Highlights

-

This review discusses the roles of MXenes in different positions/layers in perovskite solar cells.

-

The issues in different layers/interfaces and their addressal with the incorporations of MXenes in perovskite solar cells are elaborately discussed.

Abstract

With an excellent power conversion efficiency of 25.7%, closer to the Shockley–Queisser limit, perovskite solar cells (PSCs) have become a strong candidate for a next-generation energy harvester. However, the lack of stability and reliability in PSCs remained challenging for commercialization. Strategies, such as interfacial and structural engineering, have a more critical influence on enhanced performance. MXenes, two-dimensional materials, have emerged as promising materials in solar cell applications due to their metallic electrical conductivity, high carrier mobility, excellent optical transparency, wide tunable work function, and superior mechanical properties. Owing to different choices of transition elements and surface-terminating functional groups, MXenes possess the feature of tuning the work function, which is an essential metric for band energy alignment between the absorber layer and the charge transport layers for charge carrier extraction and collection in PSCs. Furthermore, adopting MXenes to their respective components helps reduce the interfacial recombination resistance and provides smooth charge transfer paths, leading to enhanced conductivity and operational stability of PSCs. This review paper aims to provide an overview of the applications of MXenes as components, classified according to their roles as additives (into the perovskite absorber layer, charge transport layers, and electrodes) and themselves alone or as interfacial layers, and their significant importance in PSCs in terms of device performance and stability. Lastly, we discuss the present research status and future directions toward its use in PSCs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Solar technology converts solar energy directly into electrical energy through photovoltaic cells. Solar cells have attracted great attention from the energy community to meet the increasing demand for sustainable green, and clean energy sources. Apart from wafer-based Si solar cells that are widely available on the market, perovskite solar cells (PSCs) have achieved the highest power conversion efficiency (PCE) of 25.7% in 2021, which is inching towards the theoretical efficiency of about 31% [1,2,3]. Furthermore, a recent study shows halide PSCs can surpass the Shockley-Queisser (SQ) PCE limit of 33.7% (predicted for a single-junction solar cell) [4]. Most importantly, PSCs are in an advantageous position for ease of fabrication and their affordable cost coming from solution-based processing [5,6,7].

Perovskite materials, such as MAPbI3, FAPbI3, and CsPbI3, have been spotlighted due to their excellent bandgap tunability, excellent light absorption co-efficient (> 105 cm−1), good charge carrier mobility (2–40 cm2 V−1 s−1), and long carrier-diffusion length in the PSCs. Despite the stellar performance, the perovskite device remains a long-standing issue due to the structural and chemical instability originating from the degradation factors related to the intrinsic shortcomings of the perovskite materials as well as at their interfaces. Researchers have explored various pathways to improve stability and performance efficiency, for instance, the development of passivating materials, enlargement of the grain sizes or single crystals, solvent engineering, additive engineering, and interface engineering [6, 8,9,10,11,12,13].

Recently, MXenes, as emerging two-dimensional (2D) layered materials, have drawn interest in various applications, including photocatalysts, light emitting diodes, transparent electrodes, nanofiltration, water purification, electromagnetic interference shielding, antibacterial activity, supercapacitors, sensors, and more [14,15,16,17,18,19,20,21,22]. 2D nanomaterials such as graphene, g-C3N4, WS2, MoS2, and black phosphorous have been demonstrated as potential additives in the perovskite absorber layer in PSCs owing to their excellent electrical and optical properties [23,24,25,26,27,28]. MXenes have been used as all-round materials starting from additives, electron transport layers (ETL), hole transport layers (HTL), and interfacial layers to electrodes in PSCs due to their excellent electrical conductivity (2 × 104 S cm−1), high charge carrier density (3.8 × 1022 cm−3), high mobility (1 cm2 V−1 s−1), high transparency, and tunable work function (WF) through controlled surface chemistry [29, 30]. With the introduction of Ti3C2Tx MXene into MAPbI3-based perovskite solar cells in 2018, there has been a tremendous surge in the use of MXenes in the photovoltaic community [31].

In this review, we aim to provide a comprehensive understanding of MXenes and their roles as additives or themselves alone in different components (classified according to photoactive absorber layer, ETL, HTL, and electrodes) and interfaces of the PSCs. In Sect. 1, we begin by introducing a brief overview of the recent research trend of PSCs. In Sect. 2, we have classified MXenes according to their roles as additives (into perovskite absorber layer, charge transport layers, and electrodes) and themselves alone in PSCs. In Sect. 3, we discuss MXenes as an interfacial layer on each layer of PSCs, followed by a discussion of MXenes’ roles in improving morphological features, electrical conductivity, mechanical stability, and WF tuning to impact electron transfer and extraction mechanism and thereby increasing the operational stability of PSCs. In Sect. 4, we suggest the future direction of an interfacial design/engineering that will realize the advent of an overarching framework for advanced PSC technology.

2 MXenes in Perovskite Solar Cells

2.1 Synthesis of MXenes

MXenes are 2D transition metal carbides, nitrides, and carbonitrides with the general formula Mn+1XnTx (n = 1–4), where ‘M’ represents an early transition metal (Sc, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, etc.), ‘X’ represents carbon and/or nitrogen, and ‘Tx’ stands for the surface terminations including –O, –OH, –F, etc. [32,33,34]. In 2011, Ti3C2Tx MXene was first reported by Naguib et al. [35]. MXenes with a distinct combination of M and X elements, number of elements at M or X sites (solid solutions at M or X sites, (M′,M′′)n+1XnTx, where M′ and M′′ are two different metals), number of atomic layers (n), ordering (in-plane or i- MXene or out-of-plane or o- MXene) of atoms, and compositions of surface functional groups (Tx) were produced, as represented in Fig. 1 [36]. For certain combinations of transition metals, ordered MXenes are energetically more stable than their solid-solution counterparts. MXenes with monolayer or multilayer morphology are usually synthesized from the Mn+1AXn (MAX) phase precursors by eliminating monoatomic layers of the A element, which is from group 13 or 14 (e.g., Al, Ga, Si, or Ge). However, some of the MXenes are also synthesized from non-MAX phase precursors [37, 38]. The high reactivity of the A element and relatively weak strength of M–A bonds compared to M–X bonds allow the selective etching of A layers from the MAX phase, typically in aqueous solution using either direct hydrogen fluoride (HF) or in-situ HF (produced through LiF/HCl mixture) [33, 39, 40]. Over the years, apart from HF-based methods, such as using HF/other acids, HF/oxidants, NH4HF2, HCl/fluoride salt as etchants, several new synthesis methods include Lewis acidic molten salts assisted etching, alkali treatment under hydrothermal condition, treatment with organic bases, etching in organic solvents, salt-solution-based acoustic synthesis, electrochemical etching, etc. [41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56].

Schematic display for 2D MXene’s structures having a general formula of Mn+1XnTx, (M = an early transition metal, X = carbon and/or nitrogen, and Tx = surface terminations of the outer metal layers, n = 1–4, examples: Ti2CTx, Ti3C2Tx, Nb4C3Tx, and (Mo, V)5C4Tx) [37]. One or more transition metal atoms may occupy the M sites of MXenes to create ordered structures or solid solutions. The ordered double transition metal MXenes can be divided into three types: in-plane ordered structures (i-MXenes), in-plane vacancy structures, and out-of-plane ordered structures (o-MXenes), where either one layer of M′′ transition metal or two layers of M′′ transition metal are sandwiched between two layers of M′ transition metal. Other configurations might be feasible, such as the bottom row of the M5X4 structure with one, two, or three layers of M′′ sandwiched between layers of M′. Predicted structures like higher-order single M or o-MXenes and high-entropy MXenes that have not been empirically proven are represented by the faded images at the bottom of the schematic.

The type and composition of surface functional groups of MXene depend significantly on etching process, and they are mainly electronegative in nature, enabling to pull electron density away from the M atoms of MXenes (i.e., shifting the Fermi energy (\({E}_{F}\)) of MXenes to a lower energy). That is, the electronic structure and WF of MXenes can be easily tuned by controlling the surface functional groups' compositions [57, 58]. In addition to an \({E}_{F}\) shift, surface dipoles induced by surface functional groups play a significant role in tuning the WF of Mxenes [59, 60]. Computational calculations such as density functional theory (DFT) through altering the M and X elements and surface functional groups can also predict several other intriguing characteristics of MXenes, such as a wide range tunability of the WF between 1.6 and 8.0 eV, superconductivity, topological insulator behaviors, metal-to-semiconductor transition, and metal-to-insulator transition [59, 61,62,63,64,65,66]. Particularly, fine-tuning the WF brings a perfect energy offset between the perovskite active layer and the charge transport layer by adjusting the vacuum level and obtaining the optimal energy-level alignment at interfaces in PSCs applications. Optimizing energy offsets is necessary to achieve effective charge separation and/or collection. The various roles of MXenes as components themselves or additives into the components in PSCs, in terms of passivating defects, crystallinity, electrical conductivity, mechanical flexibility, and moisture resistance, are discussed in the following sections.

