligand (dibenzo-[g,p] chrysene-2,3,6,7,10,11,14,15-octaol, 8OH-DBC) to construct a Cu-based conductive MOFs (Cu- DBC) with abundant and uniformly distributed Cu-O4 sites (Fig. 17a). Cu-DBC exhibits an electrical conductivity of 1.2 × 10–2 S m−1 due to the charge delocalization between metal ions and conjugated ligands. Electrochemical experiments reveal that Cu-DBC delivers obvious CO2RR activity with a maximum CH4 FE of 80% at -0.9 V vs. RHE (Fig. 17b). The experimental measurements and DFT calculations further revealed that the Cu-O4 site in Cu-DBC is easier to be reduced into low-valence Cu sites during the activation process and is more energetically favorable for the following CO2 reduction compared to nitrogen-coordinated Cu sites (Fig. 17c). Liu et al. [151] designed a conjugated, nitrogen-containing ligand hexahydroxyl-hexaazatrinaphthylene (HATNA-6OH) and further synthesized 2D conductive MOFs (Cu3(C24H6O6N6)2 1.5(NH3CH2CH2NH3), HATNA-Cu-MOF) by a solvothermal method in the presence of ethylenediamine (Fig. 17d). Owing to the synergic effects of the redox active copper catecholate nodes and favorable p-p stacking of the ligand, HATNA-Cu-MOF exhibits high CH4 selectivity with a FE of 78% at -1.5 V vs. RHE (Fig. 17e). Unfortunately, the CH4 partial current density is only -8.2 mA cm−2. In addition, Zhang et al. [152] prepared a series of Cu4X cluster-based MOFs ([Cu4X(TIPE)3]·3X, [X = Cl, Br, I, TIPE = 1,1,2,2-tetrakis(4-(imidazol-1-yl)phenyl)ethene], named as Cu-Cl, Cu-Br, Cu-I) to investigate the effect of different halogens atoms on the activity and selectivity of CO2RR products (Fig. 17f). Electrochemical experiments revealed that Cu-I is the optimal catalyst for CO2 reduction to CH4 with the highest FECH4 of 57.2% at −1.08 V vs. RHE (Fig. 17g). Meanwhile, the CH4 partial current density is up to 60.7 mA cm−2 at the same potential. In order to explore the origin of the high activity and selectivity of Cu-I, DFT calculations was also conducted. As shown in Fig. 17h, when the radius of halogen atom increase, the d-band center of Cu site is shifting closer to the Fermi level, which can significantly reduce the formation energy of the PDS and promote subsequent CH4 formation.

Reproduced with permission from Ref. [150]. d Synthesis of HATNA-Cu-MOF. e Potential dependent FE of different reduction products. Reproduced with permission from Ref. [151]. f Schematic illustration of the synthesis and structure of Cu-X. g Average FEs of CH4 at different potentials over Cu-Cl, Cu-Br, and Cu-I catalysts. h Gibbs free energy profiles of CO2 reduction reaction on Cu-Cl, Cu-Br, and Cu-I. Reproduced with permission from Ref. [152]

a Structure obtained by Cu ions and 8OH-DBC. b FEs of CO2RR products at different applied potentials. c Free energy profiles for the CO2RR-to-CH4 reaction pathway.

3.4 Methanol

CH3OH is one of the important chemicals in the production of organic compounds and synthetic gasoline [160]. Moreover, CH3OH is a promising liquid fuel to replace fossil fuels because of its environmental friendliness and ease of transportation [161, 162]. CH3OH can also be directly used in conventional internal combustion engines or in direct methanol fuel cells, making it stand out as the alternative fuel for building a sustainable society [163]. Recently, the catalytic CO2 hydrogenation to CH3OH by MOF-related materials has been investigated and several representative examples are listed in Table 5.