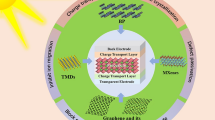

2.2 PSCs

PSCs have been perceived as the next-generation photovoltaic candidates for commercial applications due to their high PCEs, easy and scalable solution fabrication processes, and low fabrication cost [67, 68]. For high-performance PSCs, the perovskite absorber layer is the most important. The characteristics such as crystallinity, surface coverage, compactness, uniformity, phase purity, internal trap defect density, grain size distribution, and grain boundaries of the perovskite absorber layers are the pivot players in determining the PCE performance of PSCs [69, 70]. A typical planar (or mesoporous) n-i-p or inverted p-i-n PSC consists of a photoactive absorber layer, an ETL, a HTL, and two (back and front) electrodes. The front electrode is based on a glass/flexible substrate facing simulated solar light. The solar light is incident on an absorber layer, and the electrons excite from the valence band to the conduction band, forming electron–hole pairs [8, 71]. These photogenerated charge carriers are extracted by the respective ETL and HTL and then moved to the electrodes (Fig. 2a). These distinctive features determine the stability and current–voltage hysteresis. Several key factors such as bulk, surface defects and reduced charge extraction/transportation, moisture, humidity, heat, and electric field can impede the solar cell device performance and longevity [72]. These impediments can be controlled via solvent engineering, additive engineering, compositional engineering, interface engineering, device engineering, and encapsulation (Fig. 2b) [8, 73,74,75,76]. Furthermore, until now, the highest efficiency devices are Pb-based PSCs. Due to the Pb toxicity, several alternatives such as lead-free PSCs, double-PSCs, and 2D Ruddlesden-Popper (RP) and Dion-Jacobson (DJ) PSCs have been examined as promising candidates in the perovskite photovoltaic arena [77,78,79,80]. We have excluded an insightful discussion on the topics mentioned above and suggest you refer to this paper [72]. In this review, we discuss various roles of MXenes as components or parts in PSCs, as depicted in the schematic (Fig. 3). Thus, we categorized the functions of MXenes depending on the positions and the roles of MXenes as additives in the perovskite absorber layer/ETL/HTL/electrodes or as ETL/HTL/electrodes along with as interfacial layers. The discussion about their respective pros and cons is presented in the following sections.

MXenes in PSCs: Various roles of MXenes as components or parts of the components in regular n-i-p PSCs. The device structure of Glass/TCO/ETL/Perovskite/HTL/Electrode with different ILs, positions of MXenes and numbers in the parenthesis indicate the Section numbers. IL stands for “interfacial layer,” and TCO stands for “transparent conducting oxide”

2.3 MXenes as Additives in Perovskite Absorber Layers

First up, the PCE performance of a PSC depends on the light-absorbing perovskite film layer that generates the charger carriers (electrons and holes). The charge carriers are separated and collected at the respective electrodes [81]. The quality of the perovskite film is determined by crystal sizes and grain boundaries. Large crystal sizes with fewer grain boundaries are essential for maximum charge transfer and high-performance [82, 83]. In 2018, Guo et al. introduced the Ti3C2Tx MXene into a CH3NH3Pbl3 (MAPbI3) perovskite absorber layer [31]. This is the first report on an MXene’s application in a PSC. Ti3C2Tx MXene slows the crystallization rate and enlarges the size of MAPbI3 crystals with no pin holes. The O–H⋅⋅⋅I− van der Waals interaction between the methylammonium iodide (MAI) and the additive restricts uniform nucleation on the tin oxide (SnO2) layer and rather generates lesser nuclei, implying slow crystal growth or retardation of the nucleation process [84]. After annealing, the small crystals grow into large crystals. Perovskite films with Ti3C2Tx MXene additives show an improvement in light absorption owing to enhanced scattering of incident light from the large crystals [85, 86]. PSC with a device structure of indium tin oxide (ITO)/SnO2/MAPbI3:(0.3 wt%) Ti3C2Tx/2,2′,7,7′-tetrakis(N,N-di-p-methoxyphenyl-amine)9,9′-spirobifluorene (Spiro-OMeTAD)/Au achieved a PCE of 17.4%, which is 12% higher than the PCE (15.6%) of the control device. The device with the optimal amount of additives also showed an increased open-circuit voltage (Voc), current density (Jsc), and fill factor (FF). The increase in Voc is ascribed to the passivation of the perovskites by Ti3C2Tx, spurring the hole extraction and reduced recombination at the perovskite/HTL interface [87]. A schematic of a PSC with Ti3C2Tx additive and J–V curves with 0, 0.01, 0.02, 0.03, 0.5, and 1 wt% of Ti3C2Tx MXene additives are shown in Fig. 4a–b. The optimal amount of additive is 0.03 wt%. On further increase in wt%, the additives form aggregates on the surface of the perovskite films, resulting in charge trapping centers. Hence, the device performance degrades with excessive additives. The charge transfer resistance of the perovskite film with additive also reduced from 7000 to 1800 Ω, indicating fast charge transfer, and hence the Jsc was increased [31]. All-inorganic CsPbI3 perovskite has a near-ideal bandgap and thermal stability and is a suitable candidate for the development of perovskite/Si tandem solar cells. But when exposed to moisture, CsPbI3 experiences a quick phase change. Especially, the preferred p-i-n structure for perovskite/Si tandems shows a large performance difference compared to other perovskite compounds. Heo et al. reported a surface-engineered CsPbI3 layer with oxidized Ti3C2Tx MXene (OMXene) nanoplates to form effective and stable p-i-n-structured CsPbI3 perovskite solar cells [88]. In addition to improving charge separation at the perovskite-electron transporting layer interface through an improved electric field, OMXene acts as a physical barrier against moisture.

Copyright © 2018 WILEY–VCH Verlag GmbH & co. KGaA, Weinheim. c Schematic diagram of PSCs with the structure of Glass/ITO/SnO2/2D perovskite/Spiro-OMeTAD/Ag. d J–V curves of PSCs with different amounts of Ti3C2Tx doping [96]. Copyright © 2018 Springer. e The atomic structures showing the interface between the MAPbI3 (100) surface and the Ti3C2O2 MXene without Cs+ and f with Cs+ [97]. Copyright © 2021 Cell Press. g Schematic illustration of the device structure. h Reverse and forward scans for the pristine and 0.2 mg mL−1 Ti3C2Clx QDs-treated PSC devices. i EQE of the devices (the pristine and 0.2 mg mL−1 Ti3C2Clx QDs-treated) [98]. Copyright © 2022 Elsevier B.V

a Schematic of MAPbI3 planar PSCs with MXenes additives in the absorber layer. b J–V characteristics curves of PSCs with different amounts of Ti3C2Tx [31].

As a result, the p-i-n devices based on CsPbI3/OMXene dispersion with 10 wt% concentration attained the PCEs of 19.7% for 0.096 cm2 cells and 14.6% for 25 cm2 in minimodules. The pristine cell has a PCE of 18.1% with a Voc, Jsc, and FF of 1.18 V (1.21 V), 19.05 (19.85) mA cm−2, and 80.3% (81.6%), respectively. Furthermore, the encapsulated minimodule showed good stability, maintaining 85% of the initial efficiency over 1000 h while being exposed to 85 °C at a relative humidity (RH) of 85% and 1-sun light soaking. Zhou et al. reported an inorganic Cl-terminated Ti3C2 (Ti3C2Clx) MXene to passivate the surface defect states and grain boundaries of CsPbBr3 film. The addition of Ti3C2Clx MXene enlarges the crystal sizes. The solvent volatilization produced the Ti3C2Clx-tailored PbBr2 film with a high porosity [89]. CsBr can be diffused into these pores to grow the perovskite grain with sizes compared to pre-expanded volume and thus result in a high-quality CsPbBr3 perovskite film with large and compact grains. The residual stress in the soft perovskite lattice distorts the surface lattices, leading to low device performance. Introducing Ti3C2Clx MXene removes the residual stress owing to a strong Pb–Cl binding energy (301 kJ mol−1), paving the way for a high device efficiency [90]. In further work, Saranin et al. introduced MXene doping into the perovskite absorber layer in inverted perovskite solar cells [91]. MXene doping in the absorber layer significantly decreases charge recombination caused by deep trap states. More charges are collected at the perovskite/phenyl-C61-butyric acid methyl ester (PCBM) interface compared to reference devices. The MXene-based tailored cells outperformed the pristine devices and exhibited PCEs of 18.6% and steady power output.

2D RP PSCs have received significant interest owing to their exceptional stability against moisture. The bulky cations in 2D RP perovskites restrict the internal movement of ions and allow the passage of organic ions, thus resulting in the hydrophobic nature of the absorber layer [92, 93]. However, low crystallinity, disordered orientation, and inferior charge transport constrain the PCE of 2D PSCs [94, 95]. Jin et al. explored Ti3C2Tx MXene nanosheets as additives in 2D RP (BA)2(MA)4Pb5I16 perovskite absorber layer to fabricate the perovskite films with excellent electrical conductivity and mobility [96]. A homogeneous and highly crystalline perovskite film with Ti3C2Tx MXene nano-dopants was formed. After adding an optimal concentration of 0.3 mM Ti3C2Tx nanosheets, the PCE of PSC with a configuration of ITO/SnO2/(BA)2(MA)4Pb5I16-Ti3C2 MXene/Spiro-OMeTAD/Ag increased from 13.7% (without additive) to 15.7%. The Ti3C2Tx nanosheets doped-PSC also exhibited an increased Jsc of 20.87 mA cm−2, Voc of 1.11 V, and FF of 67.8%. The schematic of the PSC, 2D RP layered structure, and J–V curves of the PSC with different concentrations are shown in Fig. 4c–d. The enhanced crystallinity, orientation, and passivated trap states led to an accelerated charge transfer process in the vertical direction and are responsible for this improved performance. The unencapsulated PSCs with Ti3C2Tx nanosheets exhibited excellent stability in ambient settings with an RH of 55% [96].

In 2021, Bati et al. produced Ti3C2Tx MXene nanosheets doped with cesium (Cs) and added them to a lead iodide (PbI2) precursor solution for PSCs via a two-step deposition approach [97]. The theoretical and practical study demonstrated that Cs is crucial for enhancing PCE. The perovskite crystallization with doped Ti3C2Tx MXene results in larger crystal grains, long lifetime charge carriers, and reduced charge recombination. The PSCs combined with Cs-doped Ti3C2Tx Mxene (ITO/SnO2/FA1-xMAxPbI3-xBrx:Cs-Ti3C2Tx/Spiro-OMeTAD/Au) achieved a high PCE of 21.6% (19.0% for the pristine device) with increased Voc, Jsc, and FF. The increased Voc is ascribed to the filling of Cs+ ions into the surface MA+ vacancy. Moreover, with the introduction of Cs+, the interaction between MXene and perovskite film increases with a binding energy of −0.016 eV Å−2. In contrast, without Cs+, the binding energy between the perovskite film and MXene is −0.013 eV Å−2 (Fig. 4e–f). Additionally, the unencapsulated Cs- Ti3C2Tx MXene-doped PSC device exhibited stability by retaining 65% of its initial PCE after 2000 h [97].

High photovoltaic performance and large-scale commercialization of planar PSCs depend on the perovskite layer having a high crystallinity and long-term stability against high humidity. In 2021, Liu et al. used one-step deposition to incorporate Ti3C2Clx quantum dots (QDs) as additives in the perovskite precursor solution [98]. During the film crystallization process, the strong interaction between the Cl terminations of Ti3C2Clx QDs and Pb2+ ions slowed down the crystallization rate and induced the preferred grain orientation. This resulted in a high-quality perovskite film with high crystallinity, fewer trap-states, and less residual tensile strain. Ti3C2Clx QDs also quickened charge extraction and benefitted band alignment between the SnO2 ETL and the perovskite layer due to their top–bottom rising gradient distribution. As a result, the PSC with 0.2 mg mL−1 Ti3C2Clx QDs and a device structure of fluorine-doped tin oxide (FTO)/SnO2/Perovskite + Ti3C2Clx QDs/Spiro-OMeTAD/Ag) achieved an improved efficiency of 21.3% (18.8%) and Voc of 1.19 V with minimal hysteresis (Fig. 4g–h). The Cl-terminated Ti3C2 QDs can also prevent potential deprotonation of protonated organic amine in the perovskite, improving the overall stability. The Ti3C2Clx QDs (0.2 mg mL−1) device shows a higher integrated Jsc of 21.60 mA cm−2 than the pristine device (20.64 mA cm−2). The calculated Jsc is less than the observed Jsc by less than 5% discrepancy (Fig. 4i). Additionally, the unencapsulated device demonstrates exceptional long-term humidity stability by retaining over 84% of its initial PCE after aging for 1000 h at 40% RH in the dark at room temperature [98].

The solution method is the most common route to fabricate the perovskite films. The solution method is categorized into one-step and two-step sequential processes [99,100,101]. In the simple and facile one-step solution method, it is difficult to achieve uniform and compact perovskite films owing to the anisotropic growth of perovskites [102]. In the two-step process, the PbI2 layer is formed first, and then the MAI solution is dropped to react, and thus high-quality perovskite films without cracks and pinholes are formed. Crack and pinhole-free perovskite films are pertinent for highly efficient PSCs [103]. However, low reactivity leads to incomplete conversion of PbI2, and hence compact films are not formed owing to the presence of residual PbI2. As a result, the device performances are degraded [104, 105]. In 2021, to increase the reactivity of PbI2 by generating porous channels, Zhao et al. added 2D monolayer Ti3C2Tx (Tx = –O, –OH, and –F) MXene nanosheets into the PbI2 layer [106]. This modification enhanced the subsequent PbI2 reaction with MAI to transform into MAPbI3 completely. As a result, the quantity of remaining PbI2 in the perovskite film was reduced, and the size of the perovskite grain increased (Fig. 5a). Additionally, Ti3C2Tx MXene controls the perovskite WF, resulting in a better energy-level alignment that makes carrier extraction and injection easier (Fig. 5b). The functional groups on the surface of Ti3C2Tx were found to interact with the poorly coordinated Pb2+ in perovskites to passivate defects, having a significant impact on reducing hysteresis and inhibiting nonradiative recombination. Finally, by adding 0.03 wt% of the Ti3C2Tx additive, the PSC with a device configuration of FTO/SnO2/MAPbI3:Ti3C2Tx/Spiro-OMeTAD/Au achieved a PCE of 19.3%, demonstrating an improvement of about 18% over the control device (Fig. 5c) [106].

Copyright © 2021 Elsevier B.V. d Schematic of the PSC with Ti3C2Tx MXene additive in the perovskite absorber layer. e The stability of the PSC devices with and without D149 sensitized TiO2 and/or Ti3C2Tx doping in ambient air at RH ~ 20% without encapsulation at 25 °C [107]. Copyright © 2022 Elsevier B.V

a Mechanism diagram illustrating the preparation of high-quality two-step-processed perovskite films assisted by Ti3C2Tx additive. b Device configuration of the planar PSCs and its energy-level diagram with and without Ti3C2Tx doping. c J–V curves of the champion PSCs with different contents of Ti3C2Tx [106].

A promising contender for inorganic double perovskite solar cells without lead is Cs2AgBiBr6 PSC. The reported PCE of Cs2AgBiBr6 is approximately 3%, which limits its photovoltaic capability. Yang et al. used D149 indoline dye to make the TiO2 ETL more sensitive and Ti3C2Tx MXene nanosheets to Cs2AgBiBr6 to improve the crystallization [107]. Cs2AgBiBr6 and D149 indoline dye both have the potential to influence the photocurrent. Furthermore, the DFT was used to calculate the interface properties and electron structure. Fermi level pinning is effectively reduced while the perovskite maintains its semiconductor properties, thanks to weak van der Waals forces at the interfaces of Cs2AgBiBr6 and Ti3C2Tx. The high WF of Ti3C2Tx modifies the Fermi level of the valence band of Cs2AgBiBr6, which results in increased carrier mobility. The device showed enhanced long-term stability and PCEs of 4.5% under 1-sun illumination and 7.2% under 200 lx indoor light illumination. Furthermore, the unencapsulated devices based on Cs2AgBiBr6, Cs2AgBiBr6@ Ti3C2Tx (0.01 mg mL−1), D149-Cs2AgBiBr6 and D149-Cs2AgBiBr6@Ti3C2Tx (0.01 mg mL−1) exhibited long-term stability by retaining 70%, 74%, 83%, and 86% of their initial PCEs after 1000 h of storage at 25 °C in air at about 20% RH (Fig. 5d–e) [107]. Bykkam et al. used a 2D MXene as an additive in MAPbI3 perovskite at concentrations ranging from 0 to 20 vol% with a 5 vol% increment [108]. With an increase in the vol.% of the 2D MXene, the perovskite peak at 2θ = 14.2° shifts slightly towards the lower angle. The continuous change in peak position reflects the homogeneous distribution of strain during perovskite crystal formation and stresses induced by the 2D MXene additive. However, the perovskite film with 5 vol% additive has fewer defects and improves the photoresponse of the PSC. On further increase in additive concentration, stacking of 2D MXene occurs in the perovskite active layer, hindering the light propagation across the perovskite film and reducing the photogeneration of charge carriers. The best PSC device with 5 vol% 2D MXene additive attained the highest PCE of 13.6%, Voc of ~ 0.81 V, Jsc ~ 27.6 mA cm−2, and FF of ~ 61.1%. This is higher than the PCE of 11.4% in the PSC without 2D MXene [108].

Din et al. explored the synergistic effect of high-quality NiOx HTLs deposited by ion beam sputtering on ITO substrates and the Ti3C2Tx MXene doping of MAPI perovskite layers to increase the PCE of p-i-n PSCs [109]. The 18 nm-thick NiOx films are pinhole-free and have large-scale uniform surface morphology. For non-stoichiometric NiOx, the grazing-incidence X-ray diffraction revealed a 0.75% enlargement of the face-centered cubic lattice. Atomic force microscopy studies revealed that doping increased the size of MAPI polycrystalline grains from 430 ± 80 to 620 ± 190 nm. The best PSC with 0.15 wt% MXene doping with a device structure of ITO/NiOx/MXene-doped MAPI/PC61BM/BCP/Ag showed a PCE of 16% (14% for the undoped PSC), which is a 14.3% improvement. However, the band gap of the MXene-doped MAPI layer was found to have a one order of magnitude higher density of defect states (∼1019 cm−3 eV−1 for the MXene-doped MAPI and ∼1018 cm−3 eV−1 for the undoped-MAPI), which lowers the favorable effect of the total area of bigger MAPI grain boundaries, reducing the Jsc of the MXene-doped devices. The WF drops from −5.26 to −5.32 eV with MXene doping, which raises the Voc and FF, and thus is credited with improving the PCEs of PSCs. Such different results are attributed to large and partly delaminated multilayer MXene sheets and an increased density of states in the bandgap [109].

To improve the PCE of PSCs using a one-step coating method, Li et al. added 2D Ti3C2Tx and V2CTx MXene to a PbI2 precursor solution to fabricate perovskite films [110]. The addition of Ti3C2Tx and V2CTx additives boosted the hydrophobicity of the perovskite film, showing water contact angles of 85.4° and 69.8°, respectively, as compared to 52.9° for the pristine film. Furthermore, the additives also enhanced the shape and grain size of the perovskite films. The PCEs of PSCs with Ti3C2Tx and V2CTx additives attained 17.6% and 17.2%, respectively, compared to the device without additives (15.0%). Moreover, a distinct morphology with uniform grain size and organized layered crystal particles can be observed for perovskite films employing the V2CTx additive, indicating that the V2CTx additive controls the formation of perovskite crystal films. Due to the improved crystallinity and perovskite film quality, the V2CTx additive integrated devices can preserve 68.3% of the initial PCE after 15 days, which is greater than the devices without additives by 9.7% and with Ti3C2Tx as additive by 47.2%. Thus, V2CTx in photovoltaics offers a practical way to enhance the performance of PSCs [110].

2.4 MXenes as ETLs or Additives in ETL

2.4.1 MXenes as ETLs

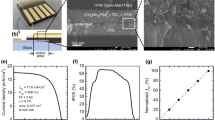

Yang et al. used Ti3C2Tx MXene nanosheets as a novel kind of ETL in planar structured PSCs that have undergone low-temperature processing [111]. The metallic Ti3C2Tx can be improved as an ETL by applying a UV-ozone treatment that boosts the surface Ti–O bonds without affecting the bulk properties, such as high electron mobility. The schematic and cross-sectional SEM image of the PSC device with a configuration of ITO/Ti3C2Tx/MAPbI3/Spiro-OMeTAD/Ag are displayed in Fig. 6a–b, respectively. The thickness of the Ti3C2Tx layer is found to be 18 ± 3 nm. Figure 6c shows a schematic illustration of the energy-level diagram for each component of the PSC device. The shift in WF of Ti3C2Tx from − 5.52 to − 5.62 eV after UV-ozone treatment enables faster electron transport. The PCE of PSC increased to 5% in the case of Ti3C2Tx ETL without UV-ozone treatment and to 17.2% with a Ti3C2Tx ETL film after 30 min of UV-ozone treatment because of an improved electron transfer. The UV-ozone treated Ti3C2Tx ETL suppressed recombination at the ETL/perovskite interface [111].

Copyright © 2019 WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim. d Schematic device structure of ITO/Nb2CTx/FA0.85Cs0.15PbI3/Spiro-OMeTAD/Ag, and. e J–V curves of the flexible and f the large area devices [112]. Copyright © 2022 Wiley–VCH GmbH

a Device architecture of ITO/ETL/MAPbI3/Spiro-OMeTAD/Ag based on Ti3C2Tx with/without UV-ozone treatment as ETL. b Cross-sectional SEM image of the PSC device. c Schematic energy-level diagram of each layer [111].

Zhang et al. fabricated 2D Nb2CTx MXene nanosheets ETL and incorporated them into the perovskite absorber layer [112]. The WF of Nb2CTx was tuned from 4.65 to 4.32 eV by replacing its –F groups with –NH2 groups through hydrazine (N2H4) treatment to match the conduction band minimum of the perovskite layer. Additionally, incorporating N2H4-treated (T-Nb2CTx) MXene nanosheets with abundant NH2 groups slows the crystallization rate of the perovskite precursor by forming a hydrogen bond with iodine ions, which encourages the creation of high-quality and oriented perovskite films. As a result, the PSC with a device configuration of ITO/Nb2CTx/FA0.85Cs0.15PbI3/Spiro-OMeTAD/Ag demonstrated a maximum PCE of 21.79% with T-Nb2CTx MXene ETLs and T-Nb2CTx MXene nanosheet additive. The highest PCE values of 19.2% and 18.3% were realized for the corresponding flexible and large-area devices (Fig. 6d–f). After 1500 h of storage, the unencapsulated devices still retain 93% of the original PCEs. This research illustrates the wide range of potential applications for 2D Nb2CTx MXene in photoelectric devices [112].

Despite many benefits of 2D Ti3C2Tx MXene, including high transparency, high conductivity, variable WF, and solution processability, the performance of the MXene-based PSC is still subpar to that of the conventional TiO2- or SnO2-based equivalent. The MXene/perovskite interface has some critical problems that need to be resolved. Wang et al. adopted a room-temperature solution technique followed by oxygen plasma treatment to use Ti3C2Tx MXene as ETL in PSCs [113]. Oxygen plasma treatment was demonstrated to form abundant Ti–O bonds randomly distributed on MXene and disrupt portions of Ti–C bonds. In addition to reduced trap states and better electron transport along the interface, the surface change made MXene WFs variable. In addition, contact angle and topography measurements were used to extensively analyze the surface tension of MXene and the related perovskite morphology. The device stability was improved, thanks to the PbO contacts between perovskite and MXene. The champion device attained a high PCE of 18.9% with a steady state output Jsc of 21.5 mA cm−2. The unencapsulated PSC with plasma-treated ETL demonstrated long-term stability by retaining 90% of its initial PCE after 750 h of storage in ambient air at 25 °C and RH of ~ 50% [113].

MXenes are appealing for use in PSCs due to their distinct features that result from surface functional groups and oxidation. Yang et al. oxidized Ti3C2Tx hydrocolloid to adjust its characteristics for an ETL in low-temperature processed PSCs [114]. The energy levels were calculated using the Vienna ab initio simulation package code, which is based on DFT. Ti3C2Tx can be oxidized to produce Ti–O bonds and significantly minimize the macroscopic defects in a spin-coated film. However, after substantial oxidation, the material changes from metallic to semiconductor. In the case of a hybrid of oxidized and pristine Ti3C2Tx, better matching of energy levels between perovskite and ETL layer results in a champion PCE of 18.3%. The improved electron mobility in the ETL, which encourages electron transport and lowers electron–hole recombination, is responsible for improving the PCE. This work illustrates the significant potential of MXene-derived materials in low-temperature processed PSCs [114].

2.4.2 MXenes as Additives in ETLs

SnO2 ETLs are extensively used in planar and flexible devices due to a lower annealing temperature (below 185 °C), and better electrical and optical properties [115, 116]. These ETLs have disadvantages of de-wetting property, low transmittance, and conductivity. On the other hand, TiO2 ETL is also commonly used for high PSC devices and requires a high annealing temperature of 450–500 °C [117]. Furthermore, the PSC with the SnO2 nanoparticle-modified TiO2 (SnO2@TiO2) composite ETL processed at low temperature shows a high PCE of 21.3%. However, the amorphous nature of TiO2 at low temperatures limits the PCE of the devices [118, 119]. In 2020, Huang et al. used a multi-dimensional conductive network (MDCN) heterojunction structure made of TiO2, SnO2, and Ti3C2Tx MXene as the electron transport layer to fabricate stable and efficient planar PSCs [120]. Based on an oxygen vacancy scrambling effect, the zero-dimensional anatase TiO2 quantum dots are in-situ rooted on three-dimensional SnO2 nanoparticles, forming nanoscale TiO2/SnO2 heterojunctions, and are surrounded by 2D conductive Ti3C2Tx sheets. The fabrication process for the (FAPbI3)0.97(MAPbBr3)0.03 perovskite thin film with the MDCN ETL is carried out using a controlled low-temperature annealing technique first in an environment of air and later in N2 (Fig. 7a). The optical quality, the crystallinity of the perovskite layer, and internal interfaces are all improved by the optimal MXene concentration of 0.02 wt% contributing more carriers with effective and speedy transfer in the device. The resulting PSCs with MDCN ETL-air and N2 attained a champion PCE of 19.1%, compared to the PCE of 16.8% for the pristine device with SnO2 ETL. Furthermore, the device with MDCN ETL retained nearly 85% of its initial performance for over 45 days in air with a humidity of 30–40%; in contrast, the pristine (control) device only retained about 75% of its initial performance [120].

Copyright © 2020 Springer. b Schematic illustration of the preparation processes of the ETL and the perovskite film. c Schematic diagram of PSC and MXene with Perovskite, efficiency, and defect density values with respect to Ti3C2Tx/SnO2 wt% [121]. Copyright © 2021 American Chemical Society. d Schematic of Cs2AgBiBr6/Ti3C2Tx@TiO2 structure with scanning electron microscope (SEM) image illustrating film quality. e J–V curves of planar Cs2AgBiBr6 PSCs based on TiO2 and different weight percentage of Ti3C2Tx@TiO2 [122]. Copyright © 2021 American Chemical Society

a Fabrication process of perovskite layer on MDCN ETL [120]. –

Defect-free polycrystalline perovskite films are highly desirable for fabricating an effective and stable PSC. However, the use of molecular materials in conventional defect reduction methods suffers from their complicated procedures, poor durability, and limited effects. Zheng et al. used a hybrid film made of SnO2 nanoparticles and Ti3C2Tx MXene nanoflakes as ETL in a planar regular-structure PSC [121]. The SnO2/MXene colloidal suspension is spun onto ITO substrates to form the ETL, and then the perovskite layer (MA0.15FA0.85PbIxBr3-x) is spin-coated on the previously coated ETL via a typical two-step deposition technique (Fig. 7b). The film properties of the top perovskite layers, such as compactness, crystal size, surface roughness, crystallinity, optical absorption, defect density, and so on, are changeable by varying the Ti3C2Tx/SnO2 ratios (0–2.2 wt%) in ETLs. Compared to a pristine device with SnO2 ETL, the defect density in perovskite films with an optimized 1.4 wt% hybrid ETL is significantly reduced from 5.65 × 1015 to 2.25 × 1015 cm3. However, the electrical conductivity of the hybrid ETL is decreased, most likely because of the geometric configuration of the added MXene. As a result, the PCE of PSCs with 1.5 wt% Ti3C2Tx/SnO2 ratio is boosted significantly from 16.28 to 20.35%, along with Jsc and FF increasing from 20.65 and 0.71 to 23.65 mA cm−2 and 0.76 (Fig. 7c). However, Voc (1.111 to 1.113 V) remained almost stable. Furthermore, the environmental stability of the unencapsulated devices is dramatically enhanced by retaining 74% of their initial PCE after 768 h of storage under an air environment at 25 °C with an RH of 30% [121].

To address the issue of the instability of the APbX3 structure and lead toxicity, the inorganic Cs2AgBiBr6 double perovskite structure is a viable development route for PSCs. However, the optoelectronic application is severely constrained by the low Jsc and PCE owing to the low crystallization of Cs2AgBiBr6. Li et al. used a straightforward method to dope single-layered MXene nanosheets into titania (Ti3C2Tx@TiO2) to serve as a versatile ETL for stable and effective Cs2AgBiBr6 double PSCs [122]. In addition to considerably increasing TiO2 electrical conductivity and electron extraction rate, single-layered MXene nanosheets also alter the surface wettability of the electron transport layer and promote the crystallization of Cs2AgBiBr6 double perovskite in solar cell devices. The Cs2AgBiBr6 double perovskite films based on both TiO2 and Ti3C2Tx@TiO2 ETLs have a similar grain size of 200–500 nm (Fig. 7d–e). The TiO2-based Cs2AgBiBr6 film contains large voids, which are pathways for current leakage. In contrast, the Ti3C2Tx@TiO2-based Cs2AgBiBr6 film is smooth and void-free. As a result, compared to a device based on TiO2 ETL, the PCE increased by more than 40% to 2.8%, and the hysteresis was significantly reduced. Additionally, the Ti3C2Tx@TiO2 device demonstrated long-term operational stability. The Ti3C2Tx@TiO2 device retained 93% of its initial PCE even after 15 days of storage in ambient air [122]. Saranin et al. doped MXene in both MAPbI3 perovskite absorber layer and PCBM layers in an inverted PSC (glass-ITO/NiO/Perovskite + MXenes/PCBM + MXenes/bathocuproine (BCP)/Ag). The MXene doping improves the band alignment at the perovskite/charge transport layer owing to the WF shift, which facilitates charge extraction at the electrodes. Hence the inverted PSC attained a PCE of 19.20% [91].

To reduce recombination losses and enhance the PCE of PSCs, defect passivation and customizing the perovskite charge transport layer interfaces are crucial. Chava et al. tailored the electrical characteristics of the ETL and the ETL/perovskite interface in inverted (pin) PSCs using Ti3C2Tx MXene [123]. A [6, 6]-phenyl-C61-butyric acid methyl ester (MPC61BM)-based ETL with MXene doping has improved electrical conductivity and band alignment at the ETL/perovskite interface. The n-doping of PC61BM was confirmed by a red shift of the Ag (2) peak in the Raman spectrum, and a localized upshift of the Fermi level measured using scanning Kelvin probe force microscopy (SKPFM). As a result, PSC devices using M-PC61BM as the ETL attained a higher PCE of over 18% than control devices using PC61BM as the ETL, with a PCE of 15.55%. Furthermore, the PSC with MXene as an interfacial layer between the perovskite and ETL with a structure of ITO/NiOx/MXene/MAPbI3/PC61BM/BCP/Ag attained a maximum PCE of 15.99% with a maximum Voc, Jsc, and FF of 1.05 V, 20.74 mA cm−2, and 74%, respectively. In comparison, the PSC with a standalone Ti3C2Tx MXene ETL showed a maximum of 2.06%, with a maximum Voc, Jsc, and FF of 0.72 V, 5.57 mA cm−2, and 50%, respectively. The addition of MXene to PSCs has demonstrated diverse effects, including improvement in carrier transport, passivation and trap state reduction, and better interfacial energy alignment [123].

Yang et al. utilized SnO2-Ti3C2 MXene (Ti3C2 Mxene + SnO2) nanocomposites with varying Ti3C2 contents (0, 0.5, 1.0, 2.0, and 2.5 wt%) as ETLs and applied in planar-structured PSCs with an architecture of ITO/SnO2 + Ti3C2Tx/MAPbI3/Spiro-OMeTAD/Ag (Fig. 8a) [124]. The corresponding cross-sectional SEM image of the PSC and energy-level diagram of each component are shown in Fig. 8b–c. The lowest occupied molecular orbital reduces from −4.39 eV for pure SnO2 ETL to −4.63 eV for SnO2 + Ti3C2Tx ETL, facilitating fast electron transfer. The PCE of the device fabricated with pure Ti3C2 as the ETL increases from 17.2 to 18.3% when SnO2 and 1.0 wt% Ti3C2 are combined. The metallic Ti3C2 MXene nanosheets demonstrated superior charge transfer pathways, improving electron extraction and mobility while lowering electron transfer resistance at the ETL/perovskite interface, resulting in higher photocurrents [124].

Copyright © The Royal Society of Chemistry. d Cross-sectional image with ITO/SnO2-MH/Perovskite/Spiro/Ag structure. e Energy-level diagram of the ITO/ETL/AL structure based on SnO2, SnO2-M, SnO2-MF, and SnO2-MH as the ETLs. f J–V curves of the champion devices based on each ETL under reverse scans for the FAPbI3 system [126]. Copyright © 2022 Cell Press. g Schematic of the planar heterojunction structure used for the SnO2-based PSCs. h J–V curves of one of the best SnO2-based and MQDs-SnO2-based PSCs devices under both forward and reverse scans. i IPCE curves and integrated current density of these two devices [127]. Copyright © 2021 The Royal Society of Chemistry

a Device architecture of ITO/ETL/MAPbI3/Spiro-OMeTAD/Ag based on representative SnO2–Ti3C2 as the ETL. b Cross-sectional SEM image of the PSC device. c Schematic energy-level diagram of each layer [124]. –

ETL materials with good optoelectrical properties and energy levels comparable to the perovskite layer are essential to meet the demand for commercialization. Niu et al. introduced Nb2C MXenes as an additive to SnO2 ETL for the first time, which caused the SnO2 grains to develop clearly [125]. The incorporation of Nb2C MXenes leads to an increase in lattice spacing of (101) and (110) planes corresponding to SnO2 ETL from 0.32 to 0.33 nm and 0.240 to 0.253 nm, respectively. Further, the roughness and average grain size increased from 3.76 and 179 nm for SnO2 ETL to 11.1 and 256 nm for the SnO2-Nb2C ETL, respectively. In addition, the Nb2C inclusion in SnO2 also reduces surface energy between the perovskite and the ETL, improving the surface wettability so that the perovskite solution can spread smoothly on the ETL. The light reflection also reduced, indicating improved light absorption and an improved fill factor. The electron mobility for the SnO2 ETLs increased from 2.3 × 10−5 to 1.39 × 10−4 cm2 V−1 s−1 for the SnO2-Nb2C ETLs, indicating faster electron transfer from perovskites to ETLs. Hence, the PSCs based on the architecture of ITO/SnO2-Nb2C/Perovskite/Spiro-OMeTAD/Ag exhibited the best PCE of 22.86% (18.96% for the control device) with improved Voc, Jsc and FF. The PSCs with the modified ETL maintain 98% of the original efficiencies after 40 days at 25 °C under a humidity of 40–60% [125].

Yin et al. utilized fluoroalkylsilane and dodecyltrimethoxysilane functionalized MXene nanosheets as dopants into the SnO2 ETL to fabricate PSC devices with modified ETL layers, respectively, denoted as SnO2-MF and SnO2-MH [126]. To fabricate high-performance devices, it is necessary to have an ETL with improved energy alignment and improved charge transfer, which will aid in the efficient extraction and transport of photogenerated carriers. The SnO2-MH ETL has improved band alignment, as evidenced by DFT calculations and ultraviolet photoelectron spectra measurements. In the meantime, functionalized MXene nanosheets exhibit strong electrical conductivity and mobility and may quickly and effectively establish a zero Schottky barrier heterojunction with SnO2. Finally, the appropriate surface energy attained by functionalized MXene additives can increase the grain size of the perovskite thin film. The schematic of PSC and the energy-level diagram of different SnO2, ITO and perovskite layers are sketched in Fig. 8d–e. The devices based on the SnO2-MH ETL with the device architecture of ITO/SnO2-MH/FAPbI3/Spiro/MoOx/Ag significantly enhanced their PCE from 21% (with no additive) to 23.66%. The champion device exhibited a maximum PCE of 24.1% with a Jsc of 25.49 mA cm−2, a Voc of 1.121 V, and a FF of 84.4% (Fig. 8f). The PSCs also demonstrated better operational stability and moisture resistance [126].

Yang et al. fabricated a modified SnO2 bottom layer to produce highly crystalline perovskite films to improve the photovoltaic performance of PSCs [127]. To produce highly crystalline and durable perovskite films, perovskite crystallization mechanisms must be modulated. Ti3C2Tx quantum dots (MQDs) were introduced into SnO2 ETL to investigate the crystallization kinetics of the perovskite. It was discovered that perovskite nucleation from the precursor solution could be induced quickly by Ti3C2Tx MQDs-modified SnO2 (MQDs-SnO2) ETL, resulting in the formation of an intermediate perovskite phase after anti-solvent treatment. As a result, the perovskite film crystal quality and phase stability are significantly improved. A steady-state PCE of 23.3%, with a Jsc of 24.96 mA cm−2, a Voc of 1.172 V, and an FF of 0.798 were attained for PSCs with a device structure of ITO/SnO2-MQD/Perovskite/Spiro/MoOx/Au (Fig. 8g–h) by taking advantage of the excellent charge extraction capabilities of the MQDs-SnO2 layer. The PSC with MQDs-SnO2 ETL has higher incident photon-to-electron conversion efficiency (IPCE) over the entire visible region compared to the pristine device. The integrated Jsc value of 24.39 mA cm−2 is very close to the observed Jsc value of 24.96 mA cm−2 as observed by a solar simulator (Fig. 8i). The fabricated PSC also demonstrated exceptional stability against humidity and light soaking [127].

2.5 MXenes as HTLs or Additives in HTLs

2.5.1 MXenes as HTLs

In PSCs, the HTL plays a vital role in controlling the crystallization of a perovskite film and the hole transfer efficiency at the perovskite/HTL interface. Although many successes in PSC by organic hole transport materials (HTMs) such as N,N’-bis(3-methylphenyl)-N,N’-bis(phenyl) benzidine, poly(trimethylene terephthalate-co-trimethylene isophthalate)-Terephthalic acid (PTTI-TPA), triphenylamine-based HTM incorporating pyridine core (coded as H-Pyr) and pyridine-based polymer semiconductor (PPY2), the organic HTLs fail to scale up the mass-production due to complexity of synthesis, purification and the manufacturing cost associated with the synthesis procedures [128,129,130]. In contrast, the common inorganic HTM NiOx requires an annealing temperature above 200 °C and is unsuitable for flexible devices. Hence, low-cost and low-temperature processed HTMs with excellent electrical properties are necessary. Nb2CTx MXene is a promising HTM due to good conductivity and an adjustable WF [131, 132]. Furthermore, the Nb2CTx MXene has three atomic layers compared to the five atomic layers of the Ti3C2Tx MXene (excluding atomic layers of surface functional groups). Hence Nb2CTx has a larger specific area, and consequently, the contact area with the perovskite layer is also larger. This promptly increased the charge transfer in PSCs. The charge transfer depends upon the WF of Nb2CTx MXene. However, the WF can be controlled depending on the type and quantity of the surface-terminated functional groups [59, 133]. As observed from First-principles calculations, the WF of the pristine Nb2CTx nanosheets with –O, –OH, and –F surface functional groups is approximately 4.7 eV, which is not enough to transport holes across the Nb2CTx/MAPbI3 interface. Commonly, O-terminated Nb2CTx shows a higher WF compared to the F- and OH-terminated counterparts. This WF difference arises due to the different surface dipole moments and a difference in charge transfer between the terminated functional groups and Nb atoms [59, 61]. In 2021, Zhang et al. synthesized the highly photoelectric Nb2CTx MXene by oxygen plasma treatment and used it as the HTL in inverted PSCs [134]. The oxygen plasma-treated Nb2CTx MXene nanosheets showed enhanced conductivity and high transmittance. The oxygen plasma treatment modified the WF of Nb2CTx from 4.68 eV (pristine) to 5.04 eV by enhancing the O functional groups on the Nb2CTx surface. In other words, the high electronegative O atoms pull electrons from Nb atoms, thus reducing the Fermi level of Nb2CTx. At the same time, the O functional groups induce a dipole moment with O atoms facing toward Nb atoms, uplifting the vacuum level. The combined effect of the downshifted Fermi level and uplifted vacuum level increased the WF of the Nb2CTx. This high WF reduced energy offset/loss at the interface between the HTL/perovskite absorber layer and eased the hole transfer from the perovskite layer to HTL, leading to suppressed charge recombination and high Jsc. Furthermore, the photoluminescence (PL) spectra from the perovskite film with the oxygen plasma treated Nb2CTx (Nb2CTx/MAPbI3) indicated the most significant PL intensity quenching, suggesting an improved hole extraction ability of Nb2CTx. From time-resolved PL spectra, the average PL lifetime is found to decrease from 16.51 ns (glass/MAPbI3) to 2.26 ns (ITO/MAPbI3), 1.64 ns (ITO/Nb2CTx/MAPbI3), and 0.72 ns (ITO/treated Nb2CTx/MAPbI3), which further confirms the excellent hole transportability of Nb2CTx. The PSC with the plasma-treated Nb2CTx MXene HTL with a device structure of ITO/Nb2CTx/MAPbI3/PCBM/Ag exhibits a higher PCE of 20.74% with increased Voc and Jsc than those with the pristine Nb2CTx (18.1%) and without Nb2CTx MXene HTLs (15.5%). The higher external quantum efficiency (EQE) values indicate the enhanced Jsc, suggesting more efficient charge separation and collection efficiency. The PSCs with oxygen plasma-treated Nb2CTx HTLs attain the highest EQE and integrated Jsc (22.75 mA cm−2), close to the Jsc values obtained from the J–V measurements (Fig. 9c). Additionally, the flexible and large area (0.99 cm2) PSCs with oxygen plasma treated Nb2CTx HTLs exhibit the highest PCE of 17.3% and 17.9%, respectively. Moreover, the Nb2CTx HTL-based PSCs show excellent long-term stability in the glovebox for 70 days and thermal stability at 85 °C [134].

Copyright © 2021 AIP Publishing. e Schematic representation of spray coating process to form the Ti3C2Tx-SCA film and structural formula of vinyl tris (2-methoxy ethoxy) silane. f Schematic diagram of a device with ITO/HTL/Perovskite/PC61BM/Ag structure. g J–V curve of PSCs based on Ti3C2Tx, with different volume fractions of SCA as HTL. h EQE spectrum and corresponding integrated current density [139]. Copyright © 2022 Elsevier

a A schematic diagram of the device structure and the structure of Nb2CTx MXene. b J–V curves of PVSCs measured under different scan directions. c External quantum efficiency (EQE) and integrated Jsc curves of different PSCs. d J–V curves of the flexible PSCs utilizing oxygen plasma-treated Nb2CTx HTL [134].

A silane coupling agent (SCA) can connect various materials and enhance the interface properties [135, 136]. Furthermore, this coupling agent reduces the cost by increasing the corrosion resistance of the material [137, 138]. However, SCA is hard to use directly for bonding. Including hydroxyl groups in SCA is a possibility to improve the interface bonding. In 2022, Du et al. fabricated an HTL by spraying Ti3C2Tx MXene nanosheets with varying concentrations of the SCA (vinyltris (2-methoxyethoxylsilane)) (0, 0.1, 0.3, 0.5, and 0.7 vol%) [139]. As shown in the schematic of the spray deposition device (Fig. 9e), the ITO glass substrate is placed on the 60 °C hot stage, and the nozzle of the spray gun is set 20 cm above. The Ti3C2Tx-SCA dispersion of different proportions was deposited uniformly on the ITO substrate, setting the spray speed of the spray gun to 2 mL min−1. A flat, pin-hole-free Ti3C2Tx film was produced with a mixing content of 0.3 V/V% by utilizing SCA to efficiently adjust the interface distribution of Ti3C2Tx after film fabrication. The superior production of Ti3C2Tx films enabled better hole transfer paths, improved hole extraction (hole mobility increases from 1.30 × 10−6 to 3.08 × 10−7 cm2 V−1 s−1), and lower transfer resistance from 369.3 Ω to 194.1 Ω at the HTL/perovskite interface. The compared values are for the Ti3C2Tx HTL and Ti3C2Tx + 0.3% SCA HTL. As a result, the device with the structure of ITO/ Ti3C2Tx-0.3SCA/MAPbI3/PC61BM/Ag exhibited an increased PCE from 11.1% (pristine Ti3C2Tx) to 13.7%. The schematic of the PSC and the J–V curves of PSCs with Ti3C2Tx-SCA, having different concentrations of SCA, are shown in Fig. 9f–g. However, the Voc dropped by 11%. The voltage drop is attributed to stacking due to high surface roughness (root-mean-square (RMS) = 0.87 nm for only nanosheet to 4.07 nm for nanosheet and SCA) and good coverage of Ti3C2Tx [38, 39]. Additionally, the calculated EQE (17.75 and 19.94 mA cm−2.) are well consistent with the observed Jsc variations (19.19 mA cm−2 and 21.30 mA cm−2) for the PSCs with or without SCA (Fig. 9h). Moreover, the PSC based on Ti3C2Tx-SCA HTL exhibited excellent stability at ambient air humidity ~ 20% and room temperature, and retained about 80% of the initial PCE after 80 h of storage [139].

2.5.2 MXenes as Additives in HTLs

As stated earlier, apart from the complexity of synthesis and purification, the poor conductivity, low carrier mobility, resistance to processing solvents, and low transmittance in the UV–vis range of the inorganic HTMs such as CuOx, Fe2O3, CuSCN, and NiOx and the organic-based polymers poly (3-hexylthiophene) P3HT, poly(triaryl amine) (PTAA), modified fluorene–dithiophene (FDT), and poly[2,5-bis(2-decyldodecyl)-pyrrolo[3,4-c]pyrrole-1,4(2H,5H)-dione-(E)-1,2-di(2,2′-bithiophen-5-yl)-ethene] (PDPPDBTE) limit the commercial applications as HTLs in PSCs [140,141,142,143,144,145,146]. Solution-processed poly (3,4-ethylene dioxythiophene):poly- (styrenesulfonate) (PEDOT:PSS) is used as a common HTL due to its high conductivity, appropriate WF, and high transparency. However, its acidic and hygroscopic nature leads to a low efficiency and stability of PSCs [147].

In contrast, transition metal carbide (Mo2C) and carbon nanotubes (CNTs) are promising HTL candidates owing to their high metallic conductivity, higher charge extraction probability, and tunable WF [148,149,150,151,152]. Hussain et al. combined Mo2C and CNTs to form a conductive Mo2C-CNT hybrid network for the first time with a PEDOT:PSS HTL in PSCs with a device configuration of ITO/Mo2C-CNT@PEDOT:PSS/MAPbI3/PCBM/LiF [153]. As seen from the energy-level diagram in Fig. 10a, the absorbed light produces electron–hole pairs as the light is incident on the active layer. The pairs get separated and move toward the ETL and HTL. The modified PEDOT:PSS with Mo2C-CNT act as exciton dissociation centers and facilitate fast charge separation between MAPbI3 and ITO and fast charge transfer to the anode. The schematic of the fabricated PSC with the modified HTL, 1.5 wt% Mo2C-CNT@PEDOT:PSS HTL, of PEDOT:PSS and Mo2C-CNT is shown in Fig. 10b. The PSC with the modified HTL exhibits the highest PCE of 12% compared to 9.2% (Pure PEDOT:PSS), 9.82% (Mo2C@PEDOPT:PSS) and 10.61% (CNT@PEDOPT:PSS) under AM 1.5 G illumination at 100 mW cm−2 (Fig. 10c). Additionally, the pure and Mo2C, CNT, and Mo2C-CNT blended PEDOT:PSS HTLs showed a conductivity of 410.12, 581.73, 604.25, and 712.34 S cm−1, respectively, thus evidencing high charge carrier collection/extraction and low internal resistance [148]. In further work, Hussain et al. decorated WO3 nanoparticles on 2D conductive Ti3C2Tx MXene sheets to fabricate an MXene/WO3 hybrid structure and then blended HTL with PEDOT:PSS for PSCs using a simple solution process [154]. The n-type WO3 semiconducting material is a promising HTL candidate owing to high electron mobilities (10–20 cm2 V−1 s−1), a tunable bandgap (2.7–3.9 eV), inexpensiveness, high stability against moisture, and possible fabrication at room temperature [6]. On the other hand, Ti3C2Tx MXene possesses high electrical conductivity (2 × 104 S cm−1) and high mobility of 1 cm2 V−1 s−1 [28, 30]. An MXene/WO3 hybrid structure with 1, 2, and 3 wt% was used with PEDOT:PSS to change the perovskite hybrid module's HTL for a highly efficient planar solar cell with a configuration of glass/ITO/MXene/WO3@PEDOPT:PSS/MAPbI3/PCBM/LiF/Al. The corresponding energy band diagram and schematic are shown in Fig. 10d–e. The energy band level of MXene/WO3 is well matched with the perovskite active layer and forms good interfacial contact. The fabricated perovskite solar cell using the optimal device configuration of 2 wt% MXene/WO3/PEDOT:PSS HTL achieves the highest PCE of 12.26 ± 0.12%. The PCEs of PSCs with pure PEDOT:PSS, WO3/PEDOT:PSS, and WO3/PEDOT:PSS are 9.19 ± 0.12%, 10.13 ± 0.14% and 11.42 ± 0.13%, respectively. Furthermore, the PSCs with pure MXene, WO3, and MXene/WO3 nanostructure as HTLs show low PCEs of 6.51%, 6.68%, and 6.87%, respectively. Additionally, the RMS surface roughness of the MXene/WO3 composite with PEDOT:PSS decreases to 21.71 nm for WO3 (35.79 nm) and MXene (34.23 nm) blended PEDOT:PSS, indicating better adaptable surface behavior with finely dispersed nanoparticles and reduced domain sizes, which results in enhanced interfaced characteristics. The MXene/WO3 heterostructure also showed high crystallinity, low shunt resistance ~ 5004 ± 68 Ω cm2, and series resistance ~ 157 ± 2 Ω cm2. These results suggest better exciton separation and passivation of trapping centers by the densely blended smooth MXene/WO3 thin films. These blended nanostructures efficiently tune the HTL/perovskite interface through their active interface for charge transfer and collection and suitably alter energy band alignment, resulting in facile charge extraction and the shortest charge carrier lifetime [154].

Copyright © 2021 Elsevier. d Energy-level diagram, e schematic view, and cross-sectional FE-SEM image of the ITO/MXene/WO3@PEDOT:PSS HTL/MAPbI3/PCBM/LiF/Al prototype structure. f J–V profiles of PSCs with pure and 2 wt% of WO3, MXene, and MXene/WO3 doped HTL [154]. Copyright © 2022 Wiley

a Energy-level diagram for ITO/Mo2C-CNTs@PEDOT:PSS/MAPbI3/PCBM/LiF/Al structure. b Schematic of the fabricated PSC with a device architecture of ITO/ITO/Mo2C-CNTs@PEDOT:PSS/MAPbI3/PCBM/LiF/Al and its cross-sectional field-emission scanning electron microscopy (FE-SEM) image. c J–V characteristics of prepared PSC devices using pure and 1.5 wt% of Mo2C, CNTs, and Mo2C-CNTs blended PEDOT:PSS HTLs [153].

2.6 MXenes as Electrodes or Additives in Electrodes

The large-scale commercialization of PSCs is constrained by the high cost of commonly used HTM—(Spiro-OMeTAD, PTAA, NiOx, etc.) and noble metal electrodes (Au and Ag) [155, 156]. Low-cost coal-based carbon electrodes are considered reasonable replacements for both the HTMs and the noble metal electrodes in PSCs. However, the PCEs of PSCs with carbon electrodes are still lower than those of conventional devices. In 2019, Cao et al. were the first to use a more conductive 2D MXene material (Ti3C2) with an energy level comparable to carbon materials as back electrodes in HTM and noble-metal-free MAPbI3 PSCs [157]. Using a straightforward hot-pressing technique at 85 °C and 0.4 MPa, a seamless interfacial contact between the MAPbI3 perovskite layer and Ti3C2 material was achieved, as seen in Fig. 11a–b. The WF of the Ti3C2 material was found to be 4.96 eV and matches well with the valence band (5.4 eV) of the MAPbI3 layer. The hole charge carriers easily transfer from the perovskite layer to the Ti3C2 electrode and the electrons from the TiO2 layer to the FTO electrode. Furthermore, the square resistance decreased from 30.93 to 25.34 Ω sq−1 as the thickness of the Ti3C2 electrodes increased from 280 to 330 mm. The Nyquist plot measured under the illumination of 100 mW cm−2 at a bias voltage of 0.60 V and a frequency range of 100 mHz to 1 MHz shows a similar series and decreased charge transport resistance. The decreased charge transport resistance means efficient hole extraction. However, as the thickness of the electrode increases further, transport resistance increases, and hence the PSC shows low photovoltaic performance. Because of the better conductivity and favorable interfacial contact between the optimally thick Ti3C2 electrode and the perovskite layer, the champion PSC based on this electrode with the device structure of FTO/TiO2/MAPbI3/Ti3C2Tx exhibited a PCE of 13.83% with a Voc of 0.95 V, a Jsc of 22.97 mA cm−2, and an FF of 63% (Fig. 11c). The resulting PCE value is 27% higher than that of the control PSC (10.87%) based on carbon electrodes. A good reproducibility in terms of manufacturability without significant batch-to-batch variations was also observed in the fabrication of PSCs based on Ti3C2 electrodes (Fig. 11d). The device also demonstrated greater stability than the conventional FTO/compact (c) and mesoporous (m) -TiO2/Perovskite/Spiro-OMeTAD/Au device for 360 h when stored at room temperature at an RH of 30%. The Ti3C2 electrode plays the role of an encapsulating layer, preventing the active or absorber layer from reacting with air and water [157].

Copyright © 2019 The Royal Society of Chemistry. e Schematic structure of the CsPbBr3 solar cell with mixed carbon electrode. f J–V curves of devices with different types of electrodes [161]. Copyright © 2020 The Royal Society of Chemistry

a Schematic diagram showing the fabrication process of the Ti3C2 electrode by the hot-pressing method. b Cross-sectional SEM image of the PSC based on Ti3C2 electrode. c J–V curves of devices with different thicknesses of the Ti3C electrode. d PCE histogram of the PSCs obtained from the measurements of 20 devices [157].

As stated earlier, the high costs of HTMs and noble metals impede the scaling of commercialization of PSCs. The straightforward manufacturing processes, low cost, and great stability of carbon-based inorganic PSCs have shown excellent performance in photovoltaics. Although devices with carbon electrodes are less efficient than those with traditional structures, interest in their potential large-scale applications has grown. However, the commercially available carbon paste forms a point contact with the perovskite layer because of the point-to-point contact in the carbon electrode. As a result, many pinholes remain at the interface between the electrode and the perovskite layer, impeding the carrier transport [158]. CNTs with a one-dimensional (1D) structure show high conductivity and direct transfer paths for charge carriers, and 2D Ti3C2Tx MXene has high surface areas and shows high conductivity via accelerating the charge carriers [31, 124, 159, 160]. In 2020, Mi et al. incorporated commercial CNTs and 2D Ti3C2 MXene into the carbon paste and formed a mixed carbon electrode for the inorganic CsPbBr3 perovskite-based PSC [161]. This mixed carbon electrode offers a network structure and a multi-dimensional charge transfer path due to a good interface with the perovskite absorber layer. MXenes nanosheets fill the voids of carbon powders. This synergistic structure significantly boosts the conductivity of the carbon electrode and carrier transport. The pure carbon electrode only shows point-to-point contact, and the device with the structure of FTO/c-TiO2/CsPbBr3/pure carbon exhibits a PCE of 5.9%. For the inorganic CsPbBr3 PSC with the mixed carbon electrode, the champion device with the configuration of FTO/c-TiO2/CsPbBr3/mixed carbon achieves a decent PCE of 7.09% with a Voc of 1.357 V, a Jsc of 7.16 mA cm−2, and an FF of 72.97% (Fig. 11e–f). Furthermore, the devices with the mixed carbon electrodes show good reproducibility and excellent stability by retaining 80% of their initial PCEs after storage in air for one month [161].

Wearable and other flexible optoelectronic systems require flexible transparent electrodes (FTEs). The excellent conductivity and transparency properties of ITO have placed it as the most reported transparent electrode material among rigid photoelectric devices [162,163,164,165]. However, poor mechanical stability (brittleness) and expensive manufacturing equipment costs of ITO electrodes prevent them from being used in flexible electronics. Silver nanowires (AgNWs) have low sheet resistance and high transmittance and are solution-processable [166,167,168]. They also show super-bending resistance and mechanical stability compared to ITO electrodes. However, AgNWs suffer from high roughness and low adhesion with the substrate and are prone to oxidation and high wire-wire junction resistance [169, 170]. Metal oxide nanoparticles and 2D materials such as electrochemically exfoliated graphene, graphene oxide, and reduced graphene oxide can modify the conductivity and roughness of AgNW networks [171,172,173]. However, poor doping stability hinders the performance of graphene-based devices [174]. Ti3C2Tx MXene, a 2D material, can enhance the performance of AgNW networks due to its high electrical conductivity, carrier mobility, tunable WF, and superior mechanical properties [126, 175]. In 2022, Chen et al. combined 1D AgNWs and 2D Ti3C2Tx MXene nanosheets to fabricate composite Ti3C2Tx MXene FTEs for flexible solar cell devices [176]. Under electrostatic interaction, a composite 1D:2D structure (AgNW:MXene) FTE is produced. The 1D AgNWs deposited on hydrophilic PET substrates are coated with the MXene nanosheets to form a conductive AgNW:MXene composite network, as shown in Fig. 12a. The MXene nanosheets weld the crossing junctions and the broken junctions. Using capillary force, 2D MXene nanosheets fill the gaps in the AgNW networks and join the wire-wire connections. These provide more continuous conductive paths, improving the conductivity of the electrodes. Additionally, the oxygen-containing functional groups of MXene nanosheets adhere strongly to the PET substrate via a strong hydrogen bonding interaction. The photoelectric performance of FTEs is determined by the figure of merit (FoM). The FTE fabricated with 5 mg mL−1 AgNWs dispersion deposited with a concentration of 0.5 mg mL−1 MXene shows an FoM by a low sheet resistance of 10.91 Ω sq−1 (12.09 Ω sq−1 for AgNW without MXene) and a high transmittance of 82.84% (81.96%) at 550 nm. The roughness of the AgNW: MXene FTEs is also decreased, as observed from the RMS roughness of AgNW: MXene FTEs (13.6 nm) compared to the pristine AgNW FTEs (19.2 nm). The mechanical endurance of FTEs determines the ability of FTE to sustain a continuous conductive path to collect charge under an external mechanical stress [177]. The PET/AgNW: MXene shows a surface Young’s modulus of 0.78 GPa, compared to 0.96 and 1.15 GPa of PET/ITO and PET/AgNW, respectively. Additionally, the AgNW:MXene FTEs exhibit superior long-term stability at 60% RH and 120 °C for 240 h, as well as strong mechanical resilience after 1,000 cycles of bending tests at a 5 mm curvature radius. Furthermore, WF matching is important for accelerating the charge transfer. The WF of AgNW:MXene is calculated to be 4.81 eV, which lies in the required normal range for optoelectronic devices. As a result, the inverted PSC with a device structure of PET/AgNW:MXene/NiOx/Perovskite/PC61BM/Ag (Fig. 12b) and an area of 0.1 cm2 show a high PCE of 20.22% (18.7% for the cell with pristine AgNWs only) with Voc of 1.06 V, Jsc of 25.16 mA cm−2, and FF of 75.5% (Fig. 12c) [176].

a Schematic of the Ti3C2Tx MXene and the fabrication procedure of AgNW:MXene flexible transparent conductive electrodes. b Flexible PSCs with the structure of PET/AgNW:MXene/NiOx/Perovskite/PC61BM/Ag. c J–V curves of the flexible PSCs based on ITO, AgNW, and AgNW:MXene electrodes [176].

3 MXenes as Interfacial Layers

3.1 At the Interfaces Between Perovskites and Electrodes

MXenes are promising candidates in photovoltaics because of their high transmittance, tunable WF (2.14–5.65 eV), and metallic conductivity. Chen et al. introduced 2D Ti3C2 MXene nanosheets as an interlayer into all-inorganic CsPbBr3 PSCs for the first time [160]. The MXene interlayer was formed on the FTO/c-TiO2/CsPbBr3 substrate via spin-coating of the Ti3C2 MXene nanosheet dispersion solution (Fig. 13a–b). The selected area electron diffraction (SAED) pattern of Ti3C2 MXene nanosheets shows a few highly crystalline layers with the device structure of FTO/TiO2/CsPbBr3/Ti3C2 MXene/Carbon to achieve a better interfacial energy-level alignment, which aids in the elimination of the energy-level mismatch, speeds up hole extraction, and lowers recombination at the interface of the perovskite/carbon electrode. Additionally, the Ti3C2 MXene nanosheets’ surface functional groups offer powerful interactions between the MXene and under-coordinated Pb atoms. This significantly lessens the deep trap defects in the CsPbBr3 films. The device with the Ti3C2-MXene interlayer displays an exceptional initial PCE of ~ 9% (Fig. 13c), with a long-term stability of more than 1900 h in a moist environment and more than 600 h under heat circumstances [160].

Copyright © 2019 The Royal Society of Chemistry. d Architecture of the perovskite solar cells, schematic structure and TEM images of Cu1.8S and Ti3C2 QDs, and the cross-sectional SEM of a complete device. e J–V curves for FTO/TiO2/perovskite, FTO/TiO2/MQD/perovskite, and FTO/TiO2/MQD/MQD-perovskite devices measured under simulated AM 1.5 sunlight of 100 mW cm−2 irradiance. f Double logarithmic J–V characteristics in electron-only devices with the structure of FTO/TiO2/Perovskite/PCBM/Ag (control), FTO/TiO2/TQD/Perovskite/PCBM/Ag (S1), and FTO/TiO2/TQD-Perovskite/PCBM/Ag (S2) devices [180]. Copyright © 2020 WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim

a Crystal structure diagrams of CsPbBr3 and Ti3C2 MXene, and schematic for the fabrication of the CsPbBr3/Ti3C2 MXene-based solar cell. b Cross-sectional SEM images of FTO/CsPbBr3/Au devices with/without Ti3C2 MXene. c J–V curves of devices with/without Ti3C2 MXene [160].

3.2 At the Interfaces Between Perovskites and ETLs

Proper device design and specialized interface engineering are required to improve optoelectronic characteristics and the charge extraction process at the selective electrodes to increase the PCE of PSCs. In 2019, Agresti et al. used 2D Ti3C2Tx MXene (Tx = –O, –OH, and –F) to tune the WF of the perovskite absorber and engineered a perovskite/ETL interface. It was observed that the OH-terminated surface of MXene reduced the WF of the perovskite, while the O-terminated surface increased the WF. This nonlinear behavior is reported in the literature [178]. Furthermore, light absorption was increased in MXene -doped perovskites. The addition of Ti3C2Tx to halide perovskite and TiO2 layers enables the adjustment of the materials' WFs without changing the other electronic characteristics. The PSC with MXene-doped perovskite active layer also showed higher PCE (17.4%) than that with the un-doped perovskite absorber layer (15.6%) [179]. Additionally, the band alignment between these layers can be altered using the dipole induced by Ti3C2Tx at the perovskite/ETL interface. WF tuning and interface engineering work together to significantly improve the PCE of MXene-modified PSCs to 20% with a Voc of 1.09 V, a Jsc of 23.82 mA cm−2 and an FF of 77.6%, as well as a reduction in hysteresis compared to reference cells without MXene [179]. Chen et al. used Ti3C2Tx QDs (TQDs) to engineer a perovskite/TiO2 ETL interface and perovskite absorber and introduced Cu1.8S nanocrystals to optimize the Spiro-OMeTAD HTL in PSCs (Fig. 13d) [180]. The QDs with a diameter of about 5.2 nm and a thickness of ~ 1 nm in the absorber layer significantly contribute to the improved crystalline quality of the perovskite film, and large grain sizes are formed. Furthermore, TQDs improve electron extraction and collection at the perovskite/ETL. Cu1.8S improves the hole extraction at perovskite/HTL interfaces. With the improved Jsc, Voc, and FF because of the synergistic effect of both TQD/Cu1.8S, the hysteresis-free PCE of PSCs significantly increased from 18.3 to 21.6% (Voc of 1.14 V, Jsc of 24.12 mA cm−2, FF of 78.70%) (Fig. 13e). The TQD and/or Cu1.8S nanocrystals doping also significantly improves the long-term ambient and light stability of PSCs by improving perovskite crystallization, reducing HTL film aggregation and crystallization, and preventing ETL from ultraviolet-induced photocatalysis. The results show that TQD and Cu1.8S can function as ultrafast electron and hole tunnels for optoelectronic devices. The trap-filled limit voltage (VTFL) values of FTO/TiO2/Perovskite/PCBM/Ag (control), FTO/TiO2/MQD/Perovskite/PCBM/Ag (S1), and FTO/TiO2/MQD/MQD-Perovskite/PCBM/Ag (S2) electron-only devices were found to be 0.82, 0.66, and 0.59 V, respectively. The electron trap-state densities of perovskites are 1.59 × 1016 cm−3 (control), 1.28 × 1016 cm−3 (S1), and 1.15 × 1016 cm−3 (S2) (Fig. 13f). The large grain size and low grain boundary density in the perovskite film resulted in a lower trap density [180]. Crystal deformations, such as lattice strain at the surfaces and grain boundaries, owing to the soft perovskite lattice, affect the charge extraction-transfer dynamics and recombination, leading to a low PCE. Zhou et al. added an inorganic 2D Ti3C2Clx MXene to the bulk and surface of the CsPbBr3 film [90]. This method dramatically reduces the superficial lattice tensile strain. The expanded perovskite lattice is compressed and confined to act as lattice "tape", in which the Pb-Cl bond functions as "glue", and the 2D Ti3C2 immobilizes the lattice. This compression and confinement result from the strong interaction between Cl atoms in Ti3C2Clx and the under-coordinated Pb2+ in the CsPbBr3 lattice. Under light irradiation, the carrier transfer is affected because defects and strain are introduced to the perovskite film. Hence, a smaller number of holes is available at the perovskite top surface. The MXene interlayer, defective states, and grain boundaries are passivated, leading to the availability of charge carriers and thus enhanced photovoltage. The champion all-inorganic CsPbBr3 PSC is finally able to attain the PCE as high as 11.08% with an ultrahigh Voc up to 1.702 V, which is the highest efficiency record for this type of PSCs to date. Additionally, the unencapsulated device exhibits almost unaltered performance at 85 °C for 30 days and at 80% RH for 100 days [90].

High-efficiency photovoltaic (PV) devices can be produced by adding 2D MXenes to the ETL of PSCs. However, the oxidation that results from the ambient fabrication of the ETLs causes an inevitable decline in the electrical characteristics of MXene. To enhance the photovoltaic performance of PSCs, Bati et al. used metallic single-walled carbon nanotubes (m-SWCNTs) to make MXene/SWCNT composites [181]. The champion device with a configuration of ITO/SnO2:MXene/SWCNT(2:1)/(FAPbI3)x(MAPbBr3)1−x/Spiro-OMeTAD/Au attained a maximum PCE of 21.42%, a Jsc of 25.09 mA cm−2, a Voc of 1.073 V and an FF of 80% with the optimum composition. The improved PL and reduced charge transfer resistance confirmed a low trap density and improved charge extraction and transport characteristics owing to the improved conductivity facilitated by the presence of carbon nanotubes and decreased oxygen vacancies on the surface of SnO2. The MXene/SWCNTs approach offers a promising route to realize high-performance PSCs [125, 181